Leaderboard

Popular Content

Showing content with the highest reputation on 11/23/17 in all areas

-

Finally!! At last there seems to be light at the end of the renovation tunnel. We had planned to have the house finished and up for sale by spring 2017 but that did not happen. Then the deadline was summer but no such luck , everything seems to take twice as long to do than planned. But at last we are nearing the finish line. The kitchen arrived at the end of October from Howdens and I thought we'd have it all fitted within a couple of weeks. Yet here we are nearing the end of November and its still not finished. Its half in but we cannot fit the breakfast bar and units till the flooring is done. We decided to keep the kitchen tiles for two reasons. A - they arent too bad - slate tiles which do clean up quite well and B - I tried taking one up and it was a nightmare. They have been concreted in, with underfloor wiring. So I agreed that we would keep them. However, that meant there were a couple of places where our new units did not match the position of the old ones and we needed some extra tiles to fill in. I found some similar tiles at Topps Tiles which should be fine. Apparently the slate tile is quite 'on trend' so it just shows that old things eventually become trendy and are worth keeping. ( I wonder if it applies to the OH??) This is the old kitchen before we took out the wall on the right hand side. That was half of the kitchen with a large range cooker taking up the other side. The breakfast bar is going where the old house wall was, which was taken out and replaced with rsj's. Once the rest of the wall was removed, we were left with a large hole as well as a lump of concrete. We worked out where the units were going and using an angle grinder, we took out the excess concrete so I could add the tiles. This was a really dusty job which the OH was not happy about doing but after covering everything up with sheets, as he cut, I hoovered up as much dust as I could and it wasnt as bad as we thought. But then when the units were placed in position, we'd got it wrong and we had to cut some more out! The OH was not impressed but in fact it only took half an hour and I had the area all cleaned up and ready for tiling. Unfortunatly that was when I came down with the flu bug which has meant no work for nearly a week, and then we are away for a few days at the weekend so its into another week before I can get the tiling done. Thats the way its been and why the renvation is taking much longer than planned. But never mind! We are getting there slowly. So here is the kitchen to date. The new sink and tap has been plumbed in and the oven (Ikea) and induction hub (Howdens) are in and working. Two sections of the Rustic Oak worktop are in place but now he is waiting for me to get back to work and get the additional tiles in place so he can add the breakfast bar units and top. The single unit on the right faces into the middle room and next to it will be a 700mm wall unit under the worktop and accessed from the main kitchen side. These units are where the wall was and it makes the kitchen much bigger. The compromise is that the breakfast bar takes space from the middle room but we think the kitchen was the important part and it does give much more storage than it ever had. The OH has been quite impressed by the Howdens units. The quality and fit have been very good and there have been some improvements made since the last kitchen we bought, ten years ago. Okay, it is not a top quality kitchen but we are very happy with it. Little things are much better. For example, the small bits of metal that support the shelves now have a little sticky up bit which locks the shelf in place so it does not slide out. And the legs were much better to fit and adjust than the old ones. The only issue occurred when he went to fit the legs onto the drawer unit (far left) and realised that the base had been put on upside down so the holes were actually inside the carcass. I rang the lcoal store and explained the problem but they did not seem to believe me (a mere woman - what would I know!!) and decided to send out a sales rep to see what the problem was. He turned up within the hour and was very good in arranging a replacement the following day once he agreed withour diagnosis. And we got to keep the old one as it was of no use to them - it would be impossible to turn the base round without damaging the unit. So all we need now are some drawer fronts and we have another drawer unit for free. In the rest of the house, the carpets and doors have been fitted to the bedrooms and stairs. The rest of the house has been plastered and I have been busy getting the garden sorted. We had pushed the garden back in front of the house to give ample room for sitting but I wanted to create a proper wall and border (I am a gardener after all). So I installed concrete foundations, then a twin wall using concrete blocks at the back and reclaimed bricks from the house. It took a lot of work but I am very pleased with the result. I did think that as the bricks were all odd sorts and colours we may have to paint the wall but it looks brilliant as it is. And we got the concrete blocks from a skip in BIcester so the only materials were the sand, cement and the coping stones for the top. I have used driveway pavers for the lawn edge and have now planted up the border. The only job now is to level the lawn and re seed where necessary. By the time we come to sell - probably in January or February now, it should all have settled in and the bulbs I have planted will be coming up - snowdrops and Narcissis. So what is left to do - finish the kitchen, clean and tile the kitchen floor, lots of odds and ends with CT1 and Filler, much painting, finish the coving in the lounge and then lay the bamboo flooring. Not much at all......1 point

-

My husband always says you can tell who is in the process of building their own house. They are the ones at the self build shows sitting on the floor outside the cafeteria with a packed lunch & flask because they don't have any money left. Tee hee!1 point

-

@johny_99 - to get condensing you only need to keep the return (to boiler) below 56/57°C, the flow can be higher. Any reasonable amount of condensing will get 10-15% more heat from the same amount of gas. Depending on the design of the system you could get a flow temp of 65°C and still be deeply condensing. I would aim for a return around 50°C. A conventional radiator at 60°C will give out about 40% more heat than at 50°C.1 point

-

I appreciate Sapele is too dark for what you are after, but I did say I'd get a picture of the porch ceiling. This is also a better representation of the actual colour. The ceiling is done with alternate narrow (94mm) and wide (144mm) boards, bevel edged and butt-jointed. The wall cladding is the same boards but board-on-board. It was the spark's idea to recess the spots into the board, which isn't really noticeable in the pic but is a really nice effect.1 point

-

Plus if you stick with LPG then no need to pay towards the radiator alterations. Work out what that would have cost and see how much gas that would pay for .1 point

-

Heat pump sales people are very fond of ignoring the laws of physics, sadly, not helped by the official test conditions being related to temperature only, not humidity, and it's humidity that REALLY hits performance hard. The specs for our ASHP show that it has a high COP when delivery a flow temperature of 50 deg C, but read the small print and you find that was done in dry air conditions and the impact of defrost cycling was ignored. Realistically, I've found out, by trial and error, that keeping the flow temperature down around 40 deg C means the heat pump never needs to defrost, at least in our installation, and always seems to run at a COP above 3, sometimes over 4. As Dave says, an efficient condensing boiler may well be a better option for you, cheaper capital outlay and reduced running costs over an older non-condensing, or only partially condensing, boiler. Also, a condensing boiler run at 50 deg C will be very efficient, they stop condensing at around 56 deg C usually, so lowering the flow temperature just that little bit can make a very significant improvement to performance (there's a big efficiency boost as soon as the boiler is running in fully condensing mode).1 point

-

To me the saving sounds too small for the capital outlay. Might a new more eficcient condensing boiler make more sense?1 point

-

The first point is that 50 deg C from an ASHP is going to hit the COP and take it well below 3, probably down below 2 or even below 1 on a damp, cool day. The COP will vary a great deal, depending mainly on two factors, the flow temperature being demanded and the relative humidity outside. Outside air temperature has a relatively small effect. The COP when an ASHP is run at a high flow temperature, like 50 deg C, will be dominated by icing and defrost cycles, something that do not feature in the official COP figures. On a day when the temperature is down around 4 to 6 deg C and the air contains a lot of water vapour (cold and foggy/misty days, for example) the ASHP will probably have to defrost two or three times an hour, for around 10 minutes each time. Every time it defrosts it runs in reverse, taking heat out of the house to warm up the heat exchanger to melt the ice that's formed. Clearly there is a negative COP during defrost cycles, plus a loss of operating time, which further reduces the net COP. The best solution at the moment if you already have an LPG installation, is to look at using a hybrid heat pump. These work by running all the heating using the heat pump, with a high COP because the heating flow temperature can be reduced right down, as long as you have UFH or over-sized radiators. The ASHP will easily run at a COP of over 3 all the time when run like this. When you need hot water, a hybrid ASHP will take some of the preheated water (normally at around 35 to 40 deg C) and instantly boost it to 50 to 55 deg C to use for showers, baths, etc. This dramatically reduces the gas consumption, as LPG is inly being used on demand, when hot water is needed. It also means that the ASHP never needs to try and deliver a high flow temperature so doesn't ice up and need to defrost. Daikin are probably the best known hybrids, with the Altherma range, but there are others. Finally, the COP divided into the unit electricity price does give you the running cost per kWh. In your case, with a COP of 3 and a unit price of 13.3p, you would be paying around 4.43p per kWh for heat from the ASHP.1 point

-

We have a ground floor utility room with all the water, electricity and ventilation equipment in it. Next to the utility room we have a wet room, the reason behind that arrangement was that if there were a flood, in theory, the water could be directed into the shower drain.1 point

-

1 point

-

I'd find new heating installers as theyre causing you unnecessary worry and should have asked different questions like • what spacings • what pipe • DO they fit any valves etc and what type ....instead of just assuming the worst . Theyre just being dicks, so stick with MBC and watch how guys who do this daily get things done. . As abve, you choose the above ground stuff, and MBC are going to use pex so let them carry on. ?1 point

-

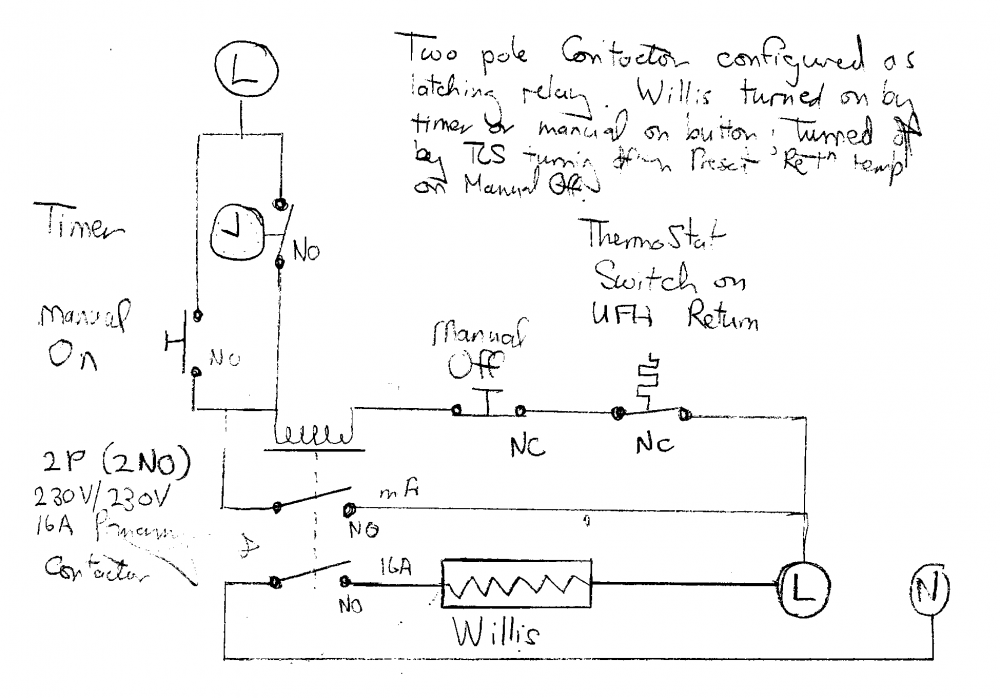

I do think that we are converging in our thinking. If you go back a year or 18 months, you (Jeremy) and I were having a debate about whether or not a buffer tank and what I would call micro blending is necessary. Is having complex sensing in the slab necessary? I've reach my own conclusions in 3 three broad steps: Researching your and other's experiences and designs and looking at them critically. This lead me to the tentative assertion that a buffer tank isn't really necessary, nor is a power limited control necessary. You can just treat the slab as a 17 tonne storage heater which you warm up a few degrees overnight. I then did some reasonably detailed modelling of the time varying dynamic of the slab, and this was enough in my mind to confirm these assertions, but modelling is modelling and also needs to be validated by real-world data. Hence my decision to add reasonably extensive instrumentation to see if my heat chunk approach where I essentially use my slab as a storage heater behaves as I modelled it. In a nutshell it does. It has always been my intent, as documents on eBuild and here, to run my system experimentally for the first year with extensive instrumentation to characterise its performance, and then to implement a final "production" control regime based on this experience. But by doing this process, my final system won't be an act of faith, but an evidence-based and informed implementation. Other's can copy the end-design if they want and skip 1-3, because someone else has done it. In my case I can happily treat my slab as a storage heater. I just have to be a little careful to put the right amount of top-up heat in each night. In terms of the relay version, I think that it would look something like this: The alternative would be drive all of this logic at 24V DC with low voltage switches and a 2P/NO relay and use it's output to drive the SSD.1 point

-

MBC installed my UFH pipework, but only the pipe, no manifolds etc. They actually used the UFH pipe from Earth Save Products (it was sent to site by them). Not cheap, and well regarded. No couplers, all full runs. No complaints here. They've done (probably) hundreds of installs. Sounds to me as though your heating supplier is just trying to bag the entire sale.1 point

-

1 point

-

1 point

-

1 point

-

Welcome to the forum. You are at the opposite end of the Notts/Derbys border. There are sound-proofed conventional vents available - my Planning Permission from back in 2013 has a condition to apply these.1 point

-

Hi and welcome, sounds interesting - look forward to hearing more.1 point

-

Welcome Jude, On this link you can download the declaration of performance for various Rationel windows. This includes the sound reducing properties. Basic triple glazing will have 3 panes of 4mm glass. This achieves around 34dB of sound reduction which is not much more than double glazing at 32-33. However, more expensive triple glazing where one pane is 6mm toughened or 6.4mm laminated achieves a much better 39dB reduction. When all the panes are the same thickness sounds can resonate through them when one pane is a different thickness, sound reduction is much improved. Even thicker laminated panes can be used for better noise reduction. The price increase for laminated glass was less than 5% on my windows, but they probably started off quite expensive. It also is much better protected against break in as you can't easily smash the windows. Most of the big triple glazing suppliers can supply this kind of glass if you want better sound reduction. They will cost around £300 per square metre of window.1 point

-

I'd get your building regs drawings done first if you haven't already. For pricing. A lot can be fixed, some will be provisional1 point

-

Hi and welcome to the fourm. Sounds like an interesting project and you will get plenty of help and advice here I am sure. I would definitely fit triple glazing (I just did) and choosing the correct type of wall insulation will make a big difference to soundproofing.1 point

-

Its been a while since I added anything to this blog, but we ve just had some professional pics back (our timber frame supplier wanted to do a case study).... so I thought I may as well add them here... Its also a nice reminder for me to see what the house would look like if I did nt have a 4 and 6 year old.1 point

-

Interesting thread, a bit concerning in some cases. I'm a Chartered Quantity Surveyor, and Project Manager (not touting for business, already too busy! :)) and have been surprised at a number of things. Has no one seen the property shows, dear architect, we have 100k budget - Architect designs to suit client requests which were unrealistic and come in at 150k. There are specific steps in a commercial construction project which should be followed, take lessons from the multi million pound developers. Look at the RIBA plan of work (Google it). Initial concept design then detailed design (for planning) , should be costed and any issues ironed out before these projects are taken to site and into contract. Why would you not have a contract? Why would you not have a pricing document? Don't get an online QS to give you national average rates that mean nothing. Go local, go small practice, negotiate fees, ensuring you know what you are getting from them. Get them to procure the contractor for you, they'll have local relationships with builders they have used before. Let the architect do what they are excellent at doing, designing the accommodation you want, but let your QS cost it and manage those costs to ensure its delivered for that. Google "find a Surveyor" to get a Chartered member of the RICS. Ask all professionals for a fixed price fee, why would you pay a QS / Architect a % of the finished costs when you have told them your budget from the start, no incentive to keep the costs down, but the reverse is true, the higher the build costs the more money they make! FMB used to do a crystal mark contract for homeowners, not sure if it's still kicking about. I tend to use JCT or SBCC (in Scotland) minor works contracts as they are simple in nature. You do need someone professional to administrator them though, useless in someone's hands who doesn't know it back to front including your contractor! When it comes to negotiations, there is no % to agree, unless you are simply talking about the contractors profits, Best course of action is to get a proper pricing document, such as an NRM cost plan or bill of quantities (I use NRM1 to provide a cost plan, but include extra details so it can be later costed by the contractor - with my figures excluded - as part of my tender exercise. A full bill of quantities will most likely terrify most contractors who do single house projects. Once you have the completed costs in from three contractors you can other benchmark your QS's costs and make sure they are right (yes, check them too, I've seen some crazy looking spreadsheets and pie charts on this site that bear no resemblance to a proper cost plan!) and also measure any variations to your contract as your build progresses. Need an extra 25m2 of walls, no problem, refer to your tender doc, get the rate per m2 they quoted and hey presto, you have the cost of the variation (that's a bit simplistic, you will also have to consider other items in any variations such as in the case of increased wall area, such as skirting, decor, slabs etc, but just trying to make a point) I hope it helps, and I'm happy to chat more if anyone is interested. Great site, keep up the good work team! Kenny1 point

-

Write to Kevin McCloud, I did. https://www.granddesignsmagazine.com/kevin-mccloud/271-kevin-mccloud-on-how-he-welcomes-spring Fabric First At Grand Designs Towers, we recently received apolite email from someone called Steamy Tea complaining that I was very, very wrong to use the term thermal mass when talking about how buildings perform: ‘There is no such thing in science. There is thermal energy and mass; they are not connected.’ Unscientific it may be, but it’s an accepted term in the building world, like ‘coolth’ and ‘flying buttress’, neither of which are scientific words. Moreover, a quick trawl across the internet will reveal that thermal mass is a common term and used by, for example, the Passivhaus Institut. So what do I do? Steamy Tea’s email is not brilliantly helpful: ‘There is also the matter of thermal inertia, this is a difficult concept to understand as it is a six-dimensional problem – three physical dimensions, one of time and one each for heat capacity and thermal conductivity.’ Ijust about understand this, but know I'll have difficulty explaining it on television, unless I make a programme for the Open University that should have been broadcast on a Tuesday afternoon in 1973. This is an important point, because a ‘fabric first’ approach to building that employs stacks of insulation arranged around materials with high thermal mass (I mean six-dimensional inertia, I think) is the future for building in climates like ours. The idea needs communicating. So thank you to Steamy Tea for being the annoying physics teacher that I strongly suspect they are. If any readers can be helpful and elucidate as to what I should say, please write to me here at the magazine (info@granddesignsmagazine.com). I’d like to clear the terminology up, before taking on the Passivhaus Institut and the entire construction science world. Here is the reply I got from Tom from the production team. Dear SteamyTea, Thanks for your comment. We will will do our best to ensure correct terminology is used. Many thanks, Tom And Thanks for your email SteamyTea. I will bear this in mind for one of our productions. Many thanks Tom GrandDesigns Boundless And people often wonder why I think Architects and house designers are tossers.1 point

-

Don't ever lose a hamster in the house mate, it'll be years before it resurfaces1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)