Leaderboard

Popular Content

Showing content with the highest reputation on 11/05/24 in all areas

-

How things can change on a six pence! After deciding to go for the ASHP, I had a couple of local firms in to quote. CVC did come back with a quote of around 20K but without a site visit, I was worried things could add up and that seemed too much. see the whole ASHP saga here; So next week, the new ASHP is being installed. And the unit is going in the back garden, under the kitchen window. This is not where I wanted it to go but the company were adamant that we could not have it at the front of the bungalow. And with certain changes in the pipeline, I am not sure now that we will be doing the extension at all. therefore I am going with the easy option for now. If at a later date, we DO decide to add an extension, we'll just have to move everything. 🤔 The reason for the big change is that the property next to this one came up for sale and after looking at it, we decided to put in an offer. It is larger than our current bungalow and while my parents need help and care, it makes sense to be next door, rather than a 20 mn drive away. It ticks all the boxes for our current situation, garage, workshops, as well as being next door so seemed the right thing to do. We now have a complete chain so are just waiting for it all to happen - hopefully January 2025. Fingers crossed! Looking to the future, we will have the option to choose which we live in and which we sell. OH prefers the new one already....... and we arent even in yet. 😁 I'll update things once the ASHP is in. I just hope it works as well as they say it will.2 points

-

Hi. I've recently done a 16th century cottage bathroom and the floor was like a piano keyboard, as you walked the floor deflected downward at each joist. Then ensued the biggest pig of a job you could wish for, getting it solid and level enough to be converted into a quality ensuite with bath and wetroom shower area. I sister'd the biggest timbers I could get in, but on both sides where it needed it, glued and screwed to death with zero nails used ANYWHERE!! You can park a car up there now. Do all the strengthening work, then get an electrician to drill the joists to re-route the cables, and then lay 22mm P5 deck, again glued and screwed, and you'll be fine. It's a LOT of work to do these properly (retrospectively) and I did have to re-do some of the plumbing tbh, but you get out of things whatever effort you put in. Good luck!2 points

-

I wouldn't think it's that far. Ayrshire will have lots, and there's probably plenty at half that distance. And Islay's incredible whiskies started as barley...from where? But I'm distracted.2 points

-

Wind driven rain will be your greatest challenge there.2 points

-

@mary Just as an example of heating water I have a basic E7 cylinder of 200lt. The bottom 3 kW element comes on at 3AM, and goes off at 4:30 AM. I have the thermostat set to 50°C. That heats enough water for 1 bath, 1 short shower and all the washing up. The cost is about 50p/day. The thing with an electric element is that it gets very hot, well over 100°C. This does not cause the water to boil because eddy currents are set up in the cylinder, these replaced the very hot water with cooler water. With a heat pump setup, the coil that transfers the energy is at a much lower temperature, often below 60°C. Even if it has a large surface area, it can still take longer for the cylinder to get up to the set temperature. This is because as the water in the cylinder approaches the coil temperature, less energy is transferred. It is not unusual for the last 5°C rise in temperature to take as long as the first 20°C rise i.e 25 to 45°C. That is an important point about using low temperature heating systems and why they are not used like a normal gas boiler. You will hear the term 'slow and steady' with regards heat pumps. They are designed to deliver energy that way.2 points

-

I’d try an electrician on a labour only quote We’ve just paid £4700 for labour only and bought the materials ourselves on a substantially larger property He was looking to come away with £30 per hour2 points

-

Hi All I just thought I would share my VAT reclaim timeline to let other people know current timings etc.. I completed the VAT 431c form using the online method (excel spreadsheet) on 4th September 10th September I received an email asking to submit 21 invoices, i sent these back the same day using the online portal I received a letter on 27th September saying how much they will be paying and queries they had regarding 5 invoices(not enough detail) Money received 1st October Re-sent the queried invoices with additional details on 9th October The remainder of the money received today (4th Nov) In all honesty I found this process very good with no issues, I rang up once to ask a question and got through straight away It certainly helped keeping an up to date record/spreadsheet throughout the build otherwise this would of been a mammoth task at the end and no doubt things would of been missed1 point

-

Not you obv @Nickfromwales Never assume that an electrician or plumber knows how to drill through a joist. The hole has to be at mid depth approximately. Holes or notches near the top or bottom reduce the strength dramatically. Plus being more vulnerable to fixings. See photo as another example of what not to do.1 point

-

I have a Drayton Wiser system with two wireless room thermostats and a control box which is wired in to the heat pump. I got this before I got my heat pump and it controlled my old oil boiler. I'm sure that oil boiler used a switched live and I have no reason to believe that the heat pump was rewired differently.1 point

-

1 point

-

https://www.gov.uk/guidance/vat-refunds-for-new-builds-if-youre-a-diy-housebuilder#making-a-claim1 point

-

Hi @Firsttimer reading similar posts to this over the last few years on here is does appear that the price of electrics is very dependent on where you are in the country and how much your house will be worth when finished as to how much a self builder will be expected to pay . Ours for 365m2 was 7k supply and fit, I did put the invoice up on another post on here somewhere.1 point

-

I would argue the toss on this. I would say there's nothing too modern about blown cellulose, EPS or mineral wool. I'd take them any day of the week over PIR, Phenolic or Aerogel insulants.1 point

-

There are 2 types of straw bail buildings. Structural and non structural. Both are expensive to build, poor performing, not environmentally good and will give you long term issues. Build from timber with modern insulation materials and plastic based vapour and air control layers.1 point

-

The story of the Three Little Pigs springs to mind!1 point

-

If you submitted an application through the Planning Portal and all required particulars were provided along with the correct fee then the council has to deem the validation date as the date they receive the application, not a date 1 or 2 weeks later when they have processed and registered the application. If they are not doing this then they are manipulating the system1 point

-

Generally speaking, the DNO's expect the incoming cable to enter the kiosk at the bottom left and they put their supply head and fuse to the left then the meter above it. That kiosk is large enough that the incoming cable can just make it's way to the left. Consumer side outgoing cable usually on the right. Assuming the DNO fit a 100A fuse the outgoing cable wants protecting by a lower rating fuse to give discrimination, I normally use an 80A switch fuse for that.1 point

-

I was going to say I'd want the control room bigger if it was for recording. My knowledge is more on a recording build, but essentially bass will be your biggest issue, so lots of mass and decouple everything where possible. You will also want to kill reflections etc especially if you're loud, so soft furnishings will help a lot with this, if you're not able to build anything in at construction. Also bass traps in unused corners (wall ceiling junction is a corner too 😉 )1 point

-

1 point

-

That's fair enough and this whole industry and self building in general can be a snake pit at the best of times! Just ensure they talk you through the flow temps, commissioning and weather compensation, and then ensure the insulation is all upgraded as well before winter!! Also to add, as part of our "whole new build" package and contracted price, our builder ear marked/paid around £14k for our 12kw Samsung incl fitting, 300l cylinder etc from joules, excl the £7500 discount, which at the time was only £5k expected.1 point

-

That's good to know. Thanks for sharing, & congratulations on reaching the VAT reclaim stage of your project.1 point

-

Trust me . Top quality . Xr batteries can shag in time . But that’s after 100’s of charges .1 point

-

An old mate of mine designed radio & TV studios most of his working life. He said - 'there's no substitute for mass'. I'm thinking sand... I might also check out the sound booths that wind instrument players can practice in.1 point

-

On Monday the second gable is poured and most of the internal bracing, corner bracing and window shuttering is removed. Tuesday rains all day so no work on site. The internal floor is under 1 inch of water with no way to escape, without us brushing it towards soil pipe. Good to know we are airtight at the floor/wall joint. The steels are installed, we were supposed to have wooden roof beams but somehow this was not calculated by the architect who insisted the roof truss company would do the calculations later. The roof truss companys only want to do the calculations when they know you are ready to order and they said the beam spans could not be done. So on the last minute we had to go back to the SE who worked out our steel beams and the total cost of roof went up £8k. I wish the architect had suggested the SE looks at the roof calculations earlier but unfortunately we just have to move on from this, and up to this point we have had no other extra costs. Since we are no longer working with the architect I have had to find a new SAP assessor who I can engage with as the build progresses. We have been discussing how changing the steel beam might change things as the vaulted ceiling can now be higher if we want. This gives us more space to heat up. I also wanted to know the effect of not putting as much solar on the roof or not having the wood burner changes the SAP results. Since having a smart meter fitted at home we have reviewed our current electric usage and decided that less solar (7.5 kwp instead of 11 kwp) but with the ability to add a battery. Also I think aesthetically one row of 15 panels will look better. Total Man days of labour week 7 is 16 days. Total to date b/f £44925 New Design Stage SAP Calculations (previously done by architect) with ongoing advice about changes that will affect the SAP and to include the As Built SAP documents and EPC at completion £720. It does seem a lot compared to online prices but for peace of mind knowing that we can if we choose to only put 6kwp of PV on the roof instead of 11kwp, is an overall saving. Total to date £456451 point

-

That concrete is dressed over the surface by the looks of it, not part of a beam. In which case knock out and replace.1 point

-

Welcome Annas As a general rule, existing floors do not have enough insulation to take full advantage of UFH, it is the insulation that needs the depth. Have a look around in the specific section on here, there is a lot of information. Using a Google site search is better that the forum's search.1 point

-

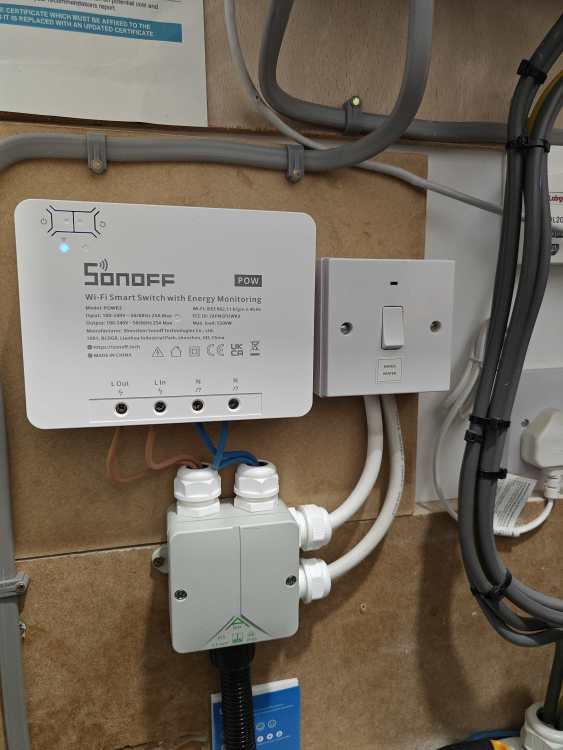

Well that was all pretty simple Sonoff POWR3, £30 from Amazon An indication 20A switch for immersion heaters, a small JB and surface mount 1G box and 2 packs of glands £15 from Screwfix. So £45 all materials. 1 hour research on adding Sonoff to Home Assistant - Added Sonoff app to phone for pairing, same app added in Home Assistant plus SonoffLAN. Simple automation, trigger - PV generation above 500W, condition battery above 98%, run immersion for 10 mins, restart automation if condition remains true. Sends me a notification. Also records energy usage so added that to home screen. Wired in parallel, so switch can trigger the immersion manually. Indication light on switch comes on when relay is triggered.1 point

-

1 point