Leaderboard

Popular Content

Showing content with the highest reputation on 09/26/19 in all areas

-

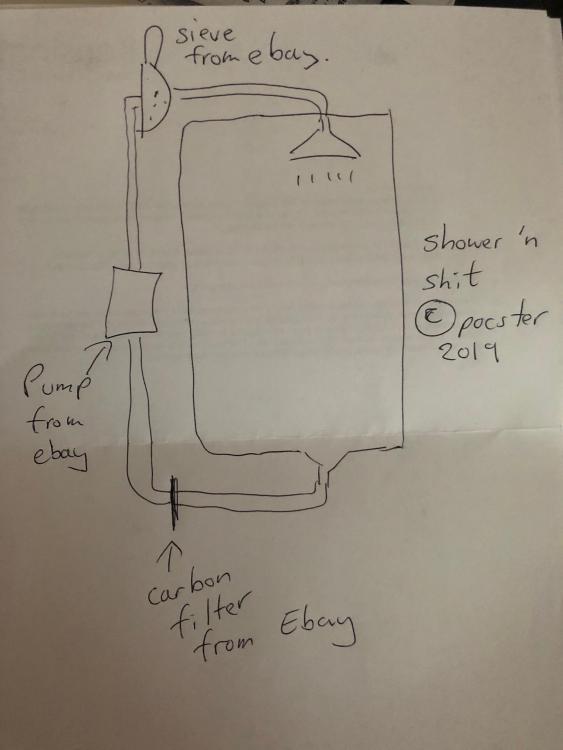

Previous discussions (I take notes): https://forum.buildhub.org.uk/topic/5187-shower-heat-recovery/ https://forum.buildhub.org.uk/topic/10061-working-out-a-scheme-for-dhw/?do=findComment&comment=171407 https://forum.buildhub.org.uk/topic/11509-recirculating-shower-system/?do=findComment&comment=1937854 points

-

Ultimately, what's the payback period for these types of technologies (include materials and labour) and the cost reduction over, say, 25 years? I know some of them can nudge up the SAP by a few points but would expect that investing in a well insulated and airtight frame, decent glazing & external doors, MVHR, PV and an efficient low temp heating system then further gains are very marginal. I would lump rainwater recovery into that category - we were lucky in that we were able to build a very cheap DIY system due to spare space in our basement design vs burying a tank. My realisation is that even with 3500l of stored water, it doesn't last that long when used in the garden. Logically it is full when it's raining and empty when it's dry so only gives a bit of a buffer - not much use during an extended dry period. Would not use in toilets due to the potential health risks of using water containing bird poo microbes - unless you include an expensive filtering system. Better in my view to use efficient taps, toilets and water using appliances. Again - once they are in use, what's the payback for installing an expensive grey water recovery system?2 points

-

For the highest recovery, you split the preheated water between the shower and the DHW cold feed. You can just supply it to the shower if connecting to both is difficult for some reason. You can also supply it just to the DHW system, but from memory that's the least-recommended arrangement.2 points

-

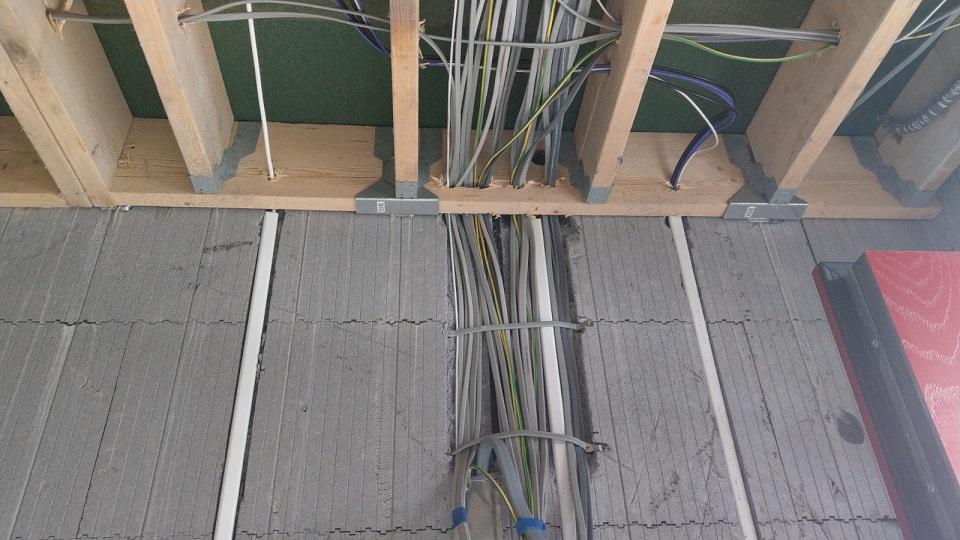

Hi, I read this article here about a little bunch of network cables , causing a standard 40mm PVC plumbing pipe to warp and leak, by leaching their plasticizer into the pipe. Network cable causing leaks in plumbing so that got me wondering about what kinda risks are there really with ICF and electric cables, the manuals call out that electric cables should always be in conduit for that reason, so the insulation around the electric cable doesn't leach out all it's plasticizer and become brittle. Is this a real risk? How far do the electric wires have to be kept from the surface of the ICF? Would you have any comments on my mates, breaker box install? Thanks1 point

-

Your link did not work, try this https://www.edwardes.co.uk/products/hager-ada145g-45a-30ma-b-curve-rcbo-type-a-ac-and-pulsating-dc-sensitive- What is your concern with that?1 point

-

So I am guessing the bottom switch fuse is the off peak feed feeding the bottom heater? So that's where you need to look, at the bottom heater. Turn the switch fuse off, take the cover off. You should see a thermostat. There will be a (often VERY tiny) overheat trip. If it has popped out, try pushing it in and see if it clicks. Otherwise you need some test gear.1 point

-

Top up systems come in many shapes and sizes but at £200 plus they aren’t cheap. Biggest issue is they all need a class 1 air gap between the mains and the rainwater supply. This is just one example. https://steelpumps.co.uk/product/electronic-mains-water-top-up-with-pump-isolation-and-alarm/ You could make one for about £20 based on that picture.1 point

-

1 point

-

If you pump from the rainwater tank to a small open header tank, and use a float switch in the header tank to control the rainwater tank pump, you can then either use gravity to supply water from the header to the toilets etc, or another small pump. You'll need something to stop the rainwater tank pump from dry running and killing itself, so that means some sort of float switch in the main tank to detect when it's empty and turn the pump off. You can then arrange a float valve in the header tank to fill that with mains water when the level drops, as the level should only drop a lot in that tank when the rainwater tank is empty. All told it's a bit of a faff, IMHO, for the modest mains water savings that might be achieved. @Bitpipe probably has the simplest system, just a collection of IBCs piped together and gravity fed with rainwater. There are some photos here somewhere showing his system, I think.1 point

-

1 point

-

I looked into rainwater harvesting for our toilets etc but apart from collecting rain on the workshop for the garden and car washing I decided to forget it.1 point

-

I'm not sure I'd use rainwater with a washing machine, TBH, given that they tend to run pretty cool nowadays. The cheapest option is to use IBCs, they normally hold 1000 litres each and can be obtained fairly cheaply as surplus. They need care if being buried, though, as they may not tolerate soil pressure that well without some reinforcement. Easy enough to just drop a submersible pump in a tank and connect it up to a pressure vessel and pressure switch so that the pump runs when the pressure drops. This is essentially how our borehole supply works.1 point

-

One of the green ones arrived with me last week. At 311 euros inc vat I can justify the punt...1 point

-

1 point

-

1 point

-

Agree - I had a mix of receipts, invoices etc. Made sure they all had a VAT number on, a few I had to write them on myself. All accepted. Those rates are not outrageous, I'd happily pay £200 to have a joiner on site for a day so horses for courses!1 point

-

For a modern house where the slab is no more than a few degrees (at most) warmer than the room and held at a steady temperature I can't see it making much difference whether there are pipes under the cabinets or not. As @Russell griffiths said, not putting them under just means the flow temperature needs to be a bit higher which might matter depending on how your loops are organized. I can see the point of not putting them under the fridge or pantry but wouldn't you need some sort of thermal break in the slab for that to make much difference?1 point

-

Only that it is about £100 more than a decent set... Frame can be had for £120, flush plate is £20, decent pan and seat you can get for £120 so....1 point

-

1 point

-

I did just this, mounted an “in built wall cabinet” on two fence posts 2 mtrs away from where it was going eventually in a garage wall (didn’t want a plastic box on our pretty brick cottage!), DNO connected it up with double socket and rcd fuses for use by builders. When the garage was finished I simply moved the box into the hole left by the builders and moved the fuse box into garage. During the foundation stage we buried a suitable cable from this into the cottage ready for its wiring. Never bothered to get DNO to move it and when they connected up the temporary box I told them what I was going to do and they said what a good idea. Just make sure the temporary position gives you enough cable to swing it into the final position.1 point

-

Yup, £350 for up to £10k and then sliding scale 3.5% to 2.5% above that. There was another thread on here about what jobs we should try ourselves and what to leave to professionals, this is one I definitely wanted someone “capable” to do, I am good at woodwork but crap at paperwork, and considering HMRC changed the rules without any notification (within three months of moving in not building regs sign off) I wanted a professional job done, and got it. I have also passed him info from this forum (another thread about VAT) about appeals lost by HMRC regarding refusal to pay VAT refund and he was greatful fir the info. Today he has a “VAT solicitor” with him and he is reviewing cases (including mine) to see where more can be gained fir customers. I cannot recommend him highly enough and I know several others have used him. “Andrew James (the VAT man)”1 point

-

Should be our job, as good citizens, to report any differences. I shall follow the governments line on honesty for the time being.1 point

-

I'll cobble something together in the garden this evening with 4 "plinths" and the laser to show you exactly but in essence yes. I'd have placed the laser level on a 5th point outside the 4 plinths. The dead level, horizontal beam fires across the top of all 4 plinths. Put the tip of the tape on top of each plinth and measure up to the laser beam. Write down the 4 figures you get. Will tell you which plinth is highest/lowest and enable you to calculate one relative to the other.1 point

-

I had this conversation with a installer and was told don't put the pipes were fridge and freezer and don’t worry about the rest We have them under the kitchen Island as we had similar concerns as you1 point

-

Amazing @Onoff Exactly the explanation I needed. Even with photos, perfect for an illiterate like me. Thanks ?1 point

-

1 point

-

1 point

-

Looking at the official parts list it uses activated carbon, sand filter and UV - the spec is, shall we say, loose! Bacteria needs to be zapped with a specific wavelength of UV for about 10-15 seconds, i.e. the water must travel slowly enough through a UV tube that the water is being exposed for 15 seconds, that is a slow flow rate, or a big long UV unit. Now I am not an expert in these matters but know enough to know that you cannot cobble together some filters and a cheapo eBay UV filter and have water with no bacteria of viruses present, if it was that simple then people could have little boxes clean up all their water! The whole thing is going about an issue, that in my eyes isn't an issue, the wrong way. I honestly think that humanity is going about environmental issues the wrong way in many cases, the answer seems to be to generate vast amounts of carbon and pollution in order to solve something that didn't really need solved, or if it did, there is a better way. In reality it is back to the problem that creates pollution in the first time, greed. So people invent "green" solutions, that are actually just business plans! First thing would be to, encourage local businesses to setup and sell fruit and veg, meat, fish, general groceries, almost like a row of shops on a street would be a good idea! Then a street like this could exist every mile or so, then people like me would walk to these shops and pickup produce as they need it, but instead we drive cars once a week to the supermarket or if you plan like my wife every 2 days! Every night after work our dog gets a walk, if it is my wife and I we often pop into our local Co-Op and pickup bits and pieces, I am going to buy a little rucksack so that I can take it with me when we go and start buying more locally when out on foot. During the bad snow people were panicking about getting to the shops, I didn't see an issue, I just got on my boots and walked, 4 mile round trip for Asda or about 2 for Co-Op, nice walk in the snow and had what we wanted for dinner. But apparently the world had come to an end. I know not everyone can do this for distance or health issues but really, as a nation we have just become so lazy and everything is such a bloody rush.1 point

-

I'm sure there was a discussion year or two about something like this, or maybe I read it elsewhere. Just go for shower waste water heat recovery. While it doesn't save water, a properly installed system will return over 50% of the energy that would otherwise be lost straight down the drain. No moving parts to go wrong, and no need to bathe in your own crap. Win-win.1 point

-

Worth bearing in mind that there are pretty much always faecal bacteria in shower waste water, at least for those in the UK that rely on toilet paper for smearing the stuff around their backside. For those that use a bidet or shattaf this may be less of a problem. Not sure I'd like the idea of having diluted shit sprayed on my face, TBH...1 point

-

It seems like a lot of difficult to recycle metal and plastics and other materials, maintenance and filters and fuss and money to save on some heating energy. I would just invest the money into some solar or ASHP etc. and just use that energy to heat my clean fresh water. We are getting good at heating with renewable sources etc. people have ASHP and Solar and all sorts so heating isn't the issue it once was. I know people who have basically unlimited free hot water now, they use tumble-dryers that cost them £0 to run from an energy standpoint and create only one off carbon emissions (i.e. production emissions from manufacture of the systems). Water is not such a huge issue, the water board clean water for us for less than a penny a litre, it leaves your plughole as grey water, it easily cleans up and helps the dirtier waste water in the system to become more dilute. I see this more and more, we are trying to solve environmental issues by using more and more resources. Frankly the whole climate change movement is targeting many of the wrong industries and environmentally "dirty" objects.1 point

-

From memory these don't meet WRAS or Building Regulations so it would have to be completely disconnected from the house supplies. The images on the site about using rainwater and solar heating it was a recipe for making some pretty nasty bacteria soup if you are not careful.1 point

-

Below ground footing blockwork often looks messy and need not imply the same team will do the same higher up the elevations, though it does appear worse than mine. The mortar mix looks strong which is correct below dpc. I would be more interested in levels and how square the plan view is.1 point

-

Yes, recently installed it, together with a new sensor string. They offered to replace the entire Sunamp, as the newer version has some improvements, including an additional temperature sensor, but the logistics of getting the old one out and down the stairs, and the new one in and up the stairs (they weigh about 150kg) meant that I refused their offer and just fitted the new controller. It's early days, in that we've had lots of excess PV generation since I swapped units over, so I've not been able to do a 100% test of all the cases where the old controller might fail to start a charge, but so far it does seem that the charge threshold has been reduced. One major snag is that I've been prohibited from adding back my indicator light - Sunamp are adamant that this should not be fitted (can't see why, there's no technical reason not to). This means I have to run the controller with the cover removed (exposing live terminals...) as that's the only way to check whether or not the relay is on (an LED on the PCB indicates this). The absence of any external indication as to what the unit is doing remains a major problem, as for those of us who have been caught out by having the unit fail to charge, with no hot water, not having the reassurance of the unit charging is a major snag.1 point

-

Has been very quiet on the Sunamp front for a while. I take that as a good sign I've finally received a response back from Sunamp, which Ive pasted below. I asked them would any mechanical or software changes be made to my Sunamp units, which are currently sat in Sunamp HQ, before being delivered @JSHarris Did you receive a new controller? How is it performing? I do apologise for the delay however I managed to track down our Technical Director who has responded as follows: My comments: As part continuous process of product improvement, we have improved the heat transfer rate between the heating element and the heat battery heat store. The power input is managed by the controller by cycling the heater on and off during the charging phase. With the above improvement, the cycling of the heater is now rarely required and therefore this has allowed us to increase the power input during heating from cold phase of charging the battery. In addition to the above, charging control algorithms have been refined and the charging is now re-enabled as soon as a small quantity of water has been run off, OR when the heat battery has lost some heat through standing losses after several hours. ther compatibility problems with some makes of diversion controllers have been resolved. Your unit will have an updated controller. Kind regards1 point

-

So the brief for the new controls engineer they appoint: Sort out the control system so it accepts charge properly. Undo the "value engineering" to replace failed parts with a different make, to make the product reliable. Spend a few pence per unit on bootlace ferrules. Add some basic status monitoring to the controller. Properly document all features like the location of an overheat resettable trip.1 point

-

I've been having some correspondence with Sunamp recently, as well as with other Sunamp customers who have had similar issues. The good news is that they are making changes to the controller firmware, that they believe will reduce or remove the failure to charge problem that we have for around 30% of the time. I believe that they have changed the charge acceptance threshold, but I don't know what they've changed it to, and TBH I doubt that it's a fixed value, given the challenges posed by trying to estimate state of charge from just three temperature sensors inside the heat battery (really a cell, IMHO, but they refer to it as a battery). Sunamp are certainly being helpful, and are sending me an updated controller, and have asked if I can assess it's performance. However, this is a Catch 22 request, as they've also said that I can't fit the status light to the new controller... The big problem this presents is that without the status light there is no way to tell whether or not the Sunamp is in the "accepting charge" state, which means that not only can I not compare it to the original controller's performance, but I have no way of knowing whether or not we are likely to run out of hot water the following day. I'm not that confident that they have really grasped the nature of charging a Sunamp from excess PV generation, either, as the suggested fix for having no indicator was to just time how long the Sunamp took to charge. Bit of a tall order when it's charging from variable power PV and you have no way of knowing when the thing is charged... My question about modifying the new controller to fit the absolutely essential status indicator has gone back to their technical people, but I have been given an interim reply that mentions it disrupting the way the controller senses the status of the heat battery, which is, frankly, BS, as the only sense mechanism is the chain of temperature sensors, and they are completely isolated from the heating element contactor (which is all that the indicator mod connects to). I'm really glad that Sunamp are looking at this issue, and have been working on a way to address it, but at the same time I've not got a lot of confidence that they actually know a lot about how either normal excess PV generation systems work, or how they interface with their product. This is completely at odds with the technical people involved in the Sunamp PV, who clearly had an in-depth understanding of what was needed to make best use of PV generation. I'm hopeful that things are looking up. though, and that I will be able to stop going into the services room every morning just to reset the Sunamp so we can be assured of getting hot water the following day.1 point

-

Yes, there is a tube down the middle and the sensors are just a bit of wires with three thermistors, covered in heat shrink and dropped down the tube. It's dead easy to pull this out, as it just sort of dangles down the tube from the top. I believe that it's just a single 2.8 kW (at 230 VAC) heating element right at the base of the cell. I've not had the lower cover plate off to look, but I think that @Barney12 has, as he had to reset the trip on his a few times I believe.1 point

-

The sample size is three that I know of. Anyone who uses timed charge and has variable hot water use may well encounter this problem, it's just a matter of when. All it takes is a day of low hot water use followed by a day of higher hot water use for the problem to manifest. We just happen to be on the cusp of the critical usage pattern every day, as our usage fluctuates between about 4 kWh some days to around 6 or 7 kWh on other days. If the Sunamp refuses to charge during the timed charge period after 4 kWh has been drawn off (which it will around 30% of the time, by my estimate) then it's touch and go as to whether we'll get as much as 5 kWh the following day before the hot water runs out. When the hot water runs out the only option is to manually boost charge the unit at peak rate so that we can get limited hot water back within about 40 minutes to an hour later.1 point

-

That sample size is most definitely 2! More importantly the 50/90% "feature" is confirmed by the manufacturer. The problem statement is about the effects of that implementation on its advertised performance NOT that the statement is incorrect.1 point

-

One thing first; I have nothing but praise for @Nickfromwales His commitment to detail (his OCD almost matches mine!), work quality and ethic are right up my street. In fact if it wasn't for his input and intervention in my personal Sunamp journey (much of which is not written on this forum) I would have personally driven from Devon to Scotland and poured the salty goop through Sunamp's letterbox! Now that's said, I'll continue: We appear again to be having endless string of conversations about "workarounds" when actually we should be focusing on what Sunamp are marketing and what you get. My focus is on the electric units (as that's my only reference point) What I believe to be factually correct based on the information provided thus far is: They are not a direct replacement for cylinders or thermal stores The usable capacity (and thus comparisons with the above) are not as advertised They do not and cannot optimise PV. That is simply an untrue statement when they have to be 50% depleted before they call for power. Also; the soft start function throws many PV diverters into a spin! Even THE MOST BASIC of DHW (and space heating) system allows you to "boost" your energy requirement to cope with scenario's where "normal" demand is exceeded. With the electric Sunamp unit you simply cannot do it. I'm sorry but that has to be a fundamental design flaw. End of chat!1 point

-

It's worth reiterating why I chose to buy a 9 kWh model, as an "upgrade" for our previous 5 kWh model, as I think it's a key issue that needs to be addressed. The situation we had with the Sunamp PV was that it was the only size unit available when we fitted it. Sunamp didn't make a bigger unit at that time, although they were developing the Sunamp Stack, that did offer the ability to increase the heat storage capacity. As it happens, 5 kWh was a good match for our daily needs, and also meant that the unit would reliably charge whenever there was any excess PV generation, or if the overnight off-peak boost was used. I chose to increase our heat storage capacity not to provide us with more hot water, but to be able to better utilise self-generation, by being able to store more self-generated energy on sunny days, so that this could be used if the following day was cloudy. Being able to store ~ 48 hours worth of heat means that we could ride out cloudy days, and not use the grid to boost the charge. Maximising the benefit from our PV generation was the aim, and not just my aim, either, I know of at least one other Sunamp customer who has made much the same decision as I did, for the same reason. At no time was I advised that increasing the capacity of the unit would possibly create a problem, because under-use could lead to it failing to charge. I'm convinced that, at the time I bought our unit, Sunamp were not aware of the potential problem that variable, or under, utilisation could create. I had all the documentation before I made a decision to buy, and there is nothing in any of it to highlight the "50% problem".1 point

-

Interestingly, for anyone looking at using an electrically heated Sunamp, charged either by off-peak electricity on a time switch, or excess PV generation, then there is a very good case for not over-sizing at all. If I had opted for a UniQ 6 as a replacement for our Sunamp PV we would definitely have not had any problems with the controller 50% threshold, as every day we would have used at least 65% of the full capacity. It was my decision (and it was my decision, Sunamp suggested I buy the UniQ 6 as a replacement for the 5 kWh Sunamp PV) to choose to over-specify, by opting for the 9 kWh model, when I knew that our requirement was usually around 4 to 4.5 kWh per day.1 point

-

FWIW, when I contacted Sunamp towards the end of last summer, looking to possibly change our Sunamp PV (rated at 5 kWh, and which reliably delivered 5 kWh) Sunamp's initial suggestion was for me to replace it with a Sunamp UniQ 6 eHW (rated at 6 kWh). At that time it was clear that they believed that the 6 kWh model would equal or exceed the capacity of the 5 kWh Sunamp PV, and given their very good track record with the Sunamp PV I had no reason not to believe this. There was no mention of needing to de-rate the new unit by 50% (or over-specify by 100%). I opted to increase the capacity to 9 kWh for the reasons given earlier, I wanted to be able to store a reserve from days when we had a lot of excess PV generation, so it could be used if the following day had very little (yesterday and today here would be a good example - yesterday we generated around 27 kWh, today I doubt if we will generate 2 kWh). At no time was there any mention of the need, or desirability, to double the capacity of the unit in order to be able to reliably deliver the required capacity.1 point

-

I've owned and lived with both versions of the Sunamp, probably one of very few that have, plus I've now got 3 1/2 years experience with these things, a fair bit longer than anyone here, and longer than any Sunamp installer (there were none at all when I fitted our Sunamp PV). I can say categorically that, as far as the electrically heated models are concerned, the Sunamp PV was significantly more reliable, worked pretty much exactly like an immersion in a hot water tank and was able to utilise all of the heat storage capacity available, i.e. the 5 kWh model could usefully store and deliver 5 kWh. On the other hand, the electrically heated Sunamp UniQ models are far less capable. They can only usefully store around half their rated capacity, even though they are practically double the weight and significantly larger. What's worse is that in practice, they can deliver LESS than half their rated capacity when used with an excess PV generation diverter. We never ran out of hot water with the Sunamp PV, with it's 5 kWh capacity, but have run out twice with the much bigger 9 kWh capacity Sunamp UniQ. What's more, we would have run out of hot water many more times if I hadn't discovered that this could be prevented by resetting the unit manually every day. I've stressed the electrically heated models above because both models we've had have only been electrically heated. If heated with hot water, then I would guess that the major flaw in the controller that we have experienced may well either not be an issue, or be an issue that can be easily worked around. As long as a hot water heated model is provided with hot water at a few degrees above the PCM phase transition temperature of either 34°C or 58°C then it will charge, if there is any charge capacity available. I'm afraid I do not agree that the solution to the flaw in the controller is to just spend a lot more money on a unit that has twice the storage capacity required. It may get around the severe design flaw in the controller, but frankly a 9 kWh unit should be able to always store and deliver 9 kWh, not be artificially de-rated by an installer to 4.5 kWh, as bodge to cover up inadequacies in the product. Apart from anything else, the specifications are clear, and if a 9 kWh model is not able to reliably deliver 9 kWh every day, then it's not compliant with the manufacturers specification, so should be marketed as a 4.5 kWh model.1 point

-

I've sat outside these exchanges for a while as I have fitted a number of SA units and wished for the 'whole picture' to be freely discussed without my interjection. I think that's been exercised so time for a spanner in the works...…. For the majority of commentators, there is a wide knowledge and understanding of how the unit works, vs say Mr & Mrs Smith who know zero and just want hot water. So, I have fitted these units ( PCM 58 btw as PCM 34 is currently removed from sale until the bench test unit achieves the required number of cycles that will confirm it's longevity / robustness ) for a good few Smiths and so far so good. I have fitted ones for pre-heat to combi boilers, one's which replaced a copper vented hot water cylinder and one's which do space heating & DHW combined. All I can do is offer my honest, impartial feedback to this exchange in order to answer the OP's questions, so FWIW; One unit, a PCM 58 size 9 Hw+I, is in and working and has been for about 5 months. This is for a family of 3, and the SA is their only means of producing DHW. If there was any issue with this I would be the FIRST to know. I have also fitted a size 6 and a size 3 in an architects house, ( the 6 doing the family bathroom / utility / kitchen and the 3 doing the ensuite only ), and likewise, as their only means of producing DHW, again, if there were issues I'd be getting shouted at accordingly. I am being shouted at by neither, and both have given me testimonials for both the units and my services in fitting them with the latter asking me to go back to undertake further work there. I felt I should comment to give some balance, and it should also be noted that I fitted the 2 units at @Barney12's home where he has had nothing but grief from day 1. Where the issues may possibly lay is in the history of these units meeting the 'adopters', where some folk were dealing with a company still in development, whereas now they refuse point blank to sell to the public, nor to respond to the public as they should have done ( or not done ) from day 1. Because they now only sell to resellers the buck stops with the installer, and the only installers permitted to buy and sell these units must prove their worth to SA and gain the necessary accreditation to boot. My point being this; that to specify and install these units you need to know how they work, what their USEFUL capacity is, and which unit is to be selected correctly for each instance. For eg; I have been asked to specify one for a client to replace a copper DHW cylinder and on paper a size 9 should suffice. As it will be heated by PV I have subsequently viewed the 9 as a 6, so at 50% depleted it would not have sufficient capacity to fulfil the needs of the household, so I have selected and subsequently recommended a size 12 unit for this particular instance. That unit will be fit and forget, and I will ever hear from them again, of that I am sure, but that is because I know how to specify these correctly. Simple. The controller 'issues' are something that are best described as 'quirks', but are known and should have be considered by SA when stating the equivalent capacities in their installation manuals, especially when they knew they would end up in the hands of folk who couldn't decipher them properly. That point is NOW moot however as the units now being distributed should only be coming to 'the Smiths' via an approved SA installer so the 'thinking' would be removed, the quirks not causing any sleepless nights, and as above they should be fit and forget. The only remaining 'issue' then is the cost, where the client may consider this approach an unnecessary expenditure, eg where a size 9 on paper should suffice, and I recommend a 12 ( so an uplift in cost of ~£300 ), and the client has to bear that uplift for me to be able to recommend a SA...…..BUT...…..they'd never be aware of that mechanism as I would just be quoting for the size / type of unit which I calculated would be suitable for their needs and they would simply either accept or decline the quote. Ultimately SA is 'the loser' in that situation as I would have to make their product look expensive where it could / should be cheaper, but all this is early days in the grand scheme where most here probably do not know that SA have now pulled away from the public as aforementioned, in recent months, to ensure this kind of error cannot happen anymore. Credit to them for raising that drawbridge, albeit a little late in the day, but as the saying goes "pointless locking the stable after the horse as done a bunk" so they ( SA ) should really have been making more effort to remain in constant / constructive dialogue with their "early adopters" which it seems they haven't. @recoveringacademic; Should you be snogging this box of salty yogurt? I'd prefer not to have to bleach that image from my mind.... @mrsRA would be a bit pissed off if there were another in your marriage.... Avoid? No. Specify properly and install to suit? Yes. Tin Hat suitably super-glued on and awaiting the flack...…..1 point

-

FWIW, I have a spreadsheet somewhere comparing at least three insulated slab systems, from when we were looking at options. One was Kore (the system that MBC normally use), one was Supergrund and another was IsoQuick. I think there was also another company, too, but I can't recall their name. Some used a lot more concrete than others, in essence they used a simpler design without local reinforcement for any internal or edge loads. IIRC, one use 250mmm of reinforced concrete. The key thing with all of them was that when you add up all the costs (and they are not easy to compare, as they all quoted on a different basis) they all cost about the same. Some had more cost in labour and steel, some had more cost in concrete, but all were within about 10% of each other in total cost. In the end our decision was based on the tie up between Kore and MBC, that meant the foundation would be installed by MBC, and for me that was the clincher, as it removed a massive amount of risk. Had we used a different foundation company to the frame company I could see that we may well end up with an argument if the accuracy wasn't spot on, and it just seem a lot easier to use one supplier for both.1 point

-

Yes, my understanding is that it’s just one element. I’ve been told that the actual heating part is much longer than a standard immersion element and is designed as such to maximise its life as its non serviceable. That’s a point worth repeating; the heating element is in no way serviceable and if it fails then the whole unit needs to be replaced. Heres whats behind the service cover0 points

-

Yes, that would probably cause the same problem that we've been seeing. The key thing here is that running out of hot water is seen as being a major problem. My wife was exceptionally unhappy when her shower ran cold because of this issue, and no amount of persuasion by me is going to convince her that spending all this money on this new box of tricks was a good move!0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)