Leaderboard

Popular Content

Showing content with the highest reputation on 09/14/24 in all areas

-

Rightly or wrongly a self build is what I have always wanted to do. More to the point there was a very specific property that I yearned to build on. This week, almost 25 years after fist imagining it I agreed the purchase of the plot, a listed threshing barn with a smidge under 1 acre surrounding it. And so with my Wife and 3 year old son beside me we will set about making the property an economical, comfortable family home which will provide for us in years to come. Excited isn’t the least of it. Interestingly, despite my existing knowledge of the construction industry as a PM (and everything which is required prior to get to this point - Joiner, Supervisor, Site Manager etc) and the long standing desire the opportunity is also extremely daunting. Wish me luck, I’m sure we’ll need it!!!4 points

-

Yes, listed building consent and planning permission. The design has had to be extremely sympathetic to the surroundings (i.e no new openings and no out of character materials externally) and there is a measurable positive impact due to the proposed demolition of an adjacent agricultural building. In fairness I can thank my father and his partner for the work that has gone into that. It certainly didn’t come first time around and there was, how to phrase it, a significantly protracted review period. Sure, I don’t have many but here’s a teaser, there will be more due course!!! I’ll be back in a few weeks to meet some architects to tender for stage 4 so I’ll be taking some then.3 points

-

I think you may have to import them. I very much hope I'm wrong. The Berlin part of my family is coming over here soon (in a VW van) . Want some ? If you want to do your own research they are called ' Dachtritte ' (in Germany) I think many of them have a mechanism for changing the angle of the tread ( because of the change of angle on many roofs.) Here's a relevant (German) website and these cost just over 100 euros - But I'm almost sure it will be cheaper easier and quicker to make your own - if you are that way inclined.2 points

-

Easy @joe90. Just been to Berlin - family stuff, and asked that very question .... The steps are put in for Chimney Sweeps. Notice each of the images above lead to the chimney. So I asked the obvious question - and was told that a chimney swept from below and from above was '...much cleaner...' And then asked the next obvious question - which was met with a shrug. The other reason for the steps (or sometimes built in hooks) was for areas which have high snowfall - and thus steep roof pitches. The hooks are also lined up across the roof such that the gap can be bridged by scaffold board held in place on ladders which have small platforms on them. And of course Health and Safety - my raised eyebrows were answered by " Well would you want your chimney sweep dad to work on a dangerously steep roof?" As a small aside, Chimney Sweeps have to (by law) sign off every woodburner stove in Berlin. They sign off to say that the wood burner stove is working efficiently. And thus have a nice-little-side-hustle. Einfach!2 points

-

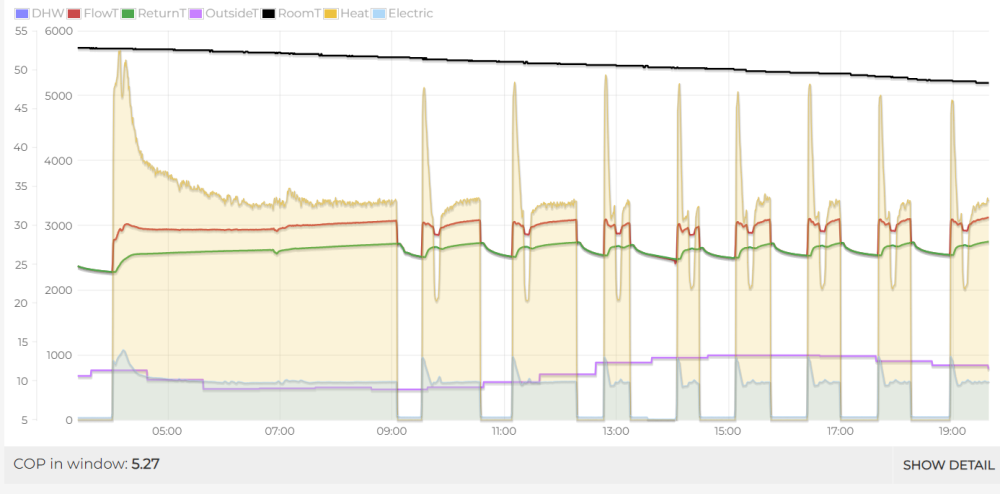

Hi, I have just started off in the exciting world of heat pumps. I have recently completed my diy install of a Vaillant 7kW unit and 250l Vaillant cylinder. Its a very simple setup with single zone covering underfloor on ground and first floors although there is only one active circuit upstairs as we don;t like bedrooms warm. I am monitoring on OEM which gives fantastic feedback so thoroughly recommend anyone doing this on their setup be it not a cheap option. Heating has been on for a few days now and I am getting strange on off periods throughout the day, is this normal? Curve was set to 0.4 but I have dropped to 0.35 as house was almost too warm. Pump has been running at around 3.3kW output and around 590W input, flow temp steady around 30degrees.1 point

-

@PhilT, thanks. That's interesting. What's the reference source for that graph? Is it as google found: "PV Optimized Control of Modulating Heat Pumps regarding PV Self-Consumption" (January 2019) by Christina Betzold and Arno Dentel? Link. I had a quick scan read. When I encountered: "The bi-quadratic-polynomial equation for describing the heat pump characteristics" I thought I might leave it to @SteamyTea and went to pour myself a drink instead.1 point

-

This depends on what you are controlling and what inputs it needs. You can't make a general choice, as it depends on context. A lot of this was discussed in my topic with this post summarising my final setup and we are pretty happy with it. In short I have a bunch of contractors in a CU extension next to the main Consumer Unit and these switch power to the HW immersion, slab heater and pump. These are in turn driven with 24 VDC control signals by an off-the-shelf ESP32 relay board running Tasmota. The Tasmota firmware is switched by my NodeRED app. I do have a lot of Zigbee sensors but I prefer to use TCP layered stacks such as Tasmota for any switched devices relating to Central and HW Heating.1 point

-

Ebay and Amazon both do 'em, I ordered a couple of simple steel ones to use as occasional platforms when we were tiling. IIRC the vendors were mostly German and Polish?1 point

-

I’m inclined to agree, architecture can and should demonstrate the past and the present concurrently. The very nature of this barns change of use (and an argument for permissions being granted) is due to its lack of relevance for its original purpose resulting in the building being in a general state of disrepair. We may seek to may subsequent applications to make additional changes but I’m inclined to believe that once we have opened each of the vertical ventilation slots (80+) you see in the photo and installed glazing to each the building will be reasonably well lit. For now it’s a compromise I’m happy to make to get moving!!! It’s a blank(ish) canvas inside.1 point

-

>>> I do question “no new openings” Me too, the openings in there right now don't look 100% authentic. I think we should concentrate on beautiful and efficient and great to live in buidings for the future. A lot of the old stuff, particularly old ag stuff, probably had 5 minutes spent on 'design'. And we're going to go out of our way to 'preserve' this? Ag buildings were built for storage and/or animals ffs. Wouldn't it be an idea to allow a little more slack for the new usage for humans? A friend has a listed place. Heritage were doing a barney about keeping some stairs - until the owners found someone in the village who had put them in in the '70s.1 point

-

Do you mean packed the frame in the brick work, or packed the glass in the frame.1 point

-

1 point

-

That spec appears to be the normal trickle vents and individual extract rates for a house without mvhr. Once you choose mvhr all those trickle vents and individual room extract rates do not apply and you design the mvhr to a different set of constant flow rates that are also listed in building regs.1 point

-

@Pocster - get the Dodgers out. I mean he's even mown the grass within a few mm of its life. There's nowt there that a bit of expanding foam won't cure.1 point

-

From an UFH perspective I originally had several zones each with a time controlled thermostat. It wasn't very satisfactory. Different rooms at different temperatures doesn't seem to work. The heat always leaks in between rooms faster than your floor can put it in. We were ending up with the system trying to heat the entire house from just one floor zone, which ended up very warm. I eventually ditched all of them for a single zone and no timer. Just a simple thermostat. Balancing by room was done by tweaking the flow rates and the flow temp was adjusted as low as possible - abkut 28C from memory.1 point

-

Similar project to me. I went with ewi, as it needed a new roof we converted it to a warm roof which allowed us to tie it to the ewi for air tightness and extend all the eaves to achieve this. You can use brick slips on ewi. We also had cavity wall insulation which had been poorly installed and as we're on the coast was a poor choice but as it's dried out it's an extra boost. We also installed new windows. We're slowly insulating under the floors with 100mm rock wool our heating bills are about a 1/3 of when we first moved in. We're still on gas but will be able to easily convert to a heat pump. Now we're slowly doing up the very dated but serviceable inside. It's a fun project and keeps me busy. It's surprising how quiet it is after all the insulation has been done and the kids are asleep.1 point

-

Welcome. Please excuse the cheeky question - you do have Planning Permission don't you.... for a Listed building? You're a magician if you have. Go to the top of the class. @Pocster will award you a jammy dodger in due course.1 point

-

Looks like a good opportunity, nothing is risk free in this space, provided you can get the plot for a good price how is the land zoned now - agricultural or ? The new planning regime looks like it will help you as infill like this should become grey belt or even brown field - if it was formerly the curtailage of one of the other properties, and there is also the new housing targets for councils so they need to build more houses. The challenge will be to get the locals onside so your plans have no objections and people / planners see your suggestion as the best use of the land and raises all boats in terms of value, character and that it matches the street scene, does not damage the overall feel of the area - essentially it looks, when finished like it has always been there. What did the planners say about the previous planning requests?1 point

-

@Post and beam, I have used that manifold on the supply side of my system (on the return-side, I use a smaller Ubbink manifold). These manifolds come with sound attenuation sponge pads that are inserted inside. Before the manifolds, on the larger diameter ducting (160mm Aerfoam) connection to the appliance, I have in-line flexible sound attenuator on both supply and extract. My system is effectively silent from the bedrooms. It is performing very well.1 point

-

Thanks for pointing this out. It makes sense - his first detailed suggestion was to build up the party wall with brick from the new concrete lintels, which I guess would avoid the point loads. It was my probably wrong assumption that the same concrete lintels would be used for the second idea he came up with that I described in my post.1 point

-

If pressure washing doesn't work, the next step up would be sandblasting. I'd not paint it.1 point

-

Hello, Just joined from Surrey. Looking at a potential property that may have significant repair works.1 point

-

I'm from London (UK). Having recently moved into a newly renovated house, there's so much left to be done. First building handrails for the stairs.1 point

-

Just been reading through my last post from end of May, and thinking how on earth did it take me so long to get to this one 🤣 A lot of blood, sweat, tears and swearing later, and i've finally finished the bathroom, which has exceeded what I imagined i might be able to create, I still keep walking in and thinking, naaa this can't be my bathroom. So another room brought to a close 🙂 Those panels on the wall were actually meant for the living room, sound absorbing panels for the home cinema, but despite having ordered 'Natural' and them looking off white on the internet, they came with a blue tinge to them so wouldn't have gone. When i asked for a refund, they didn't want them back and just sent me the money, so I thought they'd be useful in the bathroom, and have massively dampened the echo in there. Aside from not plastering the sloped ceiling, everything else you see internally i've done myself, including the cabinets, which I really enjoy making, i took woodwork at GCSE but was at school at the time when IT was just getting going and consequently we were all pushed down that route. Walls are painted with F&B Ammonite, and the ceiling is F&B Wevet, mixed by Johnstones Trade Best success? Probably trusting myself to measure 4 times, cut once, and actually get it right for once...The solid oak top on the toilet/sink back, £130 alone that cost me, but it came out bang on! Total cost for everything was just a shade under £4k. Onto my new snug next which is actually well underway, but i'll post another entry when its all done and dusted in a month or two's time!1 point

-

Hello I'm rennovating a mid 1800s cottage in West Wales so am looking forward to sharing experience and wisdom with other Member. I am also self building a timbre garden studio so look out for my first post about that in the Boilers and Hot Water forum. 🙏 Thanks in advance for any help.1 point

-

Hello guys Young guy doing a complete house refurbishment in Plymouth, Devon - here to learn about all things DIY and beyond. I will have questions for you 😁 Thanks in advance!1 point

-

1 point

-

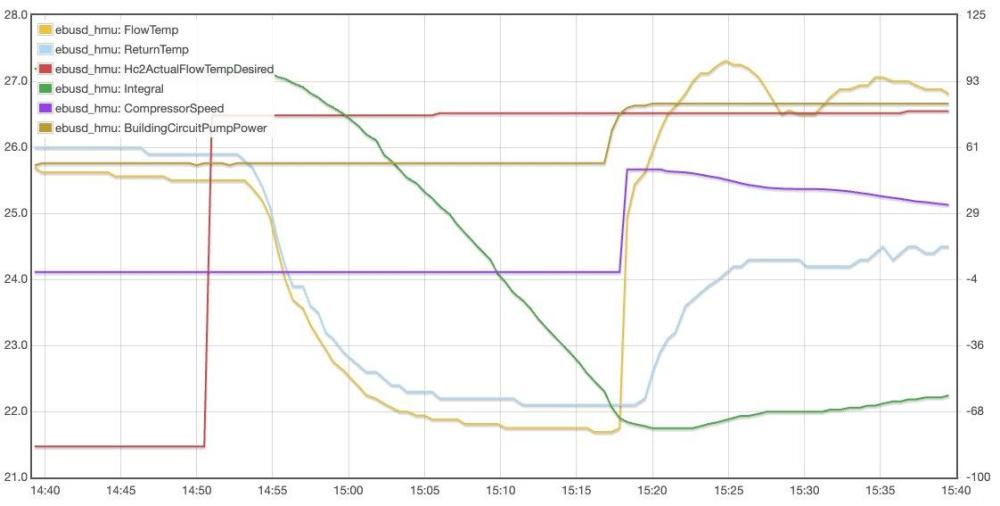

This shows this working, along with the compresor modulation: Target flow temperature increases (red) Nothing happens immedialty, as there is high integral from pevious low target temp. integral (deg.min) gradually reduces from 99 to -60 based onthe delta between actual and target flow temperatures. Once integral hits -60 heating pre-run starts and pump power increases (brown) Shortly afterwards compressor starts (purple) Compressor modulates trying to match desired flow temp (yellow) Integral increases if actual flow temp is above desired flow temp, and decreases if actual flow temp is below target. If the heat demand < min output, then (even at min compressor) the actual flow temperature will generally be above the target. If this occurs, then integral gradually increases based on excess deg.minutes. Once integral reaches 0, compressor is turned off. If the heat demand > min output then integral chaneg slightly, but won't increase to 0 over time and the unit continues to run.1 point

-

It's via installer settings of the controller or hydraulic unit (not the sensocomfort). I don't know much about control theory or PID's, but Vailant use this for couple of things I believe: - To decide when to turn on the compressor based on deficit degrees/min (vs. desired flow temp) - To decide when to turn off the compressor based on excess of degrees/min (vs desired dlow temp) This approach is preferable to a simple hystersis, especially when combined with compressor modulation (25-100% on the vaillant heat pumps). You are right, typically there is no need to adjust this and the default -60 degree-minutes is fine. But, if your ASHP is slightly over-sized and/or it is spring and you have low heat-demand, the theory says that decreasing this theshold this will result in longer cycles which should be slightly more efficient. This is because more deficit (if that is the correct term) is allowed to accumulate before the compressor kicks-in. This in turn means that the cycle should be longer as it's starting from e.g. -100 rather than -60.1 point

-

In the sailing world, boat stands for Break Out Another Thousand. I haven't figured out the self build version yet but there has to be one. I'm coming to the end of my build now, and can say it's been some of the hardest years of my life but come to the realisation it's been a series if problem solving and finding workable solutions day after day. It's all it is problems will come at you and its your resourcefulness and bloody mindness which gets you through1 point

-

0 points