Leaderboard

Popular Content

Showing content with the highest reputation on 01/23/17 in all areas

-

4 points

-

4 points

-

I'm just trying to put some balance into what is a debate about appropriate levels of safety, from my personal perspective. There can never be absolute safety, and that's the point I'm making here. Risk appetite and safety are very variable, and no two people will perceive things in the same way, which is a pretty good thing, otherwise we'd all be pretty dull. Risk must be be assessed by the individual, with the benefit of information from as many reliable sources as possible, if they are making their own choice about something that offers better, or just different, protection than the minimum required by regulation. All I've ever done here is say what my personal view is. It's not wrong, it's not against any regulation, and in my view it's a small improvement on a split board. You have a different personal view, that's fine by me, I've never once stated that you are wrong, either. We are all entitled to an opinion, and holding a different one is not an offence. Do the current electrical regulations state that you have to fit an all DP RCBO board? Do they state that fitting an all SP RCBO board is hazardous? No, the current recommended minimum acceptable standard is a CU with two DP RCDs controlling two separate sections with MCBs for each circuit within each section. The "clever" people say that's good enough for all of us, not me, I'm not one of the clever people, and I ceased to be an IEE member over a decade ago, just before the merger that formed the IET. When it comes to setting safety standards that have to be enforced, then that's done by a committee of clever people, who sit down, weigh up the facts, look at the accident and incident statistics over the last few decades, balance those with cost and consumer impact and produce a set of balanced regulations. It seems you don't agree with all of those regulations, and as it happens I don't either, but in a different way. That doesn't make me right and you wrong, or vice versa, it just means we have a different view as to where the balance lies between risk, safety, the probability of an incident happening, the types of incidents that are common, the types that are less common, convenience, cost etc. There's nothing at all wrong with that. I'm not saying, and have never, ever, said, or implied that, "my way is the only safe way" of doing anything. It's up to people reading and researching to form their own views and make their own decisions.3 points

-

Re neutral faults on a concentric incomer. It is actually a well known fault condition. If the outer sheath of the concentric cable gets punctured, water can get in and corrode the outer (unsheathed) PEN conductors. Eventually it will give out and you have no neutral. Inside the EZ it is surprisingly not much danger, but an exported earth to say a shed can rise to a lethal potential wrt local earth Carvans are the big risk where the metal bodywork is usually connected to earth and if you fed one of those with an exported PME earth you could have a lethal situation as you step in or out of the 'van, that's why the regsdemand they are fed from a TT earth. Up here, the DNO's token gesture to make TNC-S a PME is a little pig tail of "earth" wire buried in the connection pit alongside the potted joint box.2 points

-

Hi I've been a long time reader here and ebuild. I'm renting in a town called Keynsham near Bristol with a wife and two daughters. After losing a lot of money by buying a house in December 2007, we refuse to buy another new build and I have convinced the other half we should self build. So just a thanks and apologies for the bombardment of questions I will send your way.1 point

-

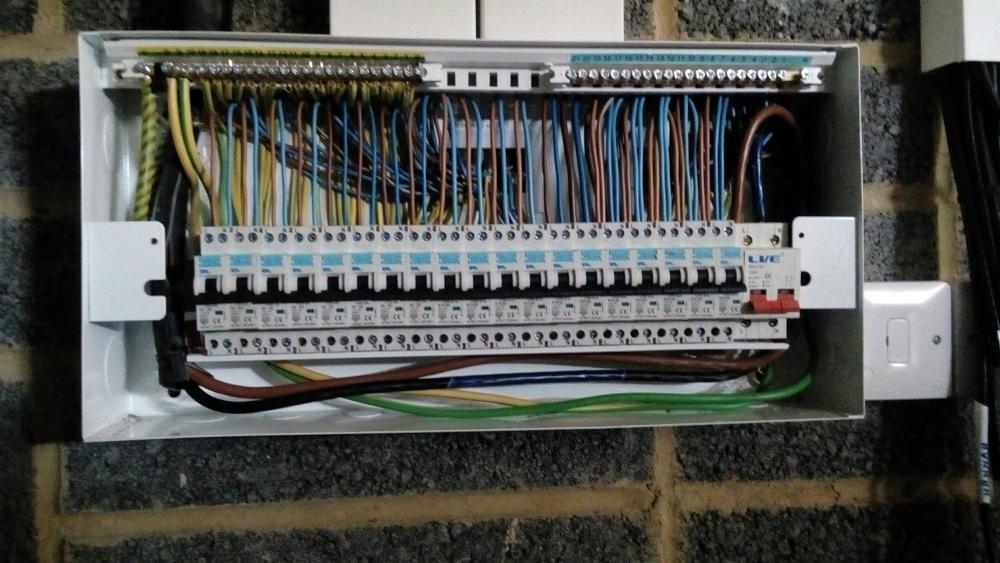

Chatting to the sparky about getting the layout of the circuits sorted and we've decided as previously it will be all RCBO. For an extra £30, is it worth splitting all of the circuits as below..? Bear in mind this is an all electric house which may in the future have solar installed (non-MCS) but only on a south westerly facing roof. Its a 3 bed house, all LED or low energy lighting. Induction hob in the kitchen and electric towel rails in 2 bathrooms along with upstairs electric tile warming (all centrally controlled) and ASHP for DHW and ground floor UFH. Immersion is for boost/legionella cycle.1 point

-

1 point

-

I apologised for the error, which wasn't as you've stated. I wrote TN-C by mistake when I meant to write TT, as well you know, as I've gone into enough detail to make this clear.1 point

-

Thank your mate for raising this question...as I think one of my mates may have asked the very same question!!!1 point

-

I could reply or just to make it more fun you could read my blog and a few others such as Jeremy Harris. There's about have a dozen of the frequent posters who have used the same supplier without any material complaints or even reservations, but others have used other TF suppliers and different construction techniques. What we chose worked for us. It might work for you. What others have chosen might also work for you. But at the end of the day, you have to make your choice as to what is best for you. If you ask here then you'll invariably get at least 2 or 3 perspectives. What I really like about this site, is that I often get out of my comfort zone, so I can research what others have done or just ask the Q. In return I give back where I do have the knowledge to contribute.1 point

-

PM + Architect + QS between them can add over 20% to a self-build. A self-build is invariably a one-off so will cost more than a like-for-like mass-built estate house, simply because the developer can amortise a lot of costs over N builds. This being said, with a self-build you and your partner have the opportunity to take on activities (if you can spare the time) that you might otherwise be paying £250-500 per day for. In our case, I've done a lot of PM in the IT world before I retired early; I also have a good 3D visualisation sense, and we wanted a fairly standard house in terms of layout, though passive-class in performance. So between Jan and I, we've done all of the design, PM, bureaucracy, and a lot of the internal trades, such as the carpentry, plumbing, etc. The end result is that we've probably saved ourselves maybe £60-80K on the cost of our build. There's a lot of other members here that have done likewise. Moreover, I suspect that there are less than a 100 commercially-build houses with comparable energy specification to ours coming on the market in UK annually. It's a long road and can be very stressful, but the payback can also be huge. And there are people here willing to help you on the journey .1 point

-

Hi, We started off with what you've got. Dpm then 2 layers of insulation - 1st at 90deg to the beams. We used 75mm celotex - this 'crushes' slightly - joints taped. Next 150mm celotex at 90deg to the first layer - if they rock (celotex is far from 'flat' - this surprised me) then use some sand to bed them onto. Take your time and you will achieve a level floor that doesnt rock. The screed will take out any imperfections. We put another sheet down under the ufh pipe and don't skimp on the clips - you dont want them lifting while the screed is going down (screeders said this wasnt unheard of). Remember to grout the B&B (ours wasnt done very well so I redid it). Dont be tempted to turn the celotex upside down - the underside foil isnt bonded on very well. Hope that helps.1 point

-

I get it a lot, no, wheel signaller sets the route so you need to know where your going, as you can't go where you don't sign. One girl asked if they have wheels because she's had only been on the underground.1 point

-

If you get a package of some sort, whether from a timber frame firm or a traditional builder, a PM should really not be necessary unless you have zero time to spend on the project or have a very complex project. PMs are not cheap, they will want a min of 10% of the build cost and that is based on their estimation, not yours. We engaged one early on and spent £1800 on a detailed budget and PHPP analysis before disengaging. We got some value for money, having next to no idea what we were doing, and the cost plan put us down the more cost effective road of timber frame vs ICF which had been our original idea. It also gave us a useful structure to plan to for costing and estimating. PHPP also gave us peace of mind that the design could work as a (near) passive house. That said, doing the PM ourselves, we came in about 20% less than their original cost plan suggested - no doubt they would have achieved similar but would have taken credit for the 'saving'. Note - I'm not disparaging PMs, I'm just suggesting that if you can put some time into managing the project yourself, or select good contractors from the outset, then you can make a substantial saving. We used lots of contractors and vendors, some for specific tasks and some for more general works but we did have a very comprehensive package from the groundworkers to build the basement and the timber frame firm to get us to airtightness (windows from separate firm). Using this forum and its predecessor, trades and fellow self builders, we managed to stay half a step ahead most of the time.1 point

-

1 point

-

These choices all come down to being informed, working out your own personal risk tolerance and weighing these up with cost and convenience, together with the potential gotchas in some installations. For example, I have a 10 way CU, filled with SP RCBOs. Despite it being a big box (in terms of depth), there is not a lot of free space in there. If it had DP single width RCBOs then I think it would be pretty stuffed, just because of the volume of wire, the SP ones are bad enough. Yes, it's very convenient to isolate a single circuit to work on it using a DP RCBO. Yes there is a tiny degree of additional protection from a couple of pretty rare fault events from using DP RCBOs. However, is it a major safety enhancement over using all SP RCBOs, with a higher rated DP RCD as a main switch? Not in my view. It's certainly better, but it's not the sort of step-change in safety we got when we first introduced RCDs. And, just as benchmark, our existing house, built around 1982/83, has no RCD, no MCBs, but wired fuses and a single DP isolator. In the 16 years we've lived here we've never had a fuse blow, or a wiring problem, and the house passes the periodic safety checks and tests I do with no problems ever showing. In terms of safety, a standard split box, with two RCDs and bunch of MCBs is actually pretty good, and a massive enhancement over the system I have in our old house. Is an all SP RCBO CU any better? Not in terms of safety, but yes in terms of user convenience. Is an all DP RCBO CU an enhancement in safety? By minuscule amount, realistically. It's big advantage is the convenience of DP isolation of each circuit for maintenance, and that's probably a good enough reason to do it. It's a bit like other risks we accept. Every planning decision I've ever seen has included a comment from a fire officer about the effectiveness of sprinkler systems and that fitting them should be a planning recommendation. However, very few people seem to take heed of that, and in my view, fire is a far greater risk to life now in a domestic situation than an electrical fault.1 point

-

Welcome This all depends on what experience you have in both areas. From what I have read on here, and my own experiences as both a project/production manager (different industries, but sometimes related), I would go for a project manager and a timber frame until made weather tight. Then organise your own subcontractors. Initial design is where you can save the money. Make it complicated and it will cost you, make it high tech and smart, it will cost a lot and probably not work. All a house is, is a thermally insulated, airtight box. Then you start to put 'holes' in it for things like doors and windows, heating and ventilation systems, wires and plumbing (and a cat flap). I often get the feeling that people start thinking about designing a house the wrong way around. The interior can become more important than the structure and this complicates things no end.1 point

-

Hi Giuseppe. Welcome to the forum! That's a healthy attitude and approach. Bear in mind that two years will FLY by!1 point

-

1 point

-

If there are fractious factions you could have the local Vicar or another functionary (King Arthur Pendragon, the local Earth Mother, or the Piper in Scotland....) come and bless it :-) "From codgers, and bodgers and ill-mannered lodgers, and stoats, and goats, and questionable scroats, and wild boars, and tame bores, and just down the lane bores, and bikers, and hikers, and people who like us... .. Good Lord, Deliver Us". Ferdinand1 point

-

1 point

-

I just wish I understood what you lot are talking about, give me woodwork any day ?.1 point

-

1 point

-

Many thanks for all that input, guys! Agree that it needs costing, and that could vary enormously depending on whether the three elements in the mix can be sourced economically. OK, not talking about 50m - that's a substantial run! - but even 50ft wouldn't come in cheap, I guess, for a decent quality close-boarded job. Plus, as stated, that would still give a large surface area for high winds to hit, which is why I wondered about the hit-and-miss method. Should have said that it backs onto a garage block, hence (a) not the prettiest and (b) will have people trundling up and down it. Height, therfore, would be in the 6ft region, and really needs to be opaque. Also thought that many people seem to use gabions as features... benches, planters etc, so it would double as a host for some kind of climbing plant down the road (fingers definitely not green so nothing to suggest in that dept!) many thanks again.... more mulling in order, nothing set in stone yet ( no pun intended!!) Cheers, Tim1 point

-

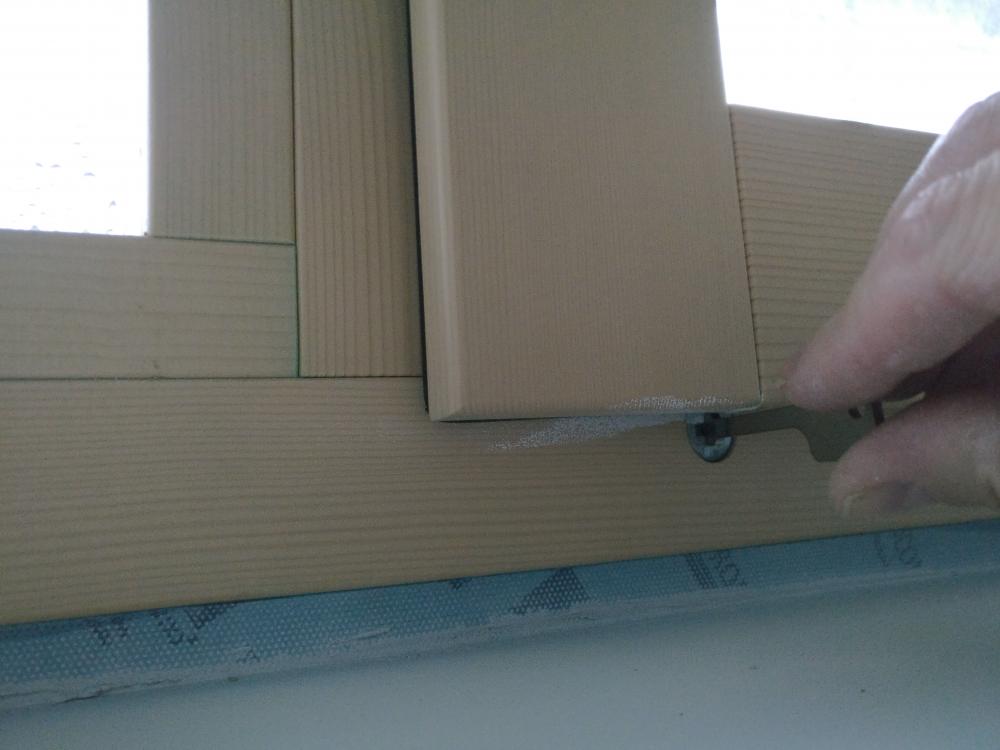

The green tape is used for the joins on any membrane as well. The window tape has a small tacky side that sticks to the window but you need the fortax 6400 to glue it to the blocks. I just sent them an email with the linear meters on it and they worked it out. Sent the cheque of and the goods arrived. Taping the floor above and below is probably your only option now.1 point

-

1 point

-

1 point

-

1 point

-

Not a lot happened over Christmas and New year while we waited for the builder, Patrick, to arrive to remove the pillar between the kitchen extention and the middle room. We initially decided to not remove the pillar but after great thought, it seemed to be the best thing - it would create more light into the dark middle room and hopefully it would make the kitchen easier to fit out. And at a cost of around £2k it was a large chunk of the budget. This is the view across the room, into the kitchen from a couple of months back. You can see how dark the middle room is. This one makes the room look bigger than it will be as we have removed the bathroom wall - it currently has an open plan loo.... The RSJ's in the garden - our only snow of the winter so far. Very exciting day when it all got going. but then, I am easily pleased...... The back wall of the house is a thick rubble wall while the kitchen extension was only build a couple of decades ago so of normal construction. But I dont think any of us realised how large the stones were in that rubble wall. Getting the RSJ's into position - I wouldnt have thought of doing that and then once all the props were in, I wouldnt have been able to bring in the steels. Good job we had an expert! This shows some of the rocks taken out of the back wall in the bedroom, above the middle room. The view into the kitchen! There had been a pillar to the right of the wall being removed on which the RSJ would sit but once exposed, Patrick was not happy with it. So he removed it all and build a new pillar. The unexpected advantage of doing this, is that now the new wall will be level with the rest of the kitchen wall, making it much easier to arrange kitchen units. This is the new pillar - much better! Patrick and the OH removing the current wooden beam. The new steels are in place and the middle room joists are refixed with steel hangers. Then its my turn to get busy. To avoid too much mess, I took out the bricks and stones individually and was able to clean off the lime mortar to leave a rather large pile of perfectly useable bricks. So this is how it looked on Saturday by the time we packed up. What a difference! we are thrilled. And we have now decided to have a U shaped kitchen with a breakfast bar where the rest of the wall is. Thats the next project for me - plan the kitchen units and get prices from Wickes, Howdens and Ikea. Hopefully before the sales run out next week. Even if it means storing them in the garage till we need them, if we can get a good price, it will be worth it. And does anyone need any large cotswold stones?? we have a few.1 point

-

Are you using Double Pole RCBOs, ? Oh, and I'd have the smoke alarms on with one of the lighting circuits, just a personal preference of mine.1 point

-

I had an issue with a tree. But I anticipated this before planning (no protection order). Next day tree had vanished! Neighbours complain (of course) and draw a picture of my plot and highlight 'non existent tree' - surely a contradiction in terms ! lol1 point

-

I left some 75mm wide sycamore saplings on my boundary when clearing it just over thirty year ago. About 5 years ago I had the last one felled and the root ground out. It was about 400mm wide by then and the root ball was even bigger!1 point

-

1 point

-

As a tip, do as Peter suggests above and use the cheapest epoxy you can get - East Coast are often cheaper then CFS , but there is another place in Cornwall that's cheaper still - I used their stuff on my last boat build, Reactive Resins (here's a link - I have no connection with them other than as a customer: https://reactiveresins.com/epoxy-resins.html ) If you want dry sand (and as Peter says it does have to be really dry) then buy play pit sand from someone who keeps it stored inside. I've used it with epoxy to even up a workshop floor and it worked a treat. As another tip, play pit sand also works well with a cheap wet sandblaster, the type that's an attachment for a pressure washer, I've found. Finally, again no plug for profit, I can highly recommend the Reactive Resins floor coatings: https://reactiveresins.com/floor-coatings-screeds.html I used their epoxy floor paint and it was nice to use (no smell, water based) and very, very tough. It's what's going down in my new workshop, I'm not even going to think about using anything else. I would have reservations about their water-based two pack varnish, though, Synacryl. I used it on a boat and frankly it was crap, lasted less that a yeatr before it started peeling off badly.1 point

-

Thanks - that's what concerns me though about this one, he's making a design change on the fly and I would be really concerned if this is not checked by an Engineer. And when there is 20 cubic metres of concrete in the ground then its a bit too late...1 point

-

B&B didnt work out much more for us. Make sure its grouted in as soon as its down or it will just fill with rubbish. Quick and easy to lay.1 point

-

The last house i built i used a flow screed on top of clipped pipes. It was pressured to working pressure during the installation. Both methods require the floor to be walked on during installation. One thing to look out for If you are putting any pipes in ducts the ducts will rise in the flow screed as there is a lot more air in the pipe and you only have 70mm of liquid to stop this1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)

.thumb.jpg.b4dcd5d056f8d4f30d7929957d3f2898.jpg)