Leaderboard

Popular Content

Showing content with the highest reputation on 11/25/19 in all areas

-

Perhaps modern minimalism has had its day: time to embrace ornamentation again. And I love the hashtag #DotD (downpipe-of-the-day). And I'd love to have downpipes like this…2 points

-

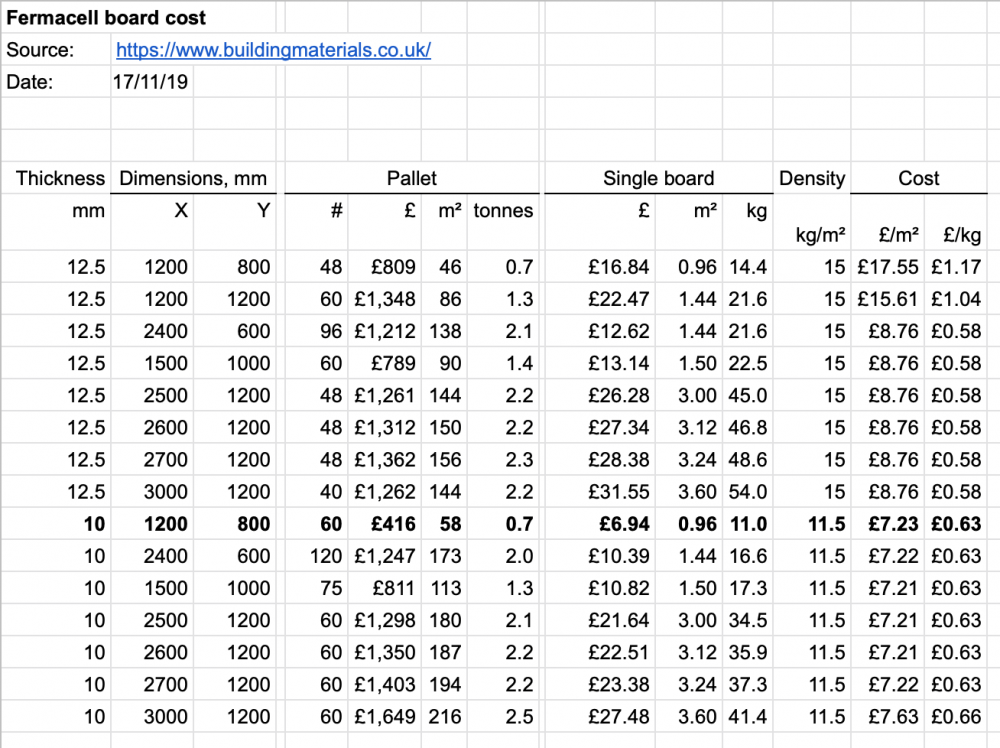

@Dreadnaught Pretty much the same as @Visti expect I haven’t got a sister so the good lady had better be up for a bit of fun. The guy on the Fermacell helpline says exactly what Visti said regarding TE so basically of no use on a new build using Fermacell. Likewise I’m planning on 12.5 throughout as it’s ‘off the shelf’. 10mm would be a special order and they would only supply full pallet loads so there is the potential to end up with loads of excess 10mm boards if I got the sums wrong.2 points

-

Well some progress. For those who wanted a picture of silencers... All suspended off chains but could easily be done with something more sound proof. The 150mm flexi pipe I've used to join the silencer to the MVHR is a pain to put on and its not overly robust. I've ordered some more connectors and I will put these into the ends of the pipes and then slide the flexi over that. All mounted in an unheated attic - it takes a lot of time to do all the insulation in amongst all that timber. Hope that's what some of you wanted to see.2 points

-

Hello all, I am John and live in north cheshire. Well, where do I start, perhaps with how I got to where I am now. Application for one infilling bungalow in green belt in 2014 refused. Appeal refused in early 2015 although inspector agreed "not inapproriate development" After discussion with new planning consultant and a trip to London to visit a planning barrister, on the public access scheme (well worthwhile), new application submitted August 17 refused again. Appeal Feb 18 validated, but start date Oct 18. Decision end of November 18 allowed with full award of costs and would you believe an indication that 2 properties could be accommodated on the infill plot. Application April 19 for 2 dwellings approved. Other plot sold and we are about to commence on build early in new year. My wife has MS and proposal is dormer bungalow 230 square meters, all accommodation on ground floor with 2 guest bedrooms and bathroom in roof space. Considering attic trusses or a SIP roof at the moment and initial approach to DNO will allow PV single phase export capacity of 12Kw and total pwer station capacity of 17Kw. As you can imagine, I have plenty to think about but a given is UFH and I have mains gas passing the doorstep. I will scan the forums for tips, many I have picked up already, and hope to keep you updated on our journey. Thank you in antipacation of your interest ,2 points

-

Reading through this lot the only thing I would add from a more hands on approach would be that if you use smaller boards make sure the team doing the jointing and finish knows this, if I turned up and you had used small sheets and there was double the joints it will cost you double the money to get it finished. I will be planning on using the biggest sheets I can find, if I can buy 4.8m in this country then that’s what I will use, I would rather pay for additional labour in fitting than having a joint every metre.1 point

-

Well the build has started. I've finished the foundations, and the blocks and bricks start on Thursday. Without a recommended company for the blown beads, we just decided to go for full fill cavities with glass mineral wool. 150mm on one wall, 100mm on the other, with PIR on the inside. The inner blocks are Celcon, with a thermal conductivity of 0.15W/mK. I know some go for more thermal mass inside, with more insulation outside, but the Celcons are what my building regs guy specked, and it should make the room heat more quickly from cold. The plan is to have a concrete oversite (on top of hardcore) and then 100mm of PIR rated at 0.022W/mK, and a warm roof with 140mm of the same PIR. Do those thicknesses sound alright? I know we'll meet building regs, but I don't know if it's worth doing any more. Re the cavities, do you think it'll make much difference whether the 100mm cavity wall insulation is 0.036W/mK or 0.032W/mK? Since the insulation is thinner than the opposite wall, I wondered whether it would be worth putting a slightly better insulation in. It's not much more expensive, but then the difference might be so negligible it's still not worth it. Thanks1 point

-

The model assumes a contractor to compare like for like. We're actually DIYing it now as my sister wants a gig for a few months. Convenient! I'll be going with square edge. Tapered just appears to be needed if integrated with other types of boards. I was thinking of 12.5mm throughout with a single layer, even on ceilings, to keep the m2 installed low due to size1 point

-

Yes, I just chose the first supplier I found on the Internet (actually the second). Good to hear that I can probably get them cheaper from other suppliers. The intent was to start understanding relative prices of different size and thickness of boards. And of course, as I only used information from one supplier and one point in time, the results might be subject to one-off factors. Don't know how many boards I will need yet (I have not yet done my version of your earlier splendid spreadsheet) but if I remember the size of your house correctly my guess is that I will need about half your number.1 point

-

1 point

-

I am now confused. What is this for then? Is that not your outside underground meter and stop tap? If no outside stop tap, how did they connect your tail? Did they fit a stop tap where they made the connection? Go on humour me and have a look.1 point

-

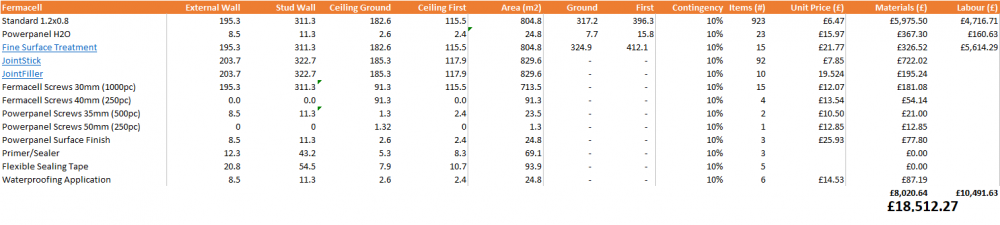

It would seem that way. I've just spoken to Fermacell technical support (I'm going to have him on speed dial). He say's there is no need to use the Powerpanel in a domestic situation. "You can use our standard panel with our waterproofing product or anyone else's waterproofing product, there all the same" he said. He made it sound to be as straight forward as it looks, aimed at us DIY'ers. Jointstick on the factory edges, 5-7mm gap on cut edges and then filled later. FST for any painted finish. And he confirmed what we all know - it's very heavy.1 point

-

You are making me , and Joe90 very jealous. Be very careful, or you may end up with the pair of us squatting at your place, with our old cars. P.s i don't take sugar in my tea, but do like lots of it please.1 point

-

You can , i'm sure, pick up, single phase, Two car post lifts, secondand, for about £500. if you had the height, use it , and sell it on when you have finished.1 point

-

Can you straighten that pipe lagging up please I find it offensive. Plus I hope all those cross head screws are aligned the same way. ?1 point

-

1 point

-

we keep going round this (wont be needed for a few months yet), and think we will go down the fermacell route and fit ourselves. I couldn't plaster but am confident I could use the fermacell filling compound so labour costs would be zero, D1 point

-

I over spec'd I guess. I saw that standard board could be used, so I may do that instead in my next revision. It is more a representation of feeling out of control! I always do this (engineering background) so that I can feel like I am making an informed decision... I am not sure whether the results are improved following a week of evening spreadsheet of good advice @ProDave, I think that is generally the way to go. I may also get a spare box of fermacell screws for other jobs in case.1 point

-

Yea I've noticed a similar thing in my bathroom. I've don't have a tanking membrane but instead I have a fabric looking uncoupling membrane with marble tiles and it takes an age for the heat to come through. We used LVT in the bedrooms and the heat comes through within 15/20 mins. instead of the hour it takes for the bathroom floor to get warm. I assumed it may have just been down to the density of the tiles but still seems oddly long to me. It is however a upstairs bathroom but with no insulation underneath as there will be (although not at this present moment in time) a heated room below.1 point

-

You can join it but I tend to stagger the covers opposite to the track so any misalignment of the lower track will be masked by the covers.1 point

-

Oil is cheap, bars and chains are not. I use Rotatech oil as it comes in 25 litre drums and it’s about £1.25 a litre. I also buy their chains but either Oregon or Husqvarna bars. Turning down oil is not something I would do - most of them are set to a correct level and it will ensure the chains don’t go dry and overheat which can soon damage the chains and the bars themselves.1 point

-

The site will be fenced off. Agree HERAS fencing is a good idea! Thanks for the replies, I will clarify with the site insurers anyway.1 point

-

1 point

-

Another option might be to just see if you can buy a suitable moulding plane and DIY it. Moulding planes come up on eBay a fair bit: https://www.ebay.co.uk/b/Wooden-Moulding-Planes/13874/bn_70234897681 point

-

1 point

-

I'd guess that it should be possible to build a solid garage floor that's a fair bit lower than the house floor, then cover that with an insulated floor to bring it up level with the other habitable areas when it's part of the utility room. If there's a need to convert that space back to a garage, then remove the raised flooring along with the partition wall.1 point

-

Richard Burbridge do this sort of thing, and maybe others. https://www.wonkeedonkeerichardburbidge.co.uk/richard-burbidge-fb463-reeded-pine-decorative-moulding-28x4mm.html1 point

-

1 point

-

1 point

-

what car do you have now and what will the next one be? Every generation gets bigger...1 point

-

1 point

-

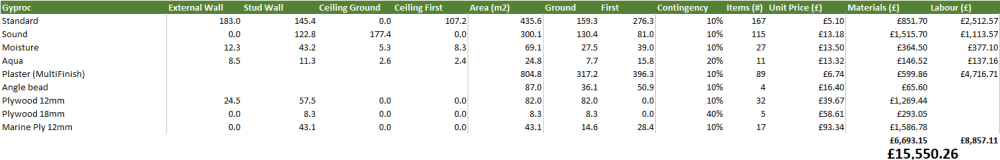

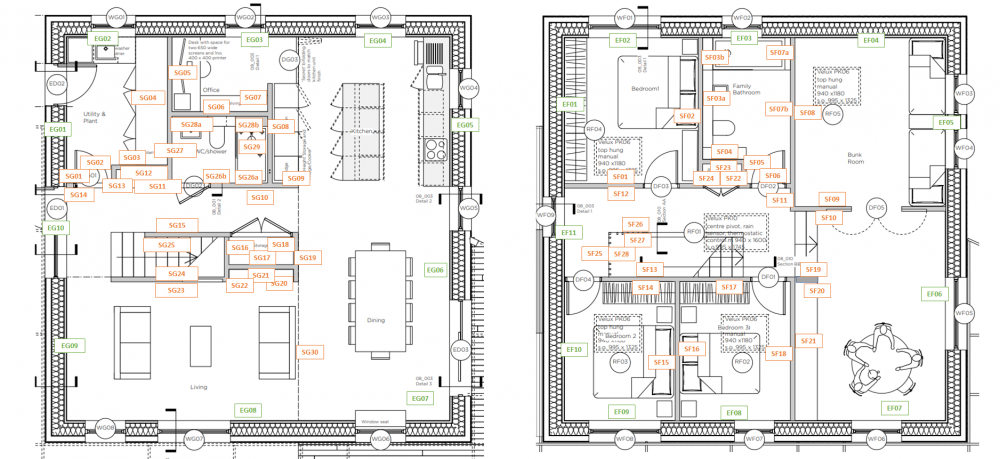

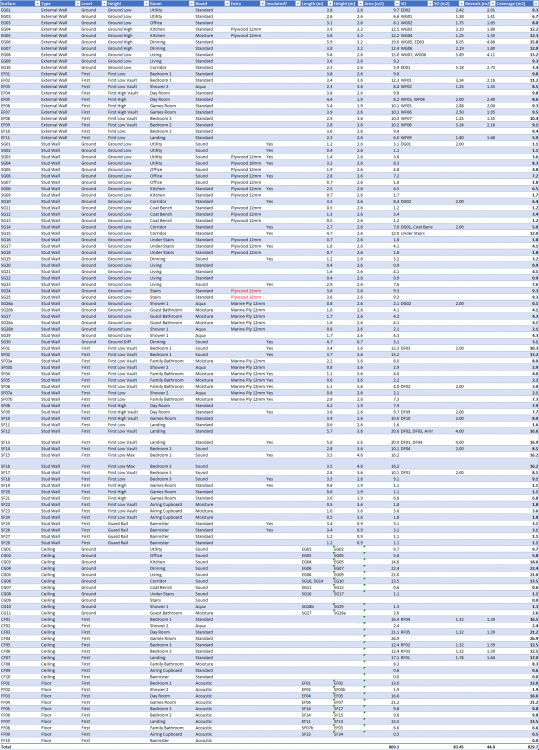

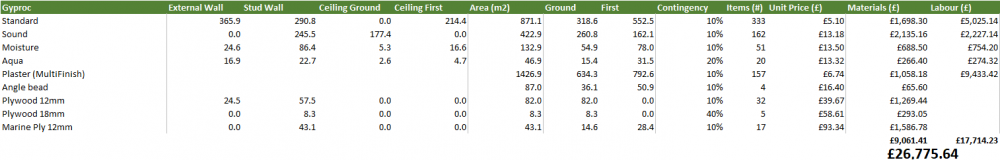

So I did the number crunching, and it looks like there is actually a good case for Fermacell if you can find a good supplier (found at £6.47/m2, making it £2.22/kg. only slightly worse than standard soundboards in my last chart). 1. Label every wall... 2. Take all the measurements... 3. Calculate labor and materials cost per m2... I've got quotes coming in at 25-33k (Double Plasterboard) - so not far off! Using only standard board I'd save ~£2k in materials. 4. Get a decent quote for Fermacell materials from here ... This is for a single layer of fermacell, equivalent density as doubled up gyproc wallboard. The labour is also an additional £1/m2 for installing these boards. The contractor also quoted more for applying the Fine Surface Treatment than skimming. 5. But what if I did just a single layer of standard wall board... This is half the density of the above except at the ground floor ceiling, and limits fixings to just areas with planned noggins or plywood backing. Using only standard board I'd save ~£1k in materials. 6. and what if no plywood backing at all... Probably the cheapest it'd get unless all the sound board was replaced with the standard board to bring it down to £11.5k.1 point

-

Here is the incident report: https://www.ife.org.uk/Firefighter-Safety-Incidents/shirley-towers-2010/346191 point

-

You are too bloody ocd fussy ! . No wonder it takes you a week to get a tile on the bleeding wall !0 points

-

the 2 posters are for sale -- only me here now -4 poster is coming to new house when built but £600 is bottom line --as they are not that old and proper ones with bottom frame work ,so suitable for floors that are not that good seen more than one 2 poster that just have the post, and no longditudinal arms on base , pull out of the floor when hairy arsed mechanic is swinging on a gearbox to get it back in scary stuff0 points

-

That reminds me of a friend that had a collection of expensive classic cars. He wanted me to rewire his second hand 4 poster he had just bought and connected himself. Not with the Maserati on the lift and the lamborghini under I was not laying a finger on the lift until there was not a car on or under it.0 points

-

0 points