Search the Community

Showing results for tags 'heating'.

-

Anyone using VDI 2035 spec for heating water in an ASHP. Been looking at it seems a smart way to go. No chemicals to turn into a muddy soup, good heat transfer etc. Monitor with a simple conductivity meter and pH meter to control to quality of the water going into and in the heating system By monitoring Conductivity (80 to 1550 microsiemens) Ph 8.2 to 10 And Scale products below 300ppm Any one using are there issues? What if any fitters are you using Do you top up via an Ion exchanger or just tap water (of suitable quality)?

- 26 replies

-

Hi Just wondering if repairs done by British Gas to my combi boiler come with a guarantee? Had it serviced under contract and some parts replaced 4 weeks ago but gradually the old problem of no hot water downstairs has returned. We were told at the time it was probably a diverter valve problem which the engineer replaced. Central heating upstairs and downstairs is fine but sink and shower hot water has recently become very slow to heat and often goes cold after a minute or two. The system pressure is down to below the safe minimum level today so we had to turn it off. I haven't noticed any leaks anywhere. A British Gas engineer is booked to come tomorrow and as there's an excess to pay on repairs with our service cover I'm wondering if it's likely that they will waive it because of the previous repairs not having been successful? All thoughts welcome. Thanks David

-

Hi, I wonder if anyone can help please ? My In-Laws bought a bungalow a few years ago that had been fitted with a Kingspan Aeromax ASHP and have had problems with it ever since. Theres a whole list of stuff that’s been allegedly done, and by several people. The bottom line is that they get plenty of hot water, but when conditions are cold they don’t get any heating.........which is kind of when you need it ! We live an hour away and I’ve been letting them try to deal with this but I feel I need to step in as they are throwing good money after bad and no one they have around seems to truly know the system. Having read this forum there seem to be some very knowledgable & helpful people about. I notice that the Kingspan are, like a few others, just a rebadged version of a make called Carrier. I also notice from some extremely insightful posts from JSHarris that these units aren’t very well set up for the UK winter. Can anyone give any advice please ? If I need to buy one of these command units to reprogramme the system, assuming anyone knows the required parameters, then I’m happy to do that. For the record, I have no experience with these systems, or heating in general but I am a mechanical engineer with some electrical experience, so I should be able to do most stuff. Thanks for any help. Cheers, Lyndon

-

Hi all, Just come across these.... Capillary Tube Mats - Radiant Heat for Natural Air Conditioning (beka-klima.de) Not big in the UK but seem to have a presence on the continent particularly Germany. Just wondering if anyone has any experience with them? Cant see anything on here from a quick search? Cheers!

-

Hi. Would appreciate some advice. We are currently having wet UFH laid. It’s on the first floor, new build. Kingspan between joists with aluminium spreader above with UFH grooved slots. What would be recommended to go as the subfloor? 18 or 22mm chipboard? We will then be having 5.5mm plywood followed by Amtico LVT (2.5mm thickness). I want to have a subfloor which is ideal depth for heat transfer from the UFH system but also sturdy enough that if doesn’t creek. Many thanks, A

- 1 reply

-

- underfloor heating

- chipboard

-

(and 1 more)

Tagged with:

-

We are building a pretty conventional Potton SIPS house with ground floor wet UFH, heat pump, insulated raft, triple glazed, MVHR..... Most of the time there will be just two of us in a 3 bedroom, 3 bathroom house; so only one bedroom & bathroom in regular use. For the first floor our plumber and project manager both want to install wet UFH. It will be in some sort of grooved or clipped panels as it will go in after the first floor flooring is down. Here's my question. I've read quite a few times on here of people who installed it but don't ever turn it on, people who didn't install and don't regret it. I haven't seen any examples where someone chose not to install it, but wishes they had. So, are you out there? thanks in advance

-

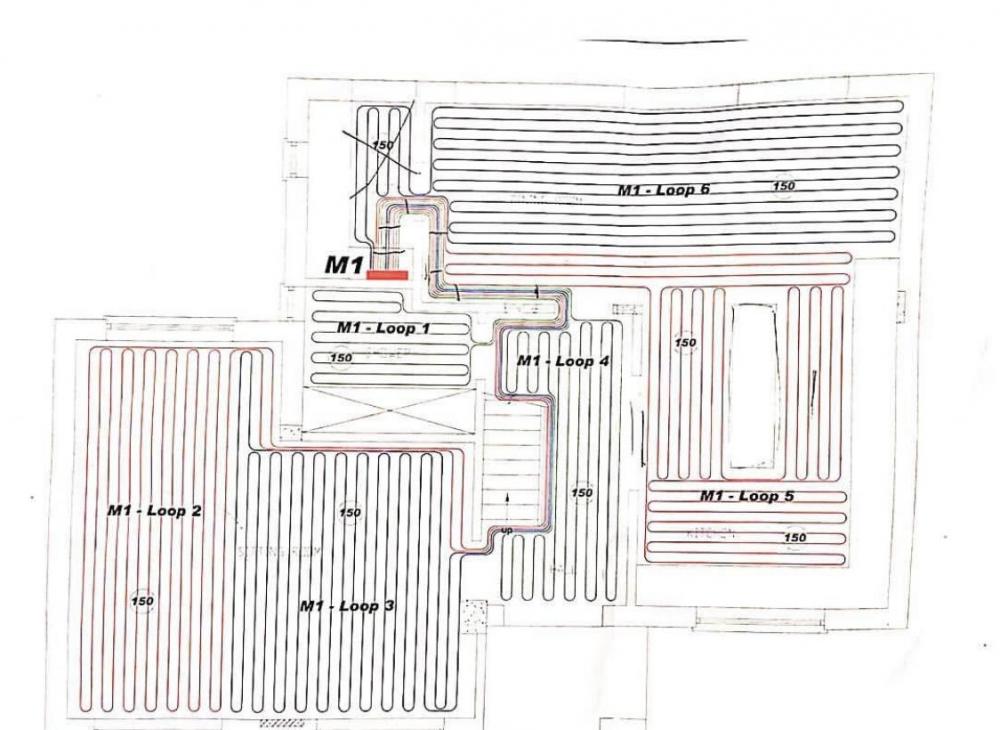

Hi all, We are getting closer to having our UFH pipes laid on the ground floor (in 50 mm liquid screed). My design is as shown in the attached image (150mm centres) , however have been told that its not the best way of having it and a spiral design would be better and give more even heating and less chance of any cracks. Is that right or is my design perfectly adequate? All the runs are less than 80m long, I didn't want to go more than 150mm on the centres as I wanted to improve heat up times on the system and the plan was to run the UFH at as low temperature as possible so that the boiler is condensation mode all the time while the heating is on (If anyone has any further information on system design in that respect it would be much appreciated). Thanks

- 12 replies

-

- underfloor

- heating

-

(and 3 more)

Tagged with:

-

I was about to reply on another thread, and realised I was hijacking it, so here is a new thread. We are putting 2 log burners into our highland conversion, and I consider myself eco considerate (got a badge for it). I'd be interested to hear if you disagree with any or all of these. FOR 1. It is very rural so it is not going to annoy or harm anyone nearby. 2. For the first 2 years there will be demolition timber, which would otherwise go where? A big bonfire probably. 3. They will provide quick heat whenever UFH is going to struggle, and allow us to keep the background heat down. A surprise change in the weather is readily dealt with. 4. Lots of surplus wood in the commercial forests around. Not the best and will require work, but otherwise it will probably be piled and burnt at some stage. 5. Aesthetically it is very attractive 6. We have an area of woods....rather lovely primitive, soggy woodland, but some can be harvested. I also favour planting some timber for pollarding. 7. The burners we are intending (Spanish) are 82% efficient. This is realistic as we have one already and it burns 30 big logs to every tiny ashpan. It has air inlets at the back to burn the fumes and you can see this working. This compares with.....what? isn't electricity 25% efficient by the time it reaches us? 8. In a well-insulated house it won't be a very big burner, or used much. 9. Other local houses have them too, and it doesn't seem to be causing any issues. 10.The flues create air flow and ventilation by stack effect, even when 'closed'. 11. There are are umpteen mills around, all with waste to get rid of. They seem to sell it even though the price doesn't seem that great to me. Otherwise it goes where? 12. If selling, they would be expected by most people. 13. We don't have to use the fires. AGAINST 1. Burning is burning, and makes fumes. 2. The air is so incredibly pure around, and there is lichen on the trees that depends on clean air. 3, Perhaps the smoke will hang around and be a nuisance. 4. The flues create air flow and heat loss when not in use. 5. Capital cost. 6. Holes in the roof. 12 against 6 isn't the issue as the weightings could be different.

- 40 replies

-

- 1

-

-

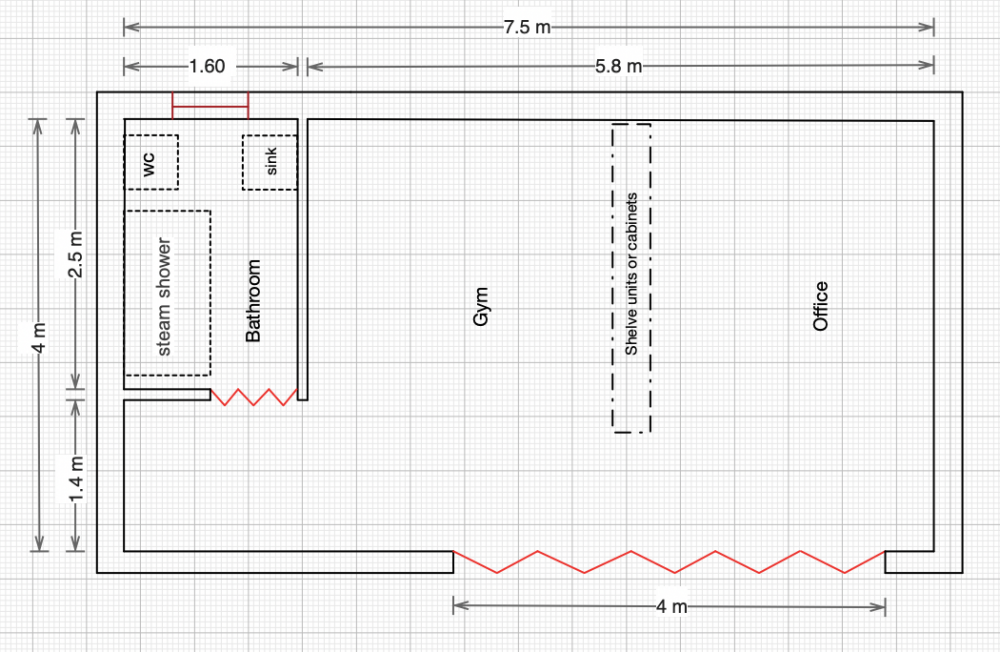

Good Evening, I am building a new outbuilding in my back garden. I am trying to figure out what the best electric heating solution (CH + HW) would be and I would like to ask you for your opinions here. The outbuilding will contain an office, a gym and a small bathroom with a steam shower unit and a sink as per the plan below. It will be used throughout the year on a pretty much daily basis. I initially thought about using electric heating mats for my UFH and a small boiler for my hot water needs but now I think there may be a better, more cost effective solution. I have seen a number of threads talking about ASHP, Ampec flow boilers and Willis heaters. It made me think about fitting a wet underfloor heating system and using one of the solutions but honestly speaking I am not sure what would be best as my knowledge and experience is limited. I would be very grateful for any advice. Martin

- 27 replies

-

- outbuilding

- garden office

- (and 4 more)

-

Hi, I'm still struggling on! I need cheap electric options for my small stable conversion for the time being. I have space for an immersion heater so could use E7 but is it worth having a twin coil or even thermal store for the future? The builder's plumber won't/can't do a Willis heater and has advised a Heatrae Sadia electric boiler (not specified which). I would like solar thermal and an ASHP in the future, but it may be some time and I need to keep costs under control and move in quickly, but without stuffing up for the future, am I overthinking as usual?

-

Can anyone give me recommendations or suggest sites where I can find out information on what type of heating system I need as I'm CONFUSED. I'm a first time self builder and navigating my way through all the information and decisions. We are building a 300sqm house (approx 177sqm downstairs and 130sqm upstairs) It's an upside down house with living upstairs and 4 bedrooms downstairs. We are planning to have underfloor heating in most spaces (radiators in bedrooms), 2 log burners and MVHR. It's a rural location, no mains gas. The previous property used oil, we are knocking and re-buliding. We were planning to go LPG gas - but I'm told to meet SAP & EPC calculations we would need to put Solar panels in as well? We've looked at ASHP but get really mixed messages on this. Any advice greatly welcome... (Thank you)

-

Hi guys. I'm at the early design stage for a new build and trying to figure out just how low a U value is good enough. I'm also undecided between a TF build and an ICF build but based on the budget quotes I'm getting, the TF approach is looking a lot more expensive. So I'm wondering is there a simple way to model what my actual heat demand will be using the various build systems to see how much of a difference a 0.15 value makes compared to a 0.12 value. Some time ago I found a thread (and now lost it!) with some spreadsheets that seem to work this out but I'm a bit stuck to know how to adapt to my build. Any help would be appreciated. Also thoughts on the ICF v TF comparison welcome. For context I will be project managing the build but looking to use a local builder and trades for most of the build work.

-

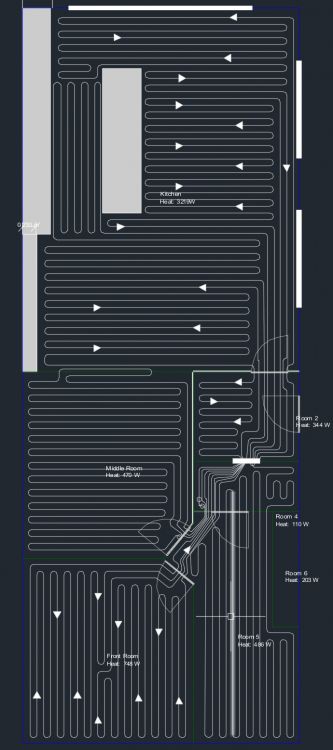

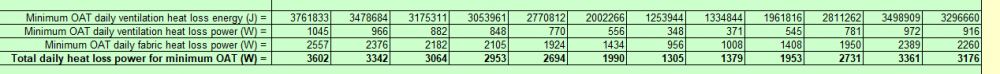

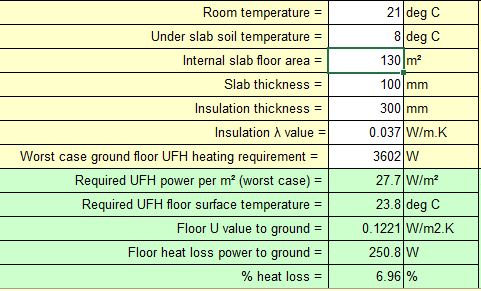

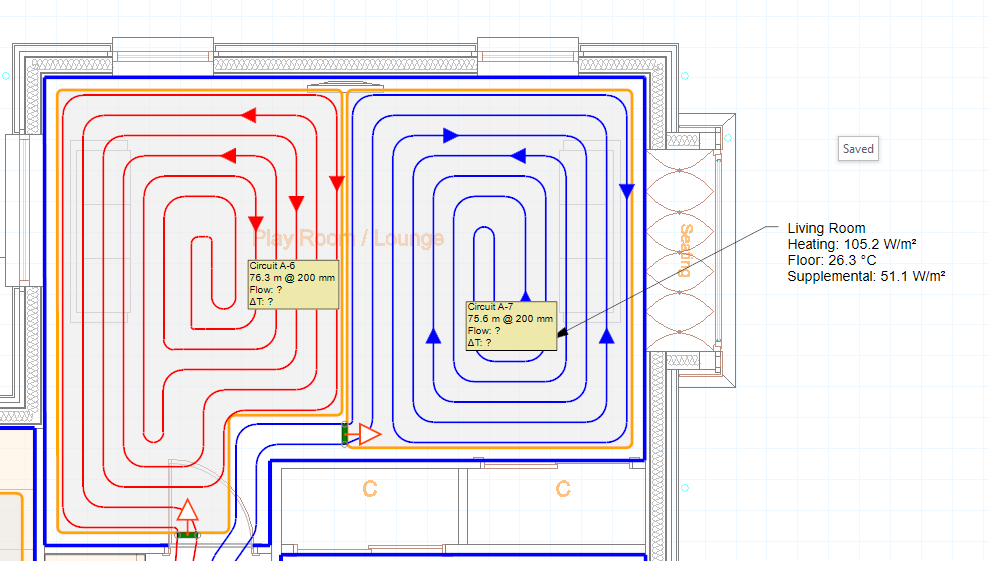

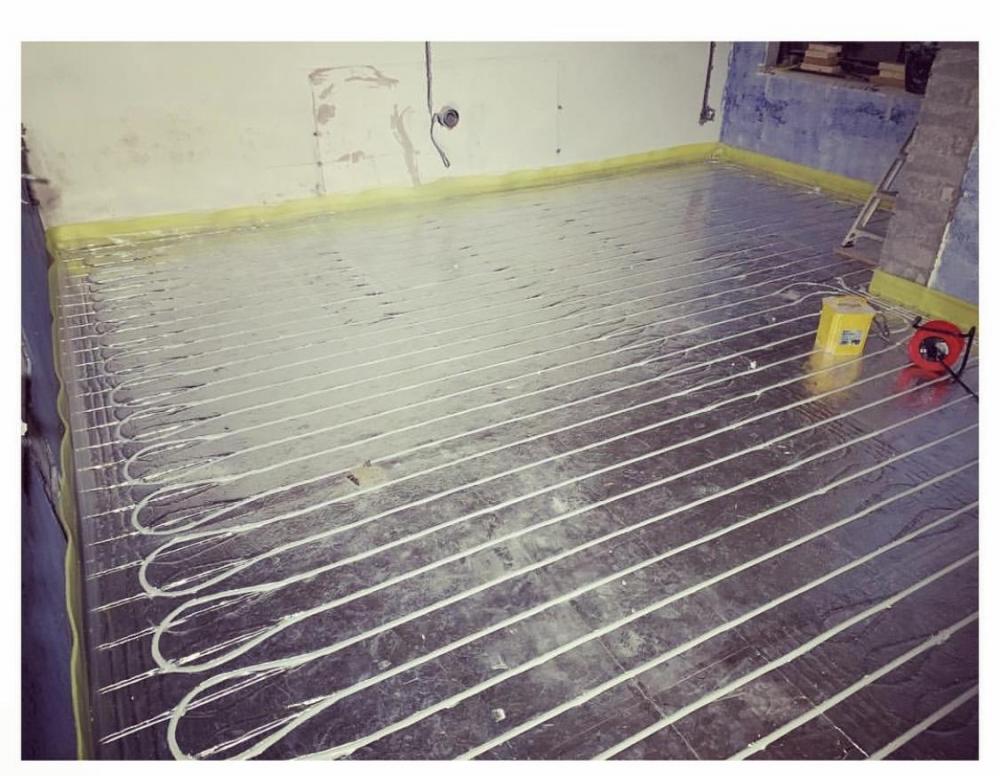

I've read various threads and views and back and forth and done some calculations based on information I have found here and of course from the very helpful spreadsheets provided by our friend @Jeremy Harris. I had pretty much decided ages ago I would get an 8.5kW Ecodan, which might go up to an 11.2kW ecodan unit. However I have not really advanced it beyond basic assumptions, what others done and some quick back of the fag packet calcs. I'm about to start foundations shortly hence, need to firm up on the UFH design for the in slab pipework and would appreciate some sense checking/ a wee nod that it seems ok. Build is SIPS with Kore insulated foundation, aiming for high levels of airtightness but not near PH (basically as best as I can get it without major hassle), Vent Axia Sentinel MVHR. ASHP which does UFH and DHW (UVC 3-400L tank). Secondary heat source of Log burner (I'm aware it's overkill likely - but I have 2 acres of woods, vaulted ceiling and need a backup in the event power ever went out). I would like to map out the steps in layman's terms to ensure they are right and I have followed it correctly from what I have read, then hopefully the thread can then be followed by others. Step 1 - Heat loss calculation: So I completed the heat loss calculator - see attached. I have a few checks to do on areas and might make minor adjustments but near as dammit it's close enough. I have added the OAT values for my local area (West Scotland, south of Glasgow) from the MET office. Now do I basically just use the 'Total daily heat loss power for average OAT (W)' value to find the maximum based on historical data and that defines the minimum amount of heating system required such below: which seems 3.6kW heat loss for January. The simply - I select a heating system which can supply this amount of heat as a minimum (ignore losses for now). So just simply selecting an 8.5kW unit would do the job easy? Step 2 - UFH design So Having found out the maximum heat loss above (3602W) then we can just plug this into the Heat loss and UFH calculator, which I have also attached. And provides the following output. So essentially, going on bare minimum I would need an UFH system which provides 27.7W/m^2 , based on 130m^2 of floor - so essentially if I don't use some slab area then I need to compensate and adjust the calc. Step 3 - UFH loop spacing So I know the total heat loss, I know how much heat input I have to supply per m^2 if I cover the whole area of 130m^2. So I get loopcad, then draw the circuits. Aiming for counter flow circuits as they provide the best option for even heat distribution, keeping circuits less than 100m in length. Now this is where I get a little lost, I have a figure of 27.7W/m^2 for the whole area to get my required heat input, however how do I correlate that with loopcad and also deciding what my spacing should be?! I have seen @PeterW mention quite a few times about the the spacing had to be adjusted but I am struggling to find the route here to confirm easily what it should be. My loopcad drawing (I've attached my current draft) showing for example 105W/m^2 in my living room, but I'm not sure how this should read in relation to my calculated figure. I'm pretty sure I'll need 200mm centres, but I'd like to ensure that was right. I've some adjustments to make to my circuits, but it's not far away. I was finding that the auto generate function for pipework isn't ideal but it works ok. The garage can be ignored - I ma installing pipework in there pre-empting possible future conversion of that area and hence pipe is cheap, so why not add it now. The manifold will go below the stairs - seems to make sense to me, I have a plant room directly adjacent and was going to put it in there but seemed better to get it out of there as I will have lots of ducts and this would clutter that up. Is it ok to run underneath the stairs? I assume I just have to tell the Joiners not to fit the stairs to the floor with big screws?! Step 4 - Zones I am only having downstairs heating, so it is a single manifold. I would prefer as few zones as possible, but a single zone wont work. I was thinking I can have two /possibly three. Zone 1 - Main family room area Zone 2 - Everywhere else excluding shower room and garage Zone 3 - Shower room Zone 4 - Garage (permanently isolated at the moment. I assume you can have multiple zones on a manifold, and can just split them up by using salus actuators?. So a single thermostat for family room can control three loops (each with an acutator) in that room? and so forth?. It's a long post , and actually I wasn't going to talk about zones but thought it was worth adding in. Thanks. Heat loss calculator - SuperJohnG.xls.xlsx Floor heat loss and UFH calculator - SuperJg.xls.xlsx Looopcad - SuperJohnG.PDF

-

hello, I have an underfloor heating system installed in my flat, it looks to be UHF manifold, the solution is from warmafloor with thermostats CC-T-764WHI and screen control 4'3''' touchscreen. However the control system is not manageable via an app/website and I would like to upgrade it to be operable with distance , replacing probably the thermostats and/or the control+screen system. However i have no idea where to start from, I have tried to find documentation on their website but there is nothing about how to upgrade (and the company isn't very responsive to messages), i found even the way to operate quite complex currenlty. I checked online how to replace thermostats which looks doable however the alternatives don't really support the same functions as the one installed so I am not sure what would happened if I proceed like that (for ex current system has a mode 'Schedule', "SetBack' etc.) Is there any resource on internet that somebody could point out, or somebody who could advise how to start on this system , do I need a professional to take care or is it possible to self change ? many thanks

- 4 replies

-

- underfloor

- smart

-

(and 2 more)

Tagged with:

-

Good evening all, I was after some advice please. We have an underfloor heating system installed with 8 zones. We are finding it takes quite a long time to heat under on certain zones. What operating pressure should the system be at? Ours is currently set to 2 bar? We are finding that front room is colder than the other rooms, the UFH is installed under floorboards in the insulation boards supplied, ontop of the floorboards we have tiles and wooden flooring. Is this right? Will the heat travel through this many layers? This is what was recommended at the time? Also what should the pump setting be set at? There are serval settings which can be selected from the front of the valve? Without leaving the UFH on all day being controlled by the thermostats it does take quite a long time to heat up? I’ll forward on the plans and the photos of you could get back to me that would be great? Cheers Ash.

- 57 replies

-

- underfloor heating

- ufh

-

(and 1 more)

Tagged with:

-

Hi there Just starting out on a house build and find there are A LOT of decisions. Planning permission has been granted but that's as far as I am. I would appreciate some thoughts on heating systems. Plan is a high level of insulation (eg CWI: 150mm thick Kingspan Eco Bead / Quinn lite block, Floor: 100mm foil backed polystyrene) , triple glazing (uPVC frame) UFH for downstairs and radiators upstairs. I've considered Heat Pumps but I am being recommended OFCH - specifically Grant Vortex. In looking at this option I came across Hybrids and wondered if anyone had experience of this: Grant VortexAir Range: https://www.grantuk.com/products/hybrids/? I live in NI so there are no grants available to apply for... Any advice appreciate Meabh

- 23 replies

-

- heating system

- heating

-

(and 3 more)

Tagged with:

-

Sometimes questions are raised as to whether it's worth increasing insulation levels and often there seems to be confusion as to what the "ideal" level of insulation is, or even what a "good" or "reasonable" level of insulation might be. I'm not sure whether or not the non-linear impact of improving insulation, in terms of the effect on the heating requirement, and hence running cost during cold weather, is widely understood. I've heard comments like "it's not worth improving the insulation from 0.16 W/m2.K to 0.12 W/m2.K because it would be 30% more expensive and only reduce the heat loss by 25%". Most of the time this is incorrect, because homes have heat sources all year around, from the occupants, incidental heating from appliances, solar gain and even pets (a medium sized dog is probably a four-legged 40 - 50W heater). So, I thought a really simple example might help some gain a better understanding of this non-linearity, and illustrate better why some are so evangelical about trying to improve insulation levels (and reduce ventilation heat loss, too, but I'll get to that another time). Let's build a pretend house, that for simplicity has no doors or windows and is a rectangular single storey box with a flat roof. For simplicity we'll assume it's on raised piles, with an air space underneath, just so we can use the same insulation level on all six sides and to make the sums simple. All I'm doing here is making a comparison, so this is a valid way of illustrating this effect. In our rectangular box house we have an average of 100W of incidental heating, coming from things like internet kit, a PC, a cordless phone base station, a TV, a phone charger, a few lights and a handful of intermittently used kitchen appliances. This is a pretty low figure - I struggle to keep our house background load below about 200W, without any lights on. The box houses two adults, giving out around 80 - 100W each and a dog, so lets say there is 220 W of heating coming from the occupants. The box also has a heating system that can deliver whatever power is needed to maintain a temperature of 20 deg C inside, and its night time, so there's no solar heating of the walls. Outside it's 5 deg C, a chilly winters night. This rectangular box is 10m long x 10m wide x 2.5m high inside, so has a total wall, floor and roof area of 300m2 and an internal floor area of 100m2, so fairly average in size (a bit bigger than our current 3 bed bungalow). So, we have a temperature difference between the inside and outside of 15 deg C (20 deg C - 5 deg C), an internal surface area of 300m2 and a constant incidental heating level of 320 W (220 W from two adults and dog, 100 W from electrical appliances and lights). First, lets see how much heat we need to put into this box from the heating system, if we have U values for the walls, floor and roof of 0.2 W/m2.K (K is degrees Kelvin, the same units as degrees Centigrade when only temperature difference is being compared): The total heat loss power, in Watts, can be calculated from the U value, the area and the temperature difference, so for this first example we get 300m2 area x 15 deg C temperature difference x 0.2 W/m2.K U value = 900 W. There is 320 W of heat coming from the occupants etc, so the heating system would need to deliver 900 - 320 = 580 W in order to keep the house at 20 deg C under these conditions. If this were by direct electric heating, then the heating cost would be about £2.09 per 24 hours. Next, let's see how much heat we need to put into this box from the heating system, if we have U values for the walls, floor and roof of 0.1 W/m2.K , in other words, we've made the insulation twice as "good", so might think we've halved the heating cost: The total heat loss power is now 300m2 x 15 deg C temperature difference x 0.1 W/m2.K U value = 450 W. This is what we'd expect, double the insulation effectiveness and halve the heat loss. However, when we now take away the incidental heat gain from the occupants, etc, of 320 W, the heating system needs to deliver 450 - 320 = 130 W in order to keep the house at 20 deg C under these conditions. If this were by direct electric heating, then the cost would be about £0.47 per 24 hours. So, by doubling the insulation level we've decreased the heating cost by about 78%, not the 50% that might have been expected. This is a very simplistic example, but it does illustrate why doubling up in insulation can give a far greater benefit than might be expected. It also shows why, when you improve the level of insulation you can reduce the heating requirement down to such a low level that for a lot of the time you don't need any heating. In that last example, turning on a few extra lights could heat this imaginary box home to a comfortable temperature on a cold night, whereas with only half the insulation it needs something that delivers 446% more heat.

- 31 replies

-

- 5

-

-

-

- insulation

- heat loss

-

(and 4 more)

Tagged with:

-

Hello all, I stumbled on this forum as part of a search for information about SunAmp batteries. I’ve spent a bit of time reading other threads on the topic and this seems to be a friendly and helpful piece of the internet. I’m on a quest to reduce the CO2 generated by the 3-bed 1960s semi (approx 98 sq m) where I live with my partner (no kids). We’ve insulated the upstairs, added some loft insulation, upgraded the double glazing and last year, we installed 5700W of solar panels and a Tesla Powerwall 2. I’d estimate we generate around 5000kWh a year from the panels, and export around 3000kWh of that. We’ve got our grid electricity usage down to about 500kWh per year. The biggest element of this being our electric shower (the Powerwall can only ever supply 5kW of the 10kW load). Gas is used for heating and hot water via a 15 year old Worcester combi-boiler - which I’m guessing is nearing end of life. Our gas usage is fairly low, but I’m looking to reduce that next, from the current 5000kWh per year (more when we have a cold winter). I'm not planning on replacing the gas boiler, meaning we'd be 100% reliant on electricity for heating and hot water. We’re on a deemed solar export tariff, and I’m looking to use as much of the energy generated as possible. I’ve also recently begun the switch to Octopus energy to take advantage of their Agile tariff, so it might be possible to shift much of our current gas energy usage over to electricity - but what would be best for us? GSHP not an option here (small garden) ASHP may be, but I’m conscious of the effort and cost of installing Underfloor heating. Air to Air an option? Right now I’m thinking a SunAmp for the hot water, or could the Uniq 12 supply our heating and hot water? Maybe we could supplement that with and a couple of electric radiators in the lounge and bedroom to keep us warm on demand? I’m not sure if that would be what we need especially if we have a long cold winter like last year (I’m on the South Coast of England). I would be grateful for any thoughts from anyone who has done similar or knows more than I do about these things. With thanks, David.

-

A new idea. In the the latest House-Planning-Help podcast (HPH280), John Bootland (the boss of the Passive House Trust) mentions putting a little radiator near the front door to give a feeling or warmth as you enter. Interesting idea; never heard it mentioned before. Here is the clip (24:35): https://overcast.fm/+NC20Ux5Q/24:35 And the podcast: https://www.houseplanninghelp.com/hph280-a-beginners-guide-to-the-passivhaus-standard-with-jon-bootland/

- 8 replies

-

- heating

- front door

-

(and 1 more)

Tagged with:

-

I am a fan of flexibility, having options, and for simplicity. When I build my new house I plan to include the wiring and pipes for both an ASHP and gas boiler. To go with the ASHP, I will also include UFH piping in my reinforced concrete raft foundation. Installing all the options at the time of the build costs peanuts. But how about adding one more cheap option: from a capital cost perspective, the cheapest of all. When I pour my my raft foundation, why don't I also include some electrical heating wire too embedded deep within the concrete? From checking on eBay, the cost of loose heating wire seems to be about £150 for 2kW. £150 really is peanuts! And it beats even a Willis heater for simplicity. Wet UFH after all needs a manifold, a pump, regulators, etc. While I would still have all the other options available later, I could use the wire heating for the first couple of years while I learn how my new house responds. What does everyone think? Bad idea?

-

Good evening everyone, My name is Vaughn and I live in Sussex. I've joined the group, both as an aspiring home builder (in the future), but also to offer advice, where I can. I specialise is heating controls (and employed by one of the world's largest heating controls manufacturers). I also ran my own plumbing and heating business in the South East for 9 years, installing gas, LPG, and biomass boilers, heat pumps, solar thermal and a little solar PV too. I have particular interest heating controls, and renewable energy sources for domestic properties. I am active on other social media platforms, mainly Facebook, Twitter and Instagram. I look forward to participating as and where I can, and learning as well as sharing knowledge within the community. Regards, Vaughn.

-

Currently have a 300 litre UVC ready for a heat pump to handle hot water + heating at a later stage but in the meantime like several others on the forum I would like to add a Willis heater between the manifold flow/return to run our UFH system. System is 3 x 100m loops all to be run as one zone in a 100mm screed. Wunda manifold is installed minus a pump at this stage. Wiring wise 3 core + earth from the stat is in place and power can be added from the plant room board easily. I would like to finalise and order the necessary components so if someone could advise if I've missed anything it would be greatly appreciated... Wilo manifold Pump from Wunda + Isolators Digital room thermostat (recommendations?) Willis jacket + immersion Timing Switch to ensure E7 use Electricians will fit all wiring and controllers but I supply everything. Possibly a 2 port valve as per @Nickfromwales recommendation in this thread but not sure if this is necessary? Trying to keep it as simple as possible at this stage.

-

- willis heater

- under floor heating

- (and 2 more)

-

Hi Folks Looking for some guidance before leaping into E bay. Have spotted a used Samsung 9KW ASHP complete with tank and buffer tank and all expansion tanks and controls etc. Following from the listing:- 250ltr Santon Premier Tank Plus Pre-Plumbed Unvented Mains Pressure Water Heater with wiring. 120ltr Gledhill SL Plus Multi Buffer EE Tank plus pump. Expansion Tanks. Samsung and Siemans Controller Units including wall mounted controller and room stat. Fernox TF1 Total Filter Unit. All Instruction Manuals. However from the limited research I have done on the tanks, they do not seem optimized for ASHP IE larger coil, although I am not certain. Also what is the real world expected service life of the heat pump and compresser. I am planning on using it to run underfloor heating and also domestic hot water, planning on fitting a 3KW PV array. Currently have gas, so new ASHP kit + PV seems expensive/long payback time, however I like being less grid dependant, but need to buy secondhand to justify the costs. No plans to register for RHI. Here is the E bay link https://www.ebay.co.uk/i/193017668167?ul_noapp=true The 9KW seems about right when comparing the results from the excellent JS Harris heat loss spreadsheet, it is posibly larger than required, but seems they run better a little oversized. thanks

-

Still at planning stage.... As we are on sloping site we are planning to have the living area on first floor and bedrooms beneath. I had it in my head that we would have a pot & beam floor as we are looking at UFH from ASHP. What about bedrooms? I have read elsewhere on here that upstairs bedrooms require little or no heat as heat comes up from heated rooms below. We won't have that. There will be a far amount of solar gain, in fact I am concerned about over heating, so will probably have MVHR system. Could this be utilised. Ideas please.

-

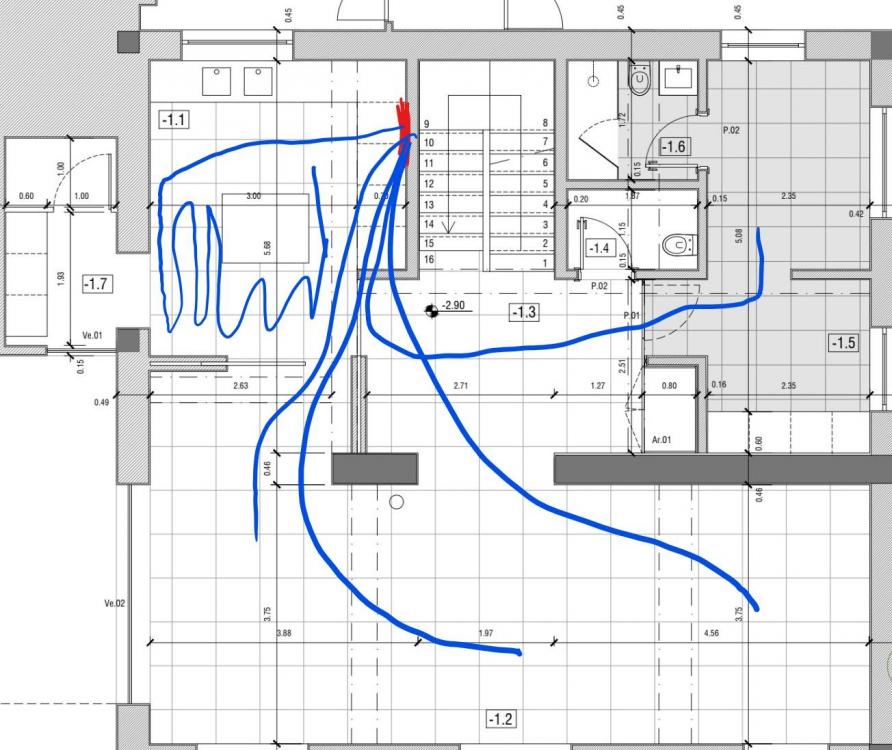

Hi all, I am just completing a conversion but hired professionals for UFL. What I find strange is that the manifold (RED) is in the kitchen, and all sections (4 excluding kitchen) go through the kitchen floor and not through the staircase (behind the kitchen) and therefore leaving the potential to overheat the kitchen, when all areas are on and kitchen is already at temperature. Should't they have taken into consideration that the kitchen is potentially the warmest place in the house and it will become a potential sauna? Also the Manifold is right behind the oven and stove. Can I should I insulate the pipes from the screed? Will lay down normal sand+cement screed... Any pointers really appreciated. Thanks