Leaderboard

Popular Content

Showing content with the highest reputation on 02/02/24 in all areas

-

Built in appliance doors have almost zero adjustment. Fit that first and then adjust the other doors to line up with it. The fun starts if you have 2 built in appliances.2 points

-

@Gaf, I didn't realise you are in Ireland, this should make the airtightness easier for you because builders are familiar the tighter regulations. When we had our slabs installed we asked hollowcore guy if wrapping the slabs was commonplace. He said yes, in Donegall he sees it all the time, but our house was the first he'd seen with wrapped slabs in Northern Ireland. If you are going to wrap the slabs then beware that during coonstruction water may run through the ends of the slab and pull the membrane down and the block layers will carry on regardless. At one place we had to slit the membrane at a GF window opening to let the water out so we could pull the membrane back into place from above! Also, to protect the membrane the brickies laid one course of block on top of it on the first floor and then (after the mortar had set of course) I taped the membrane to the block and then covered it with dpc to protect it from mortar droppings. This is almost a full time job. Also, if you are in Ireland, you should be able to get your internal walls wet-plastered for airtightness instead of dot and dab. That's what we're doing, and painting in the chases and back boxes. with pro clima aerosona viscon fibre paint. It's easier to get in Ireland than blowerproof. And I prefer it to the other one.2 points

-

Hello all I have finally got a final certificate from the Building Control and wonder if I need to do anything else? Apologies for being daft. Do I take it to the planning authority? Anyone else? Or this is it? How long do I have to submit a VAT claim? The build is finished, and decorated, just needs a good clean and can be moved in. I have attached the certificate which the Building Control issued. Is this egat you'd expect? I have informed the structural warranty insurers and they came for the final inspection a couple of days ago.final certificate.pdffinal certificate.pdf1 point

-

I rate Octopus because their customer service is less bad than many others, and you are actually in control, you can set your DD amount or as others have said just pay actual bills, if you end up too much in credit you can ask for some back etc. So many other suppliers just choose their own random amount, make silly estimates, won't let you change anything and hold onto a large credit, and won't even discuss it. In other words Octopus allow the things you expect and would hope are normal, but so many people with other suppliers have plenty of horror stories.1 point

-

It was solid build an 89 on a B If we had of added solar like the planning stated it would have taken us up to 91 A If we would have added MVRH That would have taken us back down to 89 Such nonsense1 point

-

Assuming underside of worktop level you can adjust doors all up to a packer beneath worktop1 point

-

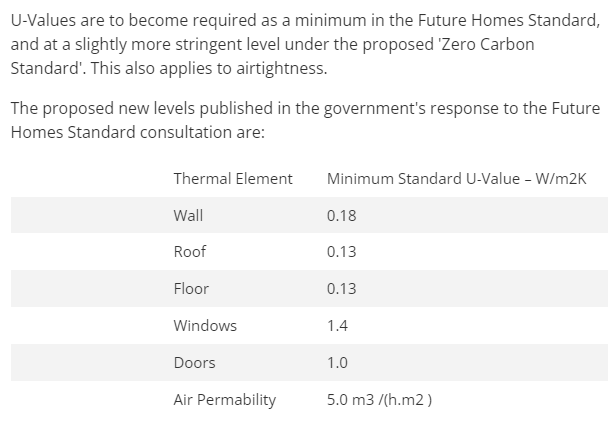

Of course, the 'Home Energy Model' is coming along in 2025 to 'replace epc'...probably another black box. Personally I would be happy for us to all adopt PHPP as it is auditable and I believe the background calcs and assumptions are all in proper research papers (but the ones I've seen are in German). Maybe the 'Home Energy Model' will correct some of the more daft epc quirks - but the targets are not at all ambitious (see below). I think BuildHub needs a political wing . I would like to see the algorithms published with rationale and research data - instead of some hidden professor's ramblings under a tiny consultancy's control then watered down by the big housebuilders. Then some for-profit software vendors with software put though an opaque 'validation process'. I'm having a bit of a grumpy day today - but if you check into Part O, that's exactly what you'll find.1 point

-

1 point

-

In 2018 our house achieved an A95 without any renewables, but we did design it to better than PH standards using PHPP.1 point

-

So long ago...and it was always vague anyway. We weren't cheating, simply trying to avoid nonsensical penalties within said black box. It also allowed us to design a building that we knew would pass, tweak insulation if necessary, and avoid shocks at the end. Our EPC assessor would discuss these things with us, and we could share our disdain, but they were very strict and professional: I think there are other types available. Solar panels to the roof that our client would fit...later. Boilers were rated wrongly...we reckoned they had inverted the adjustment factors from worst to best. Air source heating was assumed to be used for cooling in summer whether likely or not, greatly damaging the electricity use figure (which was considered to be bad energy by BRE at the time) Very dubious assessment of solar gain. If I remember more I'll come back.1 point

-

Let me start by saying an electric boiler is the most useless invention man has ever made. IF you are going to use direct electric resistance heating you are better off just with panel heaters and an immersion heater. Putting a big heater in a box on the wall and using water to move the heat around that will never make it more efficient. However it has given you wet under floor heating so that might be useful. No 1, separate out your space heating and hot water heating, before you can go anywhere you need to know what is using what. If it were me I would be fitting an electricity meter on the feed to the boiler, setting heating and hot water times differently NEVER on at the same time and taking lots of readings to see how much the HW and heating are using separately. How good are you at DIY? With help from this forum would you consider DIY fitting an ASHP? I have no idea what the regs are on Jersey but the parts are likely to cost no more than £5K and DIY might make it viable. You might be better off just with a good plumber and electrician that you can trust, and who are capable of reading an instruction manual, rather than a "specialist" heat pump company which is what I suspect you have been talking to? Do you know anything about the building construction, what levels of insulation for example, particularly under the floor? And what temperature is your UFH running at the moment?1 point

-

Soak the oats in a little water, then top up with milk. More economical. If the oats are cheap and coarse (we can't all afford Scotts you know) you might want to soak overnight. Pinch of salt, spoonful of honey. Two minutes in the microwave. Job done 👍1 point

-

Yeah, that should work fine, just be careful to not go too deep and nick the glass. They should be easy enough to come off.1 point

-

This is a really good point. Most, if not all control systems that provide modulation, whether weather comp or load compensation are really best in single zones. I was talking to a technical person at Honeywell who was indicating that as Opentherm is designed as a heating protocol it doesn't really work very well with DHW (e.g. when using Opentherm to manage priority hot water) and it is not optimal when dealing with motorized valves -it doesn't like them that much. When I've spoken to various boiler manufacturers and control manufacturers both the implicit and explicit message is the same. For example, with Worcester Bosch boilers, you can have modulation and pdhw without any zones, or you can have zones without modulation because as soon as you add motorised valves, the design of the control system means that the signal must be converted to 230v so relies on relay to work. I do think there is a mismatch between control manufacturers and boiler manufacturers and I also think that some of the boiler designs are defficient in this regard - they are often limited by silly design implementations/limitations. This makes it extremely difficult to design and install some systems that by their nature might need zoning, but especially when you consider the Building Regs Part L requirement for zoning.1 point

-

Ah, is that what they are called, an unvented water heater? Helpful to know what to search for in the first instance!1 point

-

The problem afaik is that it is not clear how the epc number is calculated - the algorithm seems to be a total black box - which is properly dumb. In contrast to PHPP, for instance, - where if you take enough trouble you can see how every little bit is calculated.1 point

-

Dead easy, just stick a lot of PV on the roof. We snuck in with our new build, above average insulation, 4kw solar array. Not sure we deserve it with windows and very in efficient floor plan (big sprawling bungalow with high ceilings) but I wasn't going to argue!1 point

-

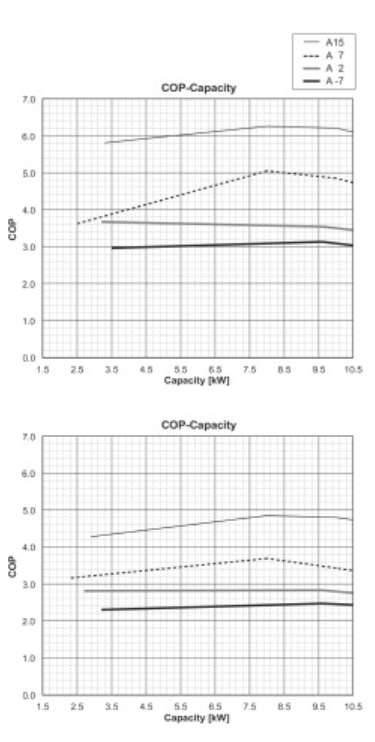

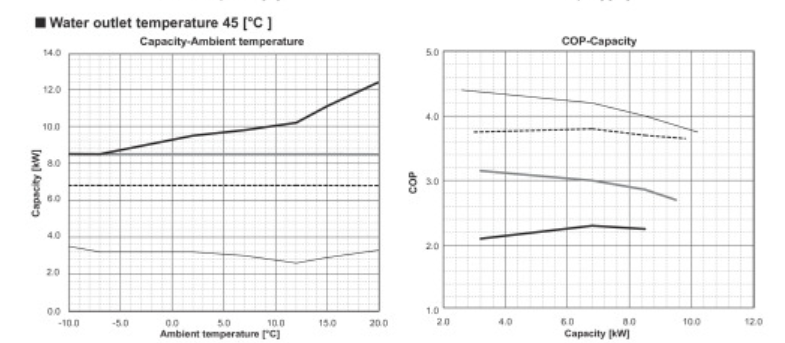

The plots are from the Mitsubishi web library, they are for an 8.5kw unit so not the same as yours and they are the COPs at an operating temps of 45C (not 35C) which is what you said you were running your unit at. The lines are at ambient temps of 15, 7, 2 and -7C The COP's are only a guide you can't take them at face value they are at laboratory test conditions but you should get in the same ball park which you are. These are the charts for the 12KW unit the first is at 35C the 2nd 45C so at 2C the 2nd bottom line you should be getting between 3-3.5 depending on whether you are running at 35 or 45C which is what you are getting1 point

-

Look for the ecodan data book, perhaps here https://www.mitsubishi-les.info/database/servicemanual/files/201803_ATW_DATABOOK.pdf Page 100 onwards, you need the exact model number. 1PH means single phase (not 3 phase) The best case COP is at air temp 15° so irrelevant this time of year.1 point

-

You haven't stated what size Ecodan unit you have but your COP's look pretty spot on to me at 45C. The 2nd bottom line on the plot on the right is COP at 45C when its 2C outside which is probably about right for Jan on average, so you should get a COP of 3 at 45C which is exactly what you are getting.1 point

-

Actually, last evening I managed to get Free RTOS working on a PICO board working, in C++ that is, which I had not tried and it does what it says on the tin so I think I will, once I have completed the terms teaching with Python, I will look at moving my personal system of systems over to that - I still have all the stuff I did with the esp blocks in prototype so lets see how I get on.1 point

-

1930's 190m2 end terrace with solid brick in existing house and cavity wall in some parts, old suspended floors uninsulated and no ewi (should of done these) whole house heated 24/7 to 21.5 with setback to 20c at night gas bill for december worked out at £6 a day this includes cooking and hot water usage (cylinder is set to recover 24/7 too whenever hot water drops below 40c)1 point

-

1 point

-

I have towel rads running on weather compensation flow temperatures on two different circuits. One towel rail is on the UFH circuit and the other 3 bathrooms are on the radiator circuit, my bathrooms are always very nice and warm but I did choose 1800Hx500L towel rails. Obviously this means towel rails won't be on in the summer but that's a bit wasteful regardless. I did wonder about that huge pump he has on his circuit, it looks expensive and totally uneccessary i've only seen those installed in mansions lol. @Dan F when you say you have mixed circuits do you mean you have electronic mixing valves? what curves are you running in your place? I'm on 0.4 for radiators and 0.35 for underfloor heating A mixed circuit for each of @Adsibob manifold would be too costly you could run the whole system from one mixer or even better straight from the boiler. I read back on a previous thread in April where we were discussing this and you said your house is split into 12 different zones... is this true? that's insane.. so you have 12 different thermostats?! This is how my boiler is running today, constantly on at low temp. I recently range rated the boiler down to 8kw, meaning @ 30KW It's insanely oversized.1 point

-

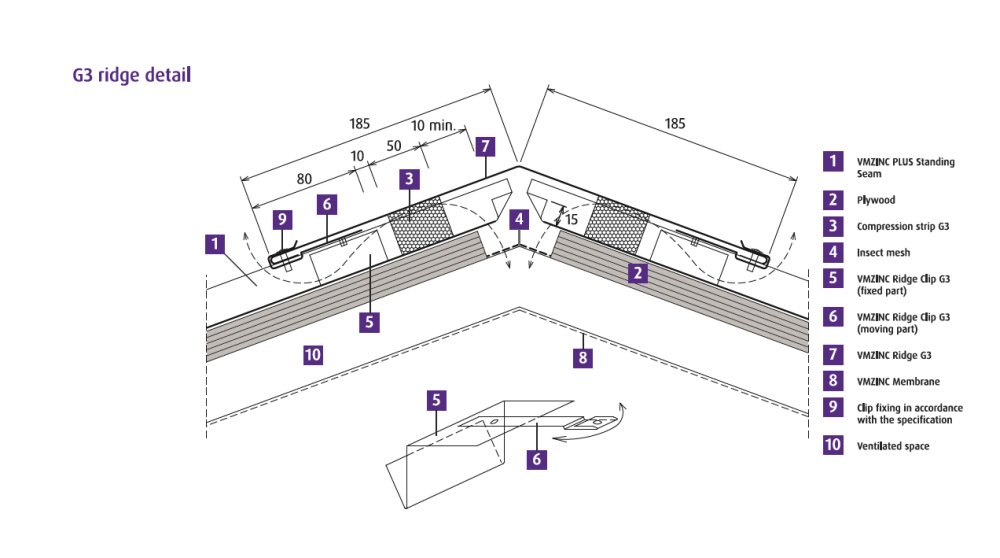

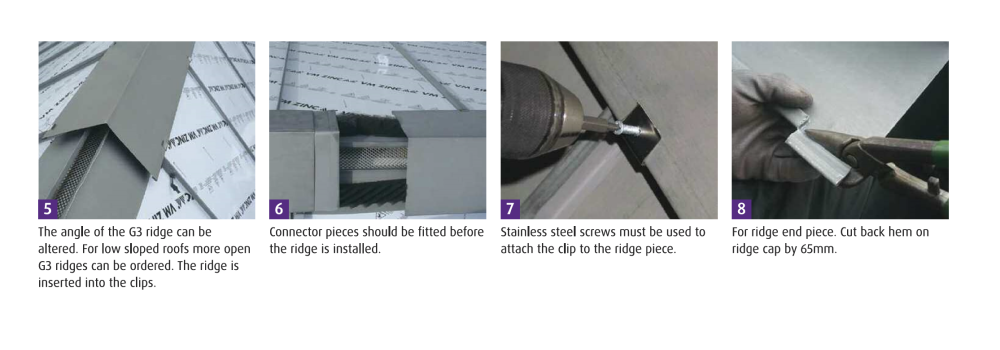

So I found the ridge construction and its the G3 standard ridge construction for zinc roofs. Which I'm ok with. In theory. Looking at the G3 roof installation, I recognise this as exactly how our roof was installed. The G3 ridge detail is described very nicely here https://www.nealroofing.com/wp-content/uploads/2018/10/Ridge-Installation.pdf This is the bit I like best at square 7. Stainless Steel screws Must be used. I think our metal roofer will be replacing the screws soon. That'll learn him to try and save a few quid.1 point

-

1 point

-

You can't really beat boiling a kettle for doing dishes. And then you can do it on the woodburner if you want. I've probably spent the majority of my life using this 'system' (and still do today, albeit on a boat).1 point

-

In theory you can't beat the market by locking in fixed prices as you need to be smarter than the bulk of the traders participating in the futures market. It may suit your particular circumstances though if the sweat of higher prices is more than the benefit of lower prices e.g. if you're on a very fixed budget. Also, the active hedging will cost the providers in manpower and they'll pass the cost onto you. In theory the floating rates should be easier and cheaper for them as they don't have to hedge - they just pass the risk on. Whether that's all born out in practice would need a very detailed analysis.1 point

-

Perimeter/joining timbers is pretty standard (still called a subframe even though it’s not underneath. Tek or other screws through the timber and into the pile cap is a cold bridge top to bottom, so sometimes deep counterbored holes are used but this is just extra work, hence the angle or U saddle brackets to prevent the cold bridge. You don’t put down the whole floor and then crawl under to fix it. fix first frame timber to caps, drop in row of panels and next frame, fix to that row of pile caps and so on. This way you always work on the ground, easy access to pile caps you are fixing, no drilling down or guessing where caps are etc.1 point

-

I've got a drain on the flow and return CH pipes that comes from the lowest point under the suspended wood floor and go straight out thro the wall and drain points are accessible via a small hatch in my decking and drain onto the gravel under my decking. only thing that is outside is the drain valve - I really should check one day if either of them actually get warm??? Picture taken before the pipes were lagged and before I put the 75mm PIR insulation above them under the floor Drains valves are to the right to (External to the house) Upper 22mm is the end of the flow and return pipes The pipes going to the left and up and to the left and the feed and return for the last rad on the system The pipework for this rad was a real dogs breakfast as it had been moved from one wall to another and the extended pipework wasn't lagged at all!!! I found similar around the rest of the house when I was under the floor1 point

-

I seem to remember all you wood burner people claiming it is the warm glow from the fire that keeps you warm.1 point

-

Ask for a price including 2 lifts (assuming you have gables ..?) and then a price for modifications. Ask for 12 weeks initially then what the weekly price is. And who does H&S inspections..? As long as it’s tagged and not modified then it will be fine. And with brick and block expect it to be built in (ie putlogs in the brickwork) and not free standing as that will add about 30% to the price.1 point

-

SWMBO is writing an Artificial Intelligence strategy document for her Department at the Management School at our local HEI. My mind turned to Buildhub and drafting our own Planning and Design Access Statements rather than employ someone....... This is what I asked Chat GPT to do for me And here's Chat GTPs answer Hmm, well thats a start - not much difference between that and a commonly available template. Downloads a random Design Access Statement Template ( in this case Zummerzet war dem Zider Apples grow) That template asks for the Design Principles that have informed the design - thus Delving at random again within this response to look through Chat GPT at which Environmental Considerations. should be considered (Point 2 above) I asked this question and Chat GPT replied and because I could not resist it ( if you've read this far, you're there before me aren't you ) ......... Tell Me oh Chat GPT, what's Thermal Mass then Ouch.0 points

-

We designed and built our own office building, thinking of it for value, comfort, future proofing, running cost and also as an advert for sustainable design. That all worked because we got awards for it, but not necessarily the right things were appreciated. It was rated D, 15 years ago (which was considered great at the time). We had it reassessed last year and it got a good B without any modification. Most of that was because ashp is now 'good', whereas then it was 'bad', such was the knowledge level at BRE. I assume a lot has been improved but equivalent nonsense is still likely to be in the box.0 points

-

The ones that wear pants under their kilts, and can't toss a caber.0 points

-

0 points

-

Do you use the remaining hot water to make porridge, with salt in it. Then put the horse hair shirt on.0 points

-

sloppy rendering, i would get rid of those cowboys 🤣0 points