Search the Community

Showing results for tags 'condensation'.

-

Hello. We have a first floor bay window that sits on a brick wall that is 1 brick deep with render on the outside. The render had a few vertical cracks which were repaired and the outside of the house was repainted a couple of years ago. Please see the photos. In the middle of the bay window is a long radiator. On the wall beneath the window cill there is damp on the left side where the cill touches the side wall and this damp continues across most of the bay under the cill. There is no dampness on the side walls above where the window cill touches them. There is also white mould on the wallpaper. Where wallpaper has been removed for photos the plaster is cracked and discoloured. Two questions - 1. Could this dampness be due to condensation? 2. Will replastering the wall then insulating it cure the problem? All thoughts welcome. David.

- 6 replies

-

- condensation

- wall

-

(and 6 more)

Tagged with:

-

I’m currently stripping out the old plasterboard on my Small Mission Hall project on the Isle of Lewis in the Outer Hebrides. The building has not been in use for years and has never really had any effective heating. interesting once the plasterboard is off, you can see small drops of condensation form on the walls. I assume this is kind of normal? I’m keeping windows open whilst I work, but I assume that it will need heating at some point to help combat this? I appreciate that 500-600mm solid stone walls are likely to have moisture/damp to some degree especially being in the Outer Hebrides! In the future, I’ll need to be adding internal insulation within a standalone stud framework.

- 2 replies

-

- solid wall

- stone wall

-

(and 4 more)

Tagged with:

-

On the last two mornings where its been pretty cold outside I've found a small amount of condensation on the insides of some of our triple glazed windows, I promised the good lady this would never happen!! The house is built to passive standard, has good airtightness and MVHR. Should I be getting condensation on the insides of the windows, and if not, what is going wrong?

- 131 replies

-

- triple glazing

- condensation

-

(and 3 more)

Tagged with:

-

I'm having a condensation issue with our "mid-60s built" garage made of precast concrete walls and metallic roof When outside air temperature drops below 10°c the walls are literally "sweating" and the roof "showering" everything stored underneath (the 2 last pictures are taken in a hotter day so it is dry inside). Worth also noting that there is an air gap between the roof and the walls, running on each side of the garage and at the rear From what I've read online the most efficient way to fix this condensation issue might be by improving the insulation, I have a limited budget and DIY skills so I'm looking at something not too pricey and fairly easy to do. For now I was considering to glue some aliminium bubble insulation foil similar to this one :https://www.amazon.co.uk/SuperFOIL-Garage-Door-Insulation-6sqm/dp/B01ENLVTBA or some polystyrene insulation boards. (Right now I'm more lining toward the aluminium foil as I'm worried about the durability of the polystyrene). Am I going in the right direction ? ? I would be really interested to have your thoughts about it ?

-

- condensation

- roof

-

(and 1 more)

Tagged with:

-

My distribution box for the MVHR ( sometimes called spigot box or manifold) will sit beneath a flat roof , but above a ceiling. The roof build up from top down is; Alvitra Avalon over 270mm of insulation on some super expensive vapour stuff - forgotten the name - the price was so traumatic 22mm OSB3 POSIs above the ceiling build up which is Vapour control layer 25mm insulation 12 mm plasterboard 2mm plaster skim. There's enough space for spigot boxes to sit comfortably under the POSIs. That means they are outside the heated envelope. (just) The supplier says not to worry : but they would wouldn't they? Everyone has that problem, said the rep, What do you think?

-

Hi, I'm requiring advice/suggestions regarding protecting my timber soleplate from condensation/moisture between it and the DPC. I've read various threads how moisture can remain through lack of ventilation, and difference in temperature of timber and blockwork beneath, but not found a relevant solution yet, if necessary at all. Please see attached drawing for the build up. The wall is built and i'm starting timber cladding in the new year. So, before cladding commences i'm wondering if there is something i can do at this stage to insulate the blockwork wall externally, without bridging DPC ??? Foundation detail.pdf

- 27 replies

-

- timber frame

- soleplate

-

(and 2 more)

Tagged with:

-

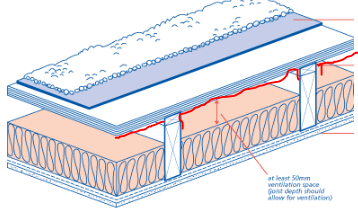

Due to circumstances I have ended up with a cold roof for front hallway/porch. During renovation of the old house, I noticed mildew on underneath of the decking due to condensation. There was quite a bit of humidity at the time when the old internal slab of the house was being dug up. Roof didn't have any insulation or VCL at this time so I can see how condensation occured between cold/warm surface of the roof deck. I'm now at the stage to insulate and plasterboard the flat roof and want to minimise any future risk. I will have a 50mm ventilation gap between insulation layer and also a VCL beneath insulation layer as in this pic: However, still a bit concerned about condensation underneath the deck itself, so was either going to stick some VCL/polysheeting directly under deck or use some liquid DPM instead: Painting on the DPM would be a lot easier and a bit safer as over time the spray adhesive with the VCL could fail causing the sheeting to come unstuck and block any airflow. Any cons for me for using a liquid DPM instead? I'd end up with 2 VCLs - good if the main VCL is punctured at some point (electrician / downlights).

- 6 replies

-

- vcl

- condensation

-

(and 1 more)

Tagged with:

-

Planning for plasterer to go over the old plastered walls with a thin skim. Of course I'd already started to prep the old walls by taking out old hooks, flaking paint etc. Now with with the humidity from the damp weather, I'm getting condensation on the walls which is evident along hairline cracks. Is there anything I can apply to prevent this (i.e. prevent the plaster soaking up any moisture) as I don't want to end up having to remove all the old plaster due to damage from the condensation. Plasterer is set to start in January, so only 5-6 wks time. There's no heating and the house is pretty open (not all doors in yet). Should I be worried? I've read of PVA, but is that going to cause an issue with the skim being applied later? I've read conflicting views about that.

- 4 replies

-

- condensation

- walls

-

(and 1 more)

Tagged with:

-

Apologies in advance for dragging up an old topic.... A large element of our build requires the use of a beam and block floor on strip footings. In an ideal world this wouldn't be the case but our site dictates it. As mentioned in other posts we are using an i-Stud frame and whilst not expecting passive standards, would like to do the best we can. I've read numerous threads regarding the issue of sole plate decay through condensation when using a cold foundation detail such as ours, and if possible I would like to minimize the risk. I'm happy to consider the use of thermo blocks etc if they are genuinely required but wondered if a simpler solution exists. I've read several comments suggesting running external insulation above and below the sole plate however that isn't possible without significantly increasing our vented cavity. The detail below uses a 215mm block with the 245mm frame overhanging by 30mm (approved by the frame engineer). This would allow space for 40mm of EPS directly below the sole plate and continuing down as far as necessary. I would finish this in a similar way to some of the MBC houses on EPS slabs - fascia board etc. Does anyone think this would be enough to minimize the condensation risk? Another option seen on the touchwood site is a basic cavity wall concept filled with EPS on which the sole plate sits, would this be a better option? Both are viable for us in terms of footing width. As always comments greatly appreciated. DewPointDetail.pdf

-

Early days yet but I'm starting to turn my attention to future projects (yes, I know). I'm sketching out some ideas for building something small and cost-effective. This would be for construction under the 'portable building'; rule and thus building regs exempt. Critical factor is cost effectiveness. Application is for glamping accommodation, studio, garden room, etc. I'm playing around with performance and cost of different materials at the moment, and I'm a big fan of corrugated steel as a cladding material (cheap, easy, fast). I also really like the idea of doing away with the whole VCL/void/battens/PB thing and simply using a ply or OSB interior sheathing layer, sealed with appropriate paint for vapour resistance, and then with all wiring etc surface mounted. Now with no VCL I think there is a risk of vapour in the structure, even if I do my best to seal the interior. So I'm looking at the vapour permeability. The frame would be most likely 45x95 stick build, fully filled with glasswool. I think I then need some sort of exterior board to hold the wool in, prior to the breather, battens, and steel cladding going on. I know that I could just use OSB on the outside, but I'm very curious about the woodfibre boards that @ProDave used. A quick glance online shows that the thinner versions of these aren't silly prices. I don't need them for racking strength, as that's what the interior osb layer will do. Question is where is it best to spend the money: beef up the frame to 145mm and just use osb outside, vs keep the 95mm frame and use say 20mm woodfibre boards as EWI. Or, should I use a different material as EWI, e.g. PIR, PUR- my gut feeling is that this isn't vapour permeable enough. Another option would be to use Kingspan's insulated roof sheets as my exterior cladding, but how do you manage vapour permeability with this system?

-

Hi All Quick question: I've got two condensation drains to connect up from my heat battery and MHRV. Whats the best way to connect to the soil stack? Annoyingly the heat battery is a 15mm pipe outlet (from a 1/2" BSP connection) and the MVHR is 21.5mm overflow type plastic pipe. Even more annoyingly the heat battery has no form of trap. I think I'm going to have to create some form of homebrew connection. Perhaps using one of these to create the sealed outlet? https://www.monsterplumb.co.uk/hotun-hiflo-shield-white-black-RATech-HW100C-dry-trap-tundish?language=en¤cy=GBP&gclid=EAIaIQobChMI49O69a7F1QIViIePCh0cRwYhEAQYBCABEgIN3fD_BwE

- 3 replies

-

- condensation

- drain

-

(and 3 more)

Tagged with:

-

Had a query for a job, and need some ideas . Bathroom ( ensuite ) with separate shower and bath, basin and WC, customers hate fans so use cross ventilation ( Windows ) when using the shower etc, don't ask. They've opted to go for a demister pad behind the large bespoke mirror and I'm wondering what's most practical to switch it on / off as required. First thought was off the lights, but with 4 lighting circuits and no guarantee which ones will be used and when, it's time to think a bit harder. Next thought is a thermistor which triggers a timer, located on the 22mm hot pipe as it enters the ensuite. Idea being that it turns on as DHW is drawn to either the bath or shower, not the basin, and stays on for say 30 mins after the pipe cools down. That's my favoured option right now, so question is, can I get a mains switching thermistor, and what would I need for a timer ? eg thermistor via a ( solid state for reliability ) relay triggering the timer / other? Thoughts plaese .

-

I was speaking to an engineer today about cooling our house should it need it. He was talking about fan coils when i mentioned cooling the slab with underfloor heating. His advised me not to due to condensation and the risk to the floor and concrete. He stated that it was due to the dew point/humidity in the house and the condensation around the pipes and on the floor. He stated it would form not just on the floor surface but under tiles and around the pipes Now i don't pretend to know anything about this but i am sure that those who have looked into cooling a slab must have considered this issue and mitigated against condensation forming. Can anyone help with this issue(if it is one)

- 21 replies

-

- dew point

- condensation

-

(and 1 more)

Tagged with: