Search the Community

Showing results for tags 'airtightness'.

-

Looking for wisdom from this forum on how to maintain an uninterrupted airtight layer between the ground floor and the first floor in our retrofit (solid brick mid terrace). The joists run front to back and on the front we have to do IWI (On the rear we’ll be doing EWI so my assumption...

- 10 replies

-

- airtightness

- joists

-

(and 2 more)

Tagged with:

-

Hi all 👋🏼, I wanted to introduce myself and our project as I anticipate I'll be in hot pursuit of the forums thoughts, opinions and experiences in the forthcoming months. We purchased a 3-bedroom 1970's bungalow in August 2022 but had some planing complications due to a par...

-

Question from a novice (not sure where to post this). How would you go about blocking up 3 extract fan vents? 2 bathroom extracts (100mm) and 1 kitchen extract (150mm) - I'm having an MVHR system installed next week (retrofit) so I want to remove and block up these 3 vents. (Obviously I'...

- 9 replies

-

- extractor fan ventilation

- airtightness

-

(and 1 more)

Tagged with:

-

I am in the situation where I am converting a garage with a pitched cold roof above. However I’ve also removed the ‘external’ wall that separated the garage and kitchen. I’m taking the opportunity to improve insulation with IWI in the garage and want to also improve airtightness. I’m hap...

-

- vcl

- airtightness

-

(and 1 more)

Tagged with:

-

@ mods not sure if this is the most appropriate section. We don't have a dedicated Airtightness one. Time: 1hr. Cost €60 Materials: 1 X Sheet of OSB or PlY 1 x Used car radiator fan including housing ( I used a...

-

Has anyone managed to find an off the shelf access hatch that can be plastered up to and on top of, that is also of a high standard of airtightness AND has some level of insulation incorporated? I am doing a basement conversion that has service hatches to rest of ground floor underfloor crawl space;...

-

I am pretty confident on what my solution is for my basement problem, but it would be prudent to push it out there for some clarification: Basement roof has been sprayed with Icynene open cell insulation (increased air tightness and likely exaggerated my issue) and since we had the roof...

- 1 reply

-

- solum

- foundations bitumen

-

(and 2 more)

Tagged with:

-

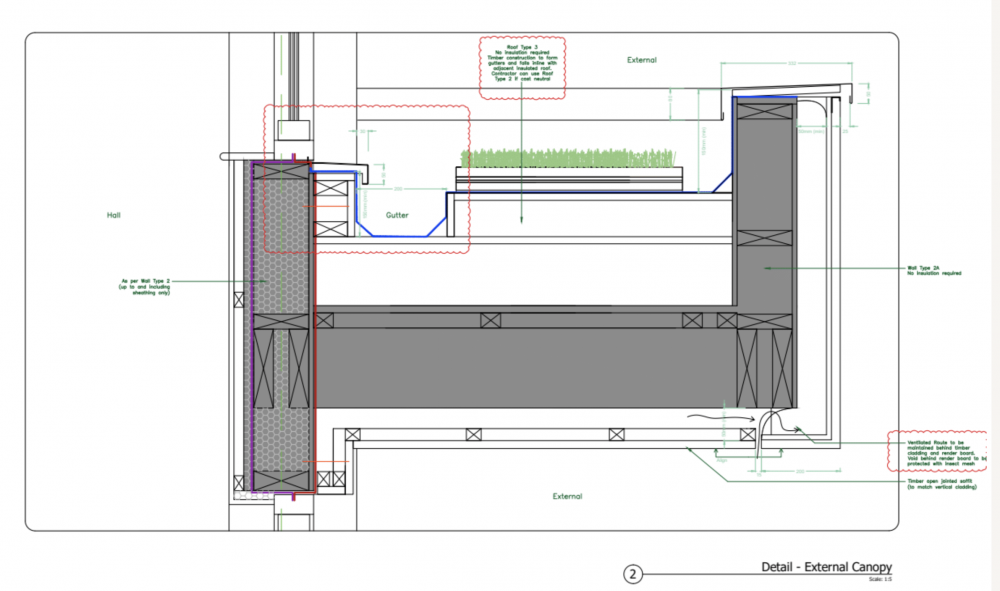

Hello, I was wondering whether anyone could offer any thoughts or advice about the following threshold detail. I'm actually an architect myself and am working solo, so I don't get the benefit of second opinions. I've always worked on larger schemes at the earlier 'conceptual' stage of p...

- 4 replies

-

- external door

- passivhaus

-

(and 1 more)

Tagged with:

-

There is another thread like this...butnit deals mainly with a brick and block home. Link here: However I wanted to capture basic logical steps for success and glean some wisdom of things that became hard before I start with the airtightness inside. I'm...

-

Bad Airtightness Test Result

AliG posted a topic in Mechanical Ventilation with Heat Recovery (MVHR)

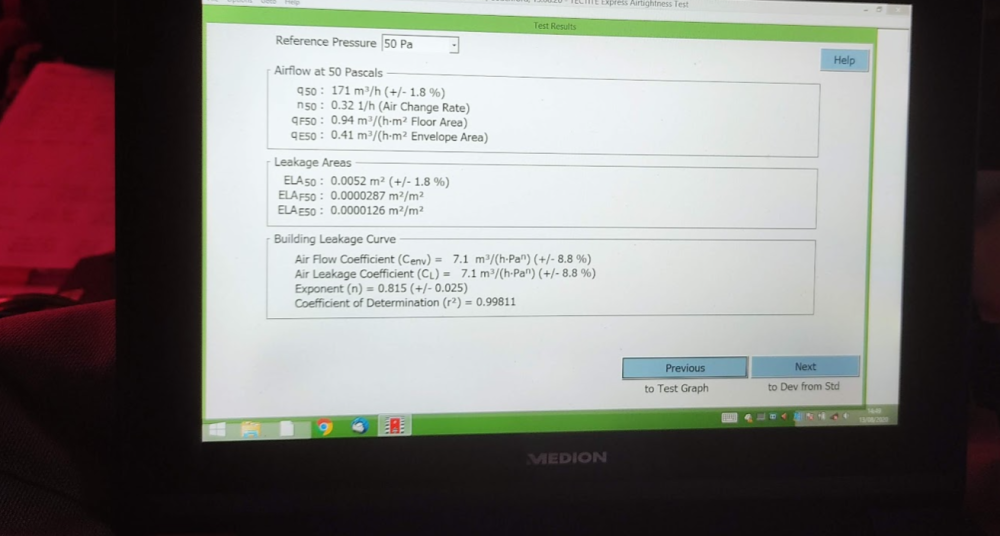

Ok. This is embarrassing but here goes. After some considerable time I finally had an airtightness test done today. I wasn’t expecting a great result because it seemed almost impossible to impress upon the builder and architect what was required and working away during the we... -

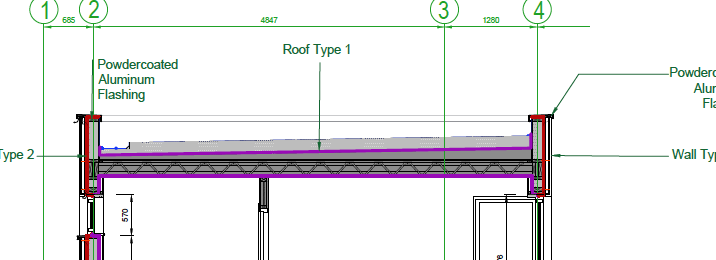

Hi, We have a warm flat roof design. This is causing two issues - Cost and airtightness 1. Cost for the Bauder Thermoplan covering is coming in at just shy of £150/sq metre fitted, based on 145sq metres of roof. Considerably more than I expected. The b...

-

I am almost done with filling in all the gaps the builders left before I get my second airtightness test. One job I have been putting off doing, but want to do is the inside of the chimney breast. The idiots put the large coat on the outside of the chimney breast, and did not...

-

I am planning a self-build on a plot that I have approval for a two-storey detached house with basement. The structure is a traditional tiled roof on full fill cavity blockwork walls, rendered on outside and painted, with an external footprint of 7.5 x 9m. Looking at air tightness I can fi...

-

We are trying to do our best to create a pretty airtight house.... Our Architect has suggested a joiner made front door. Will this be a huge source of air leakage? We are installing MVHR and ASHP and it will kill performance if the door lets wind through. Our c...

- 12 replies

-

- passivhaus

- mvhr

-

(and 1 more)

Tagged with:

-

Hello, I am going to retrofit MVHR in 1930s semi and this also goes hand in hand with getting new windows. The question is: are windows with airtightness class 3 sufficiently airtight to allow MVHR work efficiently or do I need to get windows class 4? Any experiences?

-

I had purchased all my tapes from Passive house systems and found them great to deal with. When I realised I had not ordered enough I contacted them to ask if I could purchase one more roll and could they look at the postage as it would make it a very expensive roll! Not only did they apply the disc...

-

If anyone interested I have a 15% off code for airtightness tapes with Passive house systems. The code is 15%aocx, not sure how long this code lasts but I have only just ordered and it worked for me. I have the rep's contact details so if it does not work let me know and I will contact him.

- 24 replies

-

- 2

-

-

-

- tape

- airtightness

-

(and 2 more)

Tagged with:

-

Our window fitters left the site without having fitted the Compriband sealing tape. Today they returned to fettle our door (sticky lock mechanism) and , so I thought, to fit the Compriband. They explained that the Durisol surface was too rough for the Compriband to adhere to - and would...

-

I get that masonry wall floor joist hangers are favoured over traditional in-wall fixing of joists in the pursuit of airtight homes but can these hangers cope with 100 years of cyclical loading? Here is my beef. Driving a metal nail into a brittle masonry block to attach a hanger feels l...

- 20 replies

-

- joist hangers

- metal joist hanger

- (and 6 more)

-

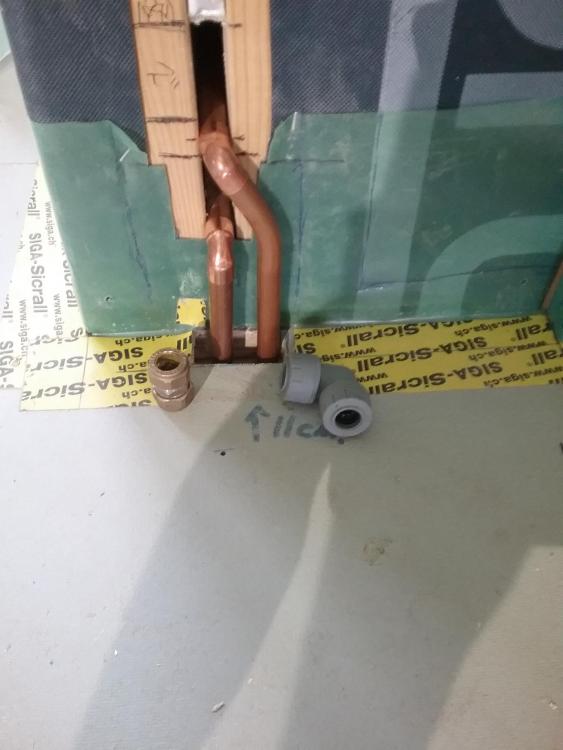

Evening all, Been getting on with some first fit plumbing in the four dormers. This is complicated by the fact that below the floors is outside (well some insulation and then outside) - so pipe work needs to go through the timber frame before going downstairs. See pic. I've got two cha...

- 6 replies

-

- airtightness

- tape

-

(and 1 more)

Tagged with:

-

Dear all, A small number of challenges for a Tuesday evening...... Challenge No 1 Picture 1 The picture below is our fire place The gap between the timber frame and the brick wall is the cavity, so any suggestions how I seal this up so that its (permanently) airtight. Would lik...

-

I'm building a warm roof timber frame house with the airtightness layer at the VCL. In one part of the building the ceiling will be vaulted, and there will be three beams at c.3m above FFL, acting as structural ties between the rafters as well as serving as somewhere to position the lighting. T...