Leaderboard

Popular Content

Showing content with the highest reputation on 01/08/23 in all areas

-

It's mostly a grid stability thing, rather than costs. Wind farms are largely not built where the demand is (the London Array being a notable exception), and as inverter-driven devices they also don't provide inertia to the system. This makes it very difficult for the grid to cope with major faults, etc. without it becoming a cascading failure. With thermal power stations, this "spinning reserve" means that in the event of a sudden load added to the system the turbines will slow down slightly, with the kinetic energy stored in the turbines and generators providing a lot of extra power for a few seconds. At present wind turbine systems can't offer this (although it's possible in theory, the way they're designed at the moment doesn't support this), so to ensure that the system can accept faults and not crash then they need to keep a certain minimum amount of thermal generation on the system. This is rapidly changing, but we aren't there yet. Batteries are already providing longer term (up to ~30 minute) response to peak demand much more cheaply than old-style peaking plant, and we're likely to see them providing synthetic inertia in the future as the technology improves. It's feasible at smaller scales at the moment, but doing it at Gigawatt scale is harder! We're also seeing flywheels being installed onto the grid to provide real inertia. These are just a giant spinning wheel attached to a motor/generator which is synchronous to the grid. If the grid speeds up or slows down, the motor/generator has to drive the flywheel and this provides better frequency stability to the grid. The annual running costs of these are much lower than those of a power station, so if you're only providing frequency stability services they're the way to go.3 points

-

2 points

-

2 points

-

+1. As you hunt for your plot simultaneously do two things. This forum is your new nighttime reading. Go into every post starting with most recent and read everything. Even the less interesting subjects or things you might not think relevant to you might turn out to be.You will begin to get a real education in so much subjects. I don’t think there is anything that hasn’t been covered, sometimes repeatedly. It’s like a free Open University of Self Building. One of the best thing I found about self building was learning so much stuff during the process, including from here. Secondly google is your friend. We are not google. Please don’t ask us something you can find out yourself. If you do post queries supply as much relevant information as you can and we love relevant photos as it makes it easier to answer questions. Many of us have been in your exact position. And after several years of hard work with our own projects we are normally have a bit of time and enjoy helping and advising. 99.9% chance someone here will have experienced a dilemma you will face. Sometimes we may have different opinions on things but will always offer our best advice. welcome.2 points

-

Neither altimeter or GPS are going to be any where near accurate enough. Maybe to the nearest 2m but that's about it. I don't quite understand your problem with the laser level but a water level kit might help: https://www.screwfix.com/p/water-level-kit-15m/3573v2 points

-

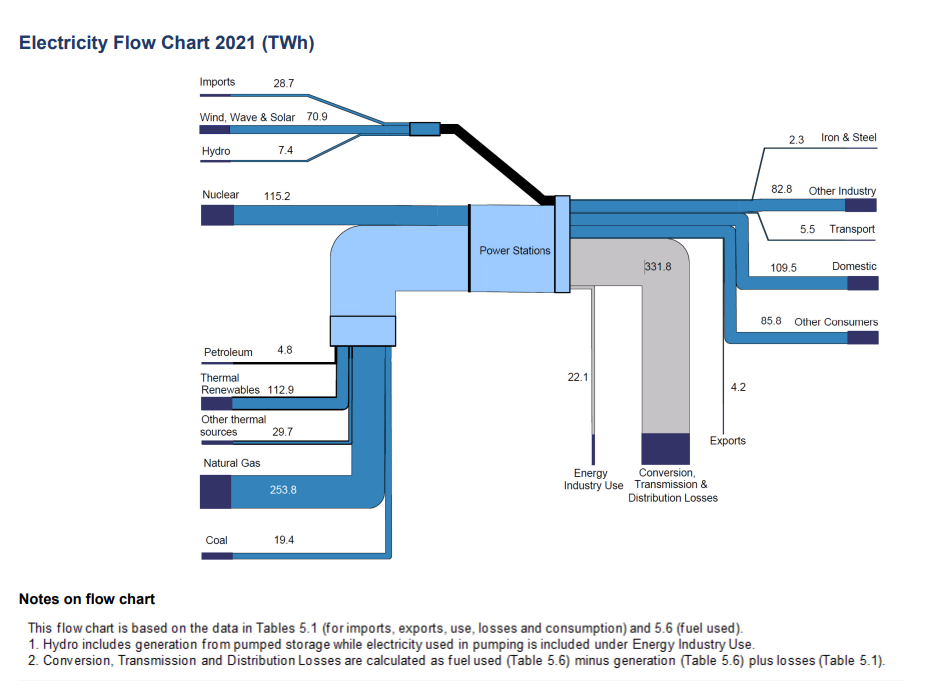

@DavidFrancis I was just about to compose a reply to your 50% losses point, but I see that @pdf27 has already done a good response. The only reference to actual losses in the report you cite was on page 4 which mentions a specific 8% loss. Transmission losses are typically of the 10% ballpark because most of the transmission these days is done at 275kV and 400kV AC, with the subsea connectors using HVDC typically at 270kV. In terms of generation losses you need to divide sources into two categories: Those with use heat as an intermediate (eg. all fossil-based generation and nuclear). Here the physics of thermodynamics dominates efficiency constraints (see the WP article on the Carnot cycle) and this places a upper bound on the conversion efficiency, with the hotter the working fluid then the greater the efficiency. Those which use superheated steam as an intermediate can at best achieve 30-35% efficiency. The latest gas-based generators use superheated exhaust at ~600°C IIRC and can get over 60% efficiency. Those that do direct energy to electricity conversion (wind, solar, hydro). Take wind as an example: a conventional wind turbine can extract at most ½Kρπr2V3CP watts from a fluid stream where ρ is the density of the fluid (air), r the radius of the blades, V the wind velocity. The last CP is a dimensionless coefficient of power; there is a empirical limit to this known as the Betz Limit (~59%) because of the macro flow characteristics of the airstream around the turbines and modern designs can get within 80% of this, say a CP of 48%. The actual losses from mechanical to electric energy are tiny in comparison with a generator conversion efficiency typically ~99%. So overall conversion losses depend on your energy mix: oil/nuclear/wood pellet at ~30%; advanced gas at ~60%; wind at 99%. So adding in the 10% or so transmission losses then your 50% is a plausible ballpark for our current mix. Hope this helps.2 points

-

1 point

-

1 point

-

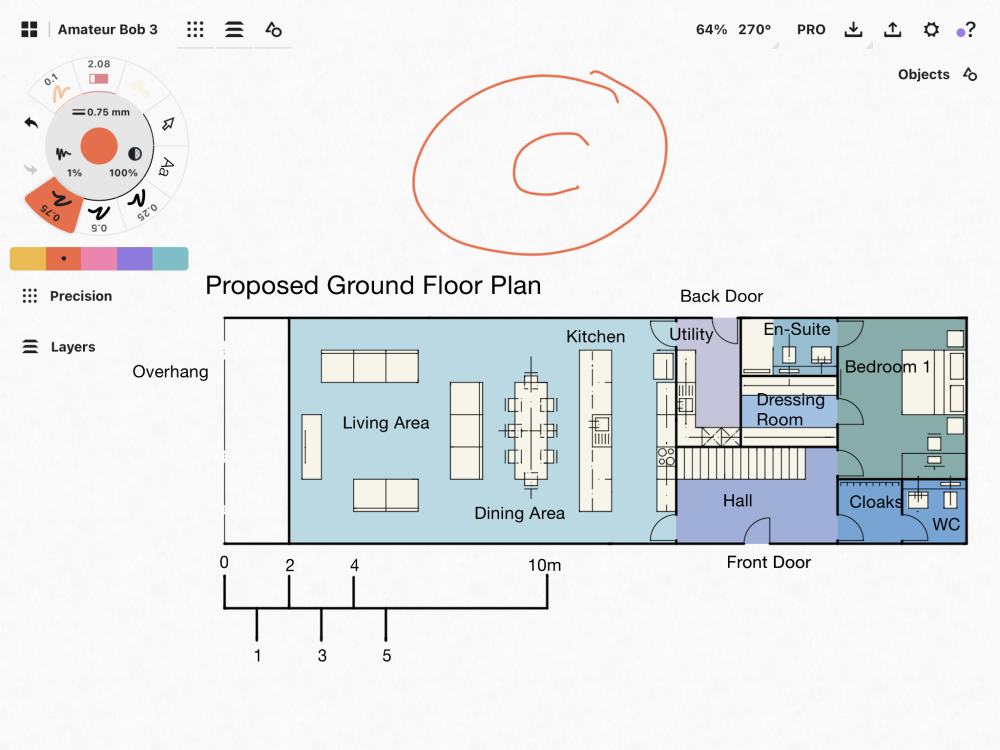

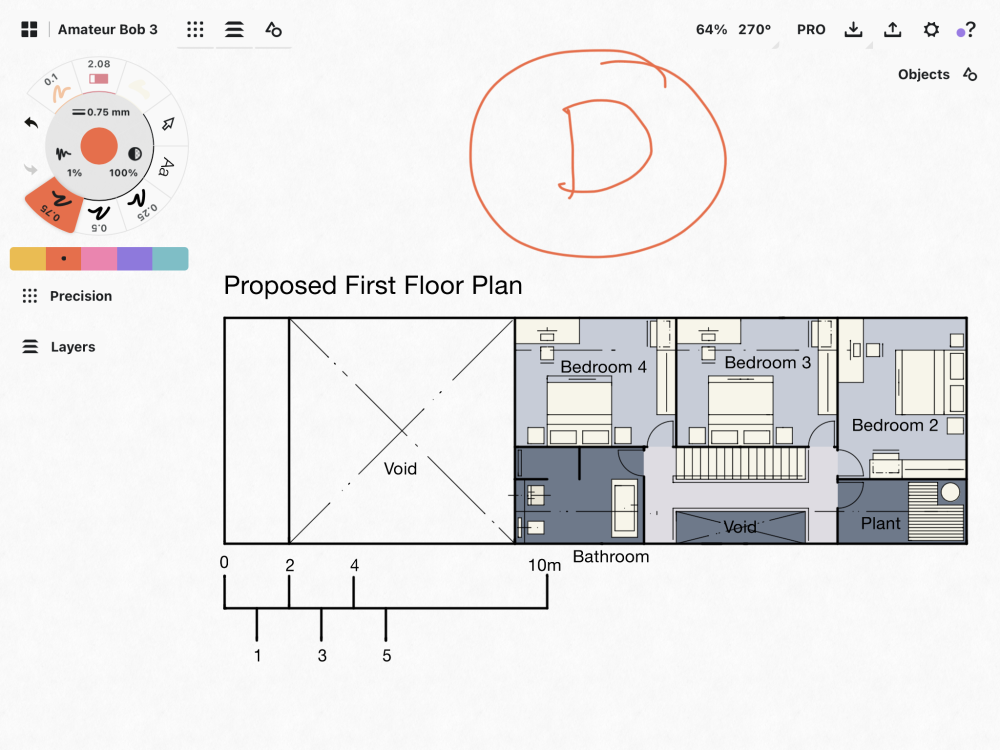

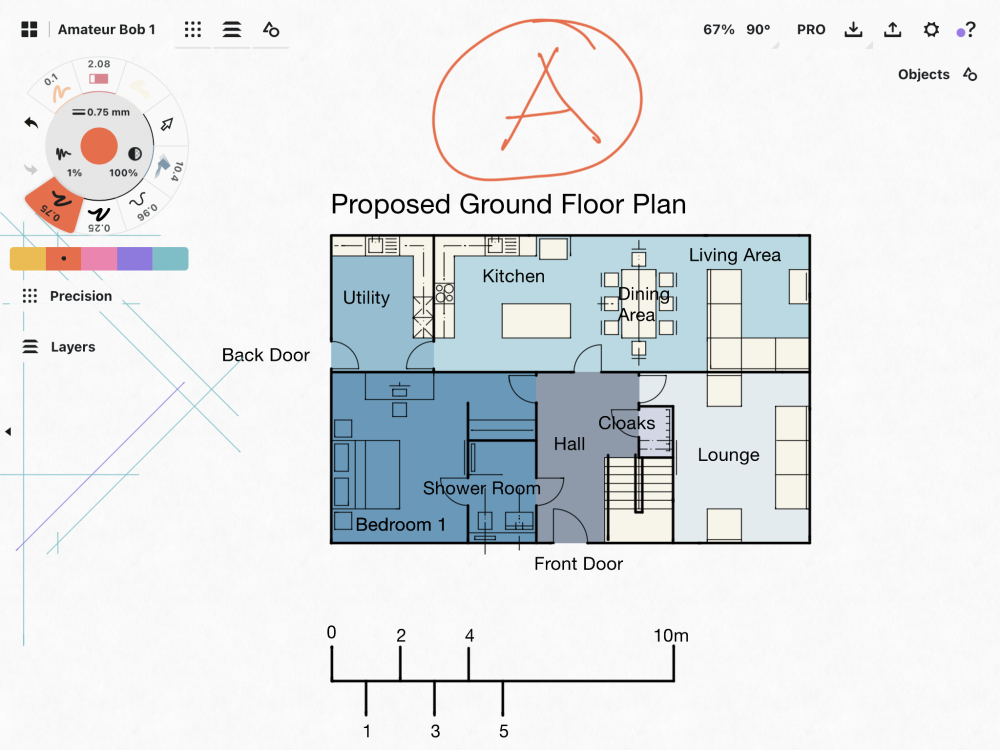

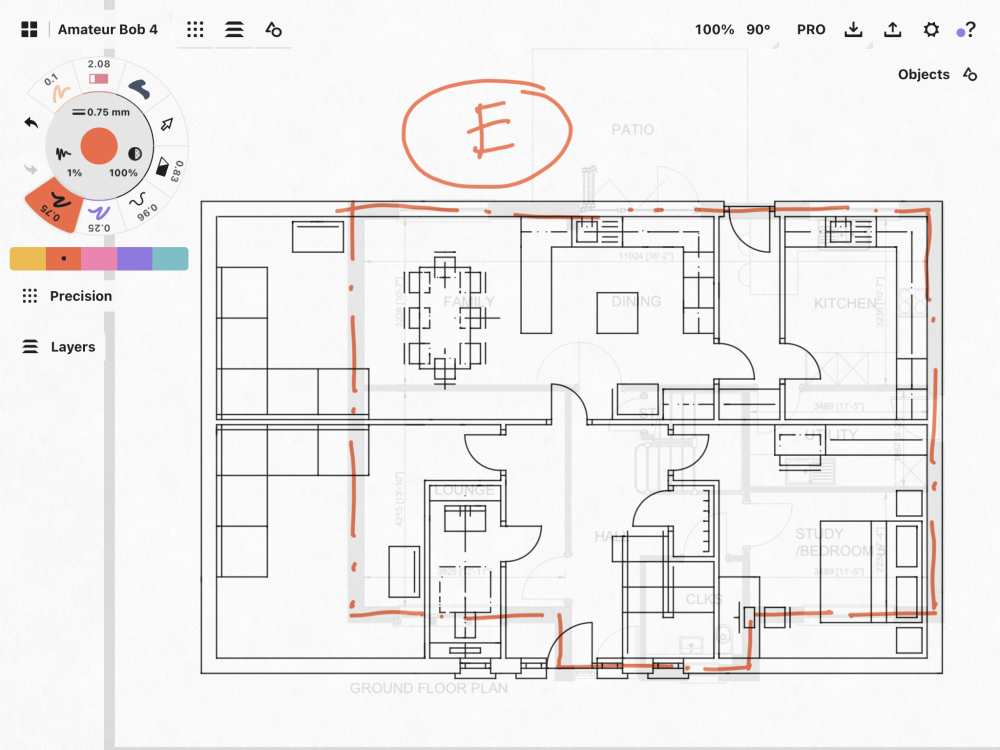

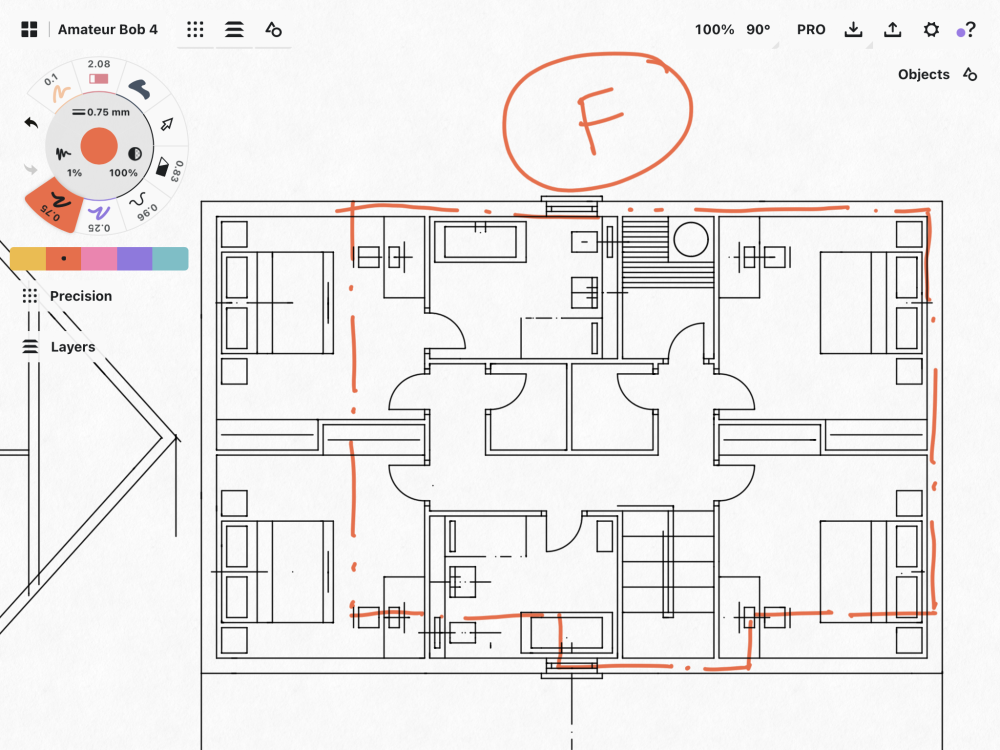

Can we dig into this? Various trades onsite and designers can be all too happy to solve their problems by doing the easy thing and shoving the problem to the next guy. Do you have any plans + pics to post and maybe the collective here could come up with some clever ideas for routing the MVHR? Rectangular ducting, combined external terminals etc all offer flexibility that your MVHR designers may not be aware of. Avoid holes in the roof if possible!!1 point

-

Do you have a laser level? I did my garage with a cheap one from Lidl. Just attach it at one side of the site onto something solid that won't move. Use a story pole ( like a 3x2" stick) to take a measurement of a known height (eg the floor) and hey presto you can transfer all heights around the site.1 point

-

I believe there's a common forward spinning reserve market that operates across several countries in the region, but yes, Danish generators are more likely to be bidding in this market with wind turbines. Low grade "waste" heat from power generation is used in some northern countries to heat water for district heating systems. I don't know how much that improves the overall effective conversion efficiency.1 point

-

1 point

-

Not all networks offer this as standard. See Which UK networks offer Wi-Fi Calling? In short you get what you pay for and the low cost offering typically exclude this. I have a sim-free Talkmobile deal which gives me effectively unlimited talk-time and texts and 15Gb data (usable in EU) but no Wifi calling at £7.50 PCM, so I am happy with this compromise: I use VoIP services such as WhatsApp for long calls, or take my mobile upstairs where I can get a good enough signal.1 point

-

One should always include a set amount of typos, spelling and grammatical errors. It lays a ready trap for the deviants to expose themselves.....😁1 point

-

1 point

-

That's overwhelmingly conversion of fuel into electricity. Fuel -> heat is pretty efficient, but heat -> electricity is not. Efficiency for the latter process varies from ~30% for nuclear stations up to ~60% for the very latest gas stations. There are transmission and distribution losses, but they're pretty small in comparison.1 point

-

The 'ideal for double thickness Plaster board' bit gives away the pull through issue you might experience with single layer stuff. 12Kg is probably too much for a single point on a single layer of PB. @Adsibob you are probably going to have to spread the load. When I needed to do this, although my need was only a couple of KG, I cut a slot in the PB slid a piece of plywood in over the place I wanted the load, secured the ply with PB screws from inside the room, fitted the 'hook' and then made good the slot with easyfill.1 point

-

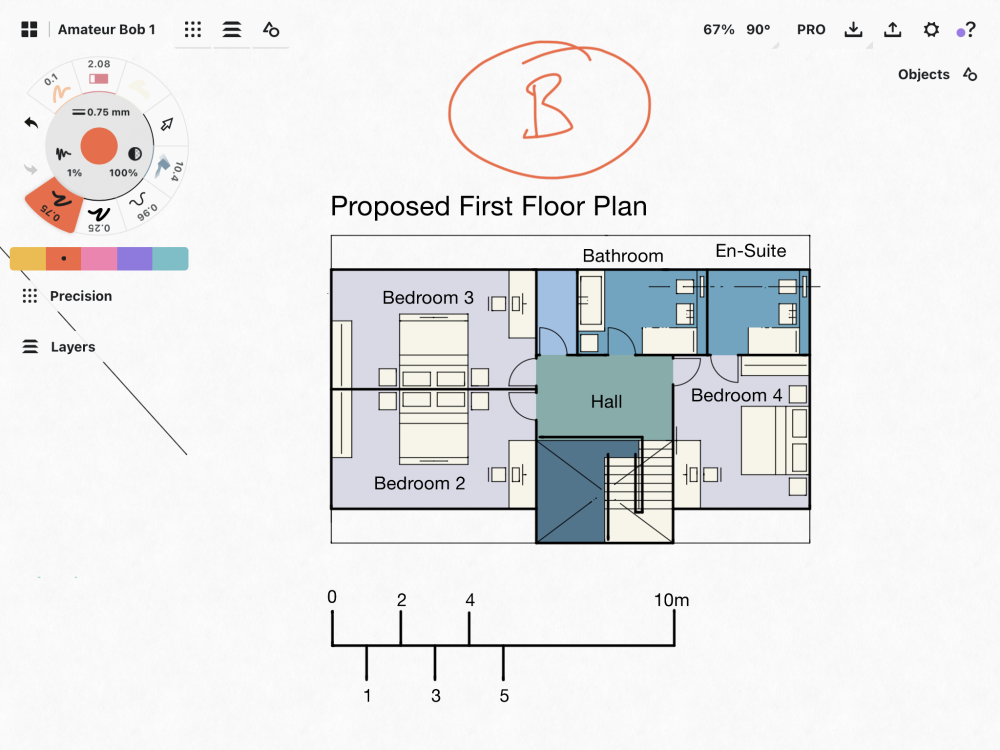

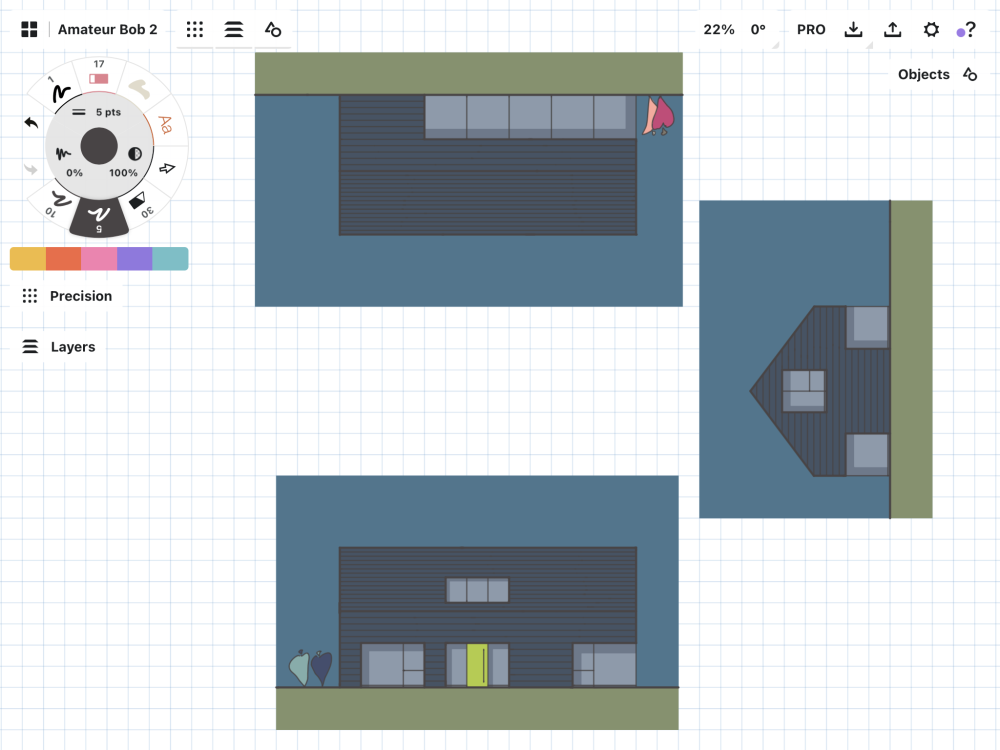

Bit late to this discussion ... we had similar planning requirement for a barn style house. The architects aim was to ‘echo’ the local vernacular but with a contemporary style so it sits well in the surroundings but doesn’t try to look old, which is often unsuccessful. Also, a fairly simple form which is not expensive to build. This particular style is unlikely to fit where you are but I would be challenging your architect to come up with something more imaginative.1 point

-

But then its a 20 year life span for a deep sea wind turbine according to Google, which are full of complex multi material composite components with no recyclablility at all, that are miles offshore. OK its not nuclear waste (quality of headache) but there are 100x more of then (quantity of headache). When these wind turbines need decommissioning I'm confident they will cause more 'environmental harm' then the equivalent nuclear waste per MW.... Until cheap energy storage becomes available, no energy source has the answer, and a mixture is required... Nuclear though has the reliability, robustness and longevity more then any other 'minimum baseload' generation sources.1 point

-

Sorry I didn't manage to check in over Christmas. Had a couple of people ask now so I may as well link this (hopefully it's allowed). I used these guys: https://ecclestons.com/shop/?filter=true&product_cat=polystyrene-bean-bag-bead-fill They're in Birmingham. I managed to secure a little discount on a bulk order compared to that price. it was an additional £200 ish delivery for a full LWB transit (35 bags they say they can squeeze in). Would be cheaper obviously if you're closer and/or have your own van. I shopped around a little, but didn't spend too much time on it, possibly cheaper elsewhere. I made sure what I got was fire retardant, although I didn't check in too much detail if it was the right spec. I did consider it - but the cost of beads would be astronomical I think (relative to the cost I was aiming for at least given this is a temporary job). If it was going to be a permanent or longer term I probably would have done it - it would have been easy enough to fire them in through the vents and/or though some 20mm holes through the floor in places. Would need to research the rot situation first, but at least if the floor fell through you'd have something nice and soft to land on!1 point

-

https://www.dan-wood.co.uk/en/projects/point-158a-e See this link. Simple barn style. Replacing void with additional bedroom. And this is turnkey. As a comparison to not being a turnkey which is obviously cheaper. Forget the layout, it’s the building size that’s relevant. Speak to a local building company they’ll give you a better estimate.1 point

-

Managed to get this done just before Christmas. Used a 250l Maxipod from copper industries . Not cheap at about €2k but it seems to be well made and has a 25 year guarantee. I installed a new galvanised tank in the attic as a header tank, this leaked at a corner but I plugged it with a small bit of silicone. I was keen to avoid any joints in the pipes, especially in inaccessible areas so it looks a bit messy where I've curved them into the ceiling space etc. As I was limited on time and skills I didn't want to pull down any ceilings or dig up floors. All pipes were routed behind cabinets etc except across one ceiling where I put them in conduit. I used Hep20 manifolds and a radial layout for the hot water with 10mm to the kitchen tap and all basins. It results in a very quick time to hot. About 6l/min at the kitchen tap which is fine. 15mm everywhere else and the flow rate is about 10l/min at the bath taps. Picked up a Triton mixer from Screwfix which works very well. In fact the DHW performance is as good as the UVC in our own house. I don't know how long the DHW lasts but it seemed to satisfy 5 adults over Christmas so it can't be too bad. The hot tap is fresh water also which is nice and there's no servicing as per UVC's etc. I think I may consider one when the SS cylinder in our own house gives in. The store is mainly heated by a Rayburn 355SFW burning a mix of soft and hardwoods on a thermosyphon/gravity circuit. It burns for about 12hrs a day so no shortage of input. I just used one pump for the CH which turns on when the bottom of the tank gets hot to circulate the water through the radiators. Thermosyphon is proportional to the temp difference between flow and return and height of the tank. I really had nowhere else to put the tank so it's base is only about 150mm above the top of the cooker and 2m horizontally away. This limits the amount of heat transfer we can get from the cooker so the rads typically never get much above lukewarm. This is fine as the long duration of burn has made the house very comfortable for the first time ever! The oil boiler is just on a timer and heats the tank directly. When the bottom of the tank is hot the CH pump kicks in on a thermostat. As the oil boiler is probably about 3 times more powerful than the cooker it has no problem with the rads but there is a lag between it coming on and heating the house, it has the benefit of heating the DHW proportion first however. Any other questions fire away.1 point

-

Quite sure you can, I think the suggestion was to save cost. A shear wall will probably work out cheaper than a WP1 point

-

Timber frame has been common in Scotland for a very long time so I would have been surprised if it was not timber frame. You can be pretty certain it was built with a 100mm timber frame. the unknown for that era is what, if any insulation was fitted in the frame. Earlier than 90's it would have been none, just a hollow frame. It would be a simple matter of unscrewing a light switch or a socket and having a look to see, but not something a surveyor would do and you would need to ask the vendor if you can do that to look and see. If there is no insulation then it is not a trivial job to upgrade it, pretty much all the plasterboard would have to come off to retro fit it, unless anyone knows if it is possible to install a blown in product, but even that would mean 2 holes in each section of wall so still not trivial. If it were me, I would ask the vendor if I could take a look.1 point

-

I know this isn’t the right sub-forum for this thread, but I never introduced myself when I joined in Oct 2020, just 2.5 months before our RE-build started (which I’ve decided is a tad harder than a new build). In those first six months I spent so much of my time on this forum that by March 2021 when it was my birthday, the forum’s name featured in a gift that SWMBO made me (basically a framed miniature model of all my favourite things, and on the miniature tablet within the miniature model was the buildhub logo - hope she hasn’t committed a copyright breach!) So just wanted to say thanks to everyone for all the support, particularly for making me feel less alone in this journey. Self building can be a very stressful, difficult thing that not many people do; I’m a terrible perfectionist and often my own enemy which makes it all the harder. But I can’t imagine how I would have done it without all the people here. Happy New Year. 2023 has simply got to be better than 2022. Or at least let’s just believe that.1 point

-

Yes a happy new year to one and all, like above this forum has helped me immensely throughout my build and frankly I consider you all to be friends (though never meeting most of you).1 point

-

We are quite luck in the sense that we have an upstairs plant room that is about 53m2 (9.5mx5.6m). It was designed to be right in the centre of the house, so wiring, plumbing and MVHR runs are radial in nature, hopefully keeping the length of runs minimised. The area was completely clear so I’ve created some skeletal walls from unistrut, with traywork to carry the wiring, plumbing and ventilation. This saved drilling holes in the plastered walls, which is my airtight barrier and the architectural brickwork. Plus if you have to move anything, you aren’t left with an unsightly hole. I’ve also started to create some partition walls (out of unistrut). It also means you have access to both side to run cables etc. I’ve only got the plumbing in so far, but it seems to be working out quite well (see pics). I don’t see why it wouldn’t work out in a smaller area.1 point

-

Thank you. It’s a new concept combining communal bathing and water saving.1 point

-

No, and now I have finished the house my wife announced she wanted a divorce, lovely judge decided she gets a big chunk despite me funding nearly all of it , and neither of us can live here 🤯 (sorry fir the rant but I am very pi##ed off), oh, and thanks fir the offer 👍0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)