Leaderboard

Popular Content

Showing content with the highest reputation on 08/19/23 in all areas

-

Nothing is treated apart from the base plate (which I also inserted to the plastic battens. Yes I have the wood treatment ready and compressor etc to spray it (so it goes into all the joints). But i will be brushing an additional coat on the cut ends first. I am thinking of using flooring varnish on the inside 🤷♂️.1 point

-

1 point

-

1 point

-

1 point

-

As above while we all give advise to help where we can this is certainly a matter where you will have to seek professional legal help.1 point

-

You appear to have a claim against the Architectural Designer - not an architect. Do you have written evidence of the instruction to produce Building Regulations Compliant drawings? If so then yes, on the face of it, you may well have a claim. What's the point of the claim? Have you suffered a material loss? I ask because you - yet - haven't mentioned how you have suffered a loss because of the non-compliant drawings. The construction has been signed off. How are you suffering a loss? Please bear in mind we are not legal experts here. Just hard-bitten, interested, supportive amateurs. To verify whether you may have a claim please consult a legal professional.1 point

-

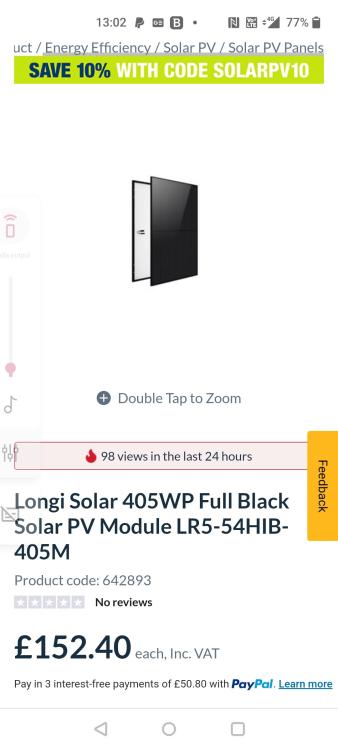

I did full DIY on the solar install, except the battery. The PV is basic install with normal inverters. My second array I did a write up on this thread. All costs are included. The battery system will be a Givenergy "all in one" system with full off grid switching in case of power cut. That isn't that cheap at £8200. Without installer permissions you cannot install and commission fully.1 point

-

Mine was something similar, I describe it as over sized architraves that are only fixed to the window and doors that let these unit float in the opening, same on both sides1 point

-

They are fixed at the bottom and cover strips either side and top allow the “logs” to shrink, there will be a 35mm gap at the top of both to allow this (I will do you a diagram later, tea break in progress 👍).1 point

-

Went past an electric wholesale yesterday they had loads of panels. I'm getting a battery, one week lead time and that's basically delivery time.1 point

-

In the end I put the doors in the sun which helped to dry out more. Tge next day they were pretty dry, sanded down with 120 grit and just applied a second top coat. Will now wait 24hours before final coat....absolute pain and an email on its way to FB with feedback!!1 point

-

At the edges of a flat roof the VCL should be continued up through the thickness of the insulation to join with the waterproof layer.1 point

-

Basically wet plaster isn’t completely airtight Dot and dab if done correctly is just as airtight as wet plaster The feed back I get from wet plaster is it can feel quite cold in comparison As with our first build I will do all the plastering myself and could do wet plaster or dot and dab Wet plaster being much cheaper But I’ll dot and dab and skim again Times have moved on1 point

-

I totally agree with your colourist, F&B can be a nightmare on wood, esp MDF. There are much better paints IMHO1 point

-

1 point

-

Make your back board (MDF, Ply, OSB etc) a little larger so in the example above it goes all the way left to the corner of the room, a bit further right behind the feed pipes and all the way down to the floor. then it is simple to plasterboard and skim around it. Set the back board flush to the wall so you are plastering up to it, NOT behind it.1 point

-

1 point

-

I've seen some pics on here before, so you're not the first, but too long ago to remember all the details. I have a feeling they were in a hallway though? I'm likely to fit a single strip as the main lighting in my galley kitchen later this year. Mainly on the grounds of practicality - there will be too many MVHR ducts and cable runs in the ceiling to fit decent downlighters, and I don't want anything projecting down to block the wall unit doors. Though I've not entirely ruled out a concealed strip. Add LED strip with a high CRI (Colour Rendering Index) to your list of requirements - that is, a CRI of at least 90.1 point

-

Define what you mean by "heat pump installers" I have fitted 4 of them now, (one being my own) and If I were not so much set on retiring, I could no doubt do a lot more. But I can guarantee I don't appear on any list of "heat pump installers" anywhere. The vast majority of plumbers and electricians, those that can read an installation manual, could fit heat pumps if there were incentives or even the will to do it. but at the moment all they see is "reasons not to get involved"1 point

-

Precast concrete lintels here separate for each leaf. No need for any cavity closer although I did make OSB window boxes. Simply install the windows just inside the outer leaf. Use A/T membrane taped to the window and tape to fix it back to the inner leaf. Screw J beads into the windows and fix your plaster board reveals and heads. Blow in EPS beads. Simple.1 point

-

There may be a newer version. https://forum.buildhub.org.uk/topic/439-fabric-and-ventilation-heat-loss-calculator/1 point

-

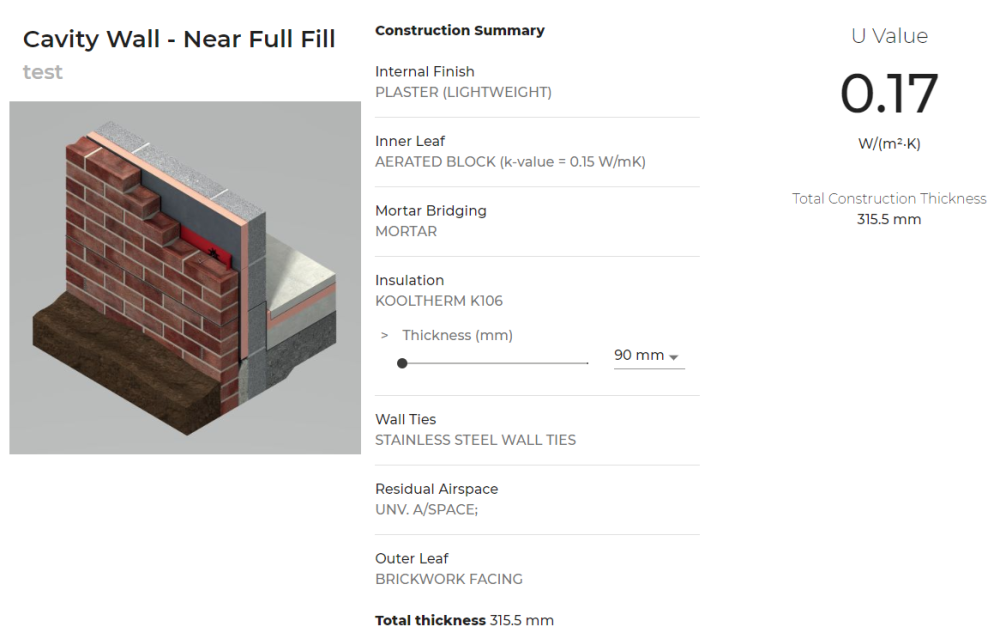

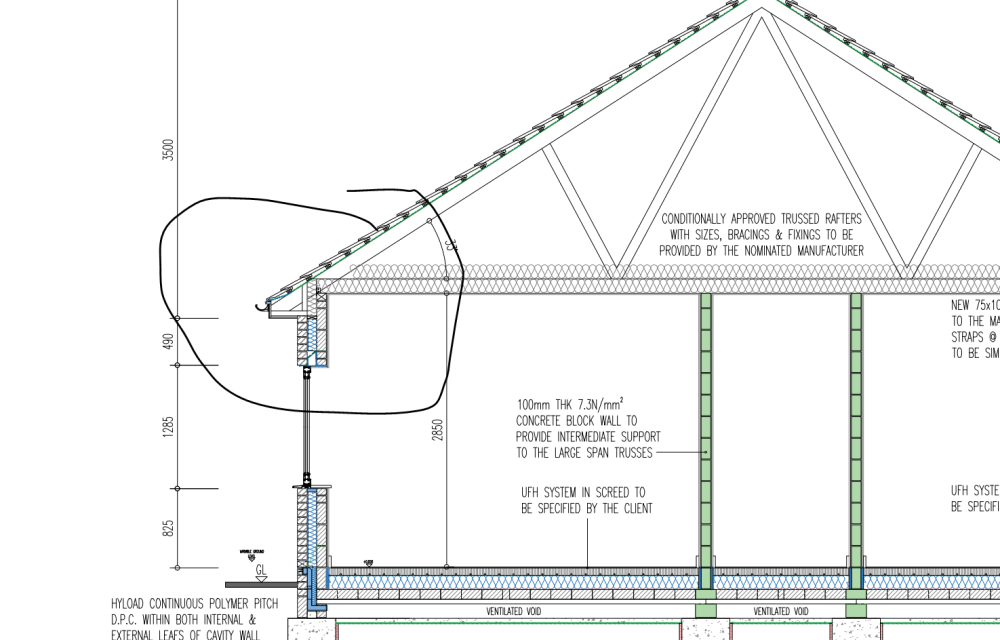

your drawings specs kooltherm sheets which will meet building regs. Expensive though and difficult to detail. May be worth moving to 150mm cavity and using full flil dritherm batts. Typical with architects they have left your roof low so sorting the insulation and keeping air flow where the trusses travel over the wall will be difficult. you will not be able to fully fill this area as it will block air flow so will have a bad cold spot. A single block higher 225mm will let you do a much better job and give higher internal ceilings, does add some cost but worth it.1 point

-

Maybe sedum is the wrong choice for green? This is what worked in Norway: https://en.wikipedia.org/wiki/Sod_roof1 point

-

I am quite strongly against green roofs as being a good thing in principle. I tried to get an HSE inspector to forbid one as it required otherwise unnecessary access to the roof during construction and in use, He agreed that would be best, but he said he didn't want to get involved. I also asked the planner if painting the words "green roof" on the surface would suffice, as it matched the plan and would be more sustainable. No, but got a giggle. They increase carbon dramatically in construction, but have little impact in life. Sedum grows in Norfolk, sedum grows a bit more, where transported to, sedum dies. But. That tower block is lunacy. I never saw the blades move on perhaps 30 sightings over the years. I haven't heard about costs...I think everyone involved keeps their heads down. But my estimates are that an extensive green roof, with public access, would have cost £5M, and the windmill feature £30M, to which allow for a reduction in floorspace. That could be recalculated into carbon used. I've always that thuis would make a good article in Architects Journal. 20 years on, what do the designers and developer want to say?1 point

-

1 point

-

Of course not. £20k more to buy it in Britain through their UK office, than buy in France and ship over, after allowing for double handling and admin. If it had been a contract requirement then we would have had to pay the uk price. So it became uncompetitive and I redesigned with a conpletely different strategy. They lost the sale. Most big projects are specified by the SE and the contractor has no choice. All the tenders will allow it and the client pays. I spoke to EU contractors I knew. They pay less on many products. The same used to apply to cars, maybe still does.1 point

-

Plenty of people take a slice of the cake to get from manufacturer costs, to the consumer cost. Import duty, vat, wholesaler profit, retailer profit, transportation etc.1 point

-

The Port of Rotterdam will take a slice. Most goods that are shipped to Europe, and geographically we are in Europe, go via there, so a bit of double handling. Then there is exchange rate fluctuation, which ever way it is done, the UK, having an independent sovereign currency, will have charges, usually higher than the $ or € as they are currencies that are in greater circulation (so 'collected' by other countries to help stabilise world trade). Then we have high storage prices because we have high property prices. So I doubt that anyone is actually overcharging because they can, we just have high costs of doing business.1 point

-

Well found. As usual, the same number of pounds as euros. Someone takes that 15%, and I think it is the manufacturer/distributor, because they can. Not brexit for once, it was always thus.1 point

-

1 point

-

What most with an ASHP + PV do anyways. When you add into that equation the stop-start of the ASHP, plus possible freezing, plus the moving parts, and then work out the reduction in longevity of all the kit outward of the cylinder, the maths really begin to shift further away from heating north of 50-55oC via the HP. Immersion is 100% efficient, zero moving parts, and is cheaper than shoplifting to replace.1 point

-

I think , without fail, the government's green deals have spent all the money on consultants and the excessive margins of approved 'specialists'. For a while you could get grants for wind turbines and hydro, regardless of them being unfit for purpose.1 point

-

@Selfbuildsarah you don’t need that much space and you can “stack” things such as the expansion vessels on top of the cylinders. First off, need to know how many showers etc you have - 10l/min is a pretty decent shower and is the maximum under the G2 water efficiency regs if you’re required to achieve that anyway. With an 70/30 of hot to cold from a 300 litre tank at 52°C, you’re at around 40 mins of shower flow before you get a cold shower. Take that tank to 72°C and you’re adding around 18 mins additional flow which is actually a fair amount. 82°C and you’re over an hour at 65 mins of capacity, and this is from a 300 litre UVC with 90% usable capacity. 300 litre UVCs are pretty easy to get into surprisingly small spaces - the Telford one is 660mm diameter and that’s not far off the same footprint as an ordinary fridge freezer. Telford custom make their cylinders at no extra charge with all ports and connections where you want them too so they are easily installed. I’ve designed variable flow installations with domino tanks using multiple UVCs but that’s for buildings such as B&Bs who want flex but limited heat loss when rooms aren’t in use and the 2 variables are always capacity and temperature - all depends on the need, and proper design from the outset.1 point

-

10l flow is pathetic. may as well use a bucket and cloth! double that. very expensive to heat on demand in daytime so not a good idea, you want to aim for overnight heating at cheap rate and have enough hot water to last through the day at a realistic usage. No way would a single tank be enough for a family with teenagers. remember ASHP cant do heating and hot water at same time either. The only thing going for ASHP over a gas boiler is its cheaper to run, everything else is a negative.1 point

-

The rinse or just scrape might depend on how often the dishwasher goes on. Ours goes on most nights economy 7 so actually about 3 in the morning but can miss a night sometimes. Also depends on pets helping to clean plates, always rinse after the dog. Husbands rule was no pets feeding from our scraps at the table 3 months that lasted, he is the biggest feeder of us all.0 points

-

0 points

-

0 points

-

maybe. nothing guaranteed. until china stops with its coal powered fire stations we should be pausing everything anyway as its pointless.0 points