LeeV

Members-

Posts

9 -

Joined

-

Last visited

LeeV's Achievements

New Member (2/5)

1

Reputation

-

Try this stuff - https://www.tesco.com/groceries/en-GB/products/253841037 It's a clear gel, wear gloves, pour some into the bottom of the oven, using a small sponge wipe it all over the inside of the oven. Leave for an hour, wipe it out with paper kitchen towel. Repeat until clean. Then rinse with a wet paper towel. If there are any nasty spots, give then a little scrub with plastic scourer. It works great. It comes with a big plastic bag, that you can put grills and wire racks into. Pour in the gel, seal the top of the bag. Massage the gel into the nooks and crannies. Leaf for an hour, massage again and repeat until clean. The contents of the bag will be truly disgusting, but the gear will be super clean. In summary, no heavy duty scrubbing, just wiping over the course of a few hours. And also dirt cheap. If it's bad you may need two packs, but still dirt cheap.

-

Sorry to revive an old thread, but I think I may be having bearing issues on my Ventaxia Sentinel Kinetic too. How loud is your unit on normal running? Before/after the new bearings. I've been having noise issues at the vents since I installed the system, I've since installed silencers which helped, but I was just in the loft working on the next round of silencers. I've not been up there in a while and thought to myself that it's actually the unit that seems quite loud/noisy, even in the low 15% setting. Which reminded me of this thread. It seems odd as the unit has few runtime hours on the display.

-

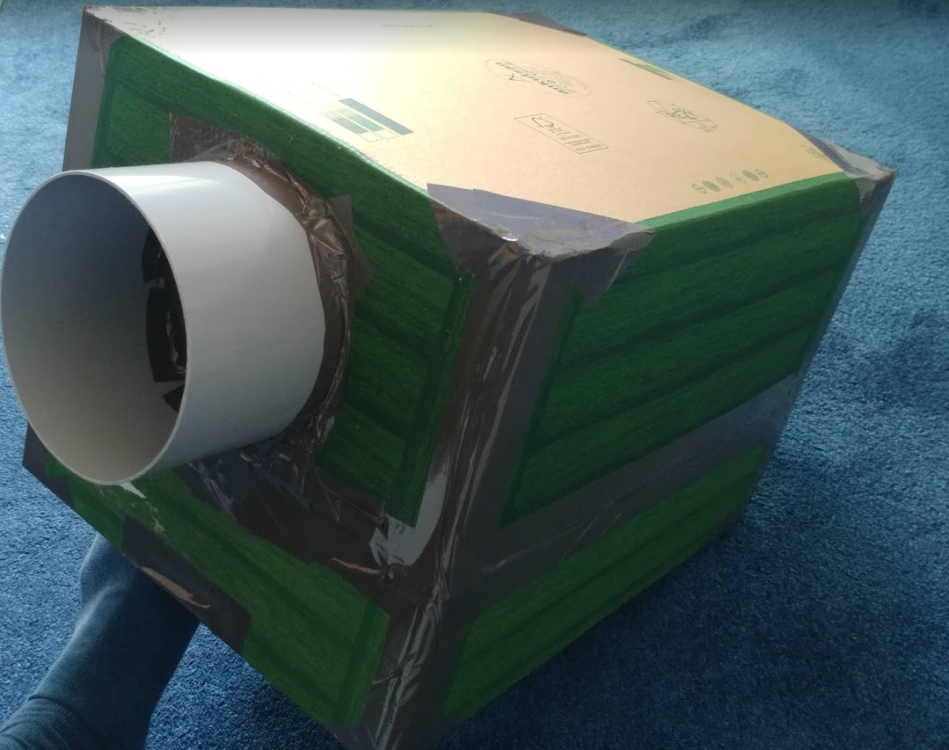

Definitely! The cardboard was only a prototype to see if it fixes the problem. Which it mostly did. I'm going to replace it with a box built from EPS Foam. Light, thick, fairly cheap and already insulated! No, they don't seem to. I was rather hoping they would too. Especially after I'd added fireproof acoustic foam to the inside of them! But no...

- 30 replies

-

- mvhr

- mvhr ducting

-

(and 1 more)

Tagged with:

-

After scratching my head for a while about which attenuator to buy, and looking at the DIY versions on this very forum, it stuck me that a "Rapid Cardboard Prototype" was needed to test if an attenuator would actually fix the problem before spending any money on something that may not work. Which lead to the abomination below. It was just as well I built it out of cardboard, as when I tried to install it, the slope of the roof meant I couldn't actually connect the ducting from the Vent-Axia. Ten minutes, a stanley knife and more tape later, I'd move the input port to the back of the box and it fitted great. And for a cardboard box full of filter material, it works surprisingly well. In the main bedroom, you can't hear the drone from the supply vent, but now the howl from the extract vent in the ensuite is really noticeable! This is great! So due the headroom constraint, it seems like I have to build a box attenuator. I'm just unsure of the details. Out of 10mm ply? Does the inside need painting? With what? Presumably bigger is better (I'm constrained by a nearby truss and the roof slope) Insulated with 50mm of EPS foam on the outside? Fibreglass mat internally seems to be a thing with commercial boxes, but I used filter material as its what I had to hand, and I don't fancy fibreglass strands being pumped into the house. I did thing of lining the box first with the fireproof acoustic foam matting I put inside the manifolds, but that didn't seem to do much there? Then building a copy for the extract manifold? Which leaves the question, won't the mat inside the extract manifold box just get soaking wet after cooking/showers as mist/water droplets hit the filter material? Then leading to mould in the box? Or is this not an issue?

- 30 replies

-

- mvhr

- mvhr ducting

-

(and 1 more)

Tagged with:

-

Yes, it's got a screen/buttons where you can set up the parameters it runs with. I'll give it go turning the speed down a bit tomorrow. Can you recommend one, in case the speed adjustment fails?

- 30 replies

-

- mvhr

- mvhr ducting

-

(and 1 more)

Tagged with:

-

@crispy_wafer it's a DIY install, there's plenty of scope to lower it to zero! The calcs suggested a fan speed of 42%, which is what it's at, from everything I've read (on this forum too), this is probably too fast, but without running it for a while it's difficult to tell. @saveasteading I don't mind the air whooshing sound, but the echo-y droning reminds me more of being on cross channel ferries more than anything else. While that was OK as a kid, it's not so good now. I've attached at rather poor video which doesn't really do it justice, but you can hear the drone at the start of the video. Obviously there is hum from the mic and it's much louder than in real life as the phone was quite near the vent, but you get the idea. droning.mp4

- 30 replies

-

- mvhr

- mvhr ducting

-

(and 1 more)

Tagged with:

-

@Redbeard Well, the Vent Axia unit is also insulated, but I was thinking another 25mm coat, or maybe two would be pretty simple to add. Especially as I have several sheets of the stuff already in the garage. You've convinced me, a job for next weekend! As for the attenuator, I didn't install any, as I'd read they weren't necessarily needed. Of course, perhaps I should have tested the system before wrapping the ducts and burying everything in rockwool. What an idiot... @saveasteading the main unit is on a wooden platform above the loft insulation. It's sitting on 25mm of EPS foam, there are metal L brackets to stop it moving but they are screwed into the platform and only touch the EPS foam wall covering the unit. The two x six way manifolds are the same but sit on boards screwed into the trusses. The manifolds are 150mm in from the top and a 90 degree bend and 6 x 90mm inlets/outs go out the side of the box. I did put an inch of acoustic foam into the bottom of each manifold (I read that on here somewhere) but even with a 90 degree bend and the foam, it's clearly not helping. I'm not sure I have the willpower left after the install to built an attenuator, so looking on BPC's site, is this the kind of thing we're talking about ? https://www.bpcventilation.com/quiet-vent-semi-flexible-silencer-range Or maybe a large insulated plastic airtight crate as a plenum? And if so, where exactly would it go? In the duct between the unit and the manifold going to the rooms? Or between the unit and both manifolds? Or on the fresh air intake from outside? Or even all three? Or would this https://www.bpcventilation.com/attenuator-silencer be any better? I guess this is what @jfb bought and @Redbeard built?

- 30 replies

-

- mvhr

- mvhr ducting

-

(and 1 more)

Tagged with:

-

Hi, I have just powered up my newly installed MVHR system, a Vent Axia Sentinel Kinetic, 2 x 6 way manifolds and 50 metres of 90 mm semi rigid plastic ducting. It's a retrofit into the existing loft space. It seems to be working fine apart from the noise. Standing under the vents I can hear a gentle 'woosh' of the air coming out of the vents, but from even further away, I can hear what I'd call maybe a 'droning' noise, it's like there is an echoing in the ducting. Not sure how to describe it better. It's not massively loud, but loud enough to raise complaints from the family. As it's a cold loft, the Sentinel Kinetic has had a 25mm EPS foam box built around it, so it's sitting on a platform, with an EPS base. The same as the metal manifolds, these have 25mm EPS outer boxes too. The ducts are strapped to the top of the trusses. The whole lot has been covered with 400mm of new rockwall insulation. Any insight into where the noise is coming from and how to fix it are greatly appreciated.

- 30 replies

-

- mvhr

- mvhr ducting

-

(and 1 more)

Tagged with:

-

Some questions on MVHR installation

LeeV replied to bluebirdnick's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Sorry to revive an old thread but I have a quick question if I may? Hi @JFDIY I've just come to the same conclusion that I need to make something, as spending £45 per supply/extract will cost more than the MVHR unit I've bought. I guess that is some ply for the base and 100mm rigid duct to connect to the ceiling vents, but what is that unit inside the duct? A 100mm to 90mm adapter maybe? Can I ask where you got them from?