Leaderboard

Popular Content

Showing content with the highest reputation since 11/17/25 in Posts

-

6 points

-

We hear sentiments like this a lot and unfortunately they are based on a misunderstanding of the respources we have. This line is promoted by certain sections of the media (who unfortunately no longer have the journalistic integrity to check their sources), and politicians on the make, and is 'encouraged' by the oil companies who source oil outside the UK but know that promoting 'British Oil' will actually lead to more sales of non-British oil in the UK! I'm by no means an expert, but I used to work for a solar company (way back, the first solar installer in the country) that was founded by a man who came from the oil industry and had first hand knowledge to impart. Without going into the weeds (which I'm in no way knowledgeable enough to do - I'm dragging this from the back of my mind from conversation 25 years ago...) you need to understand some basics of the oil industry as it has existed for the last 100 years. And a little Geology. Where to start? Oli is not what you think it is. Most oil in the world (and unfortunately the oil available off our coast) is not the black stuff you see shooting out of the ground in the Beverly Hillbillies. It is a multi coloured sludge made up of a vast array of chemicals that need careful and expensive processing to become useful - and that usefullness may not be as an energy source. Most crude oil - like that available in the UK - is only suitable for chemical productions (fertilisers, medecines, etc), not high grade energy use. Setting up oil refineries is increadibly expensive and to maximise economies of scale, a single type of process tends to be dominant in any region. Essentily, individual countries have specialised in different processes, using particular types of oil that is shipped around the world. I believe we ship 'our' sludge to South America for processing into a usable product, and vice versa). TLDR, The Geology of the North Sea does not produce the type of oil that UK refineries are specialised in, and the cost (and time frame) of converting our refineries to handle UK-sourced oil and the percieved benefits (and profits) are vastly outweighed by and dwindling resources of existing drill sites. In a heating world, WE MUST NOT drill any new fields and even if we did, the product would not power our country. Promoting th use of British Oil is a wheeze by foriegn oil producers (in bed with corrupt politicians and journalists happy to trouser a commission) which keeps the UK dependant upon their products. 'Gas lighting' in the literal sense... Another important lesson regarding 'Energy Security' has been learned from the war in Ukrain. A distributed power production that is not dependant upon a single source of energy is better able to withstand interferance from bad actors. It is very hard to cpmpletely destroy a wind or solar farm in a bombing raid, and even if you succeed, it will only be part small part of overall production. A distributed power generation will keep the lights on. But if you blow up a gas powered station - or the North Sea drilling rigs that supply your gas - it is much harder to get back up and running. To achieve a renewables based distributed grid is going to require huge investment of our aging infrastructure. But the long-term result will be lower bills, which should boost the economy as it will make manufacturing costs cheaper. Espescially if, as weve discussed before, industry is encouraged to move up North to be near the wind generation sources. We were perhaps disadvantaged compared to our European friends in the last 80 years, in that the last 'bad actor' was so very inefficiant at destroying our victorian infrastructure that we didn't have to rebuild earlier. Ironically, we probably gave Germany a boost by levelling the country and forcing a better grid to be built...6 points

-

Update: I bought the Zehnder attenuated manifold a few weeks ago and fitted it, with great difficulty. An absolute pig. I was even less happy when I turned it on and it had made absolutely zero difference. A few hundred quid and half a day down the drain unfortunately. However, there is a happy ending eventually, as today I fitted 2 of the flexible silencers @Jolo suggested, near to the terminal in the main bedroom. I used 80mm as they fitted fairly well directly over the 75mm ducting I have. It appears @Jolo has 90mm ducting? Result, I can't hear any noise whatsoever from main bedroom terminal even with my ear to it! A dramatic improvement. Tested the airflow and it hasn't reduced whatsoever. Thank you @Jolo. The only baffling thing is why the semi rigid ducting itself has caused this effect on both our systems. Mine is fixed well every 600mm, no sharp bends. I have 75mm, Jolo has 90mm. I have Quiet Vent ducting, he has Ubbink. I'm surprised more people don't have this problem? Or maybe they just put up with it?6 points

-

Zombie thread, but in case it's of interest to anyone- this was the building fix. The neighbourliness part was almost the hardest part. Our neighbours weren't aware of this issue. After raising it several times as a non-urgent but upcoming issue, we then raised it when we were going through formal party wall notice for other things like chimney removal and our loft conversion. We have a deed saying we owe them enclosure costs for the wall built on the boundary if we build on it- they suggested they would waive that. We pointed out that when we built the extension we had planning permission for, or even if we built a direct copy of theirs, there would be a pooling issue from the water directed backwards. So there needed to be a fix. We calculated the enclosure costs based on 1/2 of what it would cost us to build that same wall now (using our builder's quote). They had a quote from their own trusted builder (who built their extension) to infill the gap in the wall and redirect the gutter- seemed somewhat high but it's a small firm doing quality jobs. We offered the use of a skip bag already on our property to save on skip hire and gave them bricks from my collection as pragmatic. We then insisted on paying the enclosure costs but insisted that the fix was done. Conveniently the enclosure costs were just above half the remaining builders quote. Our neighbour (retired solicitor) drafted a memorandum of understanding, enshrining that we were explicitly paying owed enclosure costs and they were funding the remedial works to their extension, with the accompanying contract, warranty, responsibility etc being completely theirs (although the wall remains a party structure). So a blend of goodwill and pragmatism plus sticking to the agreements, but all dressed up as down-the-line obligations. All done with tea and cake in their garden. Very grateful for all advice- needed a robust understanding of where we stood (which this forum enabled) as a foundation for that amicable outcome.6 points

-

5 points

-

Been playing with ChatGTP over the last few days, generally going down a rabbit hole. Was looking for a simple way to model Weather Compensation fine tuning and or boosting during low tariff periods. So generally ChatGTP was no help. Had a search for something unrelated on Google and came across this site https://www.diyenjoying.com/2025/04/11/harnessing-the-power-of-predictive-heating-revolutionizing-home-comfort-with-home-assistant-and-derivative-sensors/ And finally a very simple modelling tool became realistic. So using the data on site above to add a couple of helpers to home assistant (hardware is already there - temp sensor). Then fine tuned for my UFH (thick screed etc). You now have a simple hourly and now 4 hourly look ahead at likely room or house temp if nothing changes. The author of that site used the information to start and stop heating, based on a generic thermostat, but taking account of floor inertia to not get swings in room temperature. So start boiler early and stop early, based on likely house temp - not actual house temp. But for weather compensation you just need a simple notification house temp is increasing or decreasing and you can simply adjust the curve. Add a bit of human looking at the day, it's stunning and room temp is increasing - no shocks don't do anything. But if it's dull outside you can decrease curve. So went back to ChatGTP for assistance. I have actually extended everything out to 4 hours to make it a little more meaningful for my house. There are few things this allows Intelligent fine tuning of WC curve. So you can see the likely house temp in 1 and 4 hrs and rate of change as a positive or negative. Options you could implement - you could run a cooler WC curve and boost during cheap periods. Could use it for batch charging alone, add some simple energy calculations based on you heating system store energy etc. Will add a few screenshots later5 points

-

Just as an update and close out of this - we agreed on a 30% refund. Happy with that, and we can paint some of them white (warranty won't be affected). Cheers for all the help.5 points

-

"With hindsight I'd have knocked it down and started again".5 points

-

Phoned round merchants this morning and - after blank-sounding noises from the first 3 - found one who had what I needed, exactly as @Nickfromwales described. The insert is part of the adaptor rather than being a separate thing as I'd first imagined. Thanks very much for the advice @Nickfromwales - I might have given up after the first couple of calls if I'd not known for sure the part existed. Bought enough to replace the T if I had to (not crawling down here twice) but there was enough length on the stub to just swap the elbow. Went together very easily, now just lying in the wet dirt waiting for the system to refill enough to do an initial leak check but it feels very secure. Now found a new go-to plumbers merchants! Couple of photos to give others confidence if ever in this position. Here's the adaptor with insert, split olive & oversized backnut (obviously the insert pushes fully into the pipe, just showing what it looks like): And then the finished joint:5 points

-

Final update... It was sorted within a week.. the team were great they came round took the old unit and installed a new one in about an hour. Shame the unit failed but can't complain about sunamp resolving it so quickly.5 points

-

I know my friends who own their own window supply company and I work with them closely, are looking to distribute Finstral and have been down in their showroom and so forth. The ex UK MD for Internorm (Andreas Simmer) is now the MD at Finstral. Good outfit, good window systems from the feedback I have received.4 points

-

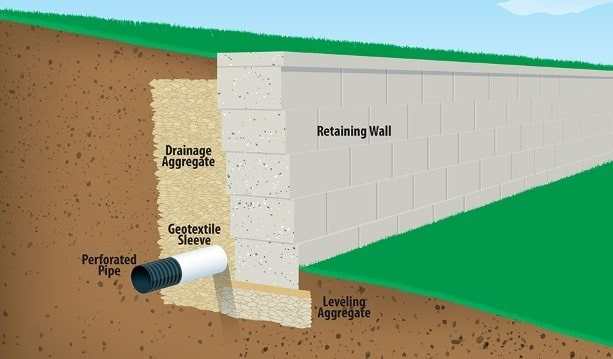

Hi @slystallone, the wall shoulld have the soil side waterproofed with a perforated pipe running around the bottom “French drain” style and backfill with pea gravel, pebbles or similar to allow any water behind the wall to go down into the perforated pipe and then away around the side. idea is to take any water away to prevent the wall from being a Dam and being subjected to water pressure. It would be worth doing a bit of digging at the wall ends to check for any existing drainage that may have been blocked etc. failing that you are looking at water management which means a lot of digging or back to cutting holes in the wall and then collecting the water to take it away in visible pipes on your side,4 points

-

"An amateur does the best job they can; a professional does the worst job they can get away with".4 points

-

The FMB is a trade association, by subscription. Make of that what you like. This is good you have seen other work, but check that was not for a relative. Check Face book and other social media for suspicious connections. Don't assume all builders are there to rip you off, many are good honest hard working folk. Just browse and if there is a rat you'll likely smell it. A fatal mistake here is to fall under the builders "charm".. you like them but don't want to uncover bad news. Be brave and grasp the nettle. You don't have to tell them you have checked them out! If you struggle on social media then get say your kids , nieces and nephews etc to check this stuff for you, they will do it in a fraction of the time! Do more due dilligence. Check companies house if they are limited. See what other links the directors have. If not limited then this can be an advantage. If something goes horribly wrong then sometimes you can chase the builders own personal assets. Check to see where they live, go to the land registry and see if they own the home (in Scotland this cost me £3.00) and how big their mortgage is. Check to see if they hold it in joint names. You can't chase easily (and nor would you probalby I hope) if the house is in joint names and you end up putting a family out their home. If vat registered then you can check their registration. If not vat registered then you need to ask them why. If their turnover is that low then how do they build houses? Once you have done this kind of due dilligence then you need to sort out a contract that is fair to all parties. To finish on a light note. I have posted this kind of stuff before. Last year a Client engaged me and told me they had followed my advice and done the full due dilligence on myself! I thought... well at least I passed and if you want to dish it out then expect the same in return!4 points

-

Thick carpet and underlay are your friends here. Job will be done and dusted this time next week and your house will be warmer for it.4 points

-

I work with someone that has a house similar to mine, it is also on E7. She decided that the old storage heaters were faulty, so had them replaced with new ones. Guess what, she paid the same to heat the house. Someone at work has lent her a small (500W) fan heater, as it 'only costs a penny to run'. A penny on her tariff is about 2 minutes use. When I questioned as to why the heater was so good and cheap to run, I was told 'because it is ceramic'. Now theses twats know my educational background, have asked me in the past about the best things to do to reduce the monthly bills, and then ignored it. I shall start taking in my bills and complain about my expenditure, which is about a third of theirs. As a general rule, if 'science' is mentioned in some advertising, the product is crap. No one mentions the polymer science of car tyres, or the electro-magnetic spectrum for a DAB radio, I really wish people would stop wishing things were magic and when they have bought them, convince themselves that they have made a good purchase.4 points

-

Coming back to this with an "update post" in case it's useful for anyone else reading who experienced the same issue. First off - just to say that I agree with all the comments from posters pointing out that my methodology for installing the IWI was wrong; if anyone is considering this I would strongly advise removal of the plasterboard prior to installing new insulated plasterboard to avoid the risk of trapping moisture. I also followed the advice above and took one electrical socket off the (newly insulated) wall and checked behind with a flashlight to see and smell what was going on... It looked fine. Used a dehumidifier intensively and then over the summer the odour naturally faded away to nothing. The game-changer (hopefully) was a chat with a local roofer who had experienced this on a neighbouring house. He suggested that our house doesn't have eaves ventilation or breathable roof membrane and is prone to condensation forming at roof level and then dripping back down the inside walls from the loft... Have rectified this with eaves vents and also fixed some external gutter leaks noticed in heavy rain, one right outside the affected room. I don't want to jinx anything but so far the issue hasn't come back so seems to be largely sorted. It was 0 degrees outside for a couple of nights so will need to see if any colder weather affects it but feeling optimistic4 points

-

First unit was the fan, the second was a 3 stage, digitally controlled diesel heater. It was a very cold day, and it was very reassuring to see that they heated the incoming air to aid the process. Only negative was that every single flat surface, and I mean EVERY one of them, gets a layer of product left on it. This included the screeded floor which was like walking on fly paper for the next 2 days. I was horrified when the team prepped and just laid 2” masking tape onto the flat sections of the new Norrsken doors and windows……with zero dust sheet or other over the glass or vertical sections of the frames. All these guys did was throw poly sheets over the precious stuff and get to work. My only criticism was that this could have been better, and a few things got residual goop on them that I’d have preferred they didn’t. Was this a problem? Nope. It just wipes / washes away pretty easily, so things like pipes and lagging in the plant room will need a bit of cleaning after, which is fine. Just could have been avoided with some better prep. This was the first time I’d been on site during one of these treatments, so next time I’ll do the shitty (more intricate) masking / sheeting ahead of their arrival. In one of the pics you’ll see a tripod near a window, and that was guffing this stuff out at a rate of knots. I inspected the window after AB stripped their seemingly rudimentary masking off, and I can report that there was absolutely no evidence of them being there. This stuff just doesn’t stick to ANYTHING vertical. Not one bit. Happy days! All told, a great team arrived on site, they were speedy and got straight to business. Prep was done (looks a bit underwhelming but does what it needs to) and they were off to the races in no time at all. Quite an impressive setup with no reliance on electricity etc; as seen they just plonk gennys down and get on with it. I’ll defo be using and promoting AeroBarrier, anytime it’s the obvious choice.3 points

-

3 points

-

AI "The revenue from the Crown Estate goes to the UK government's Treasury, also known as the Exchequer, not to the Monarch personally. Each year, the Monarch surrenders the entire net revenue profit in exchange for the Sovereign Grant, which is provided by the government to fund official duties and the upkeep of occupied royal palaces."3 points

-

Thanks for poking me on this BTW @Nickfromwales, and I hope that you and the family have a good Christmas. Mike, Do a deep search on my posts on how I heat my slab etc., as I've covered this in depth elsewhere. A few comments / adjustments: As I described in my topic Micro-controller based power switching revisited in 2024, this showed my thinking and eventual rework of my UFH control and switching revised design. This was very much a discussion leading to final solution over the course of this long topic, so read to the end. But the key points were: I replaced the SSDs with DIN mounted CU-compatible 20A 240VAC contactors for switching all power circuits, e.g. Willis, pump, DHW×2. These have 24VDC contactor coils. (The parasitic heat losses of the Contactors are a few W which is a lot more enclosure friendly than 30+W of the power SSDs.) I use a generic COTS relay module powered by 24VDC and running Tasmota firmware; this allows me to use MQTT to drive all controls. These 24VDC outputs have dry contact outputs, which I prefer safety-wise so you should have flyback diode protection across all contactor coils, again see the topic. I use ESPhome firmware ESP modules with remote DS18B20 temperature probes on my Willis, loop out and returns, DHW top and bottom and central hall to aid my sequencing and control. I have my own DIY NodeRED app doing all of my CH sequencing and control, and I also use Home Assistant (HA) as my GUI (linked via MQTT), although the CH app is independent of HA and can keep the control regime running for days without HA input. The system implements various safety interlocks (e.g. the DHW Immersions are powered off once the UVC reaches target temp, the Willis heater is powered off if it gets above 40°C.) The Willis does UFH only, as the UVC is heated by Immersion, so I have no buffer tanks or low loss headers. The heating regimes are optimised for use with Octopus Agile tariff. I have a low-energy, high "thermal mass" house, so in general I (or at least my CH control app) pre-calculates the day-ahead heating requirements and then time-shifts UFH and DHW heating to the cheapest Agile time-slots in the day to buy the electricity at lowest prices, so last night for example we put about 22 kWh into our slab and UVC at about 3p / kWh so under £1 (and another £2 to charge our EV). As I describe in my blog ,the Willis OP gets dumped into our ~17 ton of insulated slab so this heats up slowly over the, say, 6 hr heating period by 5-10°C and the return goes directly into the Willis, so it never goes above 30°C in normal operation. Yes I do have a fairly complex NodeRED app controlling everything, but the electronics and hardware set up is all stack items and cheap as chips.3 points

-

If the heat loss / system sizing calcs are in it, then ASHP spec in their quote should hold sufficient info for them to be silenced. Tell BCO they’ll give you the G3 certification etc too. Re MVHR etc, just tell them it’s too early to decide on a system or supplier, but that whatever arrangement you end up going for will be certified and accompanied by any other (relevant) compliances and a full ventilation certificate. Again, tell them you’re currently undecided but that they can assume trickle vents and basic mechanical fans for the get go. The gaps in your understanding of how these systems can benefit you is your concern not theirs, also you really should make yourself forearmed with things like the correlation between airtightness and a great end result with MVHR, vs you not beating natural infiltration rates and are then just pumping cold air into the house all winter. M&E is a whole, so best to join the dots before doing much more, just for yourself. Don’t just pay this lip service, it’s about making a high performance / low cost (& maintenance) and comfortable future-proofed home for yourselves too!3 points

-

I can’t believe anyone wouldn’t! Early design / planning before the foundation goes in is essential, as otherwise it’s just best guesswork; the birthplace of compromise or unnecessary costs to rectify later when you then see how it fecks up 1st fix etc. Fail to prepare, prepare to fail.3 points

-

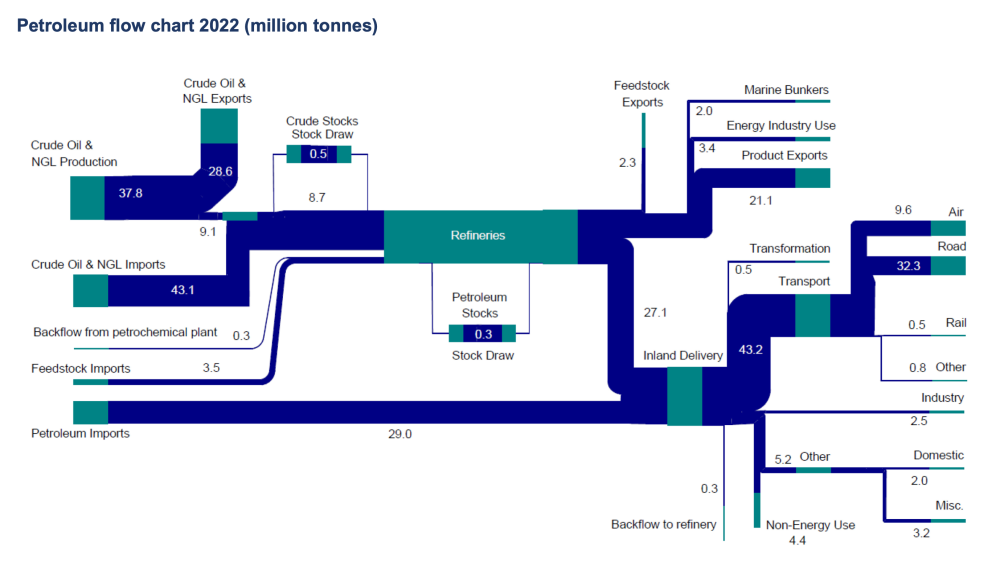

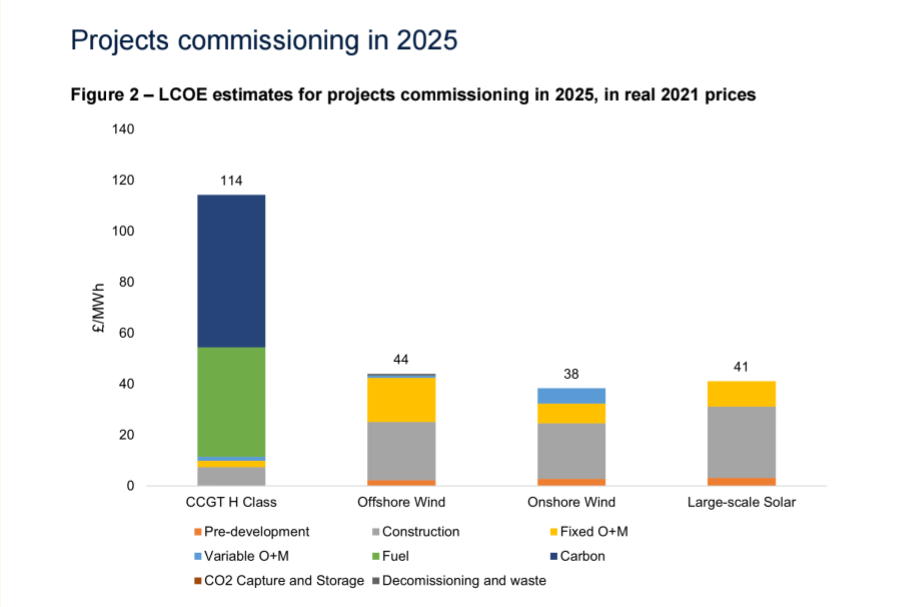

OK, Again on the energy security argument. The fossil fuel areas that the UK has access to are mature, that is to say they have past peak production. It costs about 3x to get a barrel of oil equiv (boe) out of the ground in the north Sea as it does in the Middle East. This ratio has been getting worse as the oil and gas fields produce less per well than they used to. Our refineries don't accept our oil, so we have to ship our crude abroad to be refined and import other countries crude for us to refine. Nitw how almost all our crude is exported and almost all our Refinery input is imported For gas the production situation is similar but there isn't the refinery issue. So for energy security we have a choice. A) we could increace our extraction which will result in much costlier oil and gas. This means we need to accept that burden on our economy or we need to subsidise the extraction. We then need to refit all our refineries to take this much more expensive feedstock and turn it into petrol, diesel etc. All of this woikd result in much higher prices for us in the UK and a huge drag on our economy. B) we could do the "green" thing - reduce demand for the things (oil and gas) we struggle to produce ourselves. So electrifying transport as much as possible, electrifying heating and industrial processes as much as possible. Also reducing demand by things like insulation, public transport etc. And replace the imported energy with energy produced in the UK like wind and solar (and nuclear etc). The only people who would benefit from A) are - foreign countries rich in oil and gas who would like to make money off us and have control over us ("do what we say or lights out") - oil and gas companies who would be able to make huge profits from the subsidies required to produce enough UK oil and gas. As it happens Reform have significant links to both those groups. It's rather convenient that their energy policy would be beneficial to a certain country who have been paying a close colleague/person he barely knew of the reform leader Right now, today the levelised cost per mwh of a new CCGT plant is higher than on and offshore wind and PV. If we ignore the carbon costs (dark blue) the CCGT is somewhere around £55, whilst the others are all below £44. Note the CCGT fuel costs assume world market prices and not the higher prices if we were to use only domestic gas. Crucially, the forward projections have the CCGT going up for projects built 2030,2035 etc, whilst the other ones are falling. To conclude : From a energy security perspective attempting to boost domestic extraction and refining would result in much higher energy costs for UK homes and businesses and/or huge taxpayer subsidies for the energy firms. Reducing our reliance on fossil fuels would reduce both our dependance on foreign supplies and our energy costs.3 points

-

That must have been a difficult post to write @DTL.... Well done for stepping away from a difficult problem - difficult because so much emotion is invested in buying a house and not just money. All may not be lost. You stepping away from purchase might just result in the vendors rethinking their sales strategy.3 points

-

And to add to that. Once ALL the bits of PIR closing the gap are the right size (they reach the OSB layer) AND are properly sealed so there are NO gaps for air to pass through, that will have got you reasonably air tight so no fear of cold draughts coming in from outside, then you need to go outside and add as much more insulation as you can behind those relatively thin bits of PIR. It is this sort of detail that needs to be got right NOW while you can get at everything. There have been at least 2 threads on here recently where the builders have been left to it and done a shoddy job and cold air is getting in and it can be a VERY invasive job to fix it later if not done properly now.3 points

-

OK Thanks WRT the SEPA tank registration; given that it is a self declaratory process I guess some people might just declare they have a soakaway from their tank rather than a discharge to a stream. And as you have previously discussed SEPA currently make no checks, and are only interested in investigating very large pollution events. Last week I made an online CAR application using a grid reference next to a random burn, and as part of the application you are asked to check a box according to your response to one of four questions; 1. Discharge via soakaway 2. Discharge to watercourse 3. Discharge to ditch 4. Other I could not fully complete the application as it was not real, so I am not sure what happens in the licensing process if you declare you have an untreated discharge to a stream. I have pulled out of the purchase because I have too many uncertainties on the septic tank discharge and I feel the vendors are not willing to be helpful. Many Thanks to everyone for the feedback in this thread.3 points

-

Not sure what you need a plumber for . But! Assuming it’s not gas I.e boiler install etc you can do it . I know you can . Because I did it . As mentioned hep2O is Lego for “ plumbers “ . I’d explain your exact issue / what you want done up here .You’ll get tons of help . Save you a fortune ! . Then when it leaks you can blame yourself but also fix it 😊3 points

-

But that isn't fully correct, because it doesn't take into account the gas standing charge, which goes when you remove the gas meter. So if your house consumed 6000kWh of gas per year your pay £377 for the gas plus £125 standing charge. So your 6000kWh cost you 8.35p per kWh, based on standard prices. Electric is 26.35p per kWh. So real spark gap is 3.2, not 4.2. And the above doesn't account for the approximate 80-85% efficiency of nearly all gas boiler installs. So piss poor reporting by Nesta3 points

-

3 points

-

Hi Everyone, What a wealth of knowledge on this site, and all very helpful. We have recently inherited a property which is an amazing gift, and it is an amazing plot, but...... the property is a late 80's barn conversion, and not a good conversion at that, so drastic change is required to make it habitable again. The property is a long lease (74 years remaining) with National Trust the landlord, however the property is eligible for a 999 year long lease (or virtual freehold) under the leasehold reform act due next year but we are not holding our breath that the proposed 2026 target for this reform will be achieved. Our thinking at present is partial demolition and build a new effectively self contained block with a link to the existing and then refurb that post new build. National Trust have been to visit and are open to discussion which is great because the lease terms are quite onerous as they stand now. We would like to get a new element built to enable us to move in and halve our bills and then refurb the existing element of the house. Then we have a small matter of planning within the AONB status and a (rightly) rigorous Local Plan, but a lovely challenge from a sadly departed very good friend. Good fun ahead, apart from the 200% Council Tax bill we have recently received!3 points

-

I go into panic if I’m spending more than £4 a day 😬 but then I think that’s more part of being a Yorkshire man!3 points

-

Hi all. The party is over indeed. I'm going to lay this on thick as it's time. I've picked UFH first but will turn to PV in another post. But to wet your aptetite! I've argued on this forum for a long time that underfloor heating is the bees knees. I've done this and worn the tee shirt. Long before most of you were in short pants. So if any of you can tell me how you installed and designed an UFH 22 years ago on a self build then I'm all ears! I would love to hear from you how we all flew by the seat of our pants at that time. I do hope that there may be one person. Many think they have invented the UFH wheel.. well you have not! The Scandinavians were at long time before the Brits.. I've made the case for simplicity and the need for UFH (the pipes in the slabs) to last the lifetime of the building, the cost of maintenance, reacting to how technology will evolve in terms of boilers etc. BUT what is in the concrete floor is a FIXED ASSET! Just like the walls and the roof! I also happen to be an SE who has actually been designing these slabs, insulated rafts to work with UFH for decades. So If there are any on BH that want to have a serious structural discussion with me then I would welcome that. You can ponce about with your weather compensation as much as you like, the flow rates.. your controls and buffering.. but see.. your heating has to work for 50 years so until you can make that arguement fdor life time performance, then I'll write down the value of your house if the pipes in the floor are not designed to adapt. SO GET A GRIP! I can and estate agents will also take a dim viw on a house value! Now some may just want to have a house that is a hobby, that is fine and I'm ok with that. But actually that may also make your house unsellable! Seriously.. you need to WAKE UP and smell the coffee, surveyors et al are clocking this so your hobby might come at an unexpected expense! Don't trust me. maybe ask a valuer? What I'm not OK with- if your house gets a loss of value as you have played with (and it is playing) home automation / complex UFH controls then that is a price you pay. But if you try and sell your house to some unexpecting young couple.. you can f... off., and I'm going to go hard on you! You are not going to sell your house to my kids! Advance Foundation technolgy have grasped some of it, Tanners in Ireland are competant SE's but no one has actually put all the bits together! The thing for me is that I want to design and build stuff that lasts, that delivers profit for self builders and that encourages young folk to enter the market, that benefits society. It's not a big ask? But as a designer with lots of real life experience I want to help young folk see the wood for the trees. I want them to get on the self build ladder on the self build ladder, I did it on a shoe string and that is why I keep pushing the simple stupid... as that means you can get a wider coice of Contractors.. which drives cost down. That is why I often push against the UFH complex thing and other stuff. It's also basically bonkers, but a lot of tecky folk on BH can'r see beyond 5 years.. So in summary I would like to see a lot of experienced folk on BH saying.. this works and if you are young folk embarking on a self build, on a limited budget this can work for you to. OK this is not going to go down well. But the life and future of BH is in the young folk, that are strapped for cash.. This for me and is why I'm still here.. I want to help and this is my hobby. To enthuse young folk, we need to solve problems, use our experience to say this can be not as hard as you think, if you take our advice, but at the same time give a bit of tough love if need be. PV is following much the same cycle..3 points

-

I use cone filters in each extract terminal, you would be shocked how much dust they stop getting in to the system.2 points

-

Honestly, I hadn't considered it being anything other than timber, blocks would be so much easier. Just goes to show what it's like having your brain scrambled when you're a bit out of your depth! What sort of blocks would be best for this? And yes, the drawing is shit, its what we got from a £20k Architect. Makes me feel sick.2 points

-

There is a discprecancy here. Go back and check what parmeters the Larsen truss designer was given. Ask; how do the Larsen trusses cope with the wind load. Larsen truss design is a bit of an art, it's a lot of fun mind and massively elegant, the wind loads get applied in a different way compared with a standard timber frame. The detail you show indicates that the outer and inner flange of the Larsen truss are restrained. It seems that your are on the face of it committed, but if there is an error then no point in compounding this. If I was you I would be confirming in writing to your Architect that a 40 mm screed is achievable, buildable at reasonable cost and it is going to remain serviceable ( i.e) not cause problems with the flooring. I've dabbled with this over the years and I feel that you tolerances are too tight and you are in for a nasty shock At least you'll end up paying for something that does not get delivered on site. My suggestion is that you get together with your Architect.. find out just how much they know about what is deliverable in reality. Give them a way to save face and see if you can change the levels. Bite the bullet now as later it will likely get worse. Well it will be a disater if what you are laying on is 5 - 10mm high? so now the pipe cover will be a bit of a joke. As an SE I'm very careful to set buildable tolerance limits. Ask your Architect how they are going to account for the variation in level and flatness of what you are laying on. In summary you take your chances! As an SE I'm not that fussed if your UFH does not work so well. With my desinger hat on I think this is vital to get it right, even if you have to go back and review the potential desing flaws which I think are there. It does not have to to result in a big falling out!2 points

-

Before you start any ideas about drilling into this wall you need to actually figure out what the problem is. start by clearing the top area and all that growth that is obstructing you getting a clear understanding of what is going on. it is clear from the picture that the water is running over the top of the wall, it should not be, so figure that out before knee jerking and drilling holes in an otherwise perfectly good retaining wall.2 points

-

As with most of these things, "could be", but wont be.2 points

-

Thank you to all of you, especially those who have been in similar situations and it’s useful to see that others have had similar dilemmas in regard to multiple utilities sharing the same trench. Also really useful knowing what others have been charged and it shows there’s no real continuity between prices, in essence each utility throughout the country just charge what they want. It appears that my quotes so far seem to be around the ball park figure of many others that have had similar work so it has offered some reassurance but I’d rather have many £1000’s in my pocket than lining the pockets of these companies. thank you once again all of you.2 points

-

This might help if anyone else searching for stainless steel screws for chestnut cladding / decking etc in what I found to be a significant minefield with massive cost and clearly quality differentials! A good few hours down the pan! Eventually found these and placed order today - proof will be in the pudding so no comments on quality etc as yet but feeling quietly confident. So not a recommendation - let's hope it will be................ You can also speak with a normal human who knows what they are talking about! https://www.endurastainless.com/stainless-woodscrews/decking-screws---countersunk-stainless-steel---torx-drive/decking-screw-countersunk-torx-tx-drive-stainless-steel-a4-marine-grade-316 also very interesting: https://www.fastenerusa.com/blog/tell-screw-stainless-steel?srsltid=AfmBOoogzyXC-QceFYTVxyxBdILjVskzH34yHohaOgi9x-y49Rw3NaQG2 points

-

They sound about OK to me. Our costs were (IIRC): Re-route Electricity from old house overhead to utilities block by the pole (pole on our land) down the pole along a 400mm trench, which we dug, and up into the meter box: £1200+VAT (2018) Move gas from the old house, which we knocked down, to utilities block in trench we dug and then remove it completely when we decided not to have gas £840+VAT (2018 / 2021) Do you really need Gas, might be worth working out if a ASHP might be a better solution if you are building a well insulated / air tight property.2 points

-

The cable used in those is listed as 1.25mm2 - you should go for something much heavier duty. Minimum 2.5mm2 considering the distance and use.2 points

-

I won't criticise but it is not high on my list of good signs. I assume that the exhibition advice was from FMB or a builder who is in it. The best sign is a long existence and dozens of reference projects. Any such would walk into FMB membership but probably don't want to.2 points

-

Fix panels so they face the sun at some point mid morning to mid afternoon. Plug panels together. Plug the 2 unconnected leads into an inverter using MC4 extension leads if needed. Connect inverter to nearest fuse board through an MCB specified by the inverter manufacturer. Switch the inverter on. Sit back smugly and thank the part P electrician who connected it up for you2 points

-

Well, yes, if you're not going to do it yourself, then you'll have to pay somebody to do it. You could get an M&E consultant, such as @Nickfromwales, who posts here a lot, to do the whole lot, or you might get one company to deal with CH & hot water, & a separate company to deal with MVHR, if that's what you're having. & if you're not having MVHR, I should think you just need to mention the trickle vents in the windows & give the spec' of the extractors in the bathrooms & kitchen. Somebody who knows a lot more than me will be along to help you out tomorrow.2 points

-

2 points

-

Sadly it wont. You can't possibly allow facts and figures spoil an ideological argument, or an opportunity to bash the government whatever the colour, or declare civil servants incompetent. For the avoidance of doubt your argument in incontrovertible, but apparently that no longer matters.2 points

-

This took 4 weeks, two of us never done it before (working 8 hrs days in Dec in NE Scotland), 70m perimeter, up to 3.5m high at front. Then there was a break over Christmas and new year and roof materials arrived 12th Jan First week of Feb roof on. If you exclude the Christmas break, 9 weeks, not sure where the savings of 3 months come from.2 points

-

I started with cable ties and the Ubbink plastic mounts for my 90mm Ubbink green ducting. Neither are up to the job of keeping it where you want it, not if you like nice straight runs anyway. There is a curve to this stuff from when it was rolled up. This needs a lot of persuading to behave itself.2 points