Leaderboard

Popular Content

Showing content with the highest reputation on 07/26/18 in all areas

-

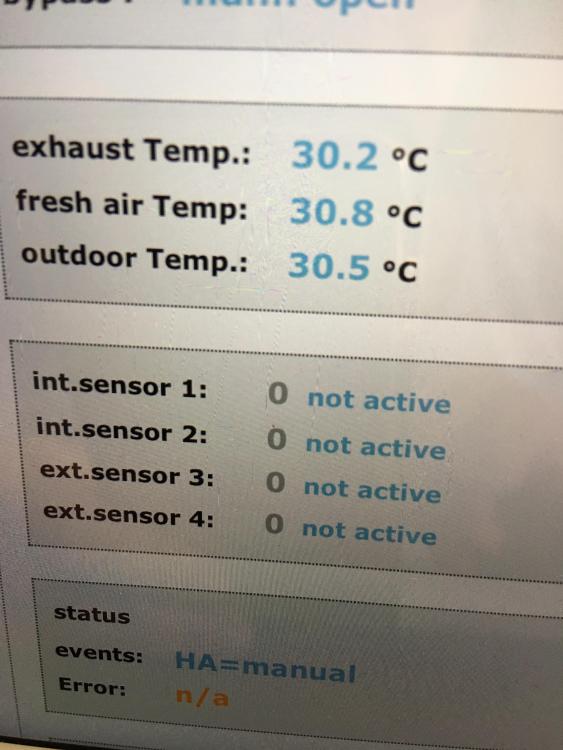

Just re-reading this and it isn't clear from my last couple of posts that I put in the code to make cooling mode accessible on our ASHP last week. I may have mentioned it on another thread. Having now had another few days with the UFC on during this hot weather, I'm absolutely certain it's having a significant effect on the temperature upstairs, despite all the cooling being downstairs. I reckon downstairs has been sitting at a very comfortable 20-21 deg C for the last few days (ASHP outputting a temperature of 16 deg C during the day - I'm just manually turning it on for most of the day while the sun is up so the PV is powering it). The temperature upstairs at the end of the day has fallen from, I guess, 26-27 deg C a few days ago to maybe 22-23 deg C last night, despite how hot it's been. Doesn't sound like much, but trying to sleep in 22 deg C compared to 26 deg C is a very different experience. In any event, I'm sold on underfloor cooling as a solution for at least knocking the edges off extreme overheating once all the passive design features have been optimised. I think that if we just get external blinds installed on our bedroom windows and install the remote blind we have sitting in the garage for our rooflight, we'll have the problem completely licked for next year.4 points

-

You are sort of correct up to a point. When starting a self build everyone has their wish list of things they would really want in their forever home. But once the calculator comes out and you start going through different quotes for the build you soon realise that unless you have a Grand designs type budget then tough decisions have to be made. Anyone that puts themselves through a self build and I mean being hands on doing some of the work or being a project manger and running the build will have worked many many hundreds of hrs and had many a difficult day to deal with. To go through all that and end up the min standard of a build would be madness in my view. You would be better off just buying a new build on some site and the most you have to worry about is the colour of the kitchen door and tiles for the shower.4 points

-

The windows were delivered last Friday. They arrived in three pallets, two of them were lifted off by the lorry's tail lift and a pallet truck. The larger pallet had to have the windows taken off manually. Unfortunately, I don't have any pictures of the offloading as it was all hands on deck. I was however involved in the lifting of the windows, on average the windows were about 75kgs each, but the french doors were double at 150kgs. Here are some of the exterior. And the interior. Facias and soffits have also been fitted around the house. The next job will be fitting the Siberian larch cladding and followed by the slates next month.3 points

-

Why should they? That may be your choice but it’s not the choice of many who are building. People build the house they want. Why? Because they can, and it’s one of the biggest motivators for a self build. Not everyone wants to build the minimum viable. There are people here who would far rather spend a bit longer in a caravan to get the house they want than go for ‘minimum viable’ and live with regret. And the people who concentrate on the detail that is important to them end up with the house they want, not the house someone else thinks they should have built.3 points

-

3 points

-

You may be onto something about the madness of self builders. May be that self building attracts people of a masochistic nature - I read all the horror stories on here such as your wall falling down and some of the members here have had some severe challenges to overcome and rather than put me off it just makes me more keen to crack on with my own build! Walls collapsing, 'level' floors not being level, extortionate quotes for an electric supply.....just puzzles to be solved. The great thing about this forum is that although in body you are doing the work yourself, in mind there is a collective will to aid/assist in these challenges. Problem solving without the collective wisdom/experience here would be bloody hard work. I'm slowly working my way through all the posts....reading about steels and rsj' s at the minute - I've learnt a lot! Read a lot of your posts Ian and it has been interesting reading your progress from when the forum started so long with all the others.2 points

-

Thats a very broad - and probably incorrect - statement ..! A lot of self builders want to pursue building what they want in a time period that meets cash flow and delivers the value they want. If you think bells and whistles is the sole domain of the self builder, you’ve not been in many show homes recently for the volume house builders. Have a read through the blogs and posts of the likes of @ProDave @Crofter @Cpd @PeterStarck and others - these are classic examples of self builders who have delivered value for themselves and they are far from high tech bells and whistles builds. They are what many would love to aspire to - beautifully delivered houses that meet their requirements.2 points

-

I just wanted to include a brief post explaining from a self-builder perspective why we have decided not to use an Unvented Cylinder (UVC), Thermal Store (TS) or combi-boiler for our domestic hot water (DHW) in our new build. Instead we are using 2 × SunAmp PV heat batteries heated by E7 tariff. So why? We decided that we don't need gas to be installed avoiding the Gas connection charges, per day supply charge and the maintenance costs on gas appliances. Big saving here. We don't have the room for a TS and we've heard too many horror stories about the problems of heat losses in a passive-house class new-build like ours, so no TS. We didn't want to get into all of the regulatory crap around installing and annual maintenance contracts for an UVC. So strike this one as well. So what is the alternative? The SunAmp is a thermal battery with an in-built heat exchanger (a bit like a combi boiler) which can store ~5kWh of heat for delivery in water typically at 50-65°C. Here is a simplified schematic of the store. (Note that I've left off all of the essential safety features such as the expansion vessel pressure relief and overflows to simplify this down to the functional essentials.) The guts of the device are a couple of Phase Change Material (PCM) cells which act as the thermal store. It in essence it works in one of two modes: Discharge Heating, where the CW supply flows through the two PCM cells and is heated to between 55-65°C and then blended with a CW mix in a TMV down to a preset output temperature. Recharge. When fed with an external electricity supply (typically PV or E7 off-peak tariff power), water is circulated internally through the cells and a 2.8kW heater to bring them up to an internally preset maximum temperature. So the SunAmps can only be charged by electricity, and there is no alternative form of heat supply. The form-factor is very small – two SunAmps side-by-side take up (d × w × h) 530 × 600 × 740 mm. The rectangular packaging also facilitates the use of internal vacuum pack insulation panels so the total standing heat loss is ~ 1kWh / day which is a lot less than a typical TS. The exact choice of PCM is specific to SunAmp, but the linked Wikipedia article lists the common ones with a phase change at around this 55-65°C range. However in terms of the physics of how this all works, it is easier to describe another common PCM that we are all familiar with and which has its phase change at 0°C: water. There are three material properties that you need to consider when looking at how a PCM works: the specific heats of the solid and liquid phases, that is how much heat you need to supply to heat 1 kg of water by 1°C and the latent heat of fusion that is how much you need to convert 1 kg of water at 0°C to ice at 0°C. I could give you the figures but a good way to think about is that you need the same amount of heat: To heat ice at -158°C to ice at 0°C To melt ice at 0°C to water at 0°C To heat water at 0°C to water at 80°C. OK these ratios and the fusion temperature differ for different PCMs (as well other properties which reflect the long term stability of the using it in cells, etc.), but that is all the proprietary stuff (discussed in the detailed below from Andrew Bissell). Even so, the bottom line is simple: the systemic heat losses are far less than alternative solutions, and Weight-for weight you can store roughly four times as much heat in a SunAmp PV store as a conventional DHW cylinder. As to why we have chosen the 2 × SunAmp PV approach, there were 2 main drivers for us: 5kWh isn't enough to meet our typical daily use, and 10kWh is so we will be able to charge our stores overnight at E7 rate and only need daytime top-up in exceptional circumstances. The pressure drop across the store in Bar is roughly 0.0142×f1.81 where f is the flow rate in ltr/min, and if you crank the numbers one store doesn't give us enough flow rate. Even so if we look at our planned use (I'll go into the figures in a later blog post), our household of 3 people has had an average use of 280 ltr/day averaged over the last 6 years. Most of this is hot water -- say 80% or at an average lift of 25°C, this amounts to 5,500kgK = 6.4kWh/day or 7.4 kWh/day allowing for heat loses. This will cost us £194 p.a. at my current electricity tariff for my household's DHW. Will I really realise the payback from additionally investing in gas or ASHP based DHW systems? I think not. PS. Slightly amended wording to reflect the earlier comment of Andrew Bissell quoted below.1 point

-

We keep having rain forecast, but it never arrives. Hopefully the weekend rain will arrive and drown plenty of biting insects, they've literally been making a meal of me this last week. Lizzie - Waitrose have lovely long chiller cabinet aisles and freezers, you could take up lurking in those although I suspect plenty of others are doing the same at the moment!1 point

-

That looks to have removed your permitted development rights. 8mx6m is building control territory and you would need to show it was moveable to class as a caravan anyway. If you have permission for a garage of this size why not go back for a variation on this ..?? Or basically build a double garage with fake doors ..?? Barn doors with windows behind would make it more secure anyway.1 point

-

1 point

-

? We're all friggin mad mate, mad. How many people do you hear gushing about wanting to self build when they hear you are self building? And then how many actually do so? That's right: none. They are the sensible ones.1 point

-

Remember I have 8 fingers, of which 5 and a half work as advertised.....1 point

-

Nice one newhome.. pinned on so I yanked them off/ prob need to replace.. if not the whole units I'll make that decision later.1 point

-

+1. This thread seems to have gone a right tangent now! FWIW I despise concepts such as Agile - not the working practices behind, more the fact that society seems obsessed with assigning names/brands to things that people have been doing for thousands of years. Someone looks at a bunch of good working practices, flowers it up, gives it and name and then sells it as a whole new concept. Pretty sure you could look at how the Romans were building roads etc. back in the day and find 'examples' or where the concepts within Agile were being applied. Introducing/sharing good workings practices is always a good thing, but why do we need to pretend these are new concepts. As for self builders wanting all the bells and whistles - seems only natural to me. However it would seem to me that self builders are a pragmatic bunch - there's a list of wants and a list of must haves. The list of wants always get pruned upon first contact with budget realities, but the list of must haves seems uncannily similar, airtightness and thermal performance are two common themes throughout this forum. Self builders are a hard working bunch to have got to the point where they can: a. Afford to do a self build. b. Have the determination to actually do so. Demographics is an interesting one. I get the impression it's generally speaking a more mature bunch on here and usually with a higher than average education level. Myself, I'm just a lowly soldier and reasonably young. I do have an engineering degree - unfortunately I've forgotten more than I remember now, a pity because I was a dab hand at CAD/Solidworks etc. back then.....feel positively thick now when I see some of the kids maths homework!!1 point

-

I work in an agile environment too! Having moved over from a traditional waterfall company, the difference in attitude alone is astonishing. I do try to apply some of the principles in my build - mostly regular stand-up type meetings with all contributors, identification of targets, sharing of progress. I do think IT attracts a different kind of person - often those that embrace change and challenge. Perhaps that's a generalisation too far, but it's been my experience so far.1 point

-

1 point

-

I think you don't get it. You can dress methods up with meaningless words and acronyms, but, as usual, it comes down to communication between the person who wants the work done and the person doing it.1 point

-

DO make sure that you use the correct nails fir joist hangers, I see so many people just use long clout nails, NO, use proper twist nails, that’s what they are made for.https://www.screwfix.com/p/easyfix-square-twist-nails-sheradised-3-75-x-30mm-1kg-pack/12788 i like “fold over the top” type hangers, feels stronger IMO. and they are thin so should not be a problem with flooring.1 point

-

1 point

-

1 point

-

“A board is thick and rigid. It is made of wood.” Arthur C Clarke. Ish. Context: The Book A Fall of Moondust said by the Chief Engineer of the Moonbase after he has been audited by the Accounting Board.1 point

-

1 point

-

Please can whomever decides to try agile with a build invite me to their first sprint kick off ... I’ll even pay my own travel as to watch a brickie and a labourer with a set of sprint cards is going to be worth every penny ..!! ?1 point

-

Just to close this off, by chance I was talking to a neighbour who happened to have a 4ft x 4ft home made CNC router in his workshop. So. rather than take up @MikeSharp01s kind offer, I decided to have a go myself, under the guidance of my neighbour, who clearly had a fair bit of experience of driving the software. I laminated up some of our left-over oak skirting boards, that were 120mm x 20mm, to make a double thickness board, with the joins offset and the grain as best matched as I could make it on the joins. I ran my router down each pair of boards to be edge glued just to make sure I got a tight joint. When epoxied together I ended up with a board about 40mm thick, 500mm long and 240mm high. We started off by playing around with the mayfly design to make it easier to route out - took a couple of ours of fiddling to simplify it and make it looks reasonable. Next, we took a thin skim of both side of the sign (it's double sided) to make sure it was dead flat. The routing out of the text and mayfly was pretty simple after that, we ran a test on a bit of MDF, which looked OK, then went for it with the oak. It came out pretty well, and I stained the oak with a dark oak wood stain, then sanded the flat surfaces to remove most of the stain, leaving the routed out bits much darker. Two coats of clear exterior finish and it looks like this, ready to go up on the gallows post I managed to get concreted in on Monday:1 point

-

Sales rep recommended larger 430x due to a tight corner on a slope, should be fitted in a couple of weeks - if I can get enough grass to grow by then1 point

-

I used to use small metal brackets that had slots in them rather than holes, stainless pan head screws in the middle of the slot and not too tight. All oak worktops I have fitted come with instructions on fitting and treatment.1 point

-

I usually drill a 6mm hole and put a 4mm stainless pan head in to hold it down so it can move sideways but not upwards1 point

-

I assume you have the instructions for fitting oak worktops as you also need a couple of coats of oil on all raw edges and underneath before fitting and fit a vapour barrier above appliances like dishwasher and washing machines .The screws holding the worktop to the units also need to be able to move to stop splitting.1 point

-

I can't think about flooring at all - too busy concentrating on not scratching the mozzy bites running up my shin:(0 points

-

Same here. No rain even when it threatens. Really need a huge downpour now. Never thought I’d say that. Loads of annoying flies around too. I leave the back door open for a bit and there are damn flies everywhere.0 points

-

0 points

-

Working on different sites here in NI I in the past was always an adventure. Depending on what side of the Street in Belfast you where building on had a direct correlation to what 3 letter words where tattooed on the "community representative" who would be working on site with you. And when I say working I mean arrive on site every Fri to just lift the brown envelope and ask you was everything ok and no locals messing with your cars.0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)