Leaderboard

Popular Content

Showing content with the highest reputation on 07/02/19 in all areas

-

Since our last entry we've been concentrating of getting the standing seam roof covering on. It's one of those jobs where it would be nice to do someone else's roof before doing your own. We're using a roofing system from Blacho Trapez, broadly similar to the Tata colourcoat. It requires no crimping and minimal special tooling. It's around half the price of Colorcoat. The HPS200 coating we chose comes with a forty year guarantee. Our first impressions is that it's a quality product that's really well thought out. I'll raise a topic thread on the roof system with detail information from our install.. Here's a link to the Blacho documentation for more info: https://www.blachotrapez.eu/pl/26/instrukcje It was another Buildhub find. Back in April we came across an entry where one of the members @Patrick Who wanted to buy his roof abroad and was looking for someone to share transport cost. Enter Patrick, we exchanged emails and found we were going to need a roof on a very different time frame as Patrick is still in the site clearance phase and we were going to be ready to start in around six weeks. Lots of emails were exchanged and there was much head scratching over which components to order, In the end it turned out that three Buildhub members wanted roofs making sharing transport even more attractive. Patrick had been in contact with Blacho for some while, he's multi lingual himself and has a Polish wife. Without their help it would have been just too complex to sort our way through the parts catalogues even with the help of google translate. Having managed to get a list of parts we thought would do the roof, it occurred to us it would be good to get the guttering from the same source. It proved to be a step too far, we decided against it as the chances of getting all the required components correct the first time round was just too daunting, All is not lost though as it now looks as though there may well be an opportunity to get some steel guttering from them in future to replace the UPVC we have. Back to the roof and installing it. The three roofs were ordered and transport arranged to collect them from the factory on 03rd and deliver them to the UK on the 6th. The other Buildhub member ordering a roof is Greg, who is a builder with a yard with plant to unload and was happy to store the roofs ready for collection. The initial plan was to have all three roofs delivered to Greg's place and then we would collect, again Greg could help out as he has a lorry. The only slight problem was some of our roof sheets are 7.2M long and too long for the lorry. More negotiation with the transport company and they agreed to do a second drop off for a an additional 200Euros. All set for an 11:30 delivery on the 6th, we had arranged to have help to unload, no machinery just bodies. To our surprise and dismay we turned up on site at 7:40am on the 6th to find the delivery lorry already waiting...with just Pat and I to unload...by hand. Help was at hand in the form of the two guys who had come that day to do our roof insulation spray foam. They were brilliant, and between the four of us we had the roof sheets off their palettes and safely stacked on site. In addition to the sheeting there where also two smaller pallets for the other roof components, such as barge boards, eaves edges, screws etc. The lorry driver was getting a little fraught by this stage as it was all taking longer than it should have, not aided by lack of a shared language and the delivery documentation all being in Polish. Having unloaded and sent the driver on his way we started to look at the delivery documentation, this time under less time pressure. It turned out we had most of Greg's and some of Patrick's accessories. No big deal as we had already arranged to follow the lorry to Greg's yard to say hello and to borrow some roof tools that he had kindly offered to lend us. Meanwhile the delivery of the materials for our render arrived, 72 x 20kg sacks plus 20 x 25 kg tubs all to be shifted onto site..Just got that cleared when our MVHR system arrived, hotly followed by a soffit board delivery. Once done we set about loading the roof bits, only to find the length and volume of bit's overwhelmed the Jazz and we had to borrow a van great for volume but not so good for the 2M lengths and required me driving with my seat fully forward. Two and a half hours of agonizing cramp we arrived at Greg's, said our hellos and exchanged parts so we had the bits we needed to complete our roof. Finally got home around 10pm, oh the joys of a self build. A day to draw breath and it was time to start putting the roof on. The sheets themselves are 540mm wide and supplied to the customers required lengths up to a maximum of 8M, Being just 0.5mm thick steel they are not heavy but they are fragile, picking up a long sheet badly will result it it creasing, so care is required handling the sheets. The sheets had been packed at the factory front to front with polystyrene packing spacers which had stuck to the surface of the sheet requiring it to be cleaned prior to installation. After a bit of head scratching we decided to use a ladder to support the sheets. With the ladder tied to the scaffold we loaded each sheet, one person pulling the sheet from the top and another raising the bottom of the ladder we managed to slide the first sheet onto the front of the roof. All a bit “Heath Robinson” but it worked. Each sheet was then fixed in place and the process repeated. Soon we had a good part of the front roof in place. Cleaning loading and fitting was taking about an 90 minutes a sheet. Doing uninterrupted areas of roof with decent access proved straight forward and the front part of the main roof was done in a couple of days. Then we started on the rear of the house. This part of roof has two large roof lights and requires sheets to be joined as the roof length 10M exceeds the 8M max sheet length. The roof has two sections one slightly shorter at 7.2M, the largest of the sheets we had ordered. It quickly became apparent that there was no way we could get a 7.2M sheet onto the roof from the rear of the house. At this length the sheet is very fragile and requires multiple supports to stop it from folding. We quickly abandoned any hope of using them. Fortunately we had ordered some surplus material, so not the end of the world. We decided to start on the side of the roof with the roof lights to allow us to minimise sheets cuts. Partick had kindly volunteered to come over to get some first hand experience of the Blacho system. We started framing the roof lights. All did not go to plan and found that we had a 10-15mm alignment problem, nothing to do with Patrick just a bad datum line. No easy way to correct this so we removed the sheets and started again from a more accurate datum line. Second time round was a better result all round and we were able to continue across the main roof section. A lot of work but worth it..now we just need a good downpour to validate the flashing. . By good fortune a thunderstorm provided a test for the flashing, all was nice and dry round the roof lights. Sigh of relief all round, the roof is now on.6 points

-

After quite a bit of hot sunny weather recently the window film we had fitted last autumn has now been tested properly. I am very pleased with it - given we had a serious overheating problem and this was the only really practical retro fit solution to it I was keeping everything crossed it would work. Well worth the money.3 points

-

In Scotland, you do indeed keep building to the building regs in force when you started, but ONLY if you keep extending the building warrant, I have extended mine twice now. At each extension BC want to know what stage you are at and the reason for extending. At 10 years since start I very much doubt the original building control has been extended, and if you let it lapse it would be a new building warrant to current regs. At least in Scotland.2 points

-

Used both the TS and No Nonsense water based specific MDF primers before with no issue. Just the other day I had to knock up a quick MDF shelf for the daughter and couldn't find any MDF primer. Found this old but unopened tin and though it had an oil slick on top it soon mixed in. Seemed watery but it was in fact bang on. Applied with a foam roller. Great coverage. Took longer to dry of course than the water based ones.1 point

-

No matter what you paint it with you will get fluffy edges so you will need to sand between coats. Expect to put on more coats than you thought.1 point

-

1 point

-

Bin the super foil. It will do nothing under a floor as it works by reduction of radiated heat, of which there is none in that build up.1 point

-

1 point

-

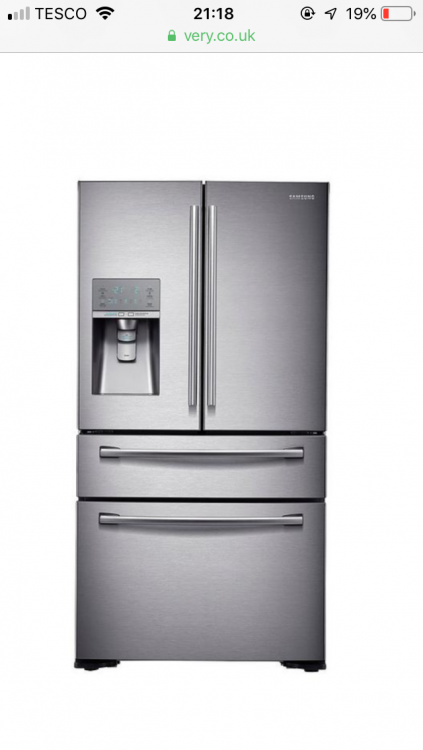

Which fridge is that I wonder? I will be wanting to choose a quiet one for the combined open plan living room and kitchen in my new build. In my present place, the big American-style fridge freezer makes a right old racket.1 point

-

sods law! We took quite a lot of inspiration from heb homes so possibly one of their designs1 point

-

Think I would stick with rads. We have 80mm of celotex under our UFH and wish we had more.1 point

-

If you are painting it with water based final coat then use a water based primer. I wouldn't bother with a special MDF primer, I've used Leyland trade acrylic and its been great, but go thinly and use two coats if needed and a light sand before your topcoat1 point

-

Fwiw I was encouraged to go for an unvented heating system. Vented is considered old hat by my plumbing friends so to save the arguments I did as I was told.1 point

-

We had a more limited choice of film due to having laminated 3g glass. If you have regular toughened 3g its not an issue. Some film providers had recommended film that was not suitable for our glass and the risk of cracking would have been much higher, others just said no film on laminated 3g. The supplier we used was excellent in researching the correct one for us. They got advice from Internorm (for warranty) and the glass and glazing federation and St Gobain. The Sentinel SX50 by Solarlux (part of St Gobain) was the best choice for us and bonus that it came in a bigger width (1875mm) too so would do our big sliders which are 1650 wide each pane. Our supplier did a great job on the fitting too. A guide to 3g and film which St Gobain gave us plus the spec sheet for our film. Sentinel Plus SX (Silver) 50 Sample Page 0314SSX50OSW.INT.pdf Glass Breakage Risk Triple Pane PDF02343PINT_1016.pdf1 point

-

? I should ask for my money back based on that! I’m sure it’s go down well well @BotusBuild and @Carrerahill thanks for the responses. I removed the innards and they seem to be sitting ok in the middle and they lift up now too. They sit a bit pointing downwards but, not too much I can do about that. Better than nothing! Im going to put the innards back in at some point (once modified or replaced) to stop any slipping around, but they seem to be sitting ok at the moment. Phew!1 point

-

When you remove the stop plate, replace it with a washer (or something similar) that is of equal thickness to the stop plate. It'll stop the handle "slopping about" (technical term ? ) BTW: Can you actually continue to use that handle as it appears to have an end date in the past? ?1 point

-

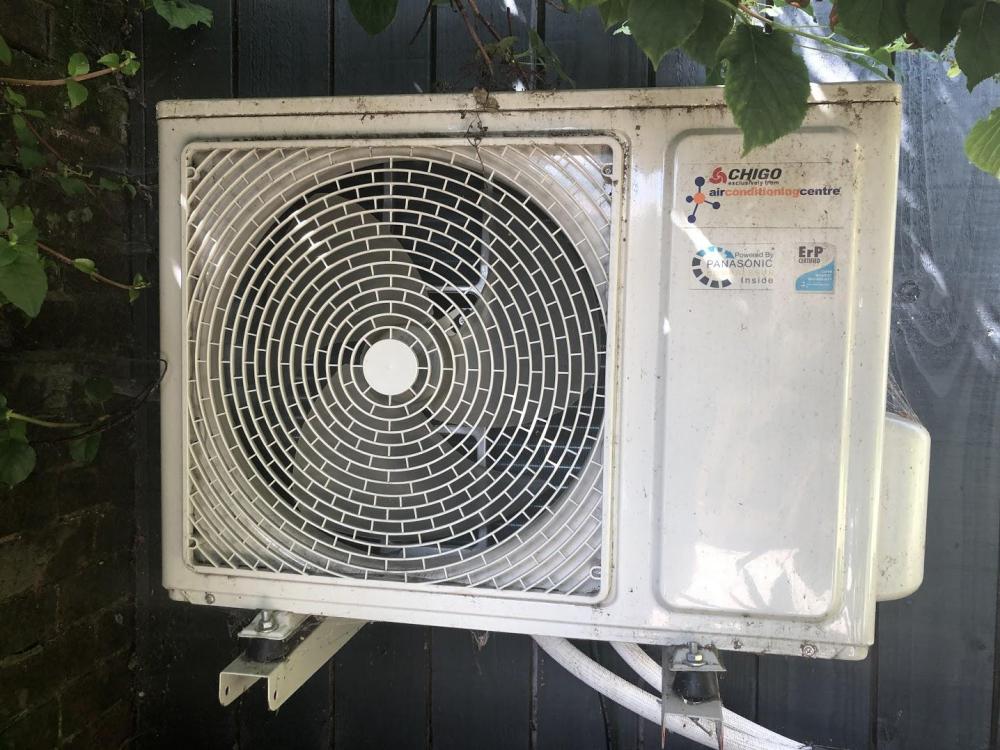

@JSHarris - Exact same units... mine are the 2Kw version (1x standalone, 1x 3 way multi-split) Can't fault them. They seem very efficient as well - the 2Kw one seems to ramp to about 700w at power on but then settles down and purrs along at about 400w when the compressor is running, and negligible when just circulating. Outdoor units are pretty much silent, theres a 'quiet' mode button on the remote that reduces them even further. The only time they make any noticeable noise is when the compressor stops, the fan ramps for 20 or 30 seconds before shutting off.... but as you already have a ASHP, you'll be used to all this.1 point

-

Remember you will need a condense drain from the unit. Make sure you have enough room the get the unit through the hatch and into position. The roof space is not that access friendly so make sure it will all work. Must have been a mission doing the insulation!1 point

-

If the square shaft which goes into the multipoint lock will be held in position by the lock mech itself then you can remove the stop plate, grind the stop lug off and refit without it also remove or modify the action of the spring. The handle will then go both ways but will have no integral position hold mechanism - but as I say, the lock mechs "home position" should hold the handle where you want it i.e. 9 or 3 o'clock position. Many UPVC door handles just swing round and round when off the door and rely on the "home position" from the lock itself. If not you would need to alter the stop plate and spring arrangement. In a word, yes it will be possible - but it comes down to a bit of luck or your ability to modify it.1 point

-

I've fitted a 2.5kw daikin unit, diy. The hole in the wall was an offcut of rainwater downpipe which I foamed around. The copper pipe is soft 1/4" & 3/8" which you need to flare into a cone with a pipe flaring kit. I bought the install kit with the unit to make life easy. This is easy to do IMO. Condensate drain is 20mm flexible pipe. You can hire the vac pump for £100 a week but I chose not to and just bubble tested the fittings. Bought the kit from Saturn sales, very helpful and thorough diy instructions supplied, although they explicitly say that if it is not fitted by an Fgas engineer then the warranty is void on the unit.1 point

-

65mm is standard as you need the two refrigerant lines, a 1/2” drain hose, power cable and a control cable. The insulation will squash slightly and the rest can be foamed.1 point

-

I have exactly the unit that was linked earlier (CPC) which was 'DIY' fit (and then later serviced by a Fgas engineer) as well as 4 fitted units in the house. The compressor is pre-charged and holds the refrigerant based on a maximum pipe length that can be found in the instructions. The pipes are just normal A/C piping and are reasonably soft so you can bend as required. I would caution, you get what you pay for here... 1) Strictly speaking this must be installed by an Fgas engineer 2) The purging method is bonkers.. but thats how the chinglish instructions tell you to do it. Vac-pump would be much better and would help confirm the joints are tight 3) My unit is still working but sometimes it seems to have a funny-5-mins. Turning it off and back on again solves this 4) The DIY fit ones take power from the indoor unit - most other systems take power from the outdoor unit 5) The 4 indoor units - pro-fitted Mitsubishi - have worked flawlessly since install I'm sure you have the skills to do the install justice but I'd go for a more recognisable brand (Mitsubishi, Daikin etc). At least then you have some options for servicing/parts in the future. As far as I'm aware a lot of the outdoor units now come pre-charged... Heres some pics of the 'no-name' unit... And the Mitsubishi units..1 point

-

Don't for one minute think all your PV generation is going to be used up by the fridge, mvhr etc. I have the same, 4KW of panels, and a 3.68Kw inverter and I only just use 95% of what I generate by very deliberately using the things like washing machine, dishwasher, tumble dryer one at a time in the daytime. And a dump controller to send excess power to the immersion heater. So in the summer you would barely be using any off peak. Would it be worth the extra standing charge and higher daytime rate? Also if you are thinking of an ASHP think about using an unvented cylinder rather than a thermal store. A thermal store needs water at a hotter temperature, which an ASHP is not going to do very well, if at all.1 point

-

In England and Wales (not sure about Scotland or NI) then the set of building regulations that apply will be those that applied when the house building regs submission was initially approved. This assumes that there was a building regs submission and that the foundations and B&B floor do have building regs sign off. However, it would make no sense to build a house now to 10 year old building regs, as quite apart from anything else it would be even less energy efficient, and cost more to run, than a house built to the pretty poor building regs we have now.1 point

-

There's an old adage: "Follow the money...." Review sites are funded by advertising in the main, and their advertisers are the very companies that are being reviewed. Are they likely to be impartial? As heck as like! It's a bit like trying to discuss the negative health impact of burning stuff in stoves to heat homes on a certain "green" (what a joke that is) forum that is sponsored by wood burning stove manufacturers... There's a very good reason that the founding members of this forum have a pretty rigid stance when it comes to remaining free from commercial influence, and relying on volunteers to run the forum and donations from forum members to keep things running. It's to try and ensure that views expressed here are a fair representation of the views of members, free from any commercial influence or bias.1 point

-

Or is it like a certain check trade type site that deletes bad reviews?1 point

-

1 point

-

We had a small precharged split unit purchased in Belgium 12 years ago. The unit came with instructions on how to separate the two units to allow the pipe to pass through a hole in a wall. As I recall the ends of the pipe had some valves that automatically sealed when disconnected.1 point

-

Progress this week. More photos than words for now. HQ is set up, including the shower. After felling the trees on site, a few big machines visited to get the logs out. Leaving the site looking like this: The last few days have then involved a lot of muck moving and getting decent material out for the tracks and base, leaving us looking something like this: Next stop, foundations!1 point