Leaderboard

Popular Content

Showing content with the highest reputation on 01/06/19 in all areas

-

We make a start on 15th October with the diggers arriving on 16th October. By the 17th October, state of play is as per the picture below. The gabion wall on the right of the plot was put in by the vendor as part of the infrastructure works. The trench on the left is for a gabion wall that we are putting in on the other boundary. As there is quite a slope from back to front, we are putting another gabion wall across the plot to act as a retaining wall. All OK so far, but there is a surprising amount of muck that came out of the trench for the gabion wall which will need to be taken off-site. On the plus side, the plot had already been stripped of topsoil and as we are using a passivhaus foundation there was not too much extra muck on top of this. The builder we are using has been involved since the early stages of the project. We didn't go to competitive tender but worked with the Architect to look for someone with experience of the build method we are using who we felt would be able to build to our budget. We are living around 3 hours drive from the site and made a decision out of necessity to continue working in our day jobs throughout the build, however we are purchasing all of the materials ourselves or via our own accounts which we expect will make the build more cost effective. This arrangement works to my strengths as whilst my practical building skills aren't great, I should be OK tracking costs and getting good prices on the materials. Original plan was to get the gabion cages in place and fill them as time allowed, but the Passivhaus foundation could not be delivered for the requested date of 24th October, so once the drainage is complete, filling the gabion cages becomes the main task to keep the team onsite busy. By 26th October, the majority of the drainage and gabion walls are complete The following week is spent finishing of the gabion walls, landscaping, groundwork and preparing the grit base for the Passivhaus foundation. There is however a further delay on the Passivhaus foundation, so a decision is made to push on with the garage to keep everyone on site busy. At the end of the week (2nd November), the slab for the garage is laid The garage progresses quickly the following week and the Passivhaus foundation arrives on 8th November. There are some small dimensional inaccuracies with the Passivhaus foundation base that need to be corrected, but I am thankful this is spotted before the concrete pour when it is relatively easy to fix. It is however another delay and distraction we could have done without. On the bright side however, there have been no nasty surprises with the groundwork / drainage. Work continues on the garage w/c 12th November with prep for the house slab starting at the end of the week. DPM and steelwork for the house slab go in on the 19th and 20th and following a review of the weather forecasts, we go for the 23rd November for the concrete pour. The concrete and concrete pump are ordered again, the rain holds off, temperature is ok and the pour goes to plan. Garage has also now been boarded.3 points

-

I did much the same as @PeterStarck, but I went around all the local builders merchant to set up trade accounts with them. One builders merchant (our local independent) told me that I didn't really want a trade account, as the discount on trade accounts is pretty small. Instead he offered me a cash account, which was cash (or card) with order and gave on average about 10% to 15% more discount than a standard 30 day credit trade account. Worth noting that trade accounts aren't about getting a discount, they are focussed on allowing tradespeople to buy materials on credit, before they get paid by their customers. As credit costs money, trade account discounts are generally nowhere near as good as cash account discounts. As it turned out, our local independent BM not only consistently gave me better prices than anyone else (and better prices than any of the tradespeople we used could buy from them for) but they also offered to try to price match, even with prices from the internet. There was only one product they couldn't price match, and that was pavers for the drive. I could buy those directly from Simply Paving for less than the price our local BM could buy them in at wholesale. Well worth asking around and letting your local BMs know that you're a self-builder, and want a cash account with the best discount they can offer, and ask if they can price match for bigger orders.2 points

-

We set up a self builder account at Jewsons and the manager gave us a list of all their building materials with the discount we would receive for each. It depends very much on the builders merchants in your area and the branch managers. There is a large variation between areas.2 points

-

@Roz in my experience they all give the story about the discount on their account.....really they like to have the control of purchasing and scheduling and they get perks for how much they spend in a year etc. plus the cashflow advantages. I would go and open an account at a reputable local bm (not jewsons they are generally more expensive than anyone else), you will get a discount from them too plus you then have the advantage of not only vat reclaim but the cash flow which if managed can give you as much ad 60 days free credit. You can always give builder authority to order on the account and check it off from delivery notes to invoices.2 points

-

@Dreadnaught we chose this wall system for practicality with access as the private drive that leads down to us is narrow (bin lorries dont come down) and lined by historic tpo’d yew trees.........we would never have got the bigger panels down. Some Tf companies were quoting us to crane panels off up the lane and bring them down one by one which would have been a real headache. In the event even though we chose the system that was easier to get on site the eps for slab came on a massive vehicle from Ireland. It had to go to nearby garden centre to be unloaded and then contents brought to site in smaller vehicles... I used good quality plasterboard which also helps with soundproofing. Our house is warm, comfortable and quiet. I have no regrets about choosing this wall system over the twin wall system. If you have an eye on sale in the future no estate agent is going to quote decrement delay in the sales particulars but the upgrade from double to triple glazing will be a big plus for a buyer.2 points

-

Here's a couple of photos of the unit I made up to find and try and seal air leaks up on our old house: It's pretty much exactly as @Ed Davies described above, a car radiator fan fitted into a bit of MDF that was cut to be a tight fit in an opened window. I swapped the original motor for a brushless DC one, mainly because I found that I could get better speed control this way, but also because the original brushed motor fitted to the fan was on its last legs, and made a heck of a noise. It was extremely effective at finding leaks, especially when set to depressurise the house. Many of the leaks could be found just from the loud noise they made; so no real need for anything fancy in the way of leak detection. Some of the worst leaks in that old house were where the ceiling met the internal plastered block walls (it was a bungalow). The gaps were tiny, too hard to see clearly, yet howled like banshees when the fan was running.2 points

-

Hi All, First of all please don't interpret the breaks between my responses as me cowering in the corner from the posts on this thread. I have a very thick skin. I understand the passion this process engenders in those who set out to build their own home. Unfortunately work commitments keep me away from the keyboard for several days at a time. The feedback I have received is mainly centered on the ground floor build up and it is in that area I am now focusing my attention. It is a little late in the day to radically change the design. I know some of you will be screaming at your screen that if not now when. However, there are other factors at stake and further delays, we were due to break ground last October, are going to have a significant impact on related projects and plans. I am now looking at Tetris B & B system and awaiting details of how this product could be incorporated in the design without significant amendment. I am also looking at Jabfloor products. To address the remarks I made when I first introduced myself last year about wanting a near passivhaus performing property this was true. However, the design of the house, the orientation in the plot and the shading by trees in neighbouring properties has meant that this goal is out of reach and so my expectation has altered. This came to light after PP when I started to assess the heating requirements of the property based on some fairly crude assumptions which are now proving to be not too inaccurate. We will have a beautiful home that will be highly adaptable and will be able to change to meet our needs as we grow old with it. It will be warm, well insulated, low maintenance and distill all of the best features of the many houses we have lived in up to this point. Our design team were chosen for many reasons but at the very start they were open that they had never worked with T/F before but having short listed several architects this team were the ones we felt most able to work with. They had a lot of experience in working with the planning authority in the same conservation area in which we are building and have achieved PP where many had questioned whether it was worth the effort. We are learning together the joys of this process and they have done much more than they have been paid for and in the last few years have become friends whom I trust. My PM, there is a team of 2, are very experienced self build and T/F builders and come highly recommended by several self builders who have used them in our area. I have visited many of these properties and I am very impressed by the quality and attention to detail they have incorporated. They will be sub contracting out the various elements of the build so we will not have a main contractor. So please do keep your suggestions flowing. Remember we all start this process at different levels of skill, knowledge, experience, priority, time and budget but we all hope to get to the same point! I am minded to start a blog on here but wonder if these threads are more likely to be open to a wider audience for comment.2 points

-

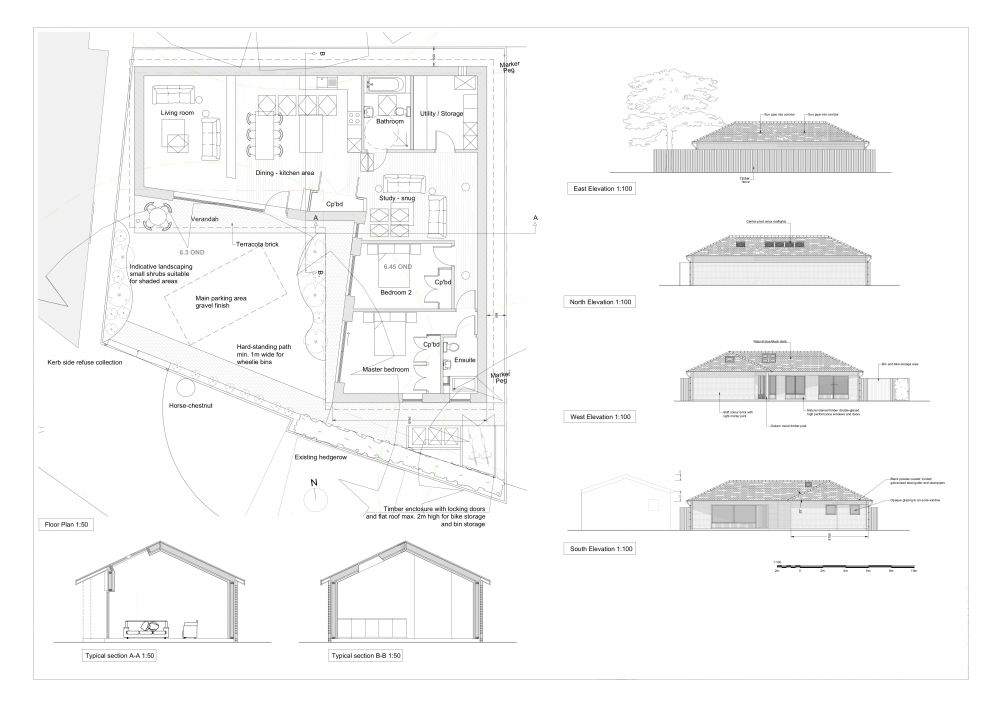

This is what has gone to planning for approval. I would welcome people's opinions, observations and suggestions for floor plan tweaks. The aim was to design a floor plan with an eye on saleability The constraints are that we are forbidden to overlook to east or north. Even roof windows are not allowed on the east but are allowed on the north. We are limited in height. And we cannot remove any trees.1 point

-

Our efforts in the latter part of 2018 was spent on getting the exterior properly wind & watertight. With just the render left to do, we could now concentrate on the insides. Starting to insulate the suspended timberfloor was the first job to do. We attached some little bits of timber to the underside of the joists, which will keep the insulation boards in place. Our primary insulation for the groundfloor is Quintherm 65mm (another two layers of insulation will be added later). Once ordered these were then cut to size using a piece of wood to score a mark and then cut with a handsaw. We left a bit of gap either side which will be filled with expanding foam to ensure a tight fit. The other insulation ordered at this stage was the Frametherm wool which is the primary insulation layer between the studs. But some will also be used to top up the gap left in the joists. The width is already in the correct size so it was just a cut for the required length and then you can pop into the studwork. Compared to the Quinntherm this is more quicker to fit. And that is that for 2018. Reflecting on the build process to date: We are exactly where I hoped we would be at this stage. A proper wind and watertight shell that can stand up to the Hebridean winter weather. Reviewing the finances we are about half way through our build budget. We have been fortunate no real issues. A problem with a wrong size velux flashing and the metal flashing provided for utility roof was provided at the incorrect angle, both were the suppliers fault! At the start of the build, I had visions of the concrete wagon sinking in the road, the windows being dropped on arrival and the trusses not being able to fit down the access. The lesson here is watch programmes like grand designs and building the dream, but don't let the drama put you off, self building, it is achievable by anybody!1 point

-

1 point

-

The vent can be on any exterior elevation, can exit through the roof centrally on a stand alone SVP run etc but cannot vent at ground level near the property / adjacent to neighbours property / other point where the 'stench' would be a nuisance. The vent is to get the gasses out of the network, so can get quite stinky. As for the insulation, I'd buy some self adhesive neoprene insulation tape and wrap the outside of the pipe to the point it becomes exposed inside / outside, sealing and weatherproofing accordingly.1 point

-

If you are on network / mains for sewerage, then each property has to provide a minimum of 1 vent to atmosphere. Making that external SVP ( soil vent pipe ) your vent to atmosphere will encourage it to become a cold vent, but unless you have made provision for a vent elsewhere youll have to go for that regardless to satisfy the BCO. Any other rising SVP can then terminate in an AAV ( air admittance valve ), making things easier for the other internal waste connections. What you 'can' do is get BCO signoff and then take the vent cap off the external stack and replace it with another AAV, thus massively reducing the cold draught that would otherwise continue to be problematic. Can you exit the building, then turn left or right slightly and drop / rise off to one side of the point that the pipe exits the building? Basically, if your stuck with the vent to atmosphere, can you put a bit of distance between the exit point of the build fabric and the natural (rising / passing ) path of the venting air? What insulation has been used? I would recommend filling the gap around the pipe with expanding foam as it will help insulate the pipe.1 point

-

Ran out of muck / couldn't be ar$ed doing another mix / call of the mild ?. That and the thought of @pocster residing in the bath! ? Getting there. No cutting today just laying. More of both tomorrow.1 point

-

Thanks @lizzie. Yes I am. Very helpful. The subject I am puzzling over is how to run my build. Who to help me by providing timely local advice, a double check on on-site quality, and local contacts. This should be the subject of a new topic I think.1 point

-

+1 to the excel suggestion if it's just to track milestones. You can work out the critical path, add key milestones etc if you wish but having completed a build I can say that mine were less accurate than predicting the lottery numbers . There are too many variables and unquantifiables to make it really meaningful and you can't really learn from previous experience as this is a one off project for most. As long as it's used as a very rough guide that's probably the best you can hope for. A better idea is to work out the budget as accurately as you can and constantly check where you are against planned spend at any point. I suspect that for most people budget is a rather larger constraint than slippage against timeline.1 point

-

Same deal for us, five years ago. MBC provided everything except the scaffolding, skips and toilet. They organised the short wheelbase, long jib crane (drove all the way down here from Bristol) and measured up to make sure their artic could get down the very narrow lane (we had ~100mm of clearance either side at one point) and over the narrow bridge over the stream in front of our plot. I warned the neighbours that we were going to block the (very) narrow single track lane for a few hours beforehand, and all were OK. They shifted their cars out and parked them around the corner so they could get to them whilst we were faffing around getting the artic unloaded. FWIW, our lane is just about 2.75 to 2.8m wide where that 2.55m wide truck is backing in, so not exactly a lot of room to spare. The driver was damned good though, and made backing into that narrow space seem easy. The hardest part of the whole job was getting the crane into the site the evening before the truck arrived. The front of the crane was up tight against the scaff around the house, the back of the crane was right up against the garage slab. The crane managed to get up the 1:6 slope of our "drive" too...1 point

-

Just to be clear, its not them suggesting the alternative wall. Its my architect and I.1 point

-

A 360 degree rotating telehander would do it as long as on site there is a spot to set up close enough to swing round and reach the majority of the build. They are big and heavy and don't move across the ground the best though.1 point

-

1 point

-

Having spent many years hiring cranes you need a crane to do your job, not one you looked at on another site. Look how small Jeremy’s one was, yet I bet his panel weighed the same crane hire is about the load verses the radius it need lifting to, height is not normally a factor unless you are on a multi storey job. What you need is a city crane developed for use in (er cities) you need to measure the width of the street to accommodate the out riggers then you need to know the load, ( which will be tiny ) then the radius to the furthest panel placements. After writing all that guff you will probably be better off unloading somewhere else and bringing to site separately. How have mbc priced this ? it could be cheaper for you to provide 3 blokes and a transit flatbed or trailer for two days to get the frame on site you can bet mbc will put a good markup on this. Who pays for the crane ? not having a crane will allow you to bribe a local farmer and pay 4 lads for a good couple of days get 10 panels on site before mbc turn up, then as they start supply them with a new panels as you transport them.1 point

-

If you look carefully you can spot "JH" on my old Prius parked in once of the photos... MJ Scaffolding were great, BTW, if anyone is looking for a scaffolder around our area. We mucked them about a lot, with short-notice requests to changed the scaff, and they responded quickly every time.1 point

-

Unless I switch it off and on again to reset it, then 9 times out of ten it won't accept any charge at all after running off two morning showers. Once or twice it has decided to accept a charge at this point without me resetting it, but that's the exception rather than the rule. The problem then is that we can have a sunny day and yet the Sunamp sits there as a dumb dead weight doing nothing at all (unless I've reset it). At this time of the year it may, possibly, cool down enough to accept the grid boost charge in the early hours of the next morning, but we've already had one occasion when it didn't, and the second shower ran cold the next morning (which is what got me involved in trying to find out what was going on). Currently, with me resetting the unit every day, it's reliably utilising any excess PV generation we may get. I can't really fault it, in terms of performance, it's just the failing in the control system that lets it down. I have a narrow DIN rail mount time switch and plan to wire that into the box to do an automatic reset, just to save me having to go in the services room and turn the thing on and off every day. I should add that this problem only occurs for users whose normal usage pattern discharges a bit less than 50% of the Sunamp's capacity each day. Those who tend to use more than 50% per day may not have a problem. For us, I wanted the additional capacity as a buffer, so that excess PV generation from one day could be stored to be used the following day, in case it was cloudy.1 point

-

1 point

-

It’s what we did for our build. I don’t see the benefit of using a non VAT registered builder for this TBH unless he is stacks cheaper. For one thing any discounts available to your proposed builder must surely be available to a VAT registered builder too and then you can get the VAT back on top of that discount. Worth asking for a couple more quotes and pricing up materials and comparing before you commit in truth.1 point

-

That's a good idea Sue, I didn't think that they might do that.1 point

-

I would try going to the BM to get a trade discount from them due to the amount of materials you will be purchasing. Then you can buy the materials yourself and still ge the VAT reclaimed.1 point

-

1 point

-

1 point

-

Thanks. Yes, Peter. I have a quote from them (and visited two of their builds). I must say I rather like Touchwood's system. And they would also offer me the advantage that their frame team are relatively local (Hertfordshire I believe) so would avoid the expense of local accommodation. Disadvantages are that, as far as I know, they only offer a full Passive-House specification product, which is inevitably more expensive than either MBC's passive option, let alone the 140mm-open-stud MBC option that I am now considering. And they don't offer a in-house foundation solution (although they do seem to recommend AFT for foundations).1 point

-

@Russell griffiths, good question. No I hadn't. I started by assuming that I would go for an MBC-style factory-built frame. Its only when I received their details and quote did I first think about deviating from the standard passive double-stud wall. Open stud is new territory for me. The advantages of going with someone like MBC are that its quick to get to weathertight compared to a stick build. And they do the foundations too, giving the impression of reducing the build riskiness. And companies like MBC also give the impression of easing the path, providing reassurance, being easier for a novice like me. I can easily appreciate that for someone with your level of experience and ability that a stick build would be attractive (I suspect you'd do the build yourself). I am much more wary as a beginner but possibly without good reason. I suppose it depends on whether I could identify a pair of chippies I truly trusted, no easy task as I am already finding that trust-filled relationships can be few-and-far-between in self build. I have already had the impression from some parties that I am viewed as a meal-ticket-on-a-plate. Having said all of this, I intend to devote plenty of time to being on site. And I am also keen to be as involved as much realistically possible given my total inexperience. Hmm, food for thought. Thanks for the comment.1 point

-

Have you considered using an i joist for the walls and getting it stick built on site, no crane no forklift, 2 chippies and a good set of drawings1 point

-

Ceilings are standard board, bathrooms are moisture resist and the special waterproof board in wet areas. Our bathrooms are fully tiled. Utility yes habito the same. We had nearly a pallet of habito left over so I have a very smart garage with walls boarded out in habito LOL..ok for hanging shelves in time I guess!1 point

-

Nail on head....installers who think they are too smart to follow the instructions! If (and when) they do install as recommended then its not a problem. btw its great I can hang anything anywhere and walls feel really solid too.1 point

-

Great attitude. It is far better to have more feedback and reject some than to not be told things and find out later that you really needed that extra insulation underneath your now-built house. F1 point

-

Every one starts their build with high hopes and the wish list. As things progress then you start to realise what effect various different aspects of orientation and site layout can have,never mind budget . If you have to make changes then make them, as it's you going to live in the house. You seem to have all your Ducks lined up so do your research on each stage and if you need a question answered post away. As for a blog its just an easier method to record your progress as you can divide it up to suit the different stages that you encounter. On a single long post the details very quickly get lost as posts can detour of topic. Have a read through a few and see if it's something that would interest you.1 point

-

Yes I agree that triple glazed windows have a far greater effect at reducing sound than the type of insulation. We have good airtightness as well, which I think is another reason our house is so quiet.1 point

-

@epsilonGreedy, In another thread From wonky shelf to self build in deepest Cambridgeshire @Lots2learn talked more about his goals and explicitly stated: So much of the advice is consistent with his wishes. His stated U-values for walls etc. whilst not quite passive class are good enough to have a well insulated and energy efficient house -- that is with the exception of his slab design which is outside the general spec of his other house components. This makes little sense to those of us who have completed our houses. I don't think that anyone here has suggested a complete change to what was been done so far, for example switching from a foundation + beam and block floor to a passive floor. I see this as an issue of making constructive suggestions going forward that can rebalance the design. So if he wants to have UFH then replacing the blockwork with something like Tetris insulated blockwork is a option that is worth considering, IMO. Also the detailed build-up of the floor profile is important. The SE has to be willing to sign it off and his chosen builder has to be comfortable / competent doing it. Are you going to have UFH or not? If so then how are you going to profile this up? However it is done, the TF sole plate has be set above the internal FFL and DPC otherwise you risk wet rot of the sole plate and the compromise of the entire TF -- as I keep saying, the devil is in the detail. Even if a classic radiator-based CH system is employed, a solid concrete floor significantly constrains the radiator placement as BRegs prevent you placing inaccessible joints in the slab, so need to design your CH topology and lay your runs unbroken before the pour. Off the top of my head, I can't think of any members with new-builds of this class or better that have decided to go with a radiator solution for the GFL. So the decision of UFH or not, upper floor heating approach, etc. really needs to be finalised at this stage before foundations and ground-floor finish are completed. In another topic, I described the whole process of self-build a bit line skiing in front of an avalanche. There is just so much to do and to lean and to get right and there is a logical sequence to be respected. I am not saying I am good at this, but at least I was good enough to complete my house within spec and near enough to within budget, so all I am trying to do here is to help others avoid mistakes that can be avoided.1 point

-

To add one more, I would think about a full size glass panel next to the door in the studio, to get light down to FF. As you are arty Types, what about stained glass or even etched glass (my favourite). F1 point

-

My service void was only 25mm and it was a bit of a PITA. All my back boxes had to have the plastic lugs cut down to prevent them hitting the back of the void. Given that you need to leave big chunks of it empty, I didn't see much point in insulating the void. An extra 25mm, on the wrong side of the vapour barrier, doesn't make a huge difference to a well insulated build up.1 point

-

A 13t digger with an extension in the boom will lift whatever you need esp if it's only a single storey. You can get diggers with no tail swing that will be not much more than 2m wide.1 point

-

@Dreadnaught get the overhanging branches trimmed ASAP ..! If it’s your drive then you can cut them back. Telehandlers come in all shapes and sizes - a baby Merlo or JCB will still lift a panel to over 4m which is plenty high enough.1 point

-

Just emailed our kitchen company following up on a query from my electrician and got a call back saying they have gone into liquidation. This is a company that has been around for 18 years apparently. Used by @Bitpipe - lovely kitchens. Anyway, our deposit (over £3K) has gone with them we guess. Any advice on how to proceed from here? We would like to take some action to retrieve some money. Or is it a waste of time? Any similar experiences and advice?0 points

-

Interesting. I don't think even that would fit on my site.0 points