Leaderboard

Popular Content

Showing content with the highest reputation on 02/21/18 in all areas

-

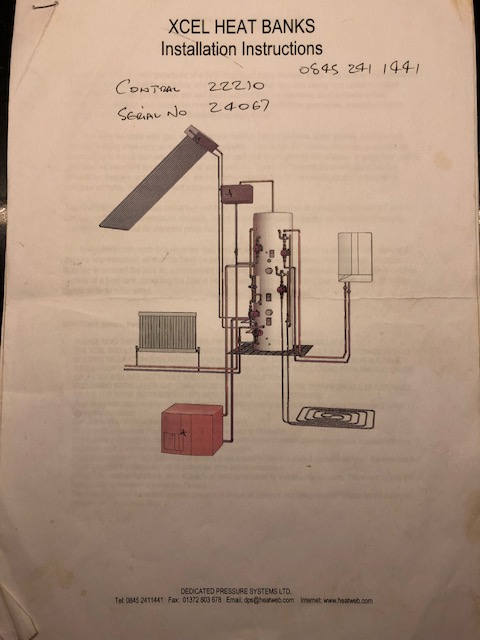

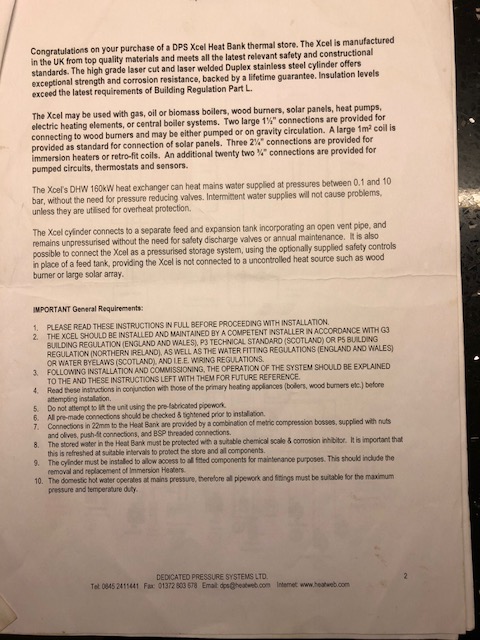

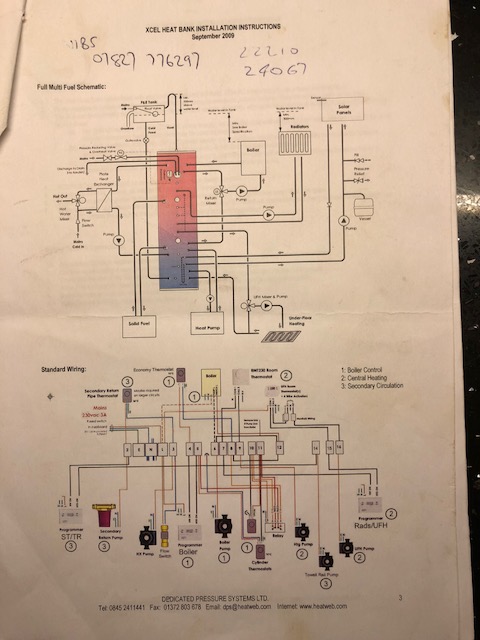

Right then, here we go...... Order of events :- ( chapter one lol ). Electric boiler which is sealed and pressurised. Thats the reason why the pressure needs topping up occasionally. It should run at around 1.5 bar- 2 bar, rising when hot, falling when cool. Vertically mounted rectangular white box to the left of the boiler, and silver pump to the left of that : White box is a PHE ( Plate Heat Exchanger ), required to hydraulically separate the sealed and pressurised body of water in the boiler from the open pipe 'gravity' fed body of water in the TS ( thermal store ). Silver pump is the pump required to circulate the water in the TS through the PHE so it can be heated by the PHE, the other side of the PHE is heated by the boiler. The black plastic tank in the cupboard is the F&E ( Feed and Expansion ) tank which keeps the TS topped up without the need to pressurise that too, eg a bit less maintenance intensive that way. Needs no attention other than to top up with inhibitor perhaps. Silver pump lower left TS. That pump circulates the water in the TS through another PHE, the one in a silver / metal box affixed to the side of the tank with the pipe going to the upper of the TS side. That heats the DHW ( domestic hot water ( what comes out of your hot taps )) in the same way the boiler PHE heats the TS. Under that pump is a thermo head which regulates the flow temp through that circuit. A naff idea as the DHW is serviced by a TMV ( thermostatic mixing valve ) anyway, thus giving you control over your maximum DHW delivery temp. A TMV is necessary with a TS as you can have very high / near scalding temperature DHW without it I assume that either runs off a Hot Water time clock setting, or is operated by a flow switch that senses you opening a tap and fires that particular pump up for the duration the tap is open. Anyone's guess without being there.....and poking @MikeSharp01's fingers in the corresponding pump connections and then opening the taps to see if he screams and when / how long etc The other two green pumps and their corresponding red - topped TMV's are space ( central ) heating flows. eg one ( the upper hotter coil ) could be going to 1st floor heating radiators, so would be set to around 55-65oC, and the other ( the lower cooler coil ) could be going to the UFH manifolds, so set at 35-40oC, hence the lack of pump and blending valve on the UFH manifolds. The water that is pumped to the UFH has already been cooled down to the correct temp by the dedicated TMV before going into the UFH loops. IMO an inherently flawed design, but it'll work if set up correctly. At the top of the TS you have the Quenching Coil, ONLY NEEDED WITH A SOLID FUEL HEAT SOURCE As you have stated that you don't have / were never having a WBS ( wood burning stove ) then fitting that was a waste of time and money. The PRedV ( with the gauge thats showing 6.5 bar, which I missed because I'm blind ) is there to limit the pressure and flow that arrives at the Quenching Coil control valve so it can operate smoothly and accurately. That valve is opened by a capillary probe that heats up and the hydraulic fluid inside expands with heat. That fluid expands and opens the control valve according to how hot the TS is, eg slightly over temp, a trickle of cold mains water, way over temp, a high flow of cold water. A good system in principle, and used on many good quality sealed and pressurised WBS's, but has no place in your house as its function is redundant. My recommendation is to remove all that and bin it, capping the cold feed to the PRedV as its knackered anyway ( it would be showing around 3 bar if functioning properly ). The black circular bit halfway up is the backup 3Kw ( assumed ) immersion heater. That should be turned on by a switch on the wall for emergency use only. Follow the cable and ensure that the switch ( usually a white switch the size of a light switch with a red neon light on it ) is off. The white rectangular thermostats ( cylinder stats ) x3, from the top down so highest is 1: 1) Summer setting - The boiler is controlled by this stat ONLY, when space heating is not required. That allows the boiler to only heat the upper portion of the TS so you can get DHW only without heating the entire TS and wasting energy unnecessarily. 2) and 3) Winter setting - Stat 1 gets ignored and 2 & 3 come into play. I have no idea why 2 stats would be so close together but tbh I think they ( technical ) may have given me duff info and its actually 1 & 2 that govern summer setting with 3 doing the winter 'full heat' of the TS. If its not, thats how I'd set it up, but id also simplify by ditching the middle stat ( stat 2 ) as I really see no need for the third one. The wires that disappear into unions on the TS are ( assumed ) the temperature probes for the ST ( solar thermal ) system, so I dont see the other rotary cylinder stats doing any of the ST referencing AFAIC. Principle of operation ( as advised from technical support ) : You should have a two-channel time-clock for toggling between summer and winter 'mode' which you will have to do manually as required. You may also have another time-clock for DHW production, depending on how its been configured. If it has a flow switch after the DHW PHE output then you might not have a DHW time-clock. Anyones guess at the moment tbh. Selecting winter mode kicks all the space heating controls into action and starts the various pumps and faff to work accordingly. Simple eh ?!? What to do next : 1) Roll your sleeves up and shout very loudly at your boiler and TS for approximately 3 minutes, only stopping to breathe in again. That'll reset everything and show it that you mean business, probably. When done, read all the above again which will allow your blood pressure to return to normal again. You'll feel better then. 2) Turn off the big chunky switch to the boiler so it goes dead. 3) Turn off all the time-clocks and turn down all the ROOM / HOUSE stats. 4) Turn the 3 TS cylinder stats to their lowest positions, marking first with a pencil their current setting. 5) Wait for the TS to go cold. 6) Switch the boiler back on, report what it does for the first 15 mins. It should cycle for maybe 2 minutes and then go into standby, whilst it does a self-diagnostic, or simply do nothing at all. It should not run and heat up the white PHE, and the silver pump for the white PHE should not run. The system should now simply be sitting in standby aka 'holiday mode'. 7) Assuming the above went accordingly ( lol ), turn on all the heating time controls you can find, but leave all ROOM / HOUSE stats set to mimimum, including the one some cock has fitted in a cupboard. Do NOT switch the black immersion heater on. 8) Turn TS cylinder stat 3 to 65oC. Report what happens for the first 5 minutes. The boiler should kick in, the pump and PHE adjacent should run and all get hot and the TS should then proceed to heat up entirely until the cylinder stat tells the boiler to switch off again, maybe an hour or so, maybe a bit less / more. This is the critical bit which will identify if the wiring is in order or not. The boiler should, at this point, be receiving instruction to heat until stat 3 tells it otherwise. If not the most recent pipe butcher has fecked something up whilst charging you for the pleasure. 9) If the boiler does not kick in within the 5 min period, turn up the stat in the cupboard and see if that has been put in line with the other controls, making sure its partnered time-clock is deffo on too. 10) If the boiler still doesn't kick in, turn up TS stat 2 to 65oC. 11) If the boiler still doesn't kick in, turn up TS stat 3 to 65oC. 12) If the boiler still doesn't kick in, turn the ROOM / HOUSE stats back up and set things back to how you had them. 13) Note when the heating / whatever came on during the above and file your report here and we'll go from there. As Dave has said, you need to try and make heating on / consumption coincide with each other to maximise efficiency. Its not ideal tbh as the TS will go cold very quickly ( so you'll soon run out of DHW between heating intervals ). The only problem is is that the system has been designed around a busy full household and its just yourself ( IIRC ) there, so basically its like driving a double-decker bus with only one passenger on board. Also, heating the TS for 3 x 2 hour bursts / 24hrs won't even scratch the surface. Whenever heating is on, the boiler needs to be on. Whenever DHW is wanted, likewise. I think id have designed it differently but I also think I would have chosen different lottery numbers last week too as I didn't win....hindsight being a wonderful thing and all that. Chapter two to follow after some feedback.5 points

-

Yes i really like the idea of putting a really small wbs in the cottage, there was an open fire for years and then a big wbs but with all the improved insulation and future ufh the need becomes one of fun rather than function. I know we have talked this subject to death but..... due to my remote location and my caveman instincts i am still going to fit one. Finding the “right” small stove will be the challenge...... i will be sitting there overheating... reading about how to repair my fuel guzzling landrover on my iPad.3 points

-

I put a small 5kw burner in my own house and used 100mm air supply duct in floor with adjustable stainless grill and a bung to completely seal when not needed as photo below. I do have MHVR and a supply and extract approx 6m apart in this room. The fire burns really well with grill open and air supply is silent when Bung is in place!2 points

-

Thank you so much @Nickfromwales! You are a star! I don’t claim to have understood all that you’ve posted but when I’m home I will read it in conjunction with the visual view and it may make more sense. The ‘cock in the cupboard’ was the local plumber who installed that thermostat in the utility room just outside the boiler room. I thought that was a bit odd as even I know that you don’t put a thermostat that controls the boiler right next to the bleedin boiler!2 points

-

For low power stoves, look at the Springdale 3KW stove available with ducted air intake kit http://www.stovesareus.co.uk/burley-springdale-wood-burning-stove.html This is almost certainly what we will fit. I wired a straw bale house a few years back. They found a stove for that that claimed to put 10KW to water and only 2KW to the room. It was installed in a big double height living room and heated a massive (I believe 2000L or something like that) thermal store. The thermal store provided DHW and UFH. The theory is you only need to light the stove every few days to top up the thermal store.2 points

-

2 points

-

I think part of the problem is if you are used to an open fire is desire to keep stoking and feeding it. We have our heating profile for the upstairs lounge without and evening boost as we use the stove. That said we have a smallish stove (6kw) in a decent room. 36sqm. We can run that without boiling ourselves for an hour or two with ease. Why? We like the flames and we live in a wood..2 points

-

Make something up that is hinged in the middle that will fit in your existing car. I know doors don't fit into a Ford C-Max. But being sensible, renting a van is the easy and cheap way as you are not going to move doors that often. Or a trailer.2 points

-

Fwiw, I absolutely HATE having customers 'dangle carrots' like that, it makes my blood boil. And its usually the ones who can afford to pay and think they have the upper hand. Thats usually where I nod my head like a good little boy, and then shove another 20% on the bill for "wanker tax". A previous customer had me pay for some trinkets, only £60-70 worth, but I took the money our of my pocket to buy them whilst the customers were on a luxury holiday. At the end of the job ( and them agreeing the job was way beyond their expectations ) I asked for the money and had to give chapter and verse to get the amount AGREED, not paid. 3 months later I get a call from said customer....could I go back and explain how to hook up the sky cables I ran for a song whilst the ceilings were down.....so along I pop. Deed done, and on the doorstep, I turn and politely say "could you transfer that £x materials money for me please?"....."we'll see" came the reply. I left. Another month or so went by. I get a call...."X item you fitted has stopped working, could you come out and fix it please?"......I replied "We'll see"....and the line went quiet. I made that person wait 3 months, with them ringing to voicemail and texts going unanswered, until I went to do the repair. Of course, one of the terms of my return was to have the outstanding money in my account FIRST. At that point I think the penny dropped. They asked for some more 'favours' whilst I was there, but I just said I was late for another appointment and thought F.U. Moral of the story.....Stump up when the bills due, end of chat. Anything else is a massive piss-take. If you want a retainer, state that thrice UP-FRONT before a single screw has been turned. There, I did my worst.2 points

-

Its fine on frost setting as room stats like that dont typically switch on / off, just up or down. Read through and if your stuck on a particular point just post here and someone will guide you through if I dont see it for any reason. Ask plenty of questions and we can crack it sooner It doesn't matter if your repeating yourself, just ask until your confident enough to push on. Your get out of jail card is simply setting everything back to how you have it now. Take some photos on your phone for reference.1 point

-

1 point

-

A few observations: I am not sure why no RCD on the smoke alarms was a C2 unless he KNEW the cables were buried in the wall. And C2 for a missing lamp from it's lamp holder, at this point I would be marching him off site....... You have a very high Ze 0f 0.52 ohms, I would be contacting your supplier, The normally accepted maximum for TNC-S is 0.35 ohms. See here https://www.ssepd.co.uk/ForContractors/ To get this corrected, contact your energy supplier who should refer it t the DNO. This won't fix anything other than stop the lights dimming when the boiler is on. Anyway, at the moment I am seeing 2 distribution boards, both feed several things. I assume EVERYTHING is powered all the time, e,g the washing machine can be used any time day or nght?1 point

-

1 point

-

I think the HM system would have done it TBH, but hypothetical unless actually being able to make it work and show you. Just sounds like a) knowing it's connected right and b) being able to show you how to use it would be the way forward. So simple1 point

-

For the record Open Office will edit PDFs; not sure whether it can do one that is that complex.1 point

-

I Have the Dewalt cordless version which is great, lasts forever on one charge. https://www.howetools.co.uk/dewalt-dcs355n-18v-multi-function-tool?utm_source=google_shopping&gclid=EAIaIQobChMI-fHY4_a32QIVo7ztCh2Q9w5kEAQYASABEgJEUfD_BwE1 point

-

Not easy but you could draw a box over it, filled - from the ADOBE COMMENT menu, then save it as a picture then upload the picture. Alternatively I think you can use the box cover and then save it as a non editable PDF but i am not sure you could not then remove the box if you wanted to enough. Alternatively get a post it note to cover it before you scan / photo it.1 point

-

First thing in the morning shut everything down so when you get home its cold. Then follow the start up process so we can see whats doing what. Note where / how everything is current set so you can go back to muddling through at the very least.1 point

-

Don't listen to him on this one - his son is at the University of Sussex (The University of East Sussex would need to be in East Sussex but it isn't cos it does not exist, yet, although curiously the University of Sussex is no longer in Sussex but in Brighton - since it became a city!) On other matters - welding, tiling, bathroom design / layout /modelling and many other interesting things you should listen to him. Welcome to THE forum.1 point

-

I have a Fein Multimaster 240v I will fight to the death over it ..!!! Only issue is eye watering Fein blade prices but I use ones from eBay and they are just as good. Cut, sand, grind, it does the lot ..!1 point

-

I fully appreciate that and im not having a dig, just my way of conveying myself sometimes isn't the best It just winds me up when what you had could have been made to work, just it seems this chap, even with the very best of intentions, could have done better. In his defence, when faced with what we see, any mere mortal would have burst into tears. Not in his defence was charging you to interfere with something above his pay grade. If he wanted to experiment he should have done the work for free. Good news is that were getting somewhere. Glass half full and all that1 point

-

if you choose to go Makita cordless don't get tempted by the cheaper earlier model that didnt have a tool-less blade change......apparently was a problematic pita. This is 2nd hand info...not my own experience..but it took the advice , and the quick release version is proving great so far.1 point

-

Crikey. Is it a nursing home or a small school ? The wiring is as over-engineered as the plumbing.....I think I feel a theme here. At least the wiring needs no work doing from a glance, as its about as good and diverse as a system could get. A microwave oven with its own circuit! and then the cooker hood has its own circuit too. God bless your late husband, he was an engineer through and through. A man after many of our hearts. I'll leave pro Dave comment on the electrics as my brains still in rehab learning about your plumbing but I don't envy his task either!1 point

-

Have a look at http://tonyshouse.readinguk.org He achieved results of less than 1.0 with a brick and block construction.1 point

-

If you're determined enough to fit one, then have a look at narrowboat stoves. There are some pretty small ones made for that market. Far from clean burning, I suspect, as their flue output often looks pretty nasty whenever I've seen one operating.1 point

-

@epsilonGreedy Heating LPG is usually half the price of forecourt vehicle which used to be half the price of unleaded. I had a 5L V8 station wagon which was converted to lpg which also fitted an 8x4 sheet flat in the back. @Ferdinand .1 point

-

63mm up to 5kw stove output from the regs IIRC Which happens to be ordinary down pipe size1 point

-

1 point

-

1 point

-

3 phase just means you effectivey have three normal mains connections. To run 24 kilowatt boiler a single phase - that most of us have, will not be sufficient. It also means that the wiring from meter to boiler needs to be treated with care as 3 phase is more lethal than single phase.1 point

-

"This is encouraging to hear and I hope air tightness is where a rookie like me can make a difference by prowling around after 5pm with an array of sealant guns. I cannot find public domain info covering airtight techniques for conventional brick & block designs." if you are trying to seal tbe house with sealant the horse has already bolted. Airtightness needs to be planned from the start of the build. Google " Denby Dale passive house" or " Golcar passive house" or " Tonys house" lots of info on traditional block and cavity build and how to make them airtight.1 point

-

1 point

-

Imagine if you were an ipad user with a wood burning stove and a dirty landrover...... devil incarnate.....1 point

-

You can get a decent build down to a very low score just with attention to detail and a few rolls of airtight tape. Windows and doors are your problem, as are any service penetrations. The problem you will face is the stove will dictate the location of the vent - some have below, some have rear entry vents. You may need to decide that first.1 point

-

Some of the issues with B&B start when you have integral garages where the beams need to be closer and deeper and the blocks on their short side. We looked at this as Building bear trees so needed heave protection however the BCO wasn’t worried in the slightest as on sand with a very low clay content. B&B in this situation needs quite a lot of detailing - from memory ours would have needed a 180mm deep beam over 4.5m with blocks on 215mm width and then a 100mm mesh reinforced concrete screed over for a garage 3.6m x 4.5m Counter that with the solution we used which was poured fibre reinforced concrete with two 8x4 of 150mm EPS “former” in the centre under the DPM which has basically created a 300mm ring beam under the edge of the garage slab. Cost was about a cubic metre extra of concrete and two sheets of insulation.1 point

-

Inside/on top, whatever works. The beauty of an old, cheap workhorse!1 point

-

Yes. We've got 3 plus a coal Rayburn (our house needs heating) and they are almost unused - one was lit twice this winter. They are messy, wasteful of space and will almost certainly overheat your rooms if you have reasonable insulation, when run hot enough to minimise pollution. Although I understand the appeal I'm completely bemused by people with near passive houses insisting on installing them. (And they're stupidly expensive for what they are!)1 point

-

Don't forget carrying the frames and facings - which will be at least 100mm longer if you get them pre-cut. Nothing worse than being chuffed at getting the doors home and not being able to put the linings in the car! Then there is hard wood flooring if you have any - weighs a lot and ours were 2225mm long - too long for a car and even if I could get 10 packs in at a time, I wouldn't have been happy with the weight. We hired a van and did a whole load of things in one day (my camper is out of action).1 point

-

They fit in a Prius, as I've carried doors flat in mine. That has a rear opening that is about 995mm and plenty of length with the rear seats down for around 5 or 6 doors stacked up before the available length becomes a problem because of the slope of the rear window. The limiting factor on every car I've had has been the width of the hatch/rear door opening mainly, not the load space inside. Of the two 4 x 4s I've owned, one was very poor, as the door opening was a lot narrower than the actual load space. I'm taking a double bed to the recycling centre later today, and was surprised to find that a folded divan base easily fitted in the back, with room on top for the headboard and rolled up mattress. So you may not need an estate, and might well find that one of the longer hatchbacks will manage OK, which may broaden your choice a bit.1 point

-

I have an 08 A6 Avant - with seats down it's quite large but the boot area is tapered at the top which can make it tricky to get big rectangular loads in - happy to take a few measurements for you if that helps.1 point

-

Thermal performance, cost & depending on the type of build, a potential issue around sole plates. We've got beam and block for a large part of our build, it's fine and was the only viable solution but we're aware of the downsides and have had to work out solutions to some of the issues.1 point

-

Odd that, the Focus Estate is larger in the back than the C-Max. Neither is a nice place to be though.1 point

-

The solar thermal system looks like it is a sealed system which means that there is ALWAYS fluid in the panels on the roof. If the controller for the solar (deltasol thing) has been switched off for any length of time then the fluid in the panels on the roof will have stagnated and probably boiled (the sun is powerful like that). This pushed up the system pressure and triggers the over pressure valve to open and you loose fluid. No big deal TBH. the system will need draining, cleaning and recharging with new antifreeze. Hopefully there are no leaks form the overheating, but it's an easy fix really. Scottish Borders is too far for me I'm afraid ?1 point

-

I haven't noticed an address just the name, but it is something that we mention from time to time just in case :-). Sometimes people eg leave the lat and long in screenshots from Google Maps.1 point

-

I think the thermal store is listed in one of the invoices I posted? 475l springs to mind. I thought that I had removed my address from everything? If I haven’t can you let me know what one it’s still showing in please and I’ll amend. I couldn’t find anything to redact easily so just scrubbed out my address pretty roughly using a tool not meant for that. My hubby didn’t design the system himself. I can’t remember what company came up with the original design, but he sourced the materials separately to get the best price. I think Wunderfloor designed the layouts for the UFH tracks and I seem to recall that we paid them a fee to do so. Before he died my hubby talked about sticking a second boiler in there for hot water, possibly a combi boiler, but didn’t get much further with it. Space would be a bit of an issue as the boiler room is pretty full. The electrics are all on the opposite wall, although that isn’t an external wall anyway, and the central vacuum unit is in the middle of the only other external wall. Not that I use that much anyway. I have a cordless Dyson that’s much easier to use . Hubby was gadget man and I just like plain and simple (and straightforward) things.1 point

-

1 point

-

That's good as 'the runs' only means one thing to me and that's a bit crap . Need to sleep as have to be up at 5 ugh. Thanks so much to everyone for the help so far. Will try to reply to anything else once I'm home from work tomorrow.1 point

-

@Russell griffiths the main difference between a ground bearing concrete floor slab and a b&b floor is one of thermal efficiency. In winter the temperature below a ground bearing slab will be a lot warmer than the air that will be circulating below a b&b floor1 point

-

@Ed_MK no, there’s no down side to using a locally based Approved Inspector instead of the LABC. Prices will be the same or cheaper Comms will usually be better too as will timescales for responses etc1 point

-

In your makeup what do the clippings, sand, driveway blocks bring to the party apart from an aesthetic (I assume) at the cost of what....70mm or more? Couldn’t you ‘stamp’ the concrete when it gets poured, with a block pattern, and add a dry shake dye to the concrete to get close to the look of the currently specced blocks?1 point

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)