Leaderboard

Popular Content

Showing content with the highest reputation on 09/16/24 in all areas

-

2 points

-

We have finally started to build. Day 1 was Monday 2nd September 2024. It was nearly 3 years from the first invoice which was for the private planning consultant to discuss and review the possibility of demolishing one of our old barns and building a bungalow on its footprint. Back then we weren’t overly confident of our chances but the consultant gave us a fairly good chance. Our current home is a listed property on 3 floors. It is far too big for us with 4 double beds, 3 baths/ensuite and two lounges. It makes a great multi generation home but no longer fits our needs. We are both in our fifties and looking to downsize into an economical to run bungalow. The old wooden barn was given away locally on condition they took it down and removed it without our help. We had birds nesting so we had a planning condition it had to come down between November and February. All that remained was the concrete down the middle, one wall and concrete lintels separating the bays. We chose a local building contractor from Bude, he came recommended and so far his groundwork’s subcontractors have been very good. The build starts with lovely weather but by the Thursday most of the UK has a yellow weather warning for rain, we had 23mm of rain Thursday, 14.2mm on Friday and another 27.7mm on Sunday. By the end of the first week we had a cleared and level site marked out ready to start on the trenches on week 2. Week one total man days of labour is 62 points

-

FYI, I have decided to go with MBC's Passive system. Yes, there is a premium, but once I started digging into the details of other offers the list of uncovered work got longer and longer. For me, the lack of thermal bridging and the promise of an insulated, air-tight, wind and weather-tight finished frame justified the premium. Just.2 points

-

Welcome to BuildHub. Sounds like an unpleasant position to be in. First thing I'd do is provide some more information. I don't know much about them, but at a guess, that would include: a plan of the site (locations of house, digester, outlet, and connections between them) any information you have about levels (particularly where the unit is supposed to drain) any photos you think might be useful Lots of people on here have experience installing/maintaining these units and I'm sure some of them will be able to help you get this sorted as cheaply as possible once they have the info they need.2 points

-

Yes, thats correct. Yes, hysterisis of 7K will mean compressor comes on at 18C. You ideally want your system designed and installed to never really use the hysterisis though IMO. If your system volume is good, but not very big, it can be a good to increase the hystersis just so that when the compressor comes on (before it dials back to minumum) it doesn't hit the 7K and turn off prematurely. This does however depend on if you have a buffer, are/aren't using mixed circuit and what your emitters are though. In some cases it may not be a good idea to have water 7-15k above target even for a short period of time. In my case I have a buffer + mixed circuits so it only means the buffer gets hotter, the circuits don't. But if you had open-loop with radiators this might not be a good idea.2 points

-

Assuming there's no obvious ingress of direct water from outside - (as ST says, check for leaking gutters etc) then this looks like classic condensation. Corners and the bottom of walls are colder, condensation happens often without even being obvious. Dust in the air sticks to it and mould grows on the dust in a damp environment. Still air behind cupboards and the like makes it worse. First job is to kill the mould so it doesn't just grow back. Curing structural condensation is not easy. You need to reduce the moisture content in the air whilst getting those colder surfaces above the dew point2 points

-

Hello team. When we designed our extension with gable end windows we knew that the window coverings/blinds would not be easy/cheap. Now that we are well into the build and I have some quotes to compare it is feeling particularly painful that 'a few bits of fabric' is costing almost as much as the windows themselves (3 sheets of glass, some timber and aluminum). I have had a few quotes, all in a similar ball park so there must be something that means they are more complicated than first impressions would suggest. Is there anyone out there who has been through the exercise and found more sensibly priced blind options (either supplier recommendations and/or alternative means of providing window coverings? We have considered curtains but want to maintain the clean/uncluttered lines that the windows are giving us. Any experience from others who have been through a similar exercise would be appreciated! James1 point

-

1 point

-

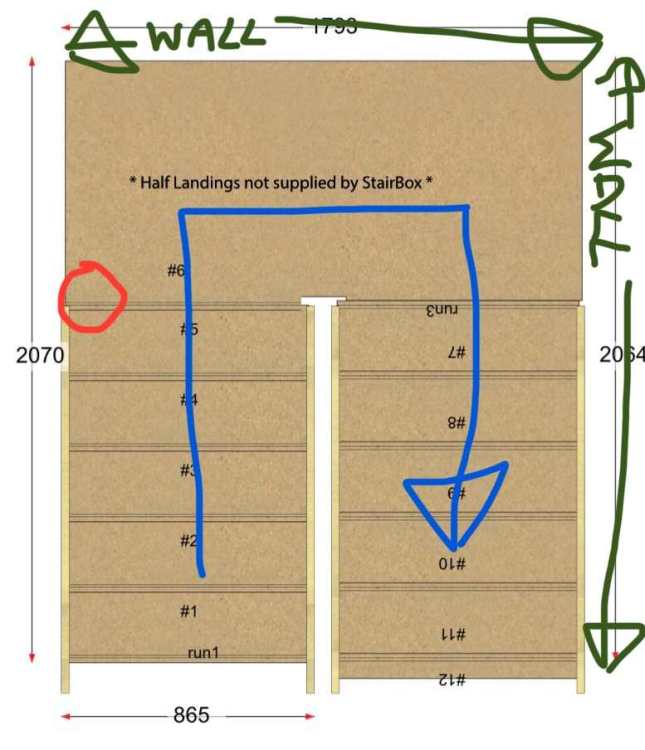

Great so ask stairbox to design as I suggested with a dog leg stringer along that side with the red circle to support that side of the half landing 👍1 point

-

Last few pages from fig 6 onwards show the varying voltage current. The voltage looks very low as the curves are for a single cell, not a full panel!1 point

-

1 point

-

Thank you. Yes we are lucky the original floor is still there, we were fortunate that despite turning it into flats they left most of the original features. Yes the triangle fill is not original, part might be, but they brought it forward to align with the stud wall. I was worried about that landing so great to know it's self supporting, which I thought it must be. I have seen one neighbours house and originally it looked like ours where you can see all the spindles. I think my builder is being careful.1 point

-

Ooh I love that floor!!! The landing is self supporting and does not need the stud wall timbers.1 point

-

@BigYin unless I missed it you don’t say on who,s land the treatment plant is?, hopefully it’s not on your land so you could install your own and leave next door with the problem.1 point

-

No one likes fixing other peoples problems, especially when its dealing with other peoples s***, so sadly it won't be cheap. 2 options, pay the money to a reputable firm and resolve it quickly and easily (but expensive, or option 2, do it yourself). If summer rain caused you a problem, got knows what the winter will bring. Get tank fixed, get drainage field sorted, or pump to ditch etc. There is no silver bullet, as you have witnessed installing these plants is no easy task, there are lots of variables. Unless you are very competent and have had drainage field tested and sized correctly, they will cause you problems. My advice would be to sort before November when the rain and winter water table starts making it troublesome to do anything until the spring. Best advice I would give, would be to call the company that empty your plant and ask for contractor recommendations (they may even offer services themselves)1 point

-

Yes I too fitted a pressure reducing valve to protect the (not fit for purpose) lousy plastic pipes and fittings used on my 'van.1 point

-

On ours I designed it and have set the flow rates. I am using the attenuators to give me flexibility, of the pipes, as much as sound attenuation. The main distribution box will have its own silencer and the two other distribution boxes will also be baffled and internally covered in acoustic foam so I am hopeful it won't be too noisy - I also have a until that has the twice the capacity needed even for boost so am expecting it to run at about 20-25% of its capacity most of the time which should keep the noise down. I can then also use a high boost for cooling via a heat battery in the bedroom distribution feed - which will be noisy but then so are fan coil units of my acquaintance.1 point

-

Rightly or wrongly a self build is what I have always wanted to do. More to the point there was a very specific property that I yearned to build on. This week, almost 25 years after fist imagining it I agreed the purchase of the plot, a listed threshing barn with a smidge under 1 acre surrounding it. And so with my Wife and 3 year old son beside me we will set about making the property an economical, comfortable family home which will provide for us in years to come. Excited isn’t the least of it. Interestingly, despite my existing knowledge of the construction industry as a PM (and everything which is required prior to get to this point - Joiner, Supervisor, Site Manager etc) and the long standing desire the opportunity is also extremely daunting. Wish me luck, I’m sure we’ll need it!!!1 point

-

Welcome to the threshing club. We've just about done a stone one (there was an opening in the wall for a threshing machine drive shaft. Plus a proper thresh hold stone. Not listed. I think we were more sympathetic to heritage than the planners. There are a few easy solutions, but a long way down the list. Now starting a steel one. Not listed but has to stay in place.1 point

-

1 point

-

Sorry it makes no sense, the UV light is last thing in the system. Pump start logic is a lagging indicator, as pressure vessel is the supply, the pump tops up the pressure vessel. You are over thinking, they are designed to stay on, not switch on off a few thousand times a year. You will pay more for bulbs and monitoring than you save in energy. Plus there is a heat up time, as it requires to heat mercury to emit the UV light.1 point

-

1 point

-

we use a nuki lock, full apple integration. hey siri open door. same as garage door opener.1 point

-

1 point

-

It's the heat pump board that matters, so your unit has the bug and: i) The default -60º min behaves like -30º min ii) It ignores any attempt to change the value, eg. to -100º min, This is bad news for over-sized systems and for systems like ours where adjusting this makes sense. See https://energy-stats.uk/vaillant-arotherm-firmware-351-06-07-problems-energy-integral/\ I had Vaillant switch mine out FoC, but I don't think anyone else has had any sucess.1 point

-

Exactly. Main reason to keep hysteresis at 7K or to keep the integral start at -60 ºmin is comfort (or any limits you need to consider for the flooring type if open loop). But in a system like ours, this isn't a concern. Using -120º will have a direct impact on the amount of cycling when demand < min power and in turn a small impact COP. Adjusting the hysteresis probably want make any difference in practice, but no harm in increasing. This brings me to another question though, do you have buggy firmware that doesn't allow this to be configured, or newer one?1 point

-

It targets a flow temperature and adjusts the compressor speed to achieve this, it doesn't target a ΔT. The "Compressor hyster. Heat." is not a target ΔT, but rather the maximum difference between target and actual flow temperature allowed before the compressor shuts down. In a large volume system when heat demand is low (autumn/spring) the primary (or potentially only) mechanism that decides when to turn compressor on/off is the energy integral calculation. This is because the flow temperature never overshoots enough to hit the 7K hysterisis limit. But, with a low-volume system, or one with too many zone controls, the 7k hysteresis will likely be the primary mechanism that controls when compressor turns off.1 point

-

The aroTHERM works a bit differently. It uses a constant flow rate and varies delta-t between around 2 and 10K.1 point

-

1 point

-

Good morning, Long time reader of the forum across the years. Time to contribute! We are in the NE of Scotland in a multiple times extended bungalow. Continuing on an RE path with home improvements. We already have a large solar array (15kW).and battery store (40kW). Looking to add triple glazing and an ashp to the existing CH wet system. Cheers!1 point

-

1 point

-

Why didn't your builder ask why there's a steel beam that's 'not needed' before building a roof around it? Agree with others the steel ridge beam is to hold your roof up, stop spread. This Robin de Jongh video explains exactly why the ridge beam works and why those collar ties are not enough, well worth 6 minutes watching. Double check that the timber above (which the rafter are fixed to) sits directly onto the steel itself, in which case the beam will do its job. If not then the timber below won't be enough to stop the roof spreading later. From the membrane on the rafters it doesn't look like the builder's following the description of the roof build up so you should clarify what they're intending - maybe they are trying to avoid the hybrid roof?1 point

-

First check the amps generated are ok on the new panel for the max allowable amps for the inverter. A write up here, worth a read. https://explorist.life/using-mismatched-solar-panel-sizes/1 point

-

it is unlikely that it is not repairable --so I bet once its out --assuming its not wraped inconcrete another self builder will take it away and repair it with new pump and media balls --after a suitable power washing out by a septic tank emptying company it sounds very retrivable once the drainfield is sorted but i would not want to share septic system with another house if at all possible--thye could be flushing anything down it and causing problems1 point

-

1 point

-

I wouldn’t mix those on the same MPPT, but somebody more experienced than me with PV might come along and say that’s wrong. I’d imagine that the output of the newer panels would be compromised, and dragged down to the output of the old panels. You may even be nearing the max MPPT voltage rating anyway. On a separate MPPT or inverter, of course, crack on - subject to DNO approval if grid tied.1 point

-

Interesting problem. A lot will likely depend up the wall itself. A 100mm block wall will unlikely withstand an eccentrically applied load but this is entirely dependent on span and all sorts of other factors. I think a “floating” structure using steel stringer spanning the half landing to the upper floor will be most efficient. This solution would result in minimal deflection and the wall loads would be imposed as planned. An engineer will tell you quickly enough the section size, weld detail and end plate/locating detail i.e pocketed or plated and bolted. A timber leg as indicated by your X or centrally in between the flights with a timber famed landing bolted to the walls (it will likely be a significant section size) would also work. It would be worth running the proposal by your engineer either way.1 point

-

Could possibly run string from above down into wall if having bespoke made then support landing off that1 point

-

First you must if there is a legal case. Is there a contract, and what does it say? If no formal contract then maybe in common law, but that needs a lawyer. It has to be one with construction industry skills. They may give you a half hour free. Then you give the builder the opportunity to remedy the situation. That will all take up a month. If you just start doing the work you will not get recompense.1 point

-

Google roof tile steps = https://www.creaton.com/products/protection-systems/roof-access-system1 point

-

Mine is easy - temperatures, flow, return and outside, that's it.1 point

-

Hello all! I bought a little pebbledash palace about three years ago now, I was certain there wa as nice house under it all, given how thick the walls are. I found a basement that had been covered up with 16 tonnes of rubbish and a lovely stone exterior! It’s been one hell of a lot of work but it’s a journey of discovery and learning! looking forward to exploring this forum!1 point

-

Be interesting to start a thread on here about getting data out of heat pumps. There are enough people, with different heat pumps, and a few people with good IT skills, should be possible to create a few basic packages that run on basic 'computers' and can store data. Leave the analysis up to the people that are interested, just create some text files of say electrical usage, run times (with timestamps) mass flow rate, flow and return temperatures, room temperature and outside air temperature.1 point

-

1 point

-

I’m inclined to agree, architecture can and should demonstrate the past and the present concurrently. The very nature of this barns change of use (and an argument for permissions being granted) is due to its lack of relevance for its original purpose resulting in the building being in a general state of disrepair. We may seek to may subsequent applications to make additional changes but I’m inclined to believe that once we have opened each of the vertical ventilation slots (80+) you see in the photo and installed glazing to each the building will be reasonably well lit. For now it’s a compromise I’m happy to make to get moving!!! It’s a blank(ish) canvas inside.1 point

-

>>> I do question “no new openings” Me too, the openings in there right now don't look 100% authentic. I think we should concentrate on beautiful and efficient and great to live in buidings for the future. A lot of the old stuff, particularly old ag stuff, probably had 5 minutes spent on 'design'. And we're going to go out of our way to 'preserve' this? Ag buildings were built for storage and/or animals ffs. Wouldn't it be an idea to allow a little more slack for the new usage for humans? A friend has a listed place. Heritage were doing a barney about keeping some stairs - until the owners found someone in the village who had put them in in the '70s.1 point

-

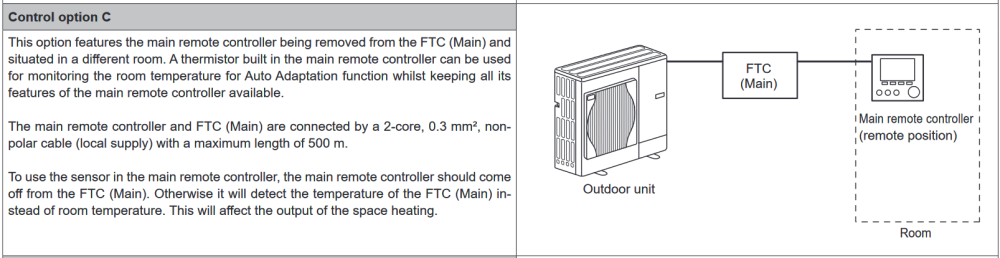

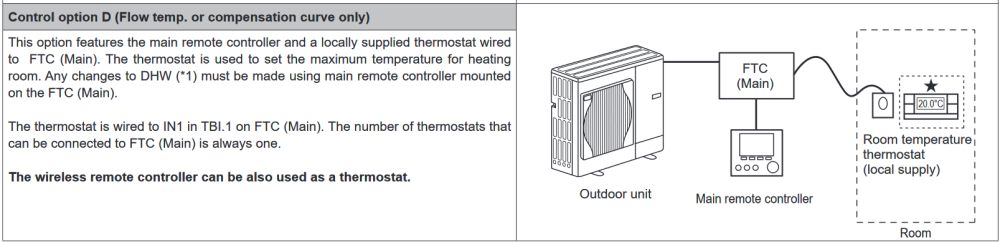

Just adding to this as I've had the exact same question (UH8 + ecodan FTC6) and managed to figure out the answer. My installer had left the ASHP configured with SW 2-1 set to ON but nothing connected to IN1 (TBI.1 7-8) with the plan being that I'd connect the demand from the UH8 once I had all of that wired up. Obviously, the heating worked just fine even without a thermostat being connected to IN1 so I wondered why anything would change once the UH8 demand was actually connected up to the FTC6 IN1. A closer look at the FTC6 manual provides the answer. Without any external thermostat input, the system operates according to "Option C": In my case, the remote controller was set to "Auto Adaptation" mode where it uses the thermistor built into the remote contoller itself to provide the "thermostat" function for the FTC - ignoring anything connected to IN1. To actually make use of the demand signal from the UH8, the controller mode must be set to either "Flow temp." or "Compensation Curve" according to the manual (Option D): In my case, I've opted to go for the "compensation curve" option and can see the ASHP turning ON/OFF in accordance with the demand signal from the UH8. I think it's essential that the operating mode of the FTC remote controller is changed from "auto adaptation" as soon as the UH8 and actuators are installed since I can envision a scenario where the ASHP eats up energy without actually providing any heating. This might happen if the remote controller is set to a higher temperature than the stats? The stats will shut off the UFH circuits once they reach target temperature but the remote controller (in auto adaptation mode) will keep running the ASHP trying to reach the higher temperature set in the remote controller. But of course this will never be achieved since the stats have already shut off the circuits .... NOTE: The FTC6 manual states that the ON/OFF cycle time of the thermostat must be 10 minutes or more to prevent damage to the compressor; however, by default the neoStat v2/Polypipe UFHSMARTW "delay start" function is set to 0 minutes (immediate). To remove any possibility of short cycling, I've increased this to 12 minute on my stats.1 point

-

A friend of mine bought a house like that. He had a survey during the buying process and the surveyor warned the corner of the landing like that was cantilevered from the rest of the building and was a structural defect. My friend of course answered, well it has not fallen down or even moved in the last 60 years so I think it is okay.0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)