Search the Community

Showing results for tags 'flat roof'.

-

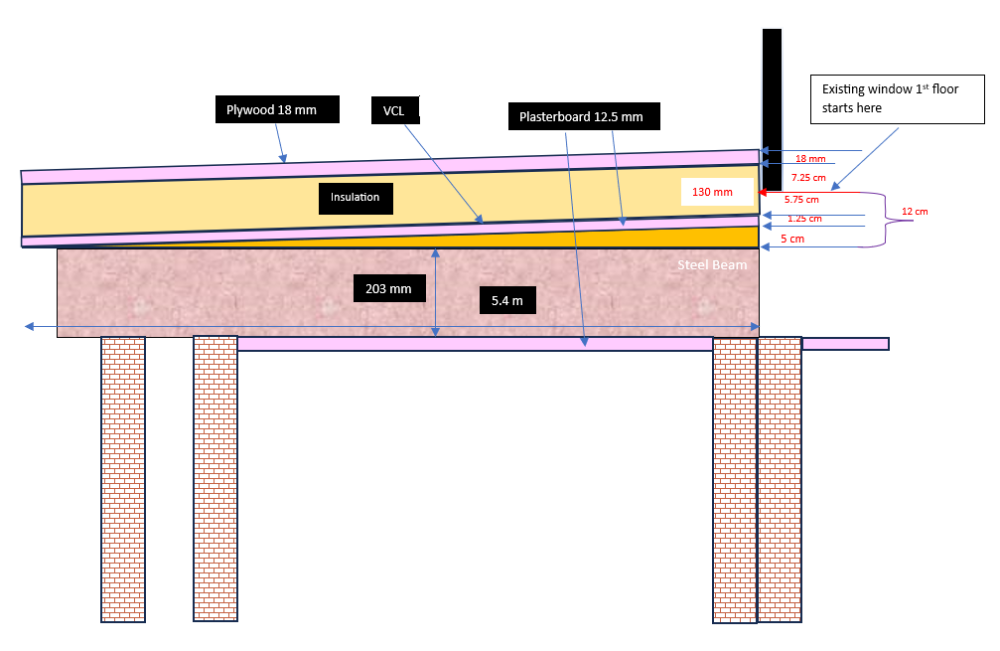

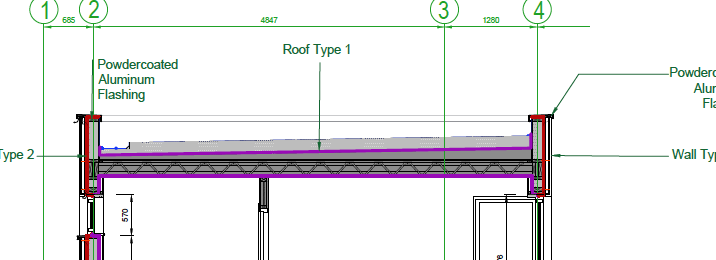

There appears to be an issue with the height of the new flat roof on the rear extension. The increased height doesn't leave enough space for proper flashing installation (clashing with Window). Unfortunately, we can't lower the steel beams as they have been welded. Could we discuss potential solutions to address these concerns?

- 8 replies

-

- flat roof

- roof design

-

(and 1 more)

Tagged with:

-

Hi all, I was wandering if anyone could help me with suggestions as to how to marry up my new warm roof build up with my neighbour’s property? The issue is that my roof was installed about 50 years ago and since then my neighbour’s property has been extended meaning there is no access to the existing fascia etc. to make this even more fun, I am going to add a warm roof build up of 170-175mm (Velutrix, 150mm PIR, 18mm OSB, GRP over existing deck). This brings the new height to around halfway up their fascia board. I have my neighbour’s consent to take my roof to meet their wall and close the 40-100mm gap which currently exists but I would appreciate any thoughts as to how best to do this while allowing the GRP to run high enough… ie. Should this be behind their fascia board? I have added a picture for reference - the gap is below the gutter line although it does not really show very well. Any input would be greatly appreciated! Many thanks in advance…

-

The only job for the VCL in a warm flat roof is to prevent water vapour condensing inside the insulation layer isn't it? Maybe it would be better to say .... condensing on any suitable surface above the VCL. Should, therefore, the VCL extend up the sides of the PIR insulation (as well as underneath it) ?

-

We are doing a renovation of our ground floor bungalow which has an extension at the rear. The previous owner had extended it around six year ago. Our building took out a spotlight in the flat extension roof to find there was no insulation, he mentioned that although this seems like a warm roof, there can still be insulation under it and he is recommending to do it to improve overall insulation. Since it is part of a larger renovation, there is no significant incremental cost to it, so I have the following question: 1. Based on my limited research, there is not supposed to be insulation within joists, so is there any benefit in doing it? 2. it seems there could be condensation issues if this is not done right, then is there a way to do it which gives benefits without causing condensation issues Overall I will be open to doing something because the cost is negligible and if there is a chance to improve insulation I want to do it, however if it doesnt give any benefit or worse can cause condensation then I would skip.

- 15 replies

-

- flat roof

- flat roof insulation

-

(and 1 more)

Tagged with:

-

Hi. My neighbour had a flat foof put on his extension in early September 2023. He loves it but doesn't know much about glass fibre. The builders put 1 layer of glass fibre matting on it 4 weeks ago but haven't topcoated it. It's too late to get a proper bond after 4 weeks surely? Why would anyone wait so long to topcoat? Just wondering.

- 7 replies

-

- flat roof

- glassfibre

-

(and 4 more)

Tagged with:

-

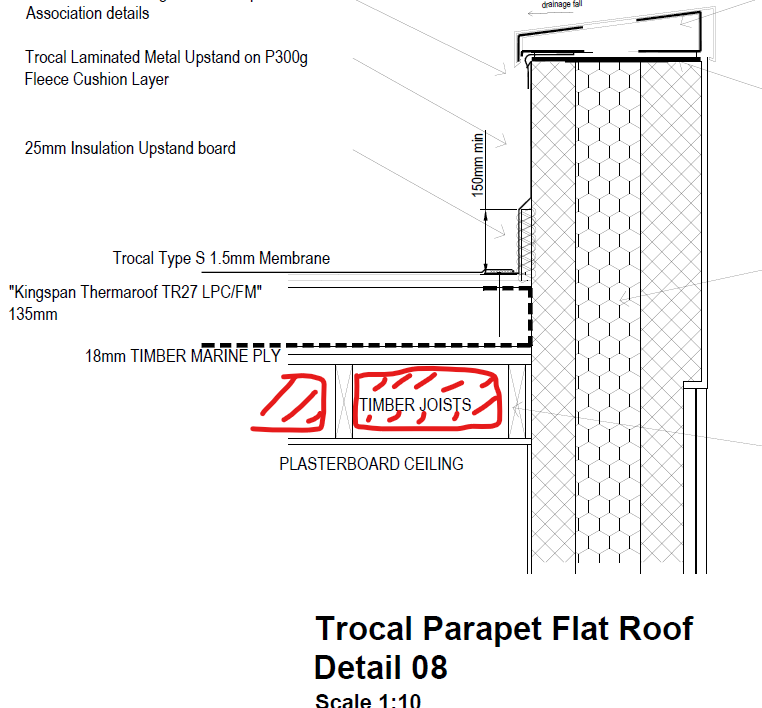

Hi All Im having a bit of a time with the Trocal install guys, most of which we have resolved, but there is one or two things outstanding. I dont have time to explain our dealings yesterday, as Im pressed for time before they come in today - but I will in due course, under the heading of things to watch out for!! - the roof is ply deck with VCL, 140mm insulation and Sikaplan S 1.5 membrane - I have a 400x400 box, which risies 150mm (i think) above insulation for the stove flue, which will be flashed. Are the upstands supposed to be insulated? - Similar question regarding the rooflight, which has some insulation as part of the kit, mainly inside or within the structure of the kit - insulate the upstands on the outside? - Are the cracks between the insulation supposed to be foamed - Im especialy thinking of where the boards meet from opposite sides of the apex? I cannot find the official Sika/Trocal details for this membrane (Sikaplan S 1.5) - anyone got a link? Thanks - Im expecting them in shortly/today... TIA, Jimbo

-

Some suggestions on waterproofing please. The flat roof to the garage is to form part of the patio. I feel the spec for the waterproofing proposed by the architect is inadequate. I also have concerns about insulation below the planter. The load bearing is provided by the beam and block flooring and I intend to build a fall towards the back of the garage where ity picks up draing form the rest of the patio. All this below porcelain tiles on pedestals The garage will have minimal heating. The two sections have conflicting text detail on the buid up, which doesn't help. Thought? 11G SECTION B-B.pdf 12F SECTION C-C.pdf

-

-

Hello folks. I'm converting an old brick garage into an office. Currently I'm levelling up the brick courses, as the old (rotten) roof achieved its slope via the bricks. These slopes weren't very pretty though and I'd been informed that the correct (modern) way to achieve this slope would be through the use of firrings. Mulling it over I've been wondering if I shouldn't just cut the angle I need into the upper side of each of the rafters though, being oversized at 195mm (I couldn't source 170s at the time, that could be delivered to my area), I wondered if I could sacrifice some of that extra depth, that I don't really need, to achieve the slope instead. Just wanted to know if I might be missing something, like bowing/sag, and that it's actually a bad idea? Thanks in advance.

-

Hey all, What are the going rates these days for flat roof installation with GRP, if the sub base has already been prepped ready for GRP install? I have flat roofs to main roof, terrace areas. Cheers C

- 1 reply

-

- grp

- fibreglass

-

(and 1 more)

Tagged with:

-

Hi, I wonder if anyone can help me make sense of this issue. We had a flat roof resurfaced and the roofer removed and reset the ridge tiles but has now offset them which looks odd to me. The pictures show before and after. Here is the explanation I received when questioning the need for this. "Hi there, we done it that way as your flat roof ends there, it's an end peak to install harris rails so it's flush we can change it if you wish buddy we done it that way for better run off on the roof from harris rail and the battern line under ridge" The flat roof is at the rear of the property and these pictures are from the front view. They fitted the old tiles but it looks like they broke one and added in a different tile. I'm just not sure how to respond now and if I should even have them back to change it. Many thanks Gary

-

Hello, I'm having kitchen extension built with a flat roof that will have a long 1.5m overhang. The roof will have GRP applied meaning an ugly GRP edge trim on top of the fascia. I would like the front of the roof to be completely flat like here: Is this possible without breaking any building regulations ? Any suggestions/recommendations would be greatly appreciated. Thanks.

-

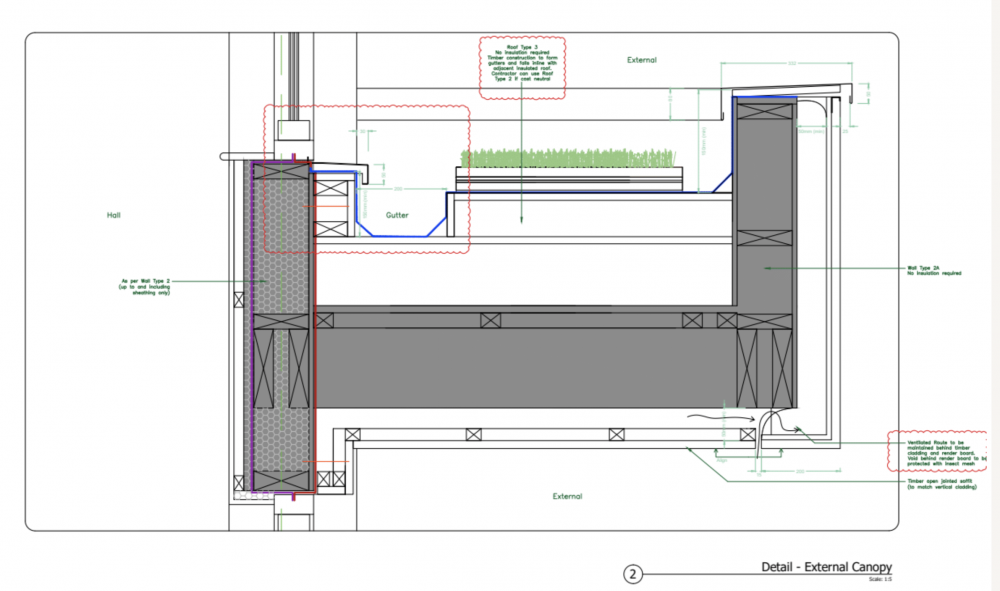

Hi, We have a warm flat roof design. This is causing two issues - Cost and airtightness 1. Cost for the Bauder Thermoplan covering is coming in at just shy of £150/sq metre fitted, based on 145sq metres of roof. Considerably more than I expected. The breakdown is Flat areas £10,000 Perimeters and roof light upstands £6000 Outlets £1000 Drainage channels £4000 A couple of questions spring to mind. Are the numbers quoted online for flat roofs, for totally flat roofs and is it normal to charge for the upstand separately? In fairness the upstand is 3-400mm tall. Are drainage channels actually necessary on top of a fall in the roof? These have been specified by the architect, but I cannot find them in standard details? We have a considerable amount of this type of detail, where the gutter area is priced at over £100 per linear metre by the looks of things. 2. Airtightness. The builder has questioned how we achieve airtightness under the roof as there will be a number of penetrations through the ceiling. Spotlights, cabling and MVHR. He also asked how do we tape the airtightness membrane with nothing above it. My thinking is that either we put airtightness membrane across the joists and then create a service area below so the only penetrations are the MVHR which goes between the joists and could be taped up. The alternative is to use two layers of plasterboard with a service void as it would be easier to seal this for the MVHR penetrations and we would tape the joints and tape the wall membrane to it in the service void. Thoughts? Looks like the airtightness question came up earlier in the year but there were no responses.

-

Not really having much information to go on when installing an ASHP on my flat roof, we decided to go ahead anyway. Questions that arose were about things like will it blow over, can the warm roof take the weight, can the warm roof take all the vibration, will it wear away the EDPM, is the condensation OK to go into the soakaway, is there much maintenance required, how heavy is the ASHP, can we get it up there, can we get the power up there, will the control cables reach where we want them, can we drill through the roof to get the pipes into the utility room without going through any services, can we waterproof the water and cable pipes to the EDPM, can the pipes be insulated. Well we couldn't find definitive answers to all these questions but we decided to do it anyway. So far, if we were to install it again, I would add to the list auto vents to both the flow and return pipes just before the ASHP as one has not been enough, and fitting later is a pain in the ... M.

-

Hi all, New member here with a bit of an issue. My wife and I have just bought our first home and we plan on converting the garage (not standalone) into a habitable room. Unfortunately the garage has a huge bulkhead inside it which severely limits its usability. Our house is semi-detached and the neighbour’s property mirrors ours pretty much exactly - there is a shared party wall between the two garages. The house is not in a conservation or other protected area. Neither of our garages are part of the original dwelling, they were part of a front extension which was done in the 1980s. The bulkhead is a result of an unnecessarily low flat roof (only about 2.5m from the outside) which means that if we were to build up the floor of the garage to match the floor height of the rest of the first floor, there would only be about 2.1m of clearance under the bulkhead (which covers half of the room). We therefore applied for full planning permission to our local council to raise the roof to 3m but they have said they will be rejecting the application because it will cause a mismatch between our property and our neighbour’s and therefore harm the character of the street. Our neighbour has also objected to our plans about six times! We have however already got a party wall agreement in place. The council's decision is due on Monday and if, as expected, they reject our application, we plan to appeal. I know the appeal process can be very long so my question is two-fold: 1. If the council refuse our application, can we still go ahead with raising the roof height of the garage to 3m under permitted development rules? This would remove our need to appeal to the planning inspectorate. 2. If permitted development rules don't permit raising the roof height, does anyone have advice on appealing a planning decision rejected solely based on "impacting the character of the street"? Thanks, RB

- 6 replies

-

- garage conversion

- permitted development

-

(and 3 more)

Tagged with:

-

Hello all! I'm looking to re-felt an existing flat roof on a town house in Crawley. It hasn't been touched for a good 30 years, although it has been repaired so is leak-free. I had a telephone chat with a duty surveyor for Sussex Building Control who seemed to suggest that a building control application isn't needed This is because the deck and below isn't being replaced, only the top felt, with additional warm roof being added on top of the existing structure. Would be good to know of anyone else's experiences! Thanks. Below is a rough outline of what we are planning. * Remove all existing roof covering to bare timber deck * Apply SA bitumen primer to whole of roof * Apply first layer of torch safe vapour control layer * Fix 50 mm timber kerb around whole of outside edge * Lay 50mm flat roof insulation boards * Create new timber outlets to downpipes * Apply torch on sanded underlay * Fix 100mm GRP drip trims to outside edge * Apply Technotorch mineral capsheet to finish

- 8 replies

-

- building control

- flat roof

-

(and 1 more)

Tagged with:

-

Looking to replace and refurbish an old flat roof. I have considered EPDM rubber rolls (Classicbond), however a roofer suggested for climates with unpredictable weather that I should consider Liquid PU or EPDM. Has anyone used this system for replacing a felt roof? I've had a look at a few vids by Steve Roofer The system looks promising, or is it too good to believe? I have come across the following products - Kemper Liquid Waterproofing - Hydrostop EU AH25 - Ecothane Liquid Rubber

-

Hi, I live in a 1930s top floor apartment with a flat roof above me. I’ve been considering getting new double glazing but I think my main issue is the roof is really poorly insulated which means the apartment gets freezing in winter and boiling in summer(31c at 1am and 26c at 7am). Is there a specific type that works best for residential? My brief searching seems to be that it’s mostly meant for commercial use and would make my apartment look a bit office like. Not sure if battening some type of lightweight insulation board against the roof and plastering over it would be a better solution? thanks

- 10 replies

-

- insulation

- flat roof

-

(and 1 more)

Tagged with:

-

I am building a single storey building under permitted development rights and am subject to a maximum build height of 2.5m. In order to get a good ceiling height I am digging below ground. The less space I can take up in the roof construction the less I need to dig out. I would like to get a U value of 0.15 or better and am happy to have any structural beams that may be required to remain exposed rather than loose space by covering them up with plaster board, providing it meets fire regulations. The building is to be an ICF construction, 12m by 6m and will not have any internal walls to provide structural support. I currently have 2 ideas: 1 an insulated floor panel called 'themafloor' by Thermohouse which is like an insulated form that can span the 6m onto which a 100mm concrete with rebars is poured - this would give a depth of 32cm but would need a small amount of additional insulation to get to a U of 0.15 along with a waterproof topping. 2 Cold pressed steel beams that span the 6m to which are attached an insulated roof panel from somebody like Kingspan. I am assuming that the cold pressed steel beams could be left exposed but I may be wrong. Any thoughts on these options and any other ideas would be appreciated.

-

I am building a single storey building under permitted development rights and am subject to a maximum build height of 2.5m. In order to get a good ceiling height I am digging below ground. The less space I can take up in the roof construction the less I need to dig out. I would like to get a U value of 0.15 or better and am happy to have any structural beams that may be required to remain exposed rather than loose space by covering them up with plaster board, providing it meets fire regulations. The building is to be an ICF construction, 12m by 6m and will not have any internal walls to provide structural support. I currently have 2 ideas: 1 an insulated floor panel called 'themafloor' by Thermohouse which is like an insulated form that can span the 6m onto which a 100mm concrete with rebars is poured - this would give a depth of 32cm but would need a small amount of additional insulation to get to a U of 0.15 along with a waterproof topping. 2 Cold pressed steel beams that span the 6m to which are attached an insulated roof panel from somebody like Kingspan. I am assuming that the cold pressed steel beams could be left exposed but I may be wrong. Any thoughts on these options and any other ideas would be appreciated.

-

So.... Old roof off this week, firings sorted so our roof has a fall on it and the professionals arrived today for the GRPing, thank god it's dry. On site at the moment and just had a sneak peak. We are so pleased with this compared to previous. This is the fall, not sure how the builders are going to deal with the exposed wood yet. Credit to the guys who were on site before 8am.

-

I had a felt flat roof replaced a few years ago by GRP. I have noticed that water is curling up behind the edge trim and round the back of the guttering onto the fascia. Some of this is making its way over the top of the fascia and into the roof structure. I think the crux of the problem maybe that the gap between the inner lip of the edge trim and the fascia is only circa 10mm. This means the gutter edge in places is mm away from the edge trim. I have removed the gutter in case it is too high and impacting the water flow, but it makes no difference. How do I solve the problem? Packing out behind the edge trim would increase the gap, but from testing it with a hose, it is not the solution as I gain maybe 7 or 8mm. Fiddly, but the best idea I have come up with is using a self adhesive flashing like AluFlash and stick it to the inside of the edge trim over the batten under the roof lip and down a portion of the fascia before trailing it in the gutter. Apart from having the edge of the roof refitted, is this my best solution or can anyone think of anything else I could do? Thanks Steve

-

GRP (God-awful Rubbish Period)

canalsiderenovation posted a blog entry in Canalside Bungalow Renovation

I'll start with the GRP roof but I'll dedicate this whole blog entry to which I will deem the God-awful Rubbish Period. This probably seems like I'm over exaggerating but there's just been a lot of things combined with work, personal etc and I have really been feeling the pressure. Intially, as they started laying the fabric the GRP looked OK but, despite what I would say is perfect conditions for the GRP going on from what I know through reading on here we, were appalled by the quality of the work. Without bombarding this blog with pics unless you really, really want to see them, just take my word for it, it was bad! I believe I this was subcontracted but as we have not been on site I think it's been done by the builder themselves. Needless to say I was not happy so met with the builder who muttered something about weather and acknowledged it was poor. There has been some improvement but I can't say I'm entirely happy but I believe this will be rectified, hopefully. I also raised the issue of the rooflight upstands not been GRPd to the roof and something is happening with lead flashing so I'm hoping that will be rectified too. Here is the current GRP as it stands, comments welcome because I don't know if I'm being over picky but I want to be prepared for meeting the builder this week so please give me your opinions. Roofing aside, thanks to the people that contributed to the thread on our ASHP and solar @PeterW and @ProDaveothers as I really feel I would have had a complete meltdown. For some reason the idea of fitting a PV immersion controller seemed to cause all sorts of issues and it's literally blown my mind trying to explain to people that should know more than me how to do it and what is needed. And my final rant, how is it despite giving delivery drivers instructions they still turn it in an articulated lorry the size of a double decker bus.... er no you will not that over a canal bridge! Took delivery of a bathroom suite after it was pump loaded over the bridge with the lorry blocking the farm who were not happy and finally unpacked it to find the whole lot was damaged. Can't get the same items now as they are out of stock but in some good fortune the bathroom company decided it was far too much hassle to collect them again so let us keep them and refund the money so we can flog them to try and pay for an alternate suite. We did finally get all our 12 panel GSE 3.84kw PV system and immersion controller for under £2300 which has now been delivered which is a relief. If the builders make as much of a dog's dinner of fitting this as they did of the GRP I'll have an absolute breakdown ? -

Ever since we moved in we have always been asked "is it two bungalows or one?" Weirdly it was designed exactly like the main picture (which was the start of our build as they were doing the footings). I think it was all a bit of a ploy. Roll back to early 70s when it was some sort of large vegetable patch. Planning permission was refused for two bungalows, various amendments and someone designed the bungalow as it is today, one bungalow suspiciously looking like two bungalows separated by a flat roof. I think they planned to build it and then attempt to get it split into two bungalows but it never happened. We have always wanted to somehow 'connect' up the roof and to be honest it's all been a bit vague on how this would be achieved. Mid build architect and builder got together, another £200 for some more beam calcs and over yesterday and today it is all looking a bit more like one bungalow. This pic is from the scaffolding and you can finally see the roof joining with the large flat roof extension. From the canal/bridge it now looks far more connected though this pic doesn't do it much justice (yesterday). And from the garden looking into our kitchen: What we really like is our ensuite, which, in the absence of any external walls will have a nice fixed rooflight on the flat roof just above our toilet/sink vanity unit which will be slightly raised from the ceiling (not the best pic).

-

Hello, I would like some info/advice regarding a cold concrete flat roof. Sorry for the length of explanation.... But first a little background info...... The house we purchased was gutted, renovated and then sold on to us by a local building company... All certs for all upgrades and works were checked and passed.... Our problem.... 1 We moved in Sept 2107 all is fine until the first frost off this winter late 2018..when we started to notice a water stain in the rear utility ceiling (formerly downstairs rear loo and storeroom). These rooms were incorporated in to the house via the kitchen to form a utlity/cloakroom and extra kitchen space..... The roof itself is around 8 inches of concrete topped off with felt.. This was refelted just before we moved in... And the rooms below batterned, insulated, boarded, skimmed and redecorated. Oh and rads fitted. Since this watermark has appeared and got worse over the last month or two.. I cut a peice of board out, to be greated with a soaking wet inner roof, droplets everywhere.... Our problem 2.... The house is a semi formerly a council house, we have great neighbours who are council tennents... They have the same sort of rooms as us but still the original loo and store (no heat sourse).. And attached to ours So taking advise online of fitting a VCL then a thick insulation then watertight layer is not really an option without affecting the council properties roof.. So I am left with trying to sort the problem from inside.. Although there is much advice regarding how this is now not advisable.and insulating from outside is they way to go... Is there anyway I can fix this from within... I am happy to take down the internal ceiling and start again. But what would be the recommended materials etc etc.. To ensure no water ingress... You can see by the images that there is no VCL inside and the insulation is very thin and not sealed in anyway. Just placed in the roof void not a good job at all.. ... Please please any advice would be gratefully received.... Mark