Leaderboard

Popular Content

Showing content with the highest reputation on 07/02/24 in all areas

-

The MCS database may be helpful, giving SCOP test results at different flow temps (typically 35 to 55) for most (possibly all?) commercially available MCS certified heat pumps, now including the new Octopus Cosy 6. https://mcscertified.com/product-directory/ While accepting that design and operation mode are most important, it is worth noting that, generally, the MCS tests show that R32 heat pumps have significantly better SCOPs than their R290 equivalents. You can see this most clearly by comparing like for like R32 vs R290 models, for example the Misubishi R32 6kW model PUZ-WM60VAA has SCOP of 4.81 at 35degC, compared to the Mitsubishi R290 6kW model PUZ-WZ60VAA (a much newer model) which has a SCOP of 4.39 at 35degC2 points

-

By lobby I didn't mean provide a submission to the local plan. As you say an individual has little power, but if you can get councillors on your side it could help shape the policy in your favour2 points

-

You require. I take it you missed the first year lecture series Manners: An Introduction. And I take it you repeated your demand because you didn’t get the response you hoped for instantly. May I suggest that if you asked in a more appropriate and courteous manner more of the many helpful peeps on this site might be happy to respond.1 point

-

1 point

-

For me I would weigh up getting a bit of professional advice (say £300 - £400 + vat) against say a days builder's labour and materials that could prove a waste of time.. or make things worse. I hope the following helps a bit. Take an old building like yours 1920's. Door frames tended to be made out of 6" x 2" timber with bricks over. The bricks and timber interacted a little so developed what we today call composite action.. in those days they knew it kind of worked but could not quantify it. Window frames were more sturdy timbers and these too interacted with the surrounding walls. I see this a lot where folk are making open plan spaces and wonder why I want to introduce wind posts and other stuff. But I point out.. hey you now have PVC windows which are very flexible.. some silicon and plastic DPCs which create slip planes.. so now there is no interaction and things start to bend / protest. For me I go back to the way to when the building was constructed.. try and understand what has changed and when.. then try and work out what to do next.. in a cost effective and buildable way. To do this well you need to examine the whole building to get a feel for it and then look in detal at the windows / doors etc.1 point

-

Is it pressurised? if not put some pressure in it and make sure it holds - only way to know is test, use air or water.1 point

-

https://oilprice.com/Latest-Energy-News/World-News/EU-Hits-Record-74-Zero-Emission-Power-Generation.html1 point

-

Welcome Tam Sustainability, the migrating metaphor, it can mean whatever you want it to mean. Personally, my take on the use of timber (in all forms) needs to be from new development, on old industrial wasteland (we have a lot of that here. Cutting down old stock and replanting is carbon dioxide equivalent release positive (generally released more CO2) and causes other environmental problems. Production needs to be in countries that have the lowest CO2 emissions (lots of renewable energy) and must be done at the largest scale that is practical. Midern mass production is generally the lowest environmentally damaging, old infrastructure and work practices are generally the worse. There are some crops, like bamboo, that can be in effect coppiced, and make a hard wearing product, so I would tend towards them. Retail price has very little to do with quality, more to do with marking and PR (I could employ a recent graduate at £25k or £70k per year to do the same job, the product would be the same). One problem with end of life usage is that timber burns, and that is how most will be disposed off, hopefully in a waste to energy plant (have a large one if those in Cornwall). Trouble is, regardless of how recently, or distantly, the tree was grown, and how long it took to grow, burning it release CO2, and that is a bad thing for a CO2 saturated atmosphere. But there is no system, that I know off, that will take used flooring and reprocessed it into a useful product that will sequester the embodied energy and carbon for a century. Transport cost do not bother me in the slightest, they are such a small fraction of the whole they are not worth considering. Transport is getting much 'cleaner' by the year. I recently had the latest round robin email from Craig Jones about ICE, I really need to look at the database again and see what has changed, it is usually surprising what has low processing emissions, and what does not. So to answer your question, I can't really. My preference would be floorboards, or chipboard, and carpet. I do like a bit of parquet though. One area I have never looked into is the processing of timber composites (I worked with plastic composited). I suspect they use very little 'chemicals' in reality and most, if properly controlled, do not pose a large scale environmental problem.1 point

-

1 point

-

1 point

-

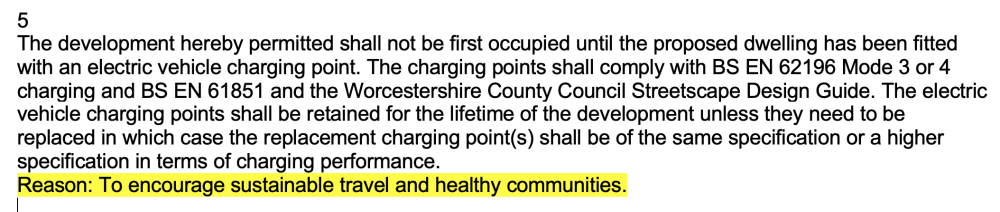

If he responds... 😉 They were very carefully crafted questions that make it difficult to respond in a wooly way that would be open to further interpretation, and he'll know exactly why I'm asking them! I have the details of what will almost certainly be my MP, as well as the details for the Green Councillor that covers the area where I currently live in Worcester, and the Conservative Councillor (who also happens to be chair of the Planning Committee) for the area that covers the plot. I intend to write to all of them to a) explain how a very sustainable development has already been refused on grounds of sustainability (!!) and b) to ask for support for any subsequent application. As you rightly note though, they're likely very busy right now so it's on my list of things to do in the coming weeks/months and possibly after engaging a planning consultant (feelers out to one of the best ones in our area right now).1 point

-

I think (hope) this gives you a bit more direction on how to proceed and if appropriate you can quote the head of planning. I know they are busy with the election but what about your local MP (all parties banging on about building more houses and being “green”).1 point

-

Part of the problem when requirements drop out of the regulations, they don't get as much attention as when new requirements arrive. Unless specifically asked, a BCO isn't likely to point out that something isn't needed anymore, they'll just ignore it. Guys on site having got used to doing things in a particular way, usually plod on until told otherwise.1 point

-

As you have worked out, second one is probably best. Priority is to ensure the adjacent paving falls (slightly) away from the house. Then it is a matter of working with the lay of the land as best you can. Trying to make the top patio fall away from the house may need a lot more excavation and a step/retaining wall1 point

-

Seems like a sound and pragmatic principle to me. I am also an exponent of the idea that you can either spend time saving money or spend money saving time AND, for me, often times its just fun to give it a go after extensive research to ensure success while having a backup route to the professionals if needed. Occasionally we do a job twice once in house and once via the professionals, EG the air test, many here do their own to get an impression of the air tightness but we need a registered outcome so had to have a professional do one as well. We ran ours got a result (.29 on the PH scale) the pro came in and got it as .2 on the PH scale so we weren't that far out and on the right side - very pleasing even though I doubled the 'cost' but learned a lot along the way.1 point

-

An update before you are next on site @Hastings in case it affects your planning. There have been no further responses from the Victron forum so I have done a bit more thinking about possible harmonic filters to fix this. The VSD manufacturer does a 50A filter <EMC Filter INFILT-M501> but it is £235 plus shipping and VAT. And filters that are too big may not be effective IME. I have actually got some sample toroidal choke cores which might well serve as the basis for a series filter, but annoyingly I cannot find enough design information, there is some stuff on the web e.g. this article and this one but mostly intended for big industrial applications so I have no way of knowing what component values would be correct for a small VSD. So we are back to the thought of replacing the pump with a smaller, single phase one. The automatic Steelpumps X-AJE80B would be good, but any of the other three mentioned upthread would also do with a suitable pressure flow control. They all have a suction lift of at least 7m which should be enough even allowing for 1m head loss in the suction line. As I wrote previously so it all depends on whether you want to stick with Steelpumps, go for something that also has spare parts availability and the best suction lift (DAB), for the lowest power consumption but not repairable (ST) or for the really cheap and cheerful option (small Clarke). Given the price of the Steelpumps option and that the rest are quite close I think my favourite would be the DAB62 e.g. from here, I see they also stock the Clarke controller which I have found works fine. HTH. Do let us know how the existing pump performs on a mains 3-phase supply if you are able to test it.1 point

-

I started reading about rain harvesting and two things hit me: even allowing for the sewage % thingy our water bills are so reasonable that payback looks unlikely; secondly the sheer tonnage of plastic involved made me feel that such laudable sounding aims might not turn out to be any kinder to our planet, maybe actually worse.1 point

-

I agree, I employed a builder to do the work I knew I was either not good at or would take to long, I did the stuff I enjoyed and was capable at doing. THAT made the self build enjoyable.1 point

-

+1 and I'm very happy to pay for my planning consultant. I've noticed BH has a strong DIY ethos. I even remember somebody on here commenting that if you don't have hands on the tools, you're not a self-builder. In my opinion, being a successful self-builder (which I'm hoping to eventually be), involves knowing when to buy help in.1 point

-

The builder is wrong. Maximum height under PD where it’s adjacent to a highway is 1m.1 point

-

I looked into this years ago and my main worry was storing and moving water above living accommodation rather than just having a waterproof cover. IF I did rainwater harvesting I would use an underground tank filter and pump.1 point

-

Trouble with Scotland MVHR is mandatory for an airtightness of 3 or below. If you hit 2.9 you have to install MVHR before BC sign off. But have to say MEV or dMEV can be made to be incredibly efficient with self modulating trickle vents and dMEV or MEV altering flow rates based on demand. Very low running costs, no filters, no heat recovery but on an otherwise well insulated house running costs are going to low anyway from a heating perspective.1 point

-

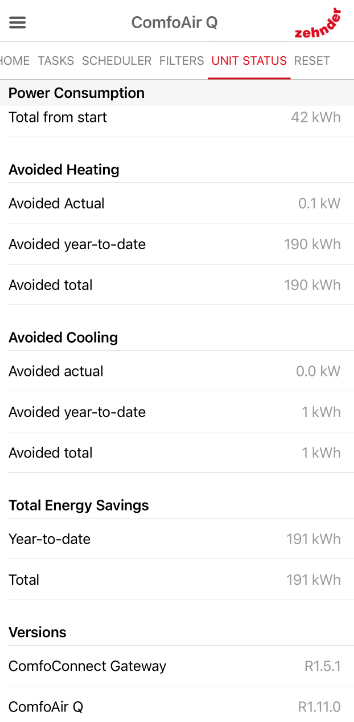

Our MVHR has been running for about a month now, had a look through the app and it claims to have saved 191kwh of heating/cooling in that time. A little sqewed maybe as all the heating has been free from the sun as the ASHP has provided none. Be interested to see if this figure stacks up later in the year as its suggesting £40 a month.1 point

-

Just to lighten the mood a bit, here have a bit of a laugh .... Yes it did hurt and I still (8 years ) later have the scar and when my foot is cold, it hurts more.1 point

-

0 points

-

If those sustainability guidelines were applied here, none of the plots in our road would have got planning permission.0 points

-

0 points

-

Yet. If everyone harvested rainwater then the % charged of the input water would no longer pay for our sewage system. Anyone fancy inventing a poo-o-meter that measures household output? Might make your millions if you patent it.0 points

-

Why not go straight to the organ grinder and not the monkey - ring the planners and get a definitive answer.0 points

-

Yep and I know of people who have ‘purposely’ achieved slightly higher than 3 to avoid putting it in. The consequence of this requirement in Scotland is if you make any reasonable attempt at air tightness you’ll be below 3 so therefore you’re better to do it properly and aim for below 1 or plan to be above 3. I was told of a situation where someone achieved just over 1, couldn’t afford the MVHR system as had run out of money so put holes in the building to get it back above 3.0 points

-

Spot on. It never ceases to amaze me that almost all "complaints" have no valid planning argument. Our own application had a neighbour that objected, with one of his objections being the poor condition of the private access road (especially in winter) and the addition of more traffic to it. I had the deeds to a number of the properties in the estate, including his, and all owners were proportionally responsible for the good upkeep of said private access road!0 points