Leaderboard

Popular Content

Showing content with the highest reputation on 05/12/19 in all areas

-

So, I know I promised tales of cladding and roofing in the last instalment, but I have reviewed my photo stream and in fact realised that the window install was the next thing. At the end of November (as we all know, winter is prime building time), we finally retrieved our bargain basement windows from storage and brought them to site. Ah, the bargain basement windows, a tale of joy, horror, stress, fury, confusion and eventual revenge all in one. I should explain. When we had secured the plot and had initial drawings from the architect and were waiting for engineering/calcs/building control drawings/services/everything else, we passed the time by getting hilariously large quotes for every aspect of the design. It kept us amused. So, after reading a lot on fabric first design and passive homes, off we trotted to our local Internorm dealer. Lovely showroom, excellent coffee, charming, if slightly oily salesperson. There was much discussion about our options - I asked about passive standard 3G timber aluclad. After a while, a large figure was mentioned. A very large figure. So large, in fact, that I actually was convinced that the salesperson was having a little joke with me. He wasn't. No further coffee was offered. We gathered our coats, emptied the complimentary biscuits into my handbag and prepared to leave shamefacedly, and preferably without admitting that we were FAR TOO POOR to afford these lovely windows. On the way out, the salesman commented off handedly and rather insincerely "Sorry we couldn't help you today. Unless you want to buy the ones in the basement, ha ha ha." Reader, I have little-to-no shame when it comes to sniffing out a bargain. I cannot be humiliated. So, I was accompanied to the basement of the showroom, whereupon I was greeted with a £100,000 wonderland of window-related (expletive deleted)-ups. Results of inaccurate measuring, bankruptcy of developers, incorrect specifying, just general inefficiency. Of absolutely (expletive deleted)-all use to anyone, of course. Apart from someone who had not fully finalised their house plans. And a salesperson who is uncommonly keen on crystallising some value from said (expletive deleted)-ups. It was a partnership written in the stars. Details of hard-nosed negotiating aside (and there was someone in the room close to tears, and it wasn't me), we came away with 15 brand new windows (including 3 large sliders), a fully biometric ex display front door with side lights, a utility door, and a large panel of glass. All pretty much passive standard, some with built in blinds, some alu-clad timber, some Alu clad UPVC. For not much money. At all. A very satisfyingly small amount of money. The architect was somewhat perturbed by this moderately unconventional approach of designing the house around already purchased windows, to say the least. For a while, I had a Quooker tap and approx £80,000 of windows as my only purchases for the house. However, he came up trumps and designed the house in such a way as you would never know that he had any design restrictions at all. The man is a quiet genius. We had cherry picked the best stuff - so all our sliders for the bedrooms are approximately (but not quite) the same size, they vary by about 30mm here and there, but they are all on different elevations of the house so you never see them right next to each other. We wanted to use one particular window in the bathroom as it had built in blinds, but it was a little too big, so we sank the bath into the floor to allow the window to have opening clearance. It looks amazing and like an intended "design feature". So, we purchased the bargain basement windows, and following our cynical, but realistic architects advice - we got a trailer and got them the hell out of that warehouse. They stayed wrapped up and palletised for approx 2 years until that fateful day in November. Now, what we should have done was quit while we were ahead, taken note of the surpassingly large number of (expletive deleted)-ups and run like the wind away from that warehouse. You will not be surprised to learn that this did not happen. We still needed our large feature window - a 5m wide, 2.7m high alu clad timber lift and slide window and matching fixed panels above. This was not cheap. Very very not cheap. But it was lovely. We decided that as we'd saved so much money with the rest of the windows, we could justify this lovely thing. We got a good, although still bloody expensive price on it, paid a 50% deposit, and were instructed to let them know when we were ready to have the window produced - as we hadn't been through building control fully yet, so didn't want to press "Go" just then. So, all well. We got on with what we needed to do, engineering, building control, life etc and gave no more thought to it. We get our building warrant. We phone up the showroom to say "yay! please make our very highly priced window!". Only, there's a disconnected tone. Odd, we think - must have misdialled. We try again, same thing. We google. Website down, emails bounce. A light sweat breaks out. The insufferable shits went bust. No one told us. It may or may not be directly related to the basement of (expletive deleted)-ups. Internorm had never heard of our order and had not received our deposit, so couldn't help. Now, thank christ that I am naturally untrusting of salespeople and INSISTED on paying £101 of the VERY LARGE deposit on a credit card. Section 75, how I love thee. We got the whole lot back. Eventually. After a lot of paperwork and phonecalls. But now we have a load of second hand windows, some with bits missing and no-one to fit them. And no-one to order our lovely slider from Help was on the way from an unexpected quarter though. Our house build is being filmed for TV, and we happened to have a filming day a couple of weeks later. Someone on the crew gave us the details of a helpful person within Internorm, who passed us on to another dealer who honoured the original price for the sliders, came up from England to fit the windows, supplied all our missing bits and were generally wonderful. So, we come to November. There are two access points to our site - one at the rear, which we can just about fit an articulated lorry up, and one at the front, on the extremely busy main street, that is cobbled and 2cm narrower than a transit with the wing mirrors folded, and only just as tall. The Internorm dealer had already made a site visit to review the access and made many sucky-teeth noises, but said "it's ok, we'll get a robot handler up from Leeds that can hold the window at 45 degrees while we drive it up." "Ooooh", we think, "A robot! Technology will save this whole scenario". The day started relatively badly when it transpired that the artic driver, instead of turning right when he should have, so he could drive straight down the street and have the windows on the correct side for unloading, had in fact, turned left and was now in the middle of fully reversing down a medieval street so long that it takes approx 8 minutes to walk from one end to the other. At 9am. Also, he was (I think) Romanian, with no English, and there were no Romanian speakers amongst the installation crew. So, when he finally arrived, after monumentally pissing off approximately 14 million local residents, the windows were on the wrong side and no room to turn. So we had to unload the rest of his lorry, stack it up on the street, taking up virtually every parking space in the place and drive the telehandler across the street, blocking all the traffic to get the window off. It is massive. Securing it on the tele handler is not a quick process. There was a lot of shouting. Also, did I mention I'm 6 months pregnant at this point? So, once unloaded, we look around eagerly for the promised technology laden robot. Looking a bit sheepish, the install crew confessed that it hadn't been available, but "don't worry, we brought something else". Great, I think! No problemo. The "something else" appeared, to my untrained eye, to be a couple of skateboards. So, we ended up with our massive window being rolled up the close on a couple of skateboards, being held at 45 degrees by a telehandler and 10 or so guys not all of whom shared a common language. To be honest, it went better than it should have done. The only hairy moment was when the tyre of the telehandler hit a drainpipe and it cracked with a noise EXACTLY like breaking glass. I was at the street end and couldn't see the window, just heard the cracking noise and a lot of a shouting. I was pretty convinced I was about to HAVE the baby. Terrifying. But, all in all ... TADAHHH! Over the next couple of days, all the windows were fitted and we were (nearly) watertight. Exciting progress.5 points

-

Ha, my inspector turned up to introduce himself, was at pains to point out he was not a planner (as they have such a bad rep around here), said it’s clay here innit, and some trees so 800mm deep should be ok.! Dig it out and give me a call, called him and he popped round and said carry on ? he then said as you have the digger on site you could dig a soakaway, I pointed out a soakaway on solid yellow clay was called a Swimming pool!,, and I suggested I piped surface water into the ditch next to it and he agreed, result!2 points

-

So, I just remembered that I actually had this blog. I'm killing time waiting for a phonecall, so, updates! Over a year later! Stuff has happened. Lots of stuff. Lots of money. Many tears. Some moments of "FFS, what?!", many moments of "HOW MUCH?" and "how the feck does this bloody shower fit together?" and a few, rare, beautiful moments of "woah, that looks awesome". The last entry ended on a lovely "woah" moment of the successful pouring of our beautiful concrete floor throughout the ground floor plan. It pissed down the next day, obviously. Then MBC went away, laden with cakes, pies and phone numbers of eligible single ladies from the area. A week later, they came back. My new job is a long commute away, and I had to work that day. On my way to the station (hideously early), I saw a truck drive past, laden with bits of house. "That's our house", I thought to myself, I just knew it. I text my husband to share the momentous culmination of our wonderful joint enterprise and was mercilessly mocked that it probably wasn't our house, as it was far too early. Ha! How I laughed when the driver called him approximately 10 minutes later to say he was stuck in the narrow road outside our site, couldn't turn the lorry sharp enough to get into the access point and was blocking every single (extremely angry) person in our medieval town from getting to work. That was a brisk drive to site for him. There were many people in hi-viz, a lot of shouting and gesturing, a lot of sharp intakes of breath, a few calls to the police to track down owners of badly parked cars and a huge amount of car horn tooting. Oh, and a LOT of apologising. But, the truck made it into the site. Just. To the never-ending delight of my small son, there was also an absolutely ENORMOUS crane. I was later informed this in fact this is an embarrassingly tiny crane, the smallest one that you can possibly hire and really hardly worth the bother. I feel like the driver may have had some adequacy issues with his crane size. So, whilst I was in a meeting, they just wacked the house together. At lunchtime, I called for a catchup FaceTime and the ground floor was pretty much finished! I mean, WHAT? The speed was insane. By the time I got to site later that evening (about 7.30pm), all the ground floor panels and internal partitions were in. My husband and I just walked around rooms, giggling insanely to ourselves at the ridiculousness of the whole thing. The next day, second storey on. Unbelievable. By the end of the week (in fact, I don't even think it was full week) the whole frame was up. We were a little shellshocked, to be honest. There was a lot of head scratching about how to run the falls on the roof. This had been discussed and obviously designed in, but our roofer had some input whilst MBC were on site. They were very good and spent a lot of time working out the best way to make it work for what we needed (singly ply membrane roof, adequate falls, hidden box gutters) and did a lot of extra work in conjunction with the other trades. Our roofer also risked the wrath of his wife by coming to a site meeting on a saturday and was subsequently late for a family BBQ oops. Oddly, once the frame was up and see could feel the room sizes in 3D, they suddenly felt absolutely massive again. Such a convincing illusion - it's very hard to visualise 3D space from a 2D footprint. Next up? The joys of roofing and zinc cladding And winter2 points

-

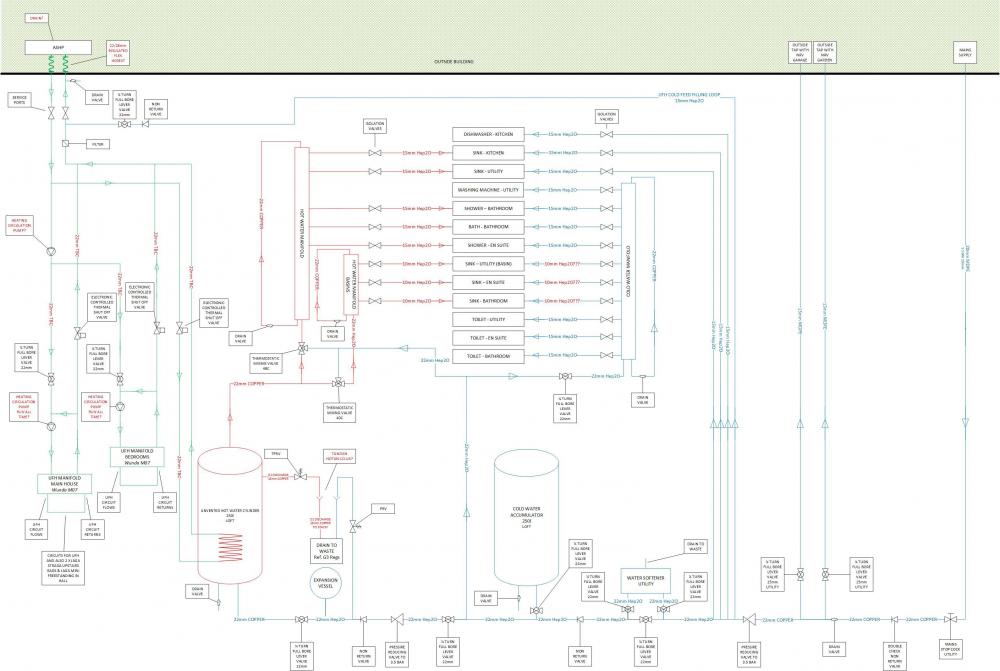

Hi all So things move glacially along here. Perhaps we'll actually get the ground works started in July but I am not holding my breath as it was (theoretically) supposed to have been December... But whilst we wait, I've been busying myself with plumbing design, trying to work out what the best option is here and I've come up with the attached so far: I'm quite sure there are numerous things I need to add/remove/correct in it but what I wanted to try and get to was a design that made sense, so I can get a plumber to get me up to AHSP/hot and cold manifold level, so I can do the Hep2O runs to each room as needed. I like @JSHarris idea of having a continually circulating UFH pump but I'm going to have two pumps and linked to this I am also not sure whether to do a single zone per manifold or split them up into zones per room. I think continuous circulation is only sensible if you have a single zone. Again, conscious of following the KISS principal and how far I seem to be deviating from it on this design so far...! My plans for the control system is Loxone but I will need to ensure I have the correct inputs into that e.g. use Loxone switches per room as thermostats to request heating (again makes more sense to have multiple zones then). Or do I just nominate two Loxone switches, one for each manifold and get that to run as required? The house isn't up to passive levels mainly due to the stretched out shape of it but it isn't too far off with 300mm EPS100 on top of beam and block floor and 300mm warmcell filled timber frame walls, 350mm warmcell filled roof. Anyone have any thoughts/corrections on the above? I am also happy to upload the Visio that sits behind this if that is of use to anyone?1 point

-

1 point

-

1 point

-

How many channels do you need ..? If it’s 3 just get a new single clock that does the lot.1 point

-

1 point

-

1 point

-

We had one done recently but it also included a drainage design for a soak away and treatment plant and it was around £1k1 point

-

1 point

-

Exactly what I’m sorting currently ..! But will fully fill them and then put mass concrete around the tops and sides before they are covered over. Can’t see why the steel framed and reinforced ones wouldn’t work.1 point

-

Welcome @Da-Dad. With this sort of query it's well worth saying which country you're in. Building and permitted-development regulations for Scotland and Northern Ireland are very different from those in England and Wales and E&W differ from each other a bit.1 point

-

If it is of any help We had a soil survey and used Geo-smart Which cost £500 two years ago But was significantly lower than other quotes As above Clay and lots of trees mine was in the planning conditions So no choice1 point

-

Oh is that all, I was thinking you where making a new start with a new house using wealthy jacks money ?????1 point

-

Hi Tim, We have clad about 1/2 of the external walls with vertical standing seem Tata Colorcoat Urban and did not cut off the external ties. We are going to use Trespa Pura on the remaining 1/2 and don't think we will bother to cut off the ties. We took the view that, particularly with the internal ties cut off, the external ties will make no appreciable impact on thermal bridging and will not interfere with our battens.1 point

-

Hi, we cut off all the internal metal ties on our Velox build using an angle grinder. We then used a face grinder to smooth the corner joints between Velox panels and glued and screwed plasterboard and skimmed. The result is no void between the face of the Velox and the plasterboard and a beautifully smooth plaster surface. Insofar as the metal ties act as a thermal bridge any impact of that has also been minimised.1 point

-

I think I would have a scoping conversation to ask him just what it is that he needs to know, and what it relates to. Examples could be soil type, beating capacity, percolation, contamination, underground gas from the landfill next door etc. You could explain the query as being so that you can properly brief a potential surveyor. That would I think help and is a genuine reason - then come back here and see if there are any good and effective ways to do it . Potentially you could do a test yourself, or modify your design etc. Or indeed ... you may require a full Condition Report. Ferdinand1 point

-

I concur with @Temp, subject to the caveat that if you are in a protected area ... eg Conservation Area, National Park etc, or what is called an "Article 4" area, there may be specific restrictions that require PP. You could ask your Council that. In this case, I would be fairly relaxed about talking to the Council. Even if they operate a "pay to talk to us about a particular case" service, you may be able to smuggle some individual questions into the 'protected area' request. If you are looking for reassurance, you could ask Planning Aid - a service run by the RTPI. But you will need to frame your questions as policy queries, rather than related to your particular case. eg Would Planning Permission be required to change a window to a door on the front of my house? https://www.rtpi.org.uk/planning-aid/ Ferdinand1 point

-

1 point

-

1 point

-

1 point

-

It’s the one I use and as long as you don’t try using 32mm wood augers in the drill it’s fine ...! I’d also grab a couple of decent impact bits as the driver has a tendency to shear off cheap screwdriver bits.1 point

-

1 point

-

1 point

-

I don't know, but adding an EPC requirement to claim the FIT was the most daft thing you could ever imagine. It added a layer of expense and bureaucracy to the process, denied some people who would well benefit for it from having solar PV, and in the case of a new build, meant you could not sign up for the FIT until the house was virtually complete and had a lodged EPC submitted (this is what locked me out because of our slow build) If "they" were really serious about increasing renewable energy take up, they should be removing obstacles, not creating more.1 point

-

Very true, @joe90, we were originally going to install a GSHP (it's on our planning consent) but switched to an ASHP when I looked at the whole life cost, which was astronomical when compared with an ASHP. The cost difference was massive, around £2k for the ASHP versus around £8k for the GSHP (both installed cost). The tiny difference in theoretical efficiency (which almost certainly wouldn't have been real in practice, due to collector loop pump running cost over the year) would never have come close to making up for the massive difference in initial cost, let alone the ongoing servicing cost that a GSHP invariably incurs. We could easily fit three replacement ASHPs over the next 30 years or so and still come out on top, although I don't envisage having to do this, as the ASHP just does it's stuff and works, needing no attention other than cleaning cobwebs out of the grill every year or so..1 point

-

If you read threads on here it appears ASHP,s are a better bet than GSHP,s. I have the room and machines to instal my own GSHP but went with an ASHP (self instal) and it was soooo much easier. I am sure others will chip in soon.1 point

-

We are about to install GS in about 2 months time. My husband is reluctant to dig the trenches and install the pipework himself even though we have the diggers etc., I know you have to be careful when you backfill the pipe in case there are any sharp stones and so sand is put over the pipes. spacing is important too. I did see one bloke who put it in himself somewhere on line and he had trouble with frost, I think he put them too close together and it didn't work. We will get back quite a bit of the money over 7 years from the government, plus it won't cost us £3000.00 a year in oil costs, the new house will be insulated up to the max. Personally I'm all for DIY but in this case not...yes it's expensive, putting in the UFH pipe looks a doddle, so maybe we will attempt that and also the pipework for the MVHR. You also get conflicting advice as to what size boiler, we have been told 8kw/10kw/12/kw and 18kw.....goodness it's a mindfield out there. Gone for the 12kw with an option to switch to a pool if we ever get around to it. 388sq m house but again loads of insulation, fingers crossed it works! Going for straight pipes not slinkies, better we think.1 point

-

Hi Guys and Gals just a quick note here to say that I am builder and have been building with Velox now for nearly 6 Years. I have used it on many new build projects, any questions please don't hesitate to ask or email me (email address removed).1 point

-

We have our building warrant, FINALLY. I have a new job. The small one has started school. MBC are here. The glorious day of the 29th August arrived, and so did the vans, carrying Brendan's crew. The sun was shining, tonnes of sand were delivered and painstakingly spread out. It's amazing how much time the MBC boys took to make sure everything was exactly level before carrying on, I found the level of care that was taken very reassuring, and of course Sean was on hand with a terrible joke whenever required. Sometimes, also when not required. Our months of waiting for the building warrant were not completely unproductive as we now have a pimped out site office, including a cast-off white leather sofa (practical colour choice for a building site), high speed wifi, a gopro to capture the build, a desk (with executive chair), first aid point, filing cabinet, H&S kit storage, many many many copies of all the plans, and most importantly of all, a tea/coffee point with fully stocked biscuit drawer. "Luxury!", as the MBC boys proclaimed. Drainage channels were hand dug the next day - a nervewracking time with measuring and re-measuring. The brand-new-just-out-of-the-box Bosch laser measurer was ceremonially launched from the top of the rubble pile by the small one, landing with an ominous crunching noise. "That will hardly have affected the accuracy at all", we thought. Still, at least we know who to blame if all the drains are in the wrong place. Over the months/years we have had various thoughts about where the kitchen island should go, but now we come to decision time. The drains and conduit must go in, today, and they are non-changeable. The island will be all our workspace (the rest is floor to ceiling units) so needs an electrical feed and hot/cold water as well as a drain for the sink, waste disposal and dishwasher. So, instead of making a decision that will inevitably be wrong, we decide to put in the two final options. 1: The architect's recommended positioning that we think is too far away from the sunny spot 2: Our preferred option, closer to the large sliding doors We try and position the pop ups in such a way that the unused one will be under a sofa or table and hopefully not too noticeable. It is almost guaranteed that the architect will be right in the end, as he always is, but it's a struggle to commit at such an early stage. The unused one will be cut off, and topped with an official plaque set into the floor, engraved with "always listen to the architect". We're justifying it as a feature. The next day was the delivery of the EPS on a very large lorry. Our site is right in the middle of town and the access is surrounded by garages and illicit parking. This time of year, there are no students around, so although the lorry is a tight fit, there are no hastily abandoned cars in the way. Next month though.... The EPS ring beam is fitted and the footprint of the house becomes rapidly visible. Although pre-warned by our architect that the space would look small with no walls up, we are both thoroughly freaked out and convinced that the rooms are all too small. There is measuring, re-measuring. comparing against plans... but nothing we can do. Thankfully, on our way back to the rented place, we drive past a new build estate that is also just at foundation level. We slowly realise that the footprint for those homes contains a 3-bedroom house AND garage. Ours is generously sized in comparison, to say the least. The next few days are taken up with making steel reinforcing cages, laying UFH pipe and checking the drainage (again). My time is spent at work, obsessively checking the weather forecast. We have, against all sensible and knowledgeable advice, decided to attempt a smooth concrete finished slab. No tiles, carpet, wood, screed, diamond polish … nothing. Trying to explain this concept to the many people involved has not been easy. Reactions have varied between trying to convince us that diamond polishing to a mirror finish is hideously expensive (we don’t want a mirror finish – there are deliberately no shiny surfaces in the whole house, as I am obsessed with matt finish and hate polishing) to “but it’ll look like a B&Q warehouse!” (my dad). MBC are also not keen AT ALL, due to a problem they had with a previous job where the finish didn’t work and all the window/door thresholds had to be redone to allow to an additional screed to go on top. Showing people a photo of a farm shed floor that had been done by a friend by just powerfloating the surface for longer than normal did not help. The conversation went along the lines of the following: “This is the finish we’d ideally like, it’s a farm shed.” “…..? A farm shed? For cows?” “Yes” “But, polished to expose the aggregate? What kind of aggregate do you want?”. “No, no aggregate. Not polished. Just powerfloated.” “But it won’t be shiny, and that needs specialist tools.” “We don’t want it to be shiny. Just smooth. Like the IKEA warehouse. Or B&Q”. “………….really?” “Yes” “hmmmm.” (sucky teeth noises follow..) The process was somewhat wearing, but we rode confidently over everyone’s objections and doubts anyway and carried on. One thing we did know (from our farm shed creating friend) was that rain during or shortly after the pour would be bad. Very bad. It’s September, in Scotland. Could have been worse. Two week ahead forecasts are notoriously inaccurate. Right? Right? I had seven different weather apps on my phone at one point, all saying the same. Thunderstorms. A 14 day forecast went to a 10 day one, then a 7 day one .. rain all week, particularly heavy on the day of the pour. Just to put the cherry on top. The day before we poured the floor, it tipped down all day. Not 5 minutes passed without freezing rain. The next day, I left for work, having deleted all the weather apps and given up all hope of a polished floor. At the site – not a cloud in the sky. Brilliant blue skies, sunshine, tonnes too much concrete. The MBC crew powerfloated the slab for much longer than they normally would, and by the time I saw it at 8pm that night, it was as smooth as we could have wished for, and a beautiful mottled grey. If I wasn’t a rabid atheist, I would have sworn I heard a troop of celestial trumpets playing. So, a perfect end to a brilliant first stage of the build.1 point