Search the Community

Showing results for tags 'mvhr'.

-

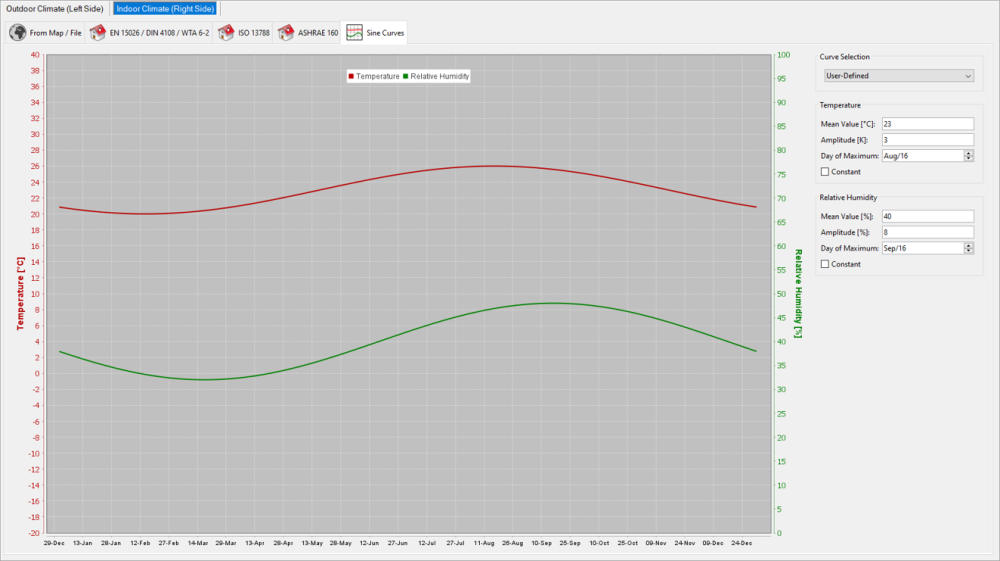

As per the title, I'm wondering if anyone with MVHR has kept a log of internal temperature and humidity data. I'm playing with the free version of WUFI, and while it can derive the internal climate by adjusting external climate data to take into account heating and aircon, there's nothing for MVHR. Which seems a surprising omission, unless it's only in the paid versions. In the absence of that, the next best option would be to define sine curves for the internal temperature and humidity, but there seems to be a lack of easily discoverable data on that. I've posted my initial guess below, but it would be good to have something to validate / correct this against:

- 21 replies

-

- mvhr

- relative humidity

-

(and 3 more)

Tagged with:

-

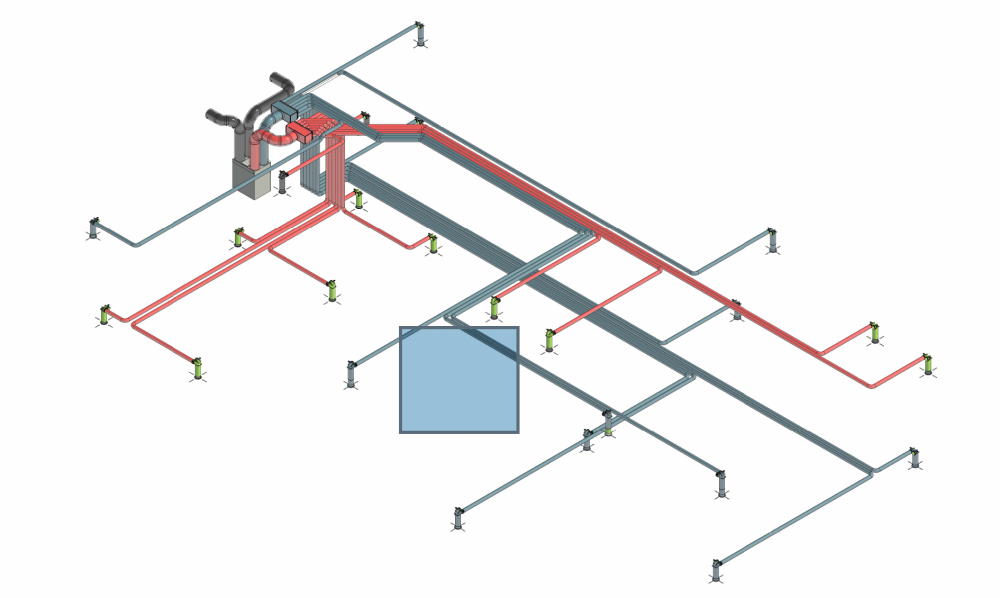

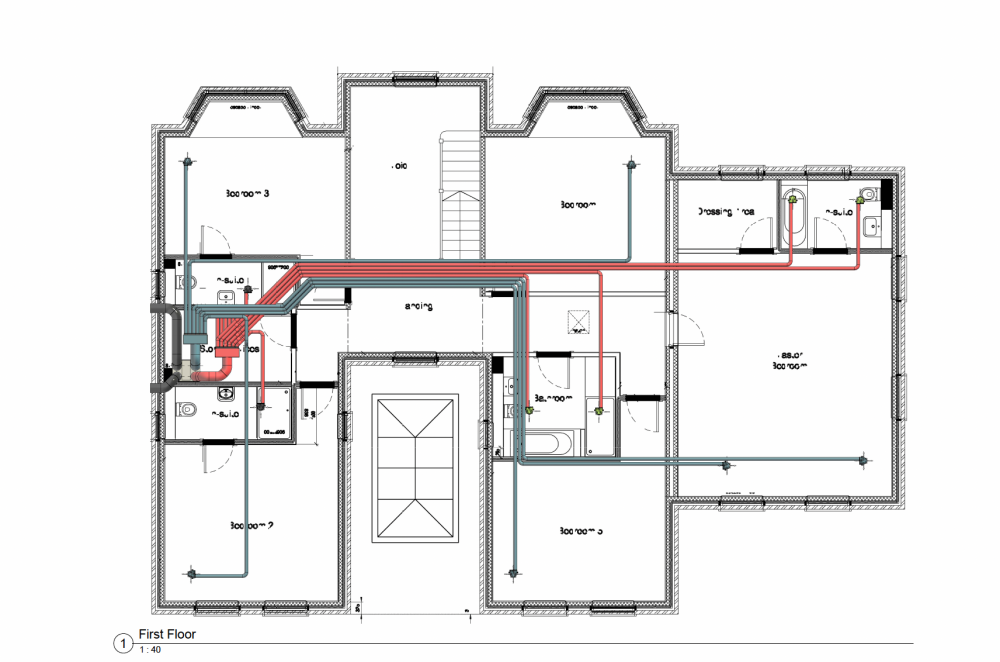

We are having MVHR installed as part of a new selfbuild project. The designer is proposing Zehnder Comfoair Q600 MVHR as per attached. The Zehnder Comfoair Q600 will be installed within the house as shown on the drawings We are having a cold roof with insulations at ceiling with 100mm across then 400mm over. Our questions are around air tightness and also not compromise on insulation. Do we need to run the ducts o the ceiling then run the 500mm insulation on top of the ducting? Any advise would be appreciated. Many thanks

- 6 replies

-

- mvhr

- mvhr ducting

-

(and 1 more)

Tagged with:

-

Hi All, I am writing to see if there is a good way to add cooling to an existing MVHR system. I have read quite a few topics from this forum on this, but they don't exactly seem to answer the question, mostly because I live in a flat where a split system is not feasible: This thread has the most information concludes that an ASHP seems to be the best option, which is not possible. This thread hints that comfort cool is ineffective. This thread stops quite inconclusively and is quite focused on a house. Here is a discussion about summer bypass, but unfortunately the unit that came with my flat seems to be the cheapest and does NOT have a summer bypass (MRXBOX95-WM2) This thread went off the rails a bit but has some ideas. The flat has huge windows on both aspects. I have done what I can to reduce heat gain with reflective film on part of the windows and big curtains, but outside shades are not an option. The flat is very well insulated and is on the 4th floor, leading it to get quite warm at night even without hot weather. For example, I aired it out yesterday and went to bed with it being 22C, but woke up with it at 25C despite the outside temperature being 12C. I suspect the cheap MVHR is part of this, but the bathroom does not have windows so I don't have much choice but to keep it on all the time. I can't seem to get it off boost mode either. Why not just open the windows at night? Unfortunately, it is quite close to a very active train line, and I find it difficult to sleep with loud trains going by constantly. As far as I can tell, these are my options: Portable A/C Pros: Cheap Cons: Loud, ugly, inefficient especially because windows are only inward opening, have to open window Get water cooled A/C installed Pros: Effective Cons: Very expensive to have done, loss of most storage space in the flat, increased water bill (??) Adiabatic cooling on MVHR, such as https://www.ventilationland.co.uk/en_GB/p/homevap-mvrh-cooler/9745/#pdpBlogs Pros: Goes onto existing system, cheaper than water cooled A/C Cons: Very little info on effectiveness (could work moderately? not enough airflow?), unclear if there are many who install these MVHR system with cooling, such as https://www.nuaire.co.uk/product-list-page/mrxbox-hybrid-cooling-system Pros: Same ductwork Cons: Can't find any reviews on effectiveness or cost I know this forum is more focused on homes, but I would appreciate any thoughts any knowledgeable folks might have.

- 19 replies

-

Following on from the excellent post by @DOIGAN where he replaced the bearings in one of the fans from his MVHR, this is a short post to detail the steps to replace the bearings in the extract fan in my Vent Axia Sentinel Kinetic Plus B (being a slightly different model and fan to that of the link below) The process I followed is basically the same as laid out by @DOIGAN in his original post. I've added a couple more pictures and descriptions below. To get at the fans, the unit has to be stripped down. First the duct spigots and blanking plates are removed. Both the back and front covers are then removed, allowing the top and side panels to be taken off - the side panels slide/interlock with the top and bottom panels. You should then have access to the fans on either side which are bolted to the poly core: I then disconnected the power connector to avoid having to try and unplug from the motherboard / cause any other issues. From this point I followed the process as per @DOIGAN Removing the circlip was a bit challenging, as for some reason the hub assembly would not depress, it turns out because the spring beneath wasn't seated properly. I managed to get the circlip off, but naturally it pinged up into the air and I spent several minutes searching for it until finally finding it some distance away. The bearings themselves (one on either end of the hub) popped out easily. I used the same bearings as @DOIGAN Reassembled and back into the MVHR unit. Cost - my time and £7.99 for a pack of 10 bearings vs £298.43 + VAT + shipping charge for a replacement fan from Vent Axia. Vent Axia were unable to give me any detail of the bearings used when I emailed to ask.

-

Hi, I have just powered up my newly installed MVHR system, a Vent Axia Sentinel Kinetic, 2 x 6 way manifolds and 50 metres of 90 mm semi rigid plastic ducting. It's a retrofit into the existing loft space. It seems to be working fine apart from the noise. Standing under the vents I can hear a gentle 'woosh' of the air coming out of the vents, but from even further away, I can hear what I'd call maybe a 'droning' noise, it's like there is an echoing in the ducting. Not sure how to describe it better. It's not massively loud, but loud enough to raise complaints from the family. As it's a cold loft, the Sentinel Kinetic has had a 25mm EPS foam box built around it, so it's sitting on a platform, with an EPS base. The same as the metal manifolds, these have 25mm EPS outer boxes too. The ducts are strapped to the top of the trusses. The whole lot has been covered with 400mm of new rockwall insulation. Any insight into where the noise is coming from and how to fix it are greatly appreciated.

- 30 replies

-

- mvhr

- mvhr ducting

-

(and 1 more)

Tagged with:

-

This week its all about MVHR. Most of the plan is sorted and I've read all the topics on here but a few stupid questions remain. Please help... 1. Voids From our ground floor kitchen we have a void that runs up through the first floor and into a vaulted ceiling with a velux. There are no openings in the void above GF so it is effectively airtight to the rafters. The void sits above the dining table and between the kitchen and living space. There will be kitchen extracts on one side and supply valves to the other side of the void. There will therefore be some passage of air across the bottoom of the void, but what about higher up where there is no ventilation? Should there be a supply or extract valve near the top? Would there be a condensation risk without ventilation? Would natural convection currents control humidity and I don't need to worry about this? 2. Pantry Should the 2m sqaure pantry have an extract or supply valve. The pantry has a single door to the kitchen with an extract about 2.5 metres away in said kitchen. 3. Fancy valves I quite like the look (and claimed acoustics) of some of the outragously expensive supply/extract valves like Lindab airy or Frankische or ergovent. Are they worth the extra dosh? Does anybody on here have them? 4. Balancing at the manifold I read on here somewhere that its better to balance at the manifold because there is less noise. Is that true?

-

Hi all 👋🏼, I wanted to introduce myself and our project as I anticipate I'll be in hot pursuit of the forums thoughts, opinions and experiences in the forthcoming months. We purchased a 3-bedroom 1970's bungalow in August 2022 but had some planing complications due to a parish council policy that attempted to dictate that "a bungalow must stay a bungalow". 15 months later our planning application was finally granted, albeit with some compromises. Here's a few points on what we're attempting... Replace existing roof (& ceilings) entirely, building up the walls ~80cm, adding a new roof with 1.2m increased ridge height and steeper pitch Upstairs will accomodate two bedrooms, bathroom and "breakout area" overlooking hallway void Large single-storey flat roof side and back extension out to locate 65sqm kitchen/diner Complete re-configuration of downstairs layout Complete replacement of heating system (gas will be cut off entirely) New ASHP (current thinking Valliant Arotherm Plus, one-zone, no buffer) UFH all-round on ground floor (retrofit lo-profile UFH on top of the existing slab (Wunda?), insulated/screeded in new extension). Possibly fan convectors in bed-rooms upstairs Complete rewire I would assume MVHR (current thinking is a radial system installed through new posi-joists, manufacturer TBH but will get BCF to design) New solar panels, and battery (current thinking GivEnergy to unlock Octopus Intelligent Flux) New double-glazing all round (Residence R7 probably) also 2.7m high, ~8m wide sliding doors at rear (either Corteso Cor-vision or Minima) The biggest grey-area for us at the moment is how much to focus on/invest in improving the insulation and air-tightness of the existing exterior walls. I'll raise a separate thread for this in due course. Fortunately we were able to leverage a second mortgage and keep our existing home so we don't intend to live in the place whilst the majority of the work is taking place. The properties are only 0.5 mile apart so I am hoping I'll be able to keep a close eye on the build whilst I work from home. We are also intending to do a little of the work our-selves as possible (i.e. fitting MVHR, UFH, painting & decorating, airtightness membrane?, etc). Thanks for having me and in advance for any advice, Ollie Fleet, Hampshire Plans 24 OD - Amendments Combined.pdf Concept Images Existing Images

-

A question for the non-smokers. My upcoming MVHR install, in an apartment, has only two possible places where the outside air intake can go: Within 1m of an external landing, where people sometimes smoke - and the smoke will sometimes get draw into the inlet. This option would have a short intake pipe, but a significantly longer exhaust (x 4). Within 1.5m of the top of a neighbouring SVP - and the smell from that will also sometimes be drawn into the inlet (not so often, but for longer). This would reverse the pipes - a short intake and a much longer exhaust. Due to space restrictions, the exhaust can only go in the other location to the intake, so I have to decide between a choice of smell-source vs exhaust pipe length. The pipes will be well insulated, but can only run through the ceiling space. In theory either smell should be eliminated by the carbon filter that I'll be installing, and if so I have a preference. But has anyone got experience of how well either smell gets filtered in practice?

- 9 replies

-

- mvhr

- carbon filter

-

(and 1 more)

Tagged with:

-

I would like to jerry-rig the MVHR unit to have it running over the winter months before I finally install it properly next spring. But how to mount it? I have about 6-weeks of cladding to finish off before I can turn to first fix. And then it will take me quite a while to get around to installing the MVHR unit properly. So realistically that won't be until next spring. I am very slow. I often camp on site as I work, treating my build as a (very well insulated) tent. The timber frame is insulated, weathertight, with windows and a temporary front door. Its also airtight (blower-door test of 0.47 ACH (n50) recently). The MVHR unit (Brink Flair 325) is sitting in its box waiting for me. And most of the ducting is already installed (with their valves). Hence, I'd like to temporarily set-up the unit and have it running over the winter months. - How to mount it? - The MVHR unit itself weighs 37 kg. - The walls are 240mm I-beam cassettes, filled with Warmcel and I know where the I-beams are located. - The external wall are currently bare 12.5 mm Smartly but will eventually be covered in 50mm insulated plasterboard. - I could power it from a 240V extension lead. - I could run the condensate drain to local external drain. Any pointers on how to do this would be gratefully received?

-

Wasn't sure where to post this but here's our observations after storm Eunice passed through. Initially we watched the storm gather, we could see that that the wind was strong but from inside there was no indication, no sound, no draughts. As the wind picked up something we were not expecting happened, we could hear and feel a draught. We have two fairly large sliders and at the peak of the storm, the wind was pushing against the slider so much that there was airflow between the slider and the fixed pane. Not much and not continuous but it was definitely happening. Our air test was done to passive standards (positive and negative pressure) so we're fairly certain there is no problem with the sliders because if there was then the negative pressure test would have exposed that. Anyone have a contradictory view? A short time later we had a power cut , that doesn't matter. The house is warm, the Sunamp is fully charged (minus two showers), what could go wrong? Well, we're fully electric so there was no cup of tea to sup whilst watching the storm play out. Information gleaned is that the power will be out for over 48hrs And of course there's no heating. But what does that matter because the house is toasty warm at about 21.5° and we've not had any heating on for days. And the house is almost airtight, apart from the few blasts that squeezed through the sliders. Thanks to @Adrian Walker's advice we have a CO2 monitor, well we bought a couple. It was quite amazing how quickly the CO2 PPM started to increase after the power cut. Obviously the MVHR was having a bit of "quiet time", so now we had a toasty warm passive house that was not working as planned. As night drew in it got worse because lots of candles were lit. The only solution was to open some windows and get some airflow. Out of interest, it was only the monitors that informed us of the poor air quality, it wasn't something we sensed. So, we have a toasty warm passive house but with no airflow so a couple of the 'tilt and turn' windows on opposite sides of the house were tilted. That fixed things, air quality wise, very quickly but it also meant the passive house was now going to cool down more rapidly than planned. There are no heating options, apart from the bio-ethanol fire) so we were getting ready to break out the cold weather gear. Fortunately power was restored about 12 hours after the cut. We have a fair amount of PV, and it was quite a sunny storm but of course the PV trips off in a power cut. We were meant to have a battery system but the that didn't happen. The M&E individual who specced that (and didn't provide) had wired in an emergency power supply from which we could run the fridge and freezer in the event of a power outage, which was a pretty smart idea, shame it never happened, but actually my advise to anyone building to passive standards, if they have a battery system then make sure that the MVHR will run off the batteries. That's the main thing we've learned. If you have built to passive standard and have a battery system, make sure your MVHR can run from the batteries in the event of a power cut, I suspect most battery systems will power an MVHR unit for ages. Without that, you're not in a passive house anymore. Oh, and we had the first BBQ of the season this evening. Bit nippy!

- 59 replies

-

- 13

-

-

-

On the last two mornings where its been pretty cold outside I've found a small amount of condensation on the insides of some of our triple glazed windows, I promised the good lady this would never happen!! The house is built to passive standard, has good airtightness and MVHR. Should I be getting condensation on the insides of the windows, and if not, what is going wrong?

- 131 replies

-

- triple glazing

- condensation

-

(and 3 more)

Tagged with:

-

Has anyone managed to find an off the shelf access hatch that can be plastered up to and on top of, that is also of a high standard of airtightness AND has some level of insulation incorporated? I am doing a basement conversion that has service hatches to rest of ground floor underfloor crawl space; house will be fixed up with oodles of insulation and MVHR hence I need something good here. In the absence of finding something off the shelf I will just get a well-gasketed plasterable hatch then inside it fix up a PIR inside a 3x2 carcass that can be screwed or similar to the inner reveal (which will be quite deep). Thanks, Tom

-

I need to improve my ventilation, and I am thinking about options. My house is a 2010 extended-upwards-sideways-and-backwards bungalow with three bedrooms and a bathroom in the warm roof - and I only have a limited number of remaining triangular roof spaces to play with. The house is reasonably well insulated, but was not targeted for near passive renovation or similar standards. One driver is checking C02 levels, which in a couple of places go up quite high, and do not come back down again swiftly (==> more ventilation should be considered). I do perhaps have room for the MVHR unit in the garage or planned to be extended utility, but also have limited spaces in which to put the ductwork etc. downstairs. Clearly an MVHR needs balancing etc, but how much benefit will I lose by not installing one in all rooms, if I can get to say 2/3 of the house? Perhaps an alternative is to adapt a strategy of a PIV upstairs, and constant HR low volume ventilation downstairs. I'm going to need to spend some time thinking about this, so I'll welcome any thoughts from anyone who has not quite been able to do a full MVHR, or has installed one in an older house. Cheers Ferdinand

-

I have a Brink flair 400 My commissioning certificate says this: The options for my system (as commissioned by the supplier) are level 0. 50m3 level 1. 180m3 level 2. 255m3 level 3. 330m3 When I realised the system was a bit noisier than usual (as mentioned in my recent exchange with @jack), I started investigating what was going on and saw that it was operating at level 2, when I seem to remember that level 1 was recommended for default use. I have turned it down to level 1 and the system is definitely much quieter, hardly audible. I think level 1 is the correct setting I should run it at, but grateful if somebody could confirm this based on the commissioning certificate which definitely counts flow rate at the higher 255 m3/hour value.

-

Reaching the final straight, need to purchase the main MVHR unit. Was originally going to get an Adroit DV110 but the prices have rocketed, the Kinetic Advance SX looks a strong contender, however the limited reviews of the App on the Apple App Store do not seem very favourable... A key feature for me is being able monitor and interact with the MVHR when away from the property, (new build is over 100 miles away from main house) I've seen the Adroit in the flesh and used the 'cloud' function and whilst clunky it does what I need. Anyone actually got a Kinetic Advance SX, how are you getting on with it and the app?

-

Hello everyone, I am writing to ask if anyone has any experience using a MVHR unit such as the Vent-Axia High-Flow to provide the ventilation on their indoor pool? The Heatstar XF Units are essentially just a bigger version except with air heating and water heating however those two factors can easily be taken care of with UFH and a pool water heat exchanger? Thanks if anyone can help.

-

Hi all, We are looking for opinions and advice on the systems we have currently specified for our build. It’s a near-passivhaus build, with MBC timber frame on an insulated raft foundation. Our predicted SAP rating is 102. The Primary fuel will be electric, there is no gas in the village, and we don’t intend to install LPG or Oil. We plan on having a large solar array (just waiting to DNO approval at the moment) and Tesla Powerwall – using the Octopus Tesla Electricity tariff, so power diverters and smart energy management are off the cards. We are looking at having a Sunamp Heat battery, in place of a hot water cylinder, and heating the house will be Ground floor UFH, and potentially using the MVHR air. We would like to run the ASHP in reverse in summer to cool the ground floor slab and the MVHR – but would still need to run it forwards to charge the heat battery. The Sunamp would be the HP version, which has primary input of (High Temperature) ASHP, and a backup option of mains electricity. This suggests 2 possibly options for Hot water in summer: 1) Run the ASHP in Heating mode when necessary to charge the Sunamp – and disconnect the UFH and MVHR art this point 2) Always run the ASHP in cooling mode when actively cooling, and charge the Sunamp from electricity (surplus from the solar in summer). Sunamp specify ASHPs to work with the heat battery, one being the Valiant aroTherm which is reversible. We wonder if anyone has done this sort of configuration and can offer advice on how they achieved it / information on how it has performed. Is there a valve / manifold product available that could handle isolating the output of the ASHP from the Sunamp or the Heating elements depending on which mode is being used on each? Our main concern at the moment is that we like a cool bedroom (17 – 18 degrees) and want to make sure we can achieve this year round with the systems we install. Here is a simple diagram of the system we are trying to describe with this post.

-

Hi, have a question about incorporating the impact of MVHR when calculating heat loss. Background: New ICF build near completion. My Heat pump installer has calculated I need 8kw of heat at -1/21. However, after incorporating the 90% efficiency of MVHR into heat loss calculations, this drops to 6.5kw. This was done by reducing heat loss through ventilation to 10%. This also synchs with my UFH room by room heat demand calcs. Theoretical efficiency of the MVHR unit is over 95%, and my u-values are conservative, eg I have double bubble-wrap foil under roof but have ignored its additional R value. Same with impact of plasterboards, render etc. So fairly confident about the stated heat losses not being more. Issue: My heat pump installer INSISTS that I should ignore the MVHR because it could fail and if that happens in the middle of -1 degree winter I need to have additional capacity for heat. He wants to install a bigger system to suit the 8kw demand. The change to the bigger unit means my outside unit will double in size, which I absolutely do not want unless I really have to. My arguments has covered the following, none of which has convinced him: - extra cost of bigger system (£1,000) will take years to be recovered through multiple failures of MVHR just when outside is really cold - even ignoring the upfront costs, having to supplement heating with electric radiators/fans for a couple of weeks every few years (IF the MVHR fails), is not actually that huge. - MCS has been non-comittal on this and says it is a design issue for the installer to decide - What happens if the heat pump fails? What happens if there is no power for 10 days? Why do we need to assume the MVHR fails? But not anything else? What am I missing here? I realise I am a little on the borderline with the 6kw system which only has a couple of extra 100 watts of power at -1 outside, but I am quite prepared to supplement that with normal electric heating when I have to. MCS have not objected, and it is my risk to take. Any advice? Is there a rule about excluding the impact of MVHR when calculating heat losses? It is just so incredibly odd that my installer wants to disregard the heat recovery impact when working out ventilation heat losses, which sure.y goes against the spirit of MCS. Thank you!

-

I will write about the install of my MVHR system, as this is something I have done myself (with help). Theo house is being built by my contractor, supervised by my Architect and QS (who is the CDM). As I am remote from the location I can only watch what happens on CCTV. When I was last there the old house was standing and we had disconnected the services. 6 Months later, I have a new house, Weather tight shell, Windows and doors in, sarking and felt on, and tiles and PV being fitted. I am doing the MVHR as I couldn’t find a company to design and install what I wanted so I did it myself. Had a slot in the schedule for me to work and got on with it. Internally the team were completing first fix joinery (all the stud work). This was the two-man team who are always on site and are doing the majority of the work, the company bring in others when required, but the two in the house whilst I was there are my main team. My design: This is my layout as planned, 2 x Brink Renovent 400 Plus units, 4 x Ubbink AE 24 port distribution boxes, 180mm insulated duct and silencers for the main runs and 350m of AE48C duct, 50m of AE34C duct with all the associated connectors and fittings. A total of 36 outlets/terminals….. Suffice to say it is a lot of equipment. It arrived on 8 pallets at around 1100 on the Tuesday morning. I sourced all my equipment from CVC who were/are great, arranging delivery slots, supplying additional equipment quickly, and I still have an outstanding order for the vent terminals and some other bits still to complete. I arrived on the Monday lunchtime after 6 days of traveling (not all to get there) and had a meeting with the site manager and the first thing we agreed on was to board out the plant room with MDF (as a final finish) so that we could install the equipment and be done with it (rather than approximately place it and then remove awaiting final plastering) This turned out to be one of the best decisions as work could be finalized and other trades could also finish work in there (First fix electrical could fit the 24 way 3 phase CU)… We also got the loft boarded out at this point to enable the first floor runs to be completed. On Tuesday morning the building team started boarding the plant room, starting on the wall that the MVHR units were to be sited as a priority, this was completed by the end of the day and then started on the attic boards. Once the delivery had arrived and I had checked it I had some initial work to do. First to install the acoustic insulation into the distribution boxes and trim the spigots to the 180mm mark and move 2 of them to the top for the ground floor. I the attached the first 2 silencers to the top mounted distribution boxes (Large jubilee clips (44-217mm) work perfectly). These would then be mounted against the ceiling with the silencers running up into the plant room. (the first floor is 250mm concrete planks and I am having a suspended ceiling to put all the services in). This is where having a builder with all the equipment to hand come in handy. One of the team then worked with me, the manifolds were fixed to the ceiling, simple concrete screws direct into the planks and then we started on the ground floor ducting. (I had pre calculated what ducts from what rolls, but that got altered on the fly when we had longer lengths remaining) The duct was run through the stud work and fixed approximately every 2 meters either with wood screws to the stud work or concrete screws to the ceiling. Rather than buying the Ubbink fixings £15.42 for 10, I used builders band £10.00 for 10m and plumbers felt £10.00 for 20m (you can probably get it cheaper) as the fixings. The above shows the 2 ground floor manifolds and you can see how the builders band and felt was used. We got most of the ground floor ducting done in one afternoon. The terminals were left dangling with about 1m to the previous fixing to allow them to be positioned by the plasterers when the fit the suspended ceiling as they will be positioned either in the centre of a ceiling tile or plasterboard (room dependent). Wednesday started out installing the MVHR units as the main ducts needed to be installed before the attic runs could be done, this also allowed time to continue boarding out the attic. The first unit was positioned on the wall and to support it extra noggins were installed behind the wall, easy when the stud work is still open: We mounted the second MVHR unit then measured and marked out the penetrations for the ceiling. Then the builders simply took down the ceiling boards, cut them out and put them, back up. The ducts then had a perfectly snug fit through the ceiling. The two silencers going into the attic had to be slightly compressed oval to fit due to a double joist. Images of the plant room with the MVHR units fitted. (already painted) Fitting the attic manifolds was a little more complicated, the supply manifold went as planned Here you can see the 2 x 90-degree bends attached to the silencer going into the manifold and all the ducts coming off. The exhaust manifold wouldn’t go in as planned and had to be rotated 90-degrees to fit between the truss webs, fortunately I had plenty of 180mm 90-degree bends for the final connections. Exhaust from below and side (one duct moved between pictures). All the exhaust ducts were relatively easy to run (crawling through the webs). 7 of the supply runs had to cross the attic and not wanting ducts in the main storage area, these were turned down to run along the joist space. On the supply manifold you can see 5 of the 90-degree elbows turning then down and below the left 3 (2 from the side and one of the front ) look like this from below: This was the plan, but on the far side as the came up beyond the truss webs (non-boarded area) I didn’t use the 90-degree bends on the far end just curved them into place. You can see the runs under the attic boards (incomplete) and moving off to the respective locations. By Thursday we had installed all the ducts and terminals (so 3 days with a builder and all the tools). We then decided to fix the first-floor terminals into their final positions (just plasterboard for first floor) so either screwing/banding them to rafters, screwing to the attic boards where available, or inserting small offcuts to attach them to. The decision was made to paint out the plant room so we removed the MVHR units and ducts, bagged the ground floor ducts and the builders sanded and filled all the screws. It was painted on the Friday (advantages of a builder and his contacts). During the week I realised I needed to order some extra circlips (not easy to get large ones) so I ordered them via CVC and also my RH sensors which were quickly delivered. I installed these into the units (whilst dismounted) not an easy task, very fiddly and not to be recommended on a unit that is already installed. And the sensor heads into a short length of 180mm insulated duct. On the ground floor units we had a short length connecting the silencer to the MVHR unit, but one was not planned for the first floor ones, however as the silencers are flexible and compressible I inserted a short length on top of the House supply and exhaust connectors for this purpose and inserted the sensor there. Sensors installed in insulated ducting (simply tie wrapped into place) I then just had to wait for my final delivery. I am planning to plumb my cisterns into the MVHR (Se the previous blog entry) however since then @Auchlossen has done a similar utilising 75mm ducting so I decided to go down that route (hence the roll of 75mm (AE34C) ducting) I did use it for some runs. I ordered 3 x OsmaSoil 3S094G 82mm Reducer to 50mm Grey 860749 to fit over the 75mm ducting and convert it to 50mm plumbing push fit. The plumber will do the rest as detailed in the previous blog. These fit almost perfectly. The first picture shoes one pushed up to the seal, the second one shoes one pushed onto the seal. They are very tight with the seal but will push on and make a good airtight fit. As part of my initial plan I purchased a HB vent terminal for experimentation, just to prove that these systems are interchangeable I fitted an offcut of 92mm (AE48C) duct into the HB terminal, no problem. So, when the question comes up can you mix and match, yes (within reason). On issue I see with the HB equipment is I am not sure how easy it is to unclip the terminals once in place as there does not seem to be a way to easily und the locking lugs. On the Ubbink equipment you can unlick them by twisting the red click ring until it disengages and then remove the duct! The roofers are currently slating the roof and will fit my vent terminals in the appropriate positions with a 500mm length of duct to protrude through the roof insulation. These will then be connected up to the MVHR ducts when a come back to do the final commissioning, fit outlet terminals and balance the system. (next year).

-

Following on form the PHPP calls it looks like we'd benefit from some active cooling. I know Jeremy has the Genvex Premium 1 and is very happy with it, but are there any others out there worth considering? The only other that I've seen so far is the Paul/Zehnder one but that's coming out at about £7.5k plus vat - the Genvex Premium 2 that we'd need is about £5k from Denmark and £5.5k from the UK (both plus vat). I'd obviously like to get that down as much as possible if I can

-

Hi there! I haven't managed to find a plot yet but for the past few months I've been designing the perfect home for my partner and I. I want it to be as "eco friendly" as possible but I'm not fussed on the technology that's used in home nowadays (ASHP's & MVHR's). That's why I've focused on a small footprint with lots of airflow around the house and just a wood burner as the main heating source for the winter. I am considering electric underfloor heating in the bathroom if needed. The shell will be made from SIP panels and will be clad in cork rather than a traditional brick, render or timber cladding. I'll also have a Solar Assisted Heat Pump for hot water as it has less moving parts than an ASHP and is ample just for our hot water use. My main stumbling block now is whether the ventilation system I want is adequate (I think it is but have no real experience apart from research online). Rather than a MVHR I've gone for a PIV system to pump in the fresh air and some old fashioned vents to exhaust the stale air. I'll be relying on air currents to transfer the heat and fresh air around rather than tons of ducting. I've attached a pic to show my ideal layout and some of my ideas. Anyone have any experience with this type of low tech build here?

- 52 replies

-

This is what my system controls would look like if I didn't have a computerised home automation system: Wait a minute, I haven't got a computerised home automation system!

-

Running all 4 in the winter is quite interesting: PV generation: About a week with overcast skies and then a couple of days of sun. January is supposed to be the low point for PV generation. Based on the EU calculator we should produce about 180kWh in January. We measured 195 which is about 6.3kWh a day on average. However generation happened spasmodically along with the weather. For example 14kWh on a good day and 0.86kWh on a poor day. EV Having the electric car meant that on the few days in the month when the PV generation was over 2kW we charged the car. We use a 3kWh plug in charger. Even with a 5.12kW system on the roof at peak generation during January we only saw a top of about 3kW, so rather than waste (send to the grid) maybe a kW or two we charge the car when generating 2kW or more and reduce the overall cost of charging the car. We calculate that over a ten year period that 1kWh used will have cost us about 10p. Hot water: Most of the excess was captured in the hot water tank using the Solic 200 controller and a 1kW twenty seven inch immersion. Twice even reaching over 60C resetting the countdown timer designed to warn us when the tank has not been over 60C for more than 10 days. MVHR The MVHR is now running smoothly with all controls working. One of the interesting items is the water coils that have been installed in the air ducts. These have increased the inlet air temperature from 17C up to 25C depending on the heating water set temperature and flow rate through the coils. Quite nice to have warmer air into the rooms in winter. Can't wait to use them in summer when cooling the bungalow using the ASHP and powering the ASHP using the PV. ASHP: ASHP kWh use over January roughly 9kWh a day for 100m2 for average 20 C over 24 hours indoor temperature. Had to move the ambient temperature sensor on the ASHP the other day because it was exposed to direct sunlight and effecting the temperature compensating mode. If it wasn't for Build Hub and the helpful contributors I would have struggled with half of this..... Thanks to everyone on here who helps. Many people who are new to the idea of ASHPs will find this a good place to start. Good luck with your project. M

-

Hi everyone I’d welcome your thoughts please, especially on heating. Wanted to reach out to you all as I’m finding it’s tough to get unbiased advice and personal experience. We’re just about to start a renovation and extension project to a bungalow. The existing building is a time capsule from 1979 with a stunning avocado bathroom suite so we need to do the works: heating, ventilation, electrics, skimming, new flooring etc. So we have a blank canvas. We’re trying to work out the classic air source heat pump vs gas, and UFH vs radiators conundrum. The existing property is 60m2 with a concrete floor (the very fashionable original self-adhesive tiles are below an equally fashionable retro carpet). Ceiling height is c.2.3m. We need to plasterboard the ceilings before skimming, so are losing a touch of height there. The extension will be 30m2. Attic insulation is going to be increased, there’s cavity wall insulation, and we’ll be putting in new windows. We’re looking at installing MVHR. The existing property’s radiators need replacing anyway and the pipes are all currently mounted on the walls, so if we went for rads here it would be a big job including all the pipework chased through the walls, etc. Even if we couldn’t afford a heat pump now, we’d want to make it as ‘heat pump ready’ for the future as possible by using low flow temp rads, etc. Because of the expense of this scenario, we wonder the actual cost difference with the alternative, which is a low-profile retrofit UFH system? I’ve been researching and awaiting quotes - I’ve heard back so far from Nu-Heat for their LowPro Max. I’m concerned with appropriateness for the existing building, cost, additional lost ceiling depth (although I’m pretty short!), and if there’s a building regs issue with presumably having no insulation with the original concrete floor. We’d like to do UFH in the 30m2 extension and have been quoted so far for Nu-Heat’s relevant system. The grant from April closes the financial gap between a heat pump and a new gas boiler, as if we went for old school gas there would be extra costs to replace the ancient combi as well as moving the gas supply (crazy money!), required to accommodate the new floor plan. So as there would be a relatively minor jump in cost to a heat pump, we’re wondering if the time is right now? And if so, how this would influence the choice of UFH vs rads in the existing part of the house? Would really appreciate your ideas, observations and experience. Big thanks

- 12 replies

-

- air source heat pump

- gas

-

(and 8 more)

Tagged with:

-

Well the combo is coming together and my wife insists that I make the controls as clear as possible "in case your not here". I wondering what she means. Still a lot to do though..