Leaderboard

Popular Content

Showing content with the highest reputation on 08/19/24 in all areas

-

A couple of weekends ago, my wife and I spent some time at the MBC factory and got to ask some questions of the team there. There were quite a few different people there; sales, design, windows, even Kevin Blair, son of the founder Joe Blair, who took us on part of the factory tour. We were there for over 2 hours, including a 1-1 session where I covered any outstanding questions I still had. It was an informative day and great to see how they've developed and expanded. Seems they just keep buying more and more space whenever any adjacent units become available! Great session and I took a lot of photos. A couple are attached but the remainder can all be found at https://www.dropbox.com/scl/fo/11i21jn1n6ko1uclcbrm7/AMtb-Jt48ljlTc0lPfiQeKk?rlkey=f08zqofj4l1qllgrxphtnawtc&st=uxhdqk71&dl=0 They seem quite busy and are seeing an increase in demand from people building lots of houses, especially in the social sector where they explained it is easier for a company to secure any additional funding required for Passivhaus standards as they can offset it against potential future requirements to help with heating costs etc. From a pure materials perspective, they acknowledged the challenges of Brexit, COVID-19, etc. and how that initially affected costs and quotes quite significantly but things are a little more settled now and as they expand, they're able to secure pricing for longer periods as they're able to commit to larger orders. They're also sourcing from multiple suppliers and multiple regions as costs and availability flex due to growing seasons etc. Process Pre-start meeting - they discuss design guidelines and decisions with you and get your architectural drawings if available. MBC redo the designs in their software, including the 3D roof design. This takes about 4 days and they can then be provided back to your architect (if applicable) to update anything that did not translate from your original vision into an engineering specification. General arrangement - that design is then turned into the build instructions for the factory. The full structural engineering package is provided by Adept who MBC have been working with for over 22 years. They have 20+ engineers. Once erected - cut all your holes for service penetrations etc. and then MBC will come back to tape etc. and provide their full airtight package. These teams are all employed by MBC so are well versed in airtight requirements. PHPP - standard MBC timber-frame features are available for PHPP modelling, but they don't do any modelling themselves; you'll need someone to do that. Building Regulations - MBC don't do building regulations drawings/documentation so your architect or an architectural designer would need to do those. File ownership - MBC don't provide you with the source files from their various software packages but will do exports in various formats for you. General MBC Passive Foundation - they don't subcontract this (technically) as they own the company that does it. This is the same for the timber-frame insulation - they own that company too. You excavate the ground to (mostly) a 100kn bearing capacity and backfill with MOT Type 3. MBC then come along and puts in MOT Type 1, sand blinding, EPS etc. If you're putting UFH in the slab, you need to do this, MBC doesn't. Then comes the concrete. Site access issues - they can work around most issues. They've not been able to find some way to make it work. They send someone to the site to investigate constraints and then plan accordingly. What things influence higher cost - big open spaces, the weight of things (like green roofs) and features that require hidden fixings or complicated connection details. They have not seen any issues with mortgage companies or warranties concerning their timber-frame installations. Materials and Sources They source their materials from different places depending on the market and where things are growing. All timber is FSC sustainably harvested with documentation. They secure pricing with suppliers based on estimated cubed usage, and swallow any pricing fluctuations once a price for your timber-frame has been agreed. External walls and floors are treated. Some locations require additional treatments for things like longhorn beetles. Windows They supply and install Rationel and Velfac windows. Solarlux (generally aluminium) as a gap filler when there are requirements that can't be met by Rationel or Velfac. The Rationel windows are primarily timber/ali-clad with a larger profile, whereas the Velfac are composite, aluminium/timber and have thinner profiles. MBC are of course happy for you to choose windows from someone else so long as you use an installer that is manufacturer-approved and that they are installed to MBC airtightness specifications which they will provide. Choosing MBC to design and build the timber-frame and to install the windows can save some time in some situations; MBC will happily place the order for the windows based on their design drawings. Some window companies will want a structure to measure against unless you are willing to take the risk of measurements being incorrect. Furthermore, there is no possibility of the timber-frame supplier and the window supplier blaming each other for any issues if MBC does both! Installation of windows is by NKG as sole installers. They are very experienced with housing and deliver consistently good quality installs. Their window systems manager, Jason, was at Rationel for 15 years, was an installer himself for 3.5 years, and before that was a carpenter. How can you save money with windows? Bifolds are more expensive than sliders. The taller and wider the glass, the more expensive it gets, large spans especially. Openers are more expensive, but only marginally so in the grand scheme of things.3 points

-

I cast my floor to falls in the wet room corner and it's stayed perfect. Took some working out along with the Geberit wall drain. I'd do it again in a heartbeat but next time use a tile levelling system.2 points

-

1 point

-

Me too. It’s very hard. So far comparing MBC with Scotframe, Frame Technologies, Fleming, Potton/KTS and Turner Timber.1 point

-

1 point

-

That was my first unit and then moved to Greenwood and you cannot tell it's running. I would just do two dMEV units, as recommended in March. Yes - See above. My wife hated the first unit we installed before the noise.1 point

-

Good info. I'm currently contracted with MBC...it's been generally good but a couple of points which anyone building in Scotland may find helpful: 1. They can't supply Rationel/Velfac windows in Scotland (someone else has the contract for that aparantly). This isn't made clear on the website. 2. The groundworks team don't want to travel to NE scotalnd to install a raft, even though the timberframe side of it is fine up here.1 point

-

Zones means a buffer, so really would not go that direction. You need to look at system volume and flow rates. But if you have fan coil up and downstairs why bother with UFH? Your making life complex and expensive. Why isn't it important, if the heat pump is short cycling you may not get any cooling effect. Plus constant stop and starts will decrease the life of the unit. I did timings last year based on PV being available, this year on and forget, runs as it needs 24/7 uses nearly no electricity. House much more steady temperature also, peaks in temperature when sun comes out are quicker brought down. Set a weather compensation curve for cooling and heating and have the system self modulating so it's either heating or cooling and never off. A simple high hysterisis thermostat to flick between the two, or simple switch. Keep it simple.1 point

-

A couple of years ago it took me several months of every weekend to do the insulation retrofit install on my suspended ground floor. Working from the crawl space under the house (I had finished floors in most of the rooms that I was reluctant to rip up, ceramic tiled and oak boarding) but I have absolutely no regrets. It has had a bigger individual impact on energy reduction than double glazed windows, cavity wall or loft insulation did. I only wish I'd done it 33 years ago when we moved in to the house - I was younger, fitter and it would have hurt less!!!1 point

-

Uw value. That is the whole window U value as opposed to UG which is just the glass. How are they installing them. You really want them foamed in with airtight expanding foam. This will give a good degree of airtightness and eliminate the thermal bridge around the frame. Many will install in the hole and then cover everything leaving a void and you get mould around the window.1 point

-

Planning appeal now submitted. Speaking with the consultant we are looking at 4-6 months of a delay based on what they are seeing in the area. The consultant is confident that we have a very strong basis for appeal. On prepping the appeal it really puts into cold hard light how the planning department have had to work hard to find a reason to refuse permission. They are required to apply an overall planning balance and should have given weight to the sensitivity we had placed across the design, orientation, scale and mass. Instead they have ignored every area where we excelled in design and effectively pointed to one subsection of a technical advise note, made a subjective judgement that it should be applied, and then used that as the entire basis for refusal. From their own guidance: "Determining planning applications and considering enforcement investigations is a process of balancing and mitigating the impacts of development. In order to do this, Planning Officers apply varying degrees of weight to different aspects of the development depending on the level of harm. Therefore, it should not be assumed that a proposal which fails to meet all, some, or even any of the above tests would be refused. An application would only be refused when, on balance and in the public interest, the cumulative impact of the development outweighs the benefits." Hopefully we will have better news around Christmas...1 point

-

They were a great company to work with when we built in 2014 - one of the best we used on the whole build. It sounds like they've tightened up and become more professional and organised, which is great.1 point

-

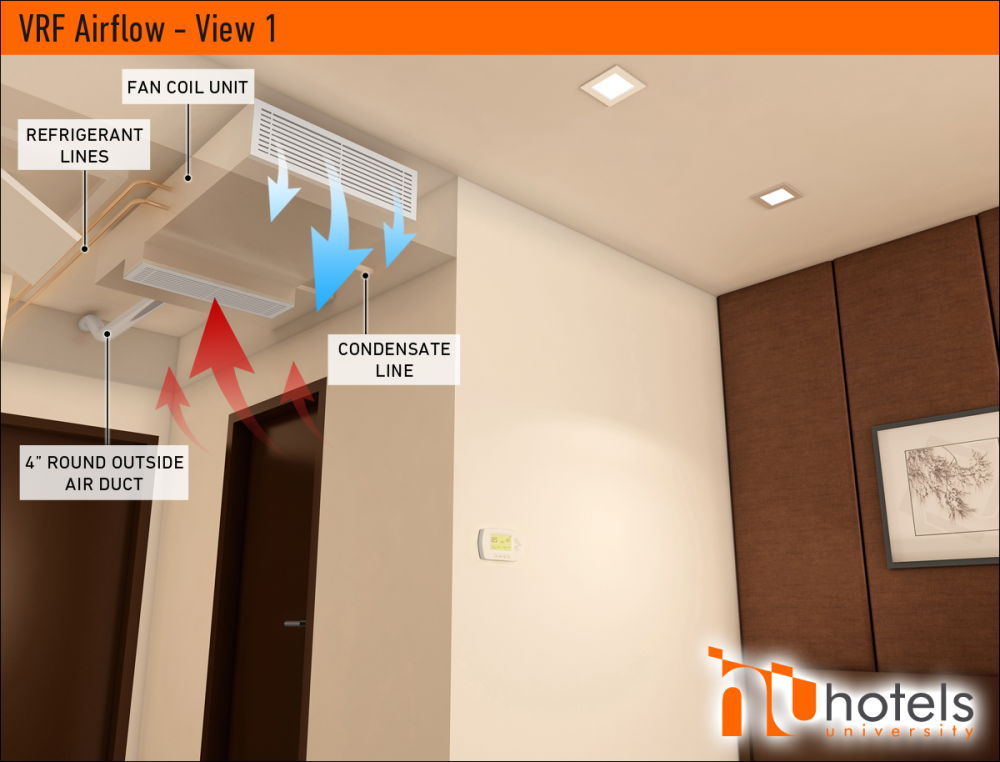

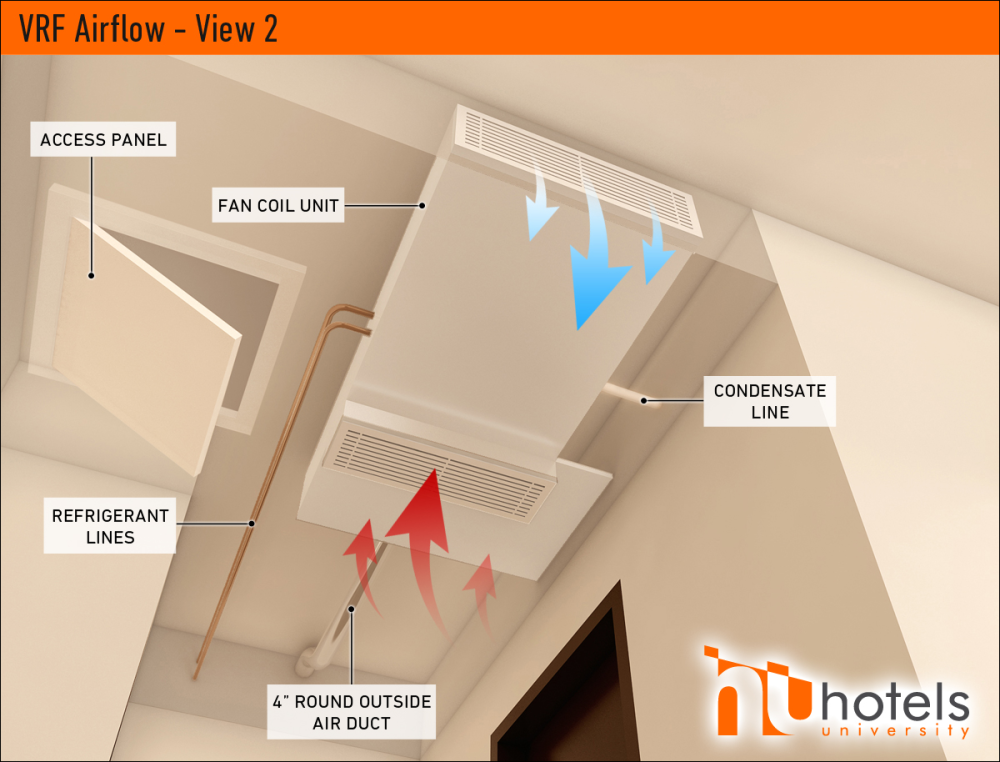

What you're describing is exactly what is being used in commercial settings for many years: VRF Systems, i.e variable refrigerant systems. You'd have experience them most probably in hotels and similar. Essentially there are big condenser units and then there is a main trunk with both hot and cold refrigeration lines branching to each unit. The cool thing is they can even balance themselves out, i.e if one unit needs cooling, and another heating, they can work between each other as condenser and evaporator and not use the big outside unit. Really cool stuff, but overkill for residential for sure.1 point

-

Hi, we are currently building a SIPS house in Perthshire. Our third building so you would think experienced but a 13 year gap and everything has moved significantly including costs! We are looking forward to learning a lot from everyone.1 point

-

Re Fan Coil Units, when we fitted ours 7 years ago, Panasonic called it an Air Rad. We went for it to provide spot heating/cooling in the main (and only) upstairs bedroom. What they didn't tell us was that, in heating mode, the valve in the unit is thermostatic and will only open when the water reaches a particular temperature (circa 50C iirc). Of course, with the ASHP running UFH for the rest of the house, the water never reaches that threshold. It works absolutely fine for cooling, but we ended up adding a small flat panel electric radiator for the odd occasion we need to heat the room. No idea if this is something that has been solved in more recent FCUs, but worth checking specs before purchasing.1 point

-

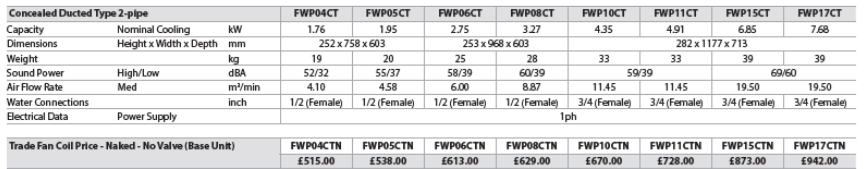

That quote about Mitsu vs Panasonic is 5+ years ago so no idea how it applies today. I've worked with 4 different Ecodan 8.5kW installs though, so can vouch it works fine for cooling. Another Daikin option is now available here: https://www.oceanairuk.com/product/daikin-fwp-2-pipe-medium-static-duct-fan-coil-unit-2-61kw-6-47kw/ It's actually the FWP-CT now, not -AT. (I swear these manufacturers much change model numbers more frequently than they sell units lol.) This is the MSRP for the naked 2-pipe FCU, just takes mains input and (I believe) a 0-10V signal to control speed -- it's inverter driven so very fine grained controlled over speed vs the old 3-speed coils, which is great for anyone like me integrating it with advanced controls (e.g. Loxone). Per JohnMo comment, I put separate thermistor on the flow pipework to shut off the fan if there's a slug of warm water in the pipe (i.e. when switching from DHW reheat back to cooling) But agree with Dave Jones that putting a concealed ducted unit is a lot of extra work, and especially so if retrofitting them like I did. If you can figure out a plan for the condensation drain and don't object to the aesthetic, wall mounted is a much more sensible way to go. The unit is actually inside the room being serviced, so ~100% efficient whereas the ducted ones always loose a bit of efficiency to air leaks, and the pipework and heat exchanger itself sitting inside a non-serviced space.1 point

-

Plus 1 Lots of videos available these days to show how systems work. Also parts can be seen at, for example, the Rubba seal website. Good luck Marvin1 point

-

1 point

-

Most definitely don’t There’s a number of reasons The first one being that the floor would be damaged marked or stained Also if anything is likely to move it’s the floor Chipping the bottoms of the wall tiles Also if the floor is running out which most are It’s neater to do the walls first1 point

-

Well I've got it wrong then haven't I... Nowt new about that. I'll dig out the plans and post them here. I bet I've got the terminology wrong, rather than the drain being a construction error.1 point

-

@garrymartin Interested to know what they said. My last quote from them for our 180sqm two storey home was £132k for the passive frame, and £44k for the passive foundation. £20k less for the High Performance frame.1 point

-

Only appliances you can reclaim VAT are extractors or hob with built in extractor. Don’t believe suppliers can zero rate any part of a kitchen unless they are fitting it, ie. you should pay the VAT and reclaim it at the end.1 point

-

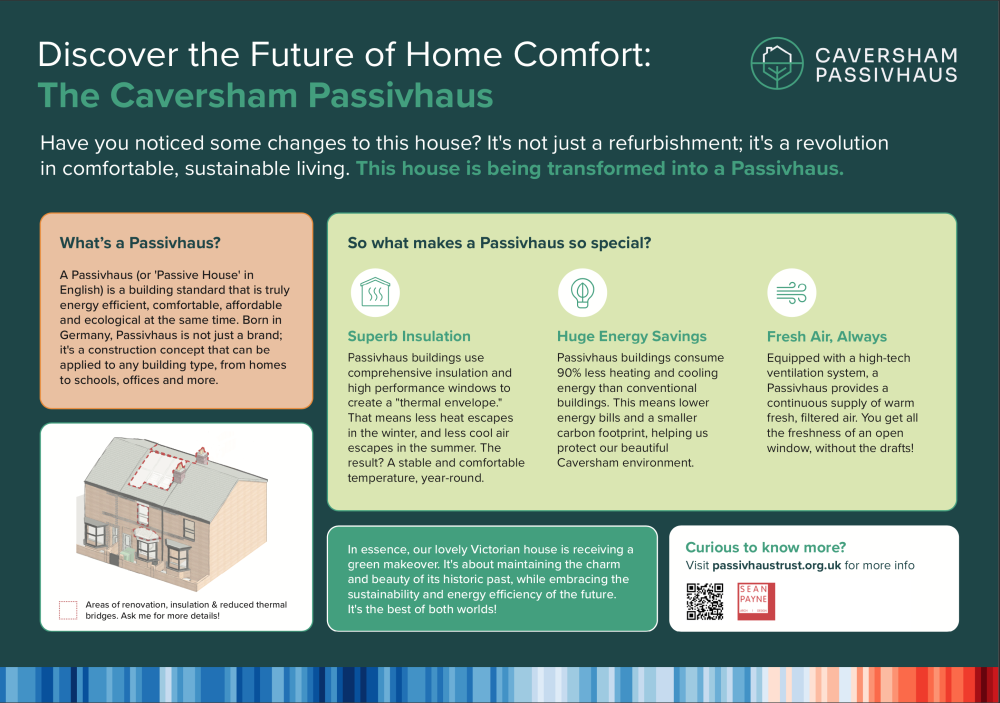

We've taken on the challenge of transforming a charming yet crumbling Victorian terrace house in Caversham into an energy-efficient gem. Our goal is to reach the EnerPHit standard with a Passivhaus retrofit. The house's unmodernised condition offers us the perfect chance to not only perform a comprehensive retrofit, but also rework the layout and expand the property.1 point

-

I did floor first then protected the floor with Correx. I then used a homemade tile levelling system to place the second tile up. For the bottom tile I turned it over, placed it on 1mm packers and marked the cut line with the laser. When you turn it back it's bang on: (I should add I can't tile to save my life! Up until then the wall boarding was all perfectly square 😂).1 point

-

Google is amazing, but sometimes you can't see the wood for the trees. Too much information and many hours lost trying to find the answer you need. Then the inevitable happens and you get side-tracked. The sun sets and you decide to put that darned DIY job off for another day. All you wanted was a simple answer to a simple DIY conundrum. Hopefully, I've found the right place for tips and advice, so no more excuses and no more delays!!!!! I've renovated two old properties and still feel like a beginner. Hopefully, I can find the answers to some DIY problems on this forum, and perhaps.... I can help others too! Thanks to all, for this fantastic forum, I wish I had found it sooner.1 point

-

1 point

-

Hi to you all recently purchased old Salvation Army Hall just received decision notice so can start conversion to two bedroom detached house.1 point

-

In my opinion you can never stop moisture, only manage it. If you apply something like bitumen then it's lightly it'll cause an issue to pop up elsewhere. Cleaning the bricks with acid will treat the symptom but for the ultimate longevity of the bricks and the building i'd be aiming for something that took away the moisture more mechanically like a french drain.1 point

-

Yes, looks like efflorescence. You can treat if with a weak acid solution, from a builder's merchants, of it bothers you.1 point

-

So he's basically gone against all standard practices, the manufacturers recommendations and all logic.. Rather than do it properly Don't allow him near your house again. When it fails, which it will.. Get a proper tradesman in.1 point

-

The Church being the largest and richest landowner in the country currently has applications going through in different locations for 8000 homes plus a land bank for another 30.000. Ask them if they've got any self build plots available.1 point

-

After the above, I did a little more fine tuning and ended up Restart hysterisis of 4.9 and shut off hysterisis of 2.8. this suits heating and cooling. Moved the heat pump on to cooling using a target flow temperature of 14.5 at 30 degrees to 15 at 20 degrees, so cooling now also self manages, been on continuously since July, hot day the heat pumps runs 45 mins on and about 20 mins off and a cooler weather doesn't switch on at all, been off since midnight. Costs nothing to run. If it's sunny I need cooling, so PV available.1 point

-

Hi. I've done conversions from gravity / pumped digital over to non-pumped where we've either fitted an UVC or a combi. It's simply a case of either having or not having the pump set for the digital shower, so you will only have a nice quiet digital "mixer" to go with your setup. All good, but remember that you can get al all exposed / surface mixer shower which will take a hot and cold feed, and have zero electromechanical / moving parts to fail. The digitals showers seem to be reliable, as long as you stick to the big names. Down to choice, but I personally don't see the value of introducing a digital mixer other than for the look / being able to switch it on from the bedside. The answer is, it'll be nice and quiet, so yes, digital + combi will get you what you're after.1 point

-

0 points

-

We knows that feeling While there, have you considered adding under-floor airtightness and insulation? /ducks0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)