Leaderboard

Popular Content

Showing content with the highest reputation on 03/30/24 in all areas

-

2 points

-

2 points

-

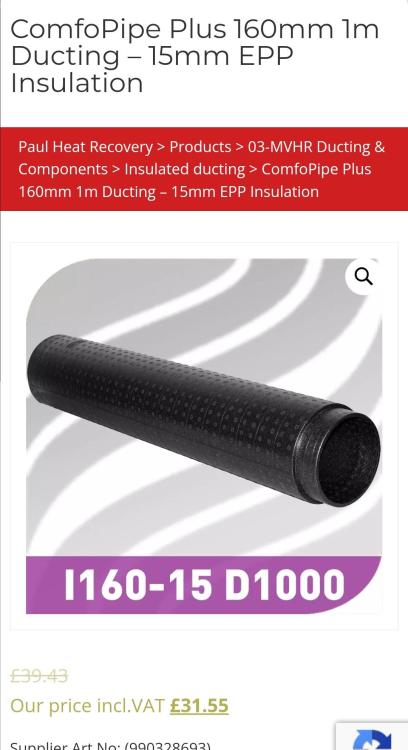

You can calculate and design it pretty easily. 75mm rigid ducting is ok for 2.5m/s flow speed so 28m3/HR. Assuming normal ceiling heights and a desired ACH of 0.3 then each pair of 75mm ducts will supply 37m2 floor area. So if you have a floor area of say 35m2 that'll be ok with one 75mm supply and one extract. If you have a floor area of 300m2. Then you'll need 8.1 pairs of supply's and extracts. Manifolds only come in 8 or 10. I would be happy with 8 in this instance as it's pretty close. Then sketch out on your plans one duct to each supply and extract room. Double up extracts for the kitchen and then for the dampest/furthest room until all the ducts are used up. Similar process on the supply side. Easy. Keep sketching until you can draw it without any ducts over lapping. That'll make it easy to install. As for materials, It's all much the same stuff. I would buy the cheapest. About £113/50m roll at a quick Google. Leave space for two of these between the mvhr unit and the manifolds. Install your supply plenums opposite the room door, usually over a window. Install the extracts close but not directly over the source of steam. Say 1-2m away and again opposite a door if possible. These ones are cheap and work fine. For the larger ducting to outside I like the rigid insulated stuff. Nice and tidy and doesn't leak as much heat as the metal. Finally site the MVHR unit inside the heated envelope, with short runs to outside for the inlet and exhaust, where it won't cause noise or vibration issues and can be serviced easily . I wouldn't skimp in the unit or buy something too obscure as you'll need parts in future. Aim to have one with a headline M3/HR of about your house volume. That way at normal rates the fans run at about 30-40%. Bargains can be had. This one is ok for about 120m² floor area. If you post your plans I'm sure we could collectively design it for you in about 15 mins.2 points

-

1 point

-

The little key in the pump was worn and not engaging. Roughly 9.5x3x2. Rang the BiL and asked if he had any. He said no, he usually makes them out of the end of a file. So I did (Draper). Quick job in the dark outside with a Fakita grinder, head torch out on the patio and a damaged pinky from the tree felling Not perfect but it seems to work.1 point

-

All plumbing done. You can just about see our tundish behind the new OSO UVC. The small extension to the consumer unit contains the 240VAC power relays to switch the Immersions and the slab Willis and pump. Everything neat and tidy. Jan is a happy lady. We've also had a couple of deep baths to celebrate. Still got to tidy the last power lead. The shelf above is my "network rack" 🤣1 point

-

Only 3 things to check really. The k-value, the moisture absorbency and the compression deflection/strength.1 point

-

Design the house you want, then run a Part O model and add mitigations. But if you are doing something complicated you’ll need to pay someone to model it, (cost us less than £400) as the simplified spreadsheet doesn’t cover external blinds, MVHR etc. or use PHPP if going Passiv.1 point

-

There used to be an English rule against any change of direction between rodding chambers, but it was dropped. As long as its roddable I think its OK. And I think the Scottish rules are less prescriptive altogether. I'd need to check.1 point

-

It think the rules just literally say at "change of direction" On my first build, it was not possible to dig the trench right where we wanted it so we had to have a shallow in line bend, and there was much sucking through teeth from the BC inspector who said I really shouldn't allow that, but he did in the end.1 point

-

1 point

-

1 point

-

1 point

-

As @joe90 says, what you do may depend on whether the mechanism extends down that far and is fixed to that part. If it is not, how about trying to get hold of some 'plastic lumber' (think some park bench seats) and scarfing that in? Wood-rot problem gone, and I for one will probably be dead before the 'plastic weevils' (take that either way) have done their stufff.1 point

-

See @Omnibuswoman’s latest few pics. Most of the web of the I-beam gone, whereas with posi’s there would be virtually zero cutting out between joists, sometimes zero.1 point

-

Pulling in pipes and ducts. Be mindful that I referred to trades prices vs DIY so savings are had both ways, one in time (you) others in cost (bringing in an installer).1 point

-

Quite normal for timber that meets the ground, normally the bottom section is replaced with a scarf joint (angled cut) it may be difficult to cut out the rotten section because of the garage door mechanism.1 point

-

Probably best to add, that MBC (and some others) do the cellulose filled frame vs SIPs, but tbh the SIPs I find to be horribly acoustically transparent vs a fully blown (graveyard quiet) offering. Apples for apples quotes should consider this, as SIPs isn’t a house I’d build for myself, ever, especially one featuring a flat / mono-pitch SIPs roof! If going down the SIPs route, defo go for pozi’s in the roof and just pump that full of cellulose. You’d thank me later, but it’s hard to fully comprehend the difference(s) unless you’re as fortunate as I am; being able to gather real live / life data from my many clients differing builds / choices (some which I now know to avoid!). Almost all seem to pay little homage to M&E design / integration, but in fairness MBC seem to embrace this far more than most others. Being ahead of the game with the M&E stuff can save a load of money with downstream trades, if addressed (identified and caught) in the early days (before the slab goes down). Simple things like not going for I-beams for one!1 point

-

Yup. Astonishing seems to be the norm. Have they also specified cross-talk and acoustic attenuators? Ah, slow connection, now showing the pics lol! Good for you, getting stuck in, and looking good so far.1 point

-

1 point

-

If funds are really tight and you can put up with the difference in insulation value, try 100 PIR over 50 EPS. The EPS is a bit more forgiving of the subfloor too...1 point

-

Hi Max. I doubt your integrity, I’m sorry to say, as I’ve seen your house and it is at least a 5 bed….something VERY fishy going on here.1 point

-

Basically the same stuff, different trade names. Buy at the best price, shop around I got mine online came direct from the factory. Prices vary daily so you need to do your legwork to find the best price. But was 70% cheaper than I could get locally.1 point

-

@Iceverge that's the clearest explanation I've seen on the forum, thank you. I spent last weekend messing around with spreadsheets trying to calculate flow rates and resistance and reached the point of giving up and admitting I'll have to pay £1000 to get someone to design the system. Now, I'll give it another go...1 point

-

Thermodynamics is more complicated than just “heat rises”. Yes, heat rises, but there will be small pressure changes causing movements in other directions. E.g suction of air into the vent will also draw down air from above, when that air moves down, it will be replaced by other air. So you are all good.1 point

-

You don’t spend any time floating around up there, so it’ll never be an issue. Comfort is perceived by the occupant, so if you are at the right temp and not turning purple, game on1 point

-

The problem with this "whole roof" PV idea is you need to choose the panels at design time and know the size of them, and then design the roof to be an integer number of panels in each direction. And solar panels don't seem to be made to standard sizes. So you either want to order your panels as soon as you draw your plans based on that size, or hope and prey that the size you want is still available when you actually come to build it. Then because supply of that size of panels is not guaranteed into the future, you might want to buy some spares and store them away safely. The next obstacle is a bug bear of mine, we have a stupid system where anything over 3.6kW may not be allowed by your DNO or may only be allowed if you pay for upgrades. If we are going to have lots of PV on every roof, that limitation is the one big obstacle that needs removing.1 point

-

1 point

-

Don't forget it doesn't have to be the full amount that's paid on the credit card to be eligible for protection... Section 75 applies if: you paid some or all the cost by credit card, with a point-of-sale loan, or with certain catalogue shopping accounts the cash price of the goods or services is more than £100 but not more than £30,000 It’s important to note that: it's the cash price of the goods or services that matters, not what you paid on your credit card or loan – for example, Section 75 applies even if you only made part of the payment using credit1 point

-

Yes we purchased our windows as two packages, ground floor and first floor, as the total was over £30k to ensure we got the cover as we had to pay it all up front at some stage or another.1 point

-

It makes no difference The rain will hit the floor and continually bounce onto the render1 point

-

You are fine with either, as AT tests are a 50pa and not 'hurricane' levels. "As built" tests are done with water sat in traps, so this will be fine. You must consider that both negative and positive pressures occur, so a 'heave' in either direction will have differing effects; a 'suck' on a waterless trap will happen regardless, but not a 'blow'. These will only be momentary vs constant, and life goes on (even in a Passsivhaus) Same happens with MVHR, it becomes temporarily imbalanced when wind blows onto the fresh and exhaust. Worry about something more significant is my advice, after you have reflected on doing the best job possible. If you can connect to an internal SVP then I doubt any issue would ever occur.1 point

-

This is what ChatGPT told me: Geological Conditions: The effectiveness of geothermal heat pumps (GHPs), especially those utilizing boreholes to access geothermal energy, heavily depends on the geological conditions of the area. The mention of "hot rock" refers to geothermal gradients, which are more favorable in some regions than others. In areas with volcanic activity or hot springs, for example, the geothermal gradient is higher, making geothermal energy more accessible and efficient. The UK's geology is not as conducive to high-temperature geothermal energy as some other regions, like Iceland or parts of Scandinavia. This doesn't mean geothermal heat pumps are ineffective in the UK; rather, they may not achieve the same efficiency levels seen in areas with more favorable geothermal conditions. Industry Practices: The reply also highlights issues within the UK's ground source heat pump industry, suggesting that a lack of expertise and the presence of poor-quality work have impacted the sector. In any emerging technology or energy solution, the quality of workmanship and the expertise of the providers play crucial roles in its success and public perception. If early adopters face problems due to poor installation or ineffective systems, it can lead to skepticism and reluctance among potential users. Market Dynamics: The scenario described suggests that market dynamics, where lower-quality providers undercut better-qualified companies, have also played a role. This can lead to a situation where the market is flooded with subpar installations, diminishing the overall confidence in the technology and making it difficult for higher-quality providers to compete. In summary, while geological conditions may not be as optimal in the UK for high-temperature geothermal energy exploitation as in some other countries, the technology for low to medium enthalpy systems (like those used in ground source heat pumps) is still viable. The issues appear to stem more from industry practices, the expertise of providers, and market dynamics rather than the technology itself being unsuitable. Addressing these challenges could help unlock the potential for geothermal energy in the UK, similar to its successful deployment in Sweden and other countries.1 point

-

We do down here. Cornwall has pioneered DRH generation, still doing it. The local swimming pool was meant to be geothermally heated, £1.3m later they put a heat pump in. But that is not really relevant to domestic heating. As others have said, GSHPs are either ASHPs, taking advantage of local weather, or WSHPs, relying on deeper ground water. @ronaldgibbons Your floor insulation is going to be important. Most building companies are happy to say their designs meet building regulations. Not that expensive to exceed them where it really matters.1 point

-

Yep it’s all good. Zero issues. It’s still happily blowing bubbles into my poo at it’s set intervals ?1 point

-

Graff specification is 150mm firm base (we're going to do a weak mix of concrete on our super hard ground) and then back filled with pipe bedding/granular fill 500mm out from the tank. Ill take some photo's1 point

-

Got in yesterday and happened to say it felt a bit cold. "Oh yes, it was warm this morning but not as warm as it usually is!" said SWMBO. That plus she thought she could "smell oil" by the boiler. Oil boiler was starting then locking out, the 90-120 Riello RDB2 burner. Checked the cap, first, AOK. Photocell clean, solenoid ok. Plenty of oil. Traced to the pump. Chucked a pressure gauge on and zilch. Took the pump off and rotating the shaft it felt a bit gritty. Somehow I found what appeared to be a brand new pump sat in the garage! Chucked it on, set to 8bar and happy days! Last night everything working. Just came in today from a day's tree felling and and the bloody thing is locking out again.0 points

This leaderboard is set to London/GMT+01:00