Leaderboard

Popular Content

Showing content with the highest reputation on 03/22/24 in all areas

-

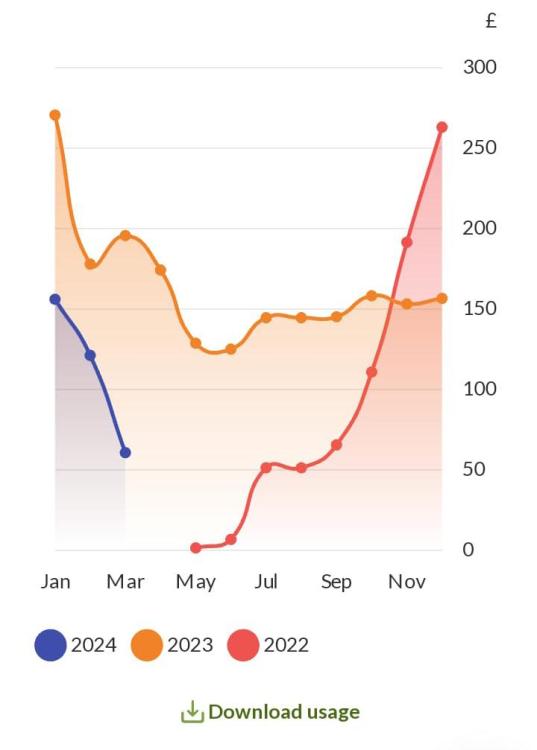

All the reading of posts on here at the design stage and the hard work implementing the experience of others on your own self build can be summed up / justified with just 1 image. Even when building on a very tight budget. This is my energy usage @ The Windy Roost since we got here. Upto January 24 we were in the static, we were never really warm used Air to Air heatpump for heating, hot water and cooking was LPG. We also had around 4 summer months of our cabins being used, again electricity for heating and cooking, DHW is LPG. The blue line makes me feel warm and fuzzy inside. That's our electricity for the self build, a whole house fully electric and blissfully warm with ample DHW. (With some limited cabin usage). To all self builders going through this, it's worth the effort👍.5 points

-

I think it has dramatically improved productivity. EG getting the same job done with less time and less people. Take an average DIY project. We get inspiration from something like Pinterest or Instagram Vs trekking to a library to borrow a specific book. Then we research how it's done on youtube and Buildhub. Avoiding many of the pitfalls of doing it the wrong way and wasting loads of time through trial and error or asking our 1 mate who has tried it before. The I draw it up on my laptop in SketchUp, make a Google sheets doc for the quantities. Try calculating by hand the amount of OSB to sheath an awkward roof VS just clicking on the surfaces in 3d model and you'll soon see how much time it saves. We order materials from Screwfix and the merchants on our phones, pay with cards and they magically appear the follow day. No need to take time off out day job. Before we'd have needed to drive into town, go to the bank, withdraw cash, visit the BM, load it all into a trailer and haul it home. Then look at all the amazing things that weren't available to my grandfather at an affordable price that massively speed up building and often enable a job to be done safely by one person. Here's a few I use that springs to mind. 1. Cordless electric tools. Take on a 9*3 a few times with a hand saw and then tell me technology hasn't improved things. 2. Cable ties 3. My mobile phone. I use it for everything. From all the above bits up to "walkie talkie"ing my wife to flick a remote switch or valve while I investigate the other end. 4. Laser levels. 5. Modern adhesives, tapes and expanding foams. 6. Cheap safety equipment like gloves, disposable overalls, dust masks, goggles and hearing protection keep guys out of the sick bed and in work every day of the week. 7. Cherry pickers Vs ladders 8. Cement mixers. 9. Volumetric concrete lorrys. 10. Conputer designed roof trusses. 11. Cranes, including those wonderful truck mounted remote control ones. 12. eBay gumtree etc allow me to afford stuff like ASHPs at a cheap price. 13. Led Headtorches3 points

-

I have always held the view an electric boiler is a solution looking for something to solve. If you are going to heat the house with electric resistance heating, just fit individual panel heaters, controlable room by room. An electric boiler just adds complications and cost to achieve the same aim (if you are lucky) of heating the house by direct electric resistance heating.3 points

-

No, they Think they know more than me 🥷 which is why I have never lost a fight with planners or building inspectors. 😎 knowledge is power.2 points

-

Scottish building regs are different - extracts below "Guidance is given to minimise the risk of explosion due to malfunction of an unvented hot water vessel by: ensuring that such installations are carried out by appropriately qualified personnel" And "be carried out by a person with appropriate training and practical experience. This might include current membership of a registration scheme operated by a recognised professional body. the installer should be a competent person" Our rules basically say should be a competent person with suitable training and experience. This might be demonstrated by membership of a recognised scheme. I have the experience and training certificate to demonstrate competency. If there's problems it is no different to anything else, the person that signs on the dotted line is the responsible person, member of a sign off scheme or otherwise.2 points

-

@sam I’m not keen on your walls being so low in the ground, I would put both layers of insulation inline on top of each other so the outer edge is flush, then fit the sole plate on top of both layers. I would look at a denser insulation for the perimeter maybe xps300 or eps 300. I would stagger all the joins in the insulation and glue it all together to form one big slab. I would also glue the chipboard flooring down so it all acts like one big chipboard insulation sandwich, sort of. your bigger problem will be stopping it blowing away. 1m long threaded rod buried in the ground below your drainage layer, coming up through your sole plate could fix this. what do you want to do in there as 4m square is rather small. and the cost per m will be extremely high, it won’t cost much more to make it a bit bigger.1 point

-

"Can you show me where it says that please" generally ended the debate. I had some issues with LA bcos who had a self confidence beyond their knowledge. I think it was related to being all powerful fof decades. But did I dislike that more with the old timers or the day release boy, I'm not sure. They would always ask for an extra 100mm out of a trench. Apparently nobody had ever refused. No, unless you are you paying for it? With planning it can be more nebulous though. This is not wandering off the subject, but adding background and context. Basically explain what you want and why it is a good thing before they have to ask.1 point

-

I feel like a plant room is one of the most likely sources of a fire in a house (we have solar inverter, all networking gear, CCTV, MVHR, solar diverter etc) after kitchen and tumble dryer... We had all our walls ply lined, ceiling boarded with fire board and standard board on the walls. Fitted fire door as well and smoke detector. Only piece of exposed wood (consumer unit board) was painted in intumescent paint.1 point

-

Are you just making issues to fix. Ply gives a good surface to mount things to. Your fire risk is way lower than a kitchen or utility (clothes dryer) for example, or your phone on charge overnight.1 point

-

1 point

-

Point tooken, to a degree, but water vapour permeability is often talked of as 'breathability', so the lay-up I described has 2 a/t layers and a 'breathable' construction (Brick/lime/WF/lime). Unless there is an inherent damp issue then in this example I don't feel I'd be risking trapping any moisture (but also I acknowledge myriad ways of cat-skinning!).1 point

-

I agree. Many things can also be done to an existing house. My annual usage is a gnats over a quarter what they were when I moved in. What does upset me is the number of post asking for advice or help, after they have built. It really is not hard to design in a decently insulated floor and make the walls a bit thicker.1 point

-

Good good. Maybe you could update your blog. If you get a spare moment. I've been following with much interest. I love the nerdy details like floor/wall/roof insulation buildup and window specs etc....1 point

-

1 point

-

Yup. Cheaper than shoplifting. ASHP is a no brainer if you can, otherwise (as it’s an attic essentially) then A2A air con for heat and cool. Average CoP north of 3. Air conditioning in an office in a loft in the summer will be heavenly, and I doubt it would be otherwise survivable. Windows wide open / drafts / noise etc isn’t always practical in an office, unless it’s in the middle of nowhere and deadly quiet? I’d sack the UFH off and go A2A.1 point

-

1 point

-

I can confirm, BC (Scotland) were happy with my self certified G3 compliance and signed off my build today.1 point

-

I remember the 18 months we spent in the static, which happened to include the winter with the "beast from the east". It proved it was possible, just, to survive in that in a winter storm but boy it needed a lot of heat. We lit the stove in November and it hardly went out until March and it was a challenge keeping up with firewood to feed it. Now I read of people in "ordinary" houses with high heating bills and sit smug in our comfortable house with low bills. It is definitely worth it. It is widely assumed by most that your largest household bill is energy. It is most certainly NOT in our case, it is council tax, and sadly that is one I cannot reduce by making any changes. I have said before, if you applied the same criteria to council tax as you do heating bills, then we are in "council tax poverty"1 point

-

Ah i get it, Individual slats not strong enough? I have recently re built some garden benches and mid span I connected the slats together underneath with a piece of steel so they were connected together to spread the load and it works well.1 point

-

1 point

-

Exactly - we have loads we want to do with the space, just as you're doing, including growing our own vegetables which is a huge undertaking on its own. In the current climate as well, people are spending more time at home, pursuing hobbies/interests, etc. - a good thing1 point

-

Already in Japan people in the 80,s continue to work (if able). Yes I have always thought suddenly retiring from full time is a nonsense (mind I did it but had to build a house 🤷♂️).1 point

-

Osb is horrible to paint, use ply if only using wood, I used fermacel on top of osb as it has a fire rating. if you don’t think you need a fire rating then just ply, don’t paint with standard emulsion it will have every single workman’s handprint on it, use a gloss or I used eggshell as it’s not shiny. not particularly cheap though compared to a 10 litre tin of white Matt.1 point

-

If I was the developer I would build to the latest standards, or better, and promote it heavily. Then when people do a google search they would see what fine houses I make, rather than an unfortunate event. The marginal costs would be very small.1 point

-

Why not use the same steel as the legs (I presume steel?) make squares not U shapes (just need another length in the corner where no leg.1 point

-

A local company called TimberTech up the road from me in Ireland - run by two brothers. You know its good when all the trades know them and can't recommend them enough! Did want MBC back in 2016 but just didn't get my act together fast enough! They moved to the UK! Don't have twin wall stud and cellulose but did get Kore passive raft and have decent Architects drawings for insulation and other details to get the performance I'm after. Just picked up today some Gutex woodfibre board I'm thinking of using and Bosig Phonotherm for around the inside of the window openings. Waiting on a date for window measuring, a quote for the brick/blockwork, brise soleil bracket details to send onto my structural engineer and dozens of other details I've to talk to TimberTech about tomorrow as they finish in a week! Roof is on and felt/batons next week, tiles after Easter. The Velux rooflights arrived too and are big and heavy. Another Blog post coming soon I think! If anyone is in Ireland and wants to check them out they are here: http://www.timbertechhomes.ie1 point

-

Score deeply in diamond patterns with edge of a scraper.1 point

-

Soak with a sponge and the paint should wash off. key the surface up if it’s a bit shiny. 40 grit sandpaper will give it a key.1 point

-

Any decent flexible tile adhesive should stick. What paint is it? If vinyl then you may find it will come away in sheets if you get behind it, if so peel it off where you are tiling, if it’s stuck well then tile over it.1 point

-

1 point

-

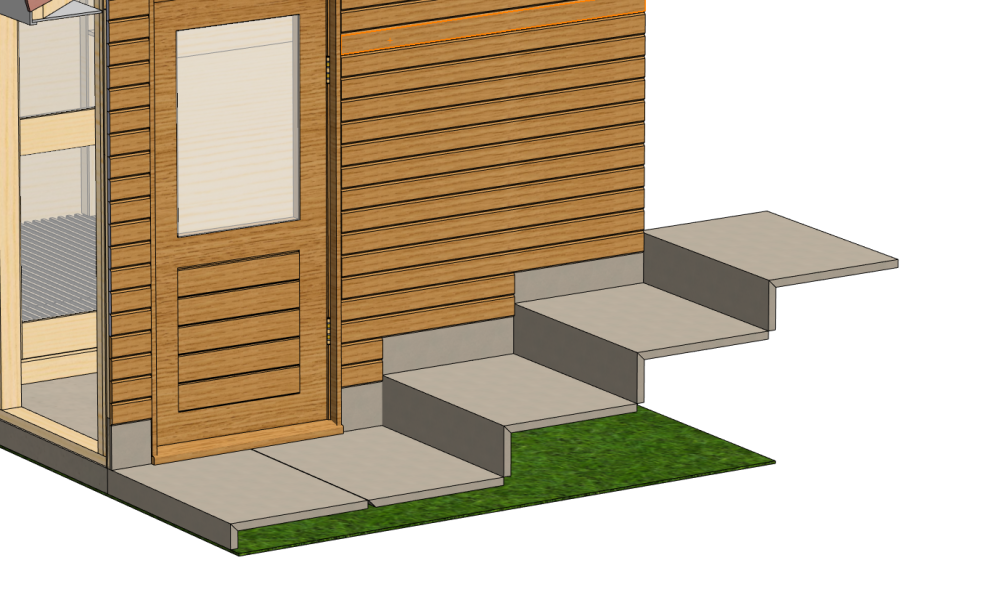

and then let us see the finished product please. Looking at the last picture again, has the sill been closed of at the end? If that was opened up, any water escaping wouldn't be sitting on the step.1 point

-

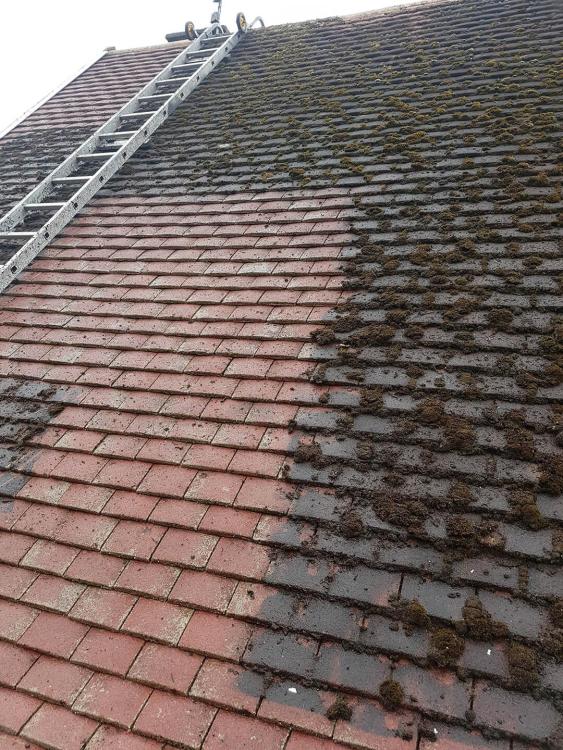

It's definitely worth it if you are starting to notice it from the ground looking up. My roofer told me that instead of seeing it as a way of making your roof look nice, it's better to think of it as a preventative measure. A full roofing replacement later down the line will be much more expensive than roof moss removal now. There is no best time of year to remove moss from a roof either.1 point

-

If you are fitting the windows up to the existing render I would just foam the gap between the masonry and the frame and run a small bead of sealant between the edge of the render and the frame on the outside. Compriband not required.1 point

-

Guys most 20 yrs old don’t / can’t / wtf want to work . No shagging so less babies . Population drops and productivity drops . Aliens land - tell us what (expletive deleted) wits we are . Turn us into their sex slaves . Sorted ! - don’t sweat the small stuff !0 points

-

Is that you with 44 (forty four) bricks - that's a lift if ever I saw one. the HSE would have something to say adding all that weight to a wooden ladder's rungs!!!!0 points

-

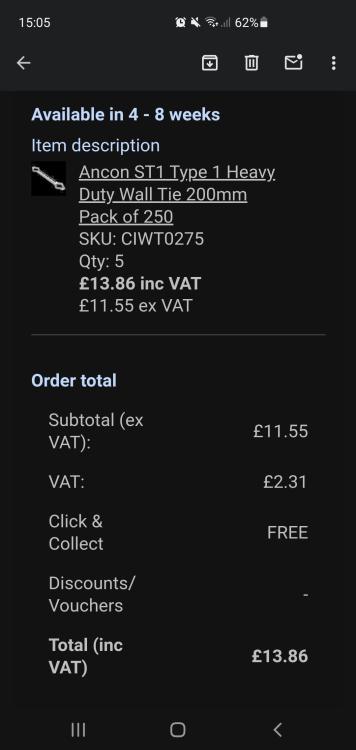

They have a 4-8 week lead time on them,so i have a bit of time to wait0 points

-

Well we keep being told that automation etc will make us all more productive and increase leisure time. I have been fed that mantra since school and I am still waiting for that to be the case. But it should be possible. Time for those that kept on telling us that to prove it. It won't be my problem, and not my daughter's either so I won't worry about it.0 points

-

If that's the garden room.... What's the house look like!? I'm looking forward to my garden room, as a converted shed! 😆0 points