Search the Community

Showing results for tags 'eps'.

-

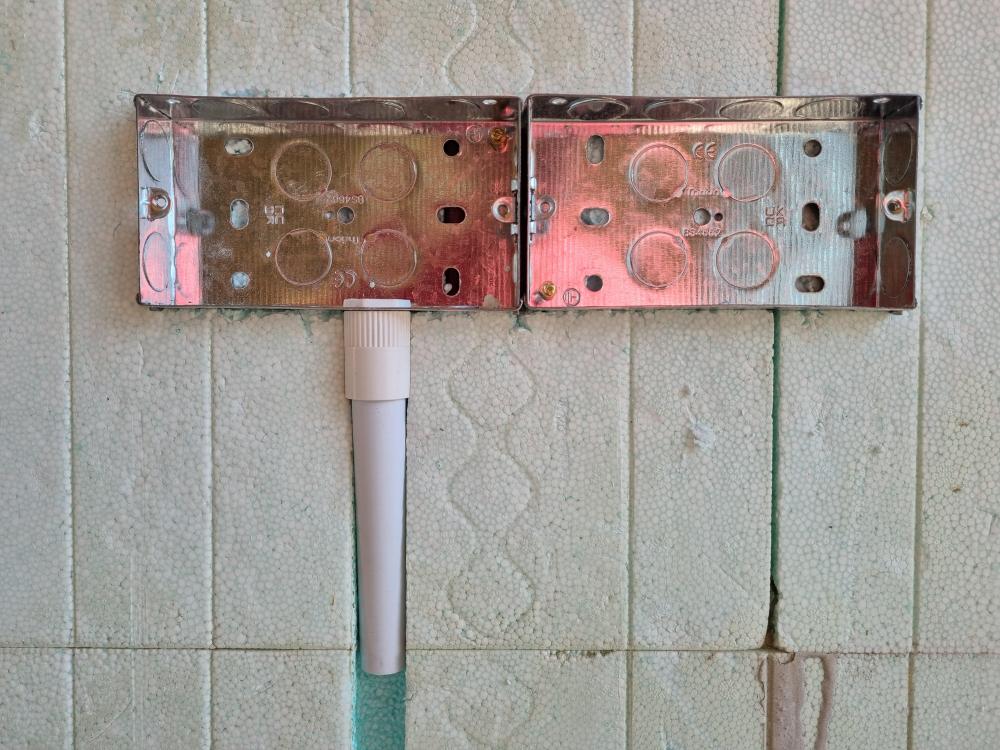

Several months ago on a thread I can no longer locate, I committed to donating the location to create a short video of installing conduit for running electric cable to sockets in EPS insulation, specifically in this case Nudura. Well, finally, I bought a roundtuit, and we have results. For...

-

I was wondering what you think about insulating under a block and beam floor. Building control specifies approx 200mm ventilated gap under a suspended block and beam floor. I am quite unsure of why this is. Apart from expanding of clay floor underneath, I can't quite see a reason (with suspended tim...

- 35 replies

-

Hi, We're planning a self build with an insulated EPS foundation and UFH on top, in the floor slab. Does anyone know if we can polish this floor slab up to make a polished concrete floor? and does this work out cheaper than say, tiling the floor, as we're not doubling up on materials?...

- 13 replies

-

- polished concrete

- inslated floorslab

- (and 4 more)

-

So the floor is going in. The second half of the sub-floor area of concrete was done diy by family and friends, using fibre reinforced concrete. A great success, and who needs groundworkers, as long as you have one skilled person and 4 barrows with 4 helpers? 150mm of insulation is...

- 12 replies

-

Hi there, I've a 125m2 extension being erected next year with a pretty basic floor slab planned. Floor covering 65mm Screed UFH Pipwork 150mm PIR insulation 100mm c35 concrete with mesh Whilst looking at the overall prices of each piece of work...

-

Just starting to dig to find the drain pipes that poke out of our MBC EPS slab foundation (thank goodness we took photos a year ago ?) and wondering how to best finish up against the EPS when getting back up to finish ground level. we have put some rat mesh over the EPS. Can we simply ba...

-

The raft foundation gang have been in today, loads of them and great progress. I heard a cuss as one of the gang had broken the upstand off a piece of the EPS which I was assured would be fixed. When I returned to site the fix was in place, but as you'll see from the pics the fix, using...

-

So I have had a ten ton digger pecking rock out to make way for a basement and extension. Was planning on 200mm EPS under the slab, and 200mm EPS around the exterior of the basement walls. I do have two walls against the existing house to retain the house founds, as well as creating the basement wal...

-

I've got a small area of wall with two skins of block/brick with a gap 15-20mm that I want to fill with insulation, it's below DPC so I don't think mineral wool etc. Current idea is either spray foam or loose EPS beads/shavings. Any other options I might of missed?

- 1 reply

-

- spray foam

- eps

-

(and 1 more)

Tagged with:

-

I have just bought a property which was newly built in 2013 , shortly after being occupied the property was fire damaged. The UFH system was decommissioned shortly after the fire which extensively damaging the wooden joists & rafters however did not impact on the floor slab. The building was left ex...

-

I've realized we have the available height to add an additional sheet of insulation under our 100mm ground floor slab. Originally I had planned on using 2 x 100mm EPS70 with the DPM underneath as stated by Jabfloor. If I add an additional 100mm sheet on the bottom would there be any issues using it...

-

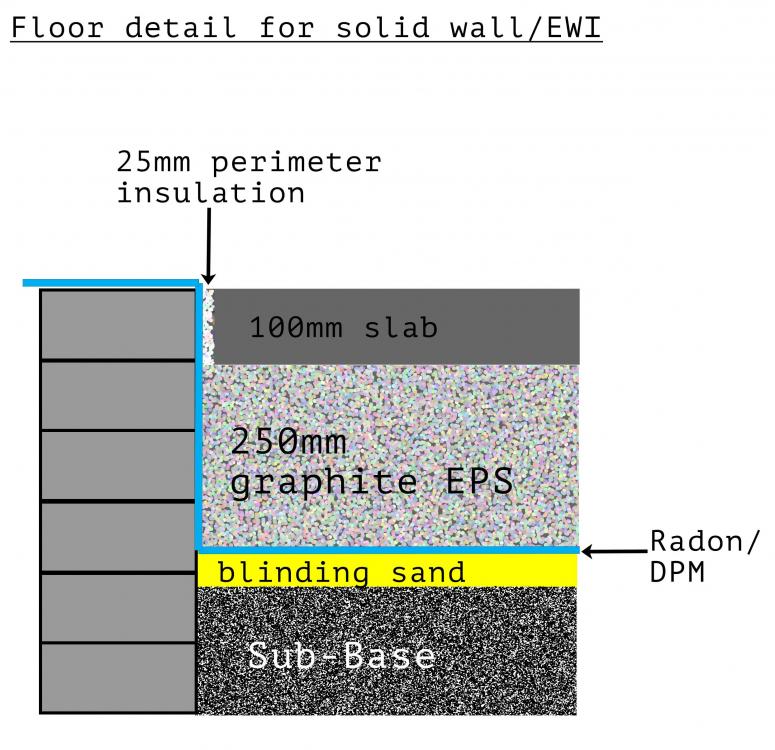

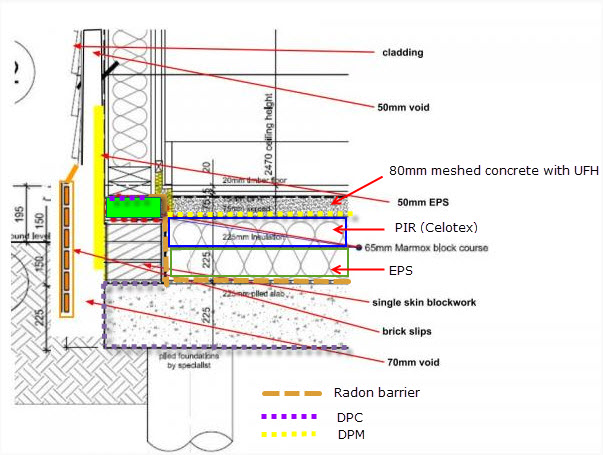

Slab Insulation, UFH and Mesh

MarkH posted a topic in Energy Efficient & Sustainable Design Concepts

Here's our floor construction. I'd appreciate any opinions on it and in particular on a couple of details currently in decision limbo: 1) I'd assumed the DPM would go as pictured in this diagram - under the insulation - as it seems to make sense to have it contained within the waterproof... -

Hi guys, I am looking for a bit of advice on a external wall insulation system and where I can buy it. I am thinking of insulating part of my house and a recent extension (within past 10 years I think) which seems to have shocking insulation, part of the house I would just want to render...

- 3 replies

-

- eps

- insulation

-

(and 2 more)

Tagged with:

-

Okay, big iceberg delivery yesterday, so now I need to start laying the insulation for my slab: Bungalow has two extensions which are piled slabs – both extension slabs will have a mix of PIR and EPS. The bungalow floor has been dug up, hardcore is down and I am ready to fil...

-

Hi All, I previously removed an exterior brick wall in order to extend lounge. Where my new slab extension meets the old bungalow cavity wall, I need to decide what to do with the cavity that goes down to a depth of approx. 800mm to the footings before I lay down my new floor slab. The...

-

Just levelling off my last few rooms with sand prior to laying down my EPS/PIR boards. I remember on ebuild someone suggested to me that it wouldn't hurt to sprinkle down some ant powder with the sand. It's probably overkill, but I don't want any ants in there creating a labyrinth of tunnels that ma...

-

Our contractors effectively treated the EPS slab as if it was level ground (i.e. they ignored it) and built their traditional steel lattice & formwork / shuttering on top. Slab and a 100mm kicker first and then built off this as they did the walls in sections. The kicker is necessary to hold the ver...

-

Apologies about another "who shall I contact?) posting. Again, I just don't want to miss out on any obvious suppliers/merchants out there and as insulation is one of may main cost areas, I'm looking to get the best price I can....obviously. I'm looking to get a mix of EPS and PIR for under sla...

- 6 replies

-

- insulation

- suppliers

-

(and 3 more)

Tagged with: