Leaderboard

Popular Content

Showing content with the highest reputation on 08/06/19 in all areas

-

Google found some info.. Try contacting.. Timber Decking and Cladding Association.. https://www.tdca.org.uk/ Looks like they have guides with drawings.. No 9: "Detailed openings Vertical Clading" https://www.tdca.org.uk/media/3778/woodcampius_css9.pdf Elsewhere.. About page 13 onwards (pages aren't numbered) http://www.woodcomponents.ie/wp-content/uploads/2016/03/MTS-Cladding-Detail-and-Design.pdf Some of the example photos show joins staggered on adjacent boards. On my horizontally clad out building I staggered the joints over at least three different positions so they didn't form an obvious line. Bit of info in here .. https://www.silvatimber.co.uk/media/pdfs/Thermowood/Thermowood-Technical-Instructions.pdf .. mentions chamfering the lower edge of boards (page 7).2 points

-

I have used a lot of different hand saws and last year I purchased a selection of saws from Rutlands and I have to say they are by far the longest lasting , best quality saw I have used to date. One of the biggest pluses is they are coated in a paint that prevents rusting and helps them to run super smooth. Living in a coastal environment rust is a constant problem with sharp hand tools and it’s a joy to have found a saw where I don’t have to constantly maintain it to prolong its life. So for all those self build DIY fans these would be my recommendation ! I have absolutely no connection to the company I just want to share my good experience and what I feel is a good value piece of kit.2 points

-

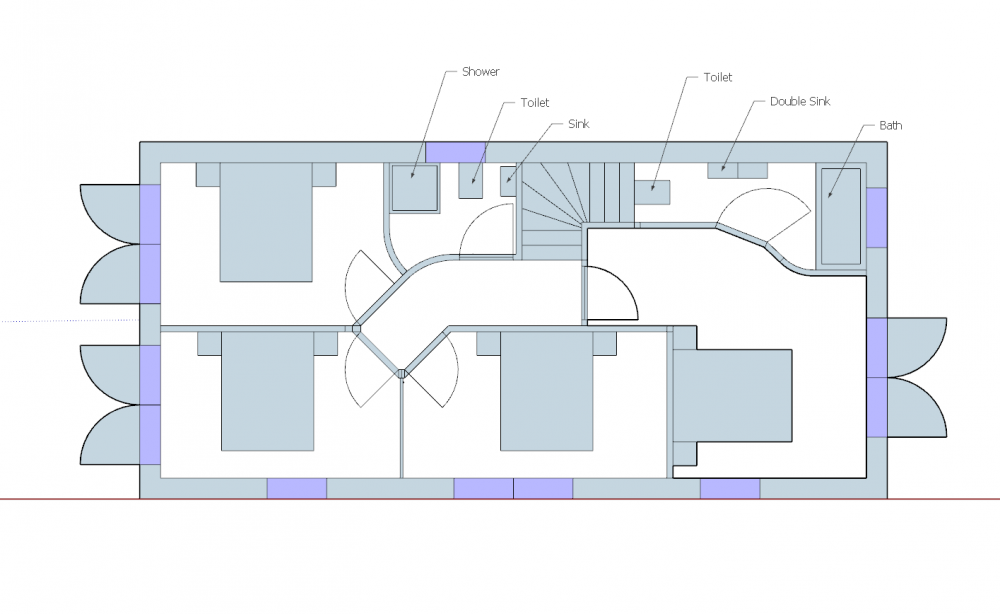

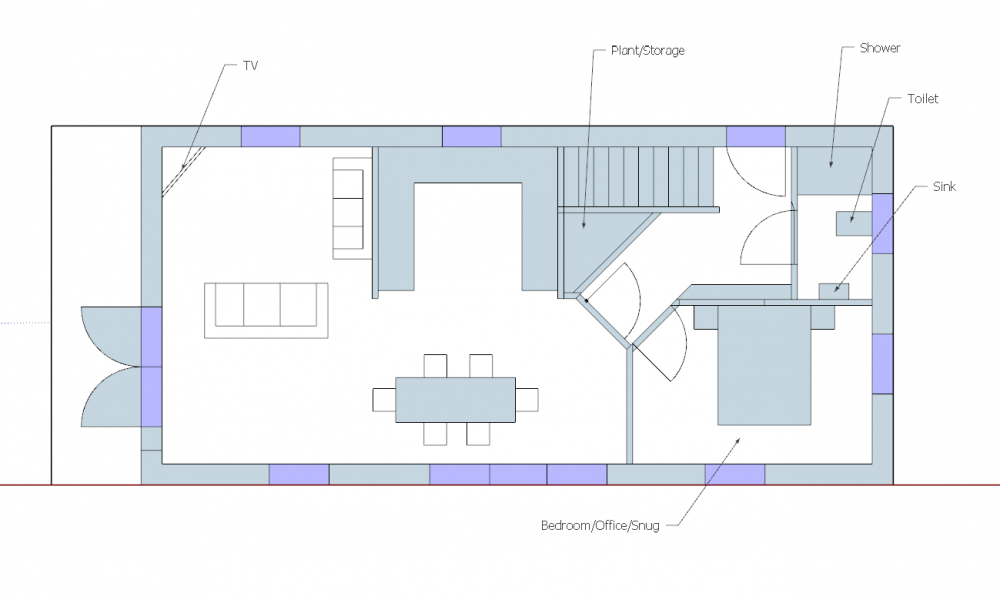

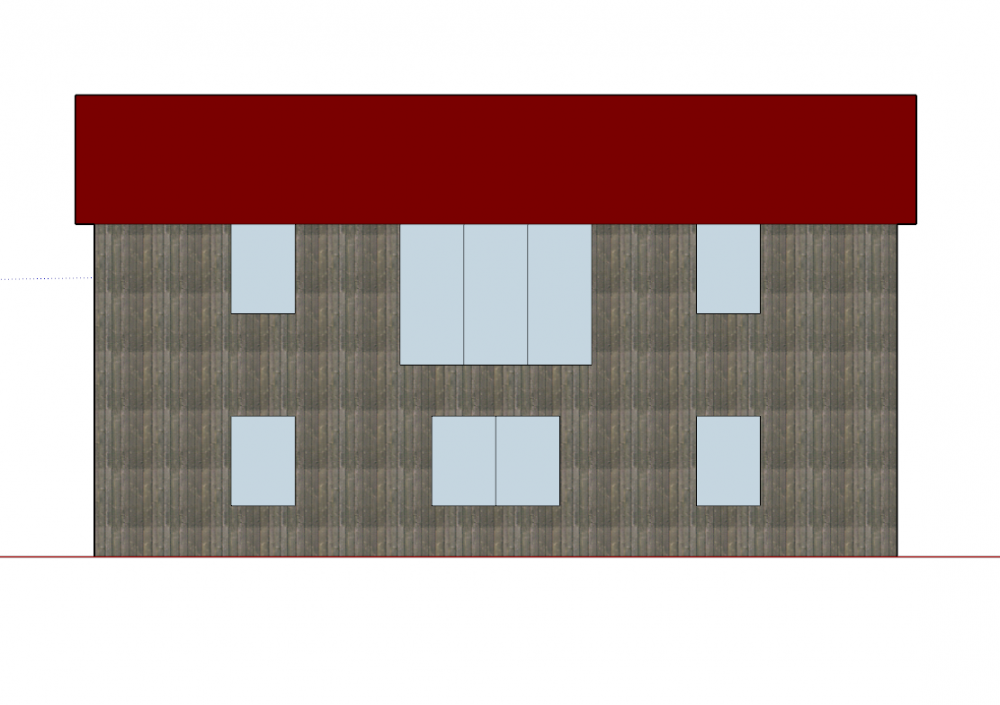

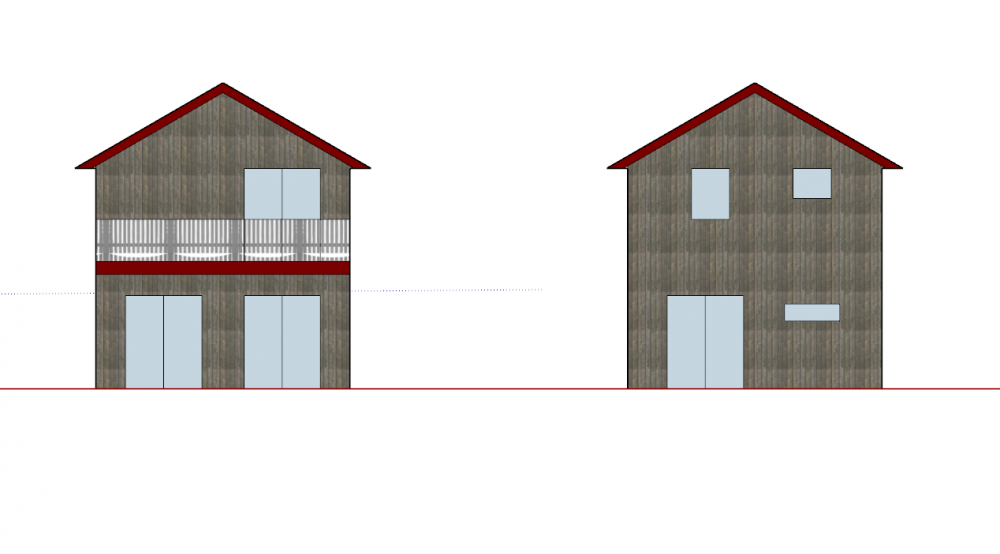

Right, I'll throw my hat in the ring. Its remarkable the things you achieve while your spawn is up at the witching hour sprouting new fangs. I've made a couple of assumptions. External walls 350mm, internal 100mm. All beds in the drawings are 1550x2000 (queen size). I didn't get around to drawing in any storage but I hope the locations I've left will be obvious. I hope you don't mind me changing the upstairs. I've included an extra room here that could be used as an office or sitting room. Failing that, as an extra bedroom should you ever find yourself too old or too drunk, or indeed too old and too drunk to tackle the stairs. Try as I could I wasn't able to fit a bath tub into the family bathroom downstairs at least not in a horizontal orientation. I've included a shower in the upstairs W/C for use with the aforementioned bedroom and as it's opposite the stairs should prove a welcome fallback just in case all lower ones are occupied. As per @Ferdinand suggestion I've endeavoured to extend 3 of the bedrooms into the garden with large doors. And the 45 degree doors seem to have freed up some space @ProDave GROUND FLOOR FIRST FLOOR SOUTH ELEVATION EAST +WEST ELEVATIONS2 points

-

Hi all, and thanks for adding me to the forum. My brother in law has progressive MS and now struggles greatly to climb the stairs - in time he won't be able to manage it at all. We hope to extend to the rear ground floor of their house to create a living space for him. The budget is limited, so I hope to take on much of the work myself to try to keep costs down. I'm currently at the design stage, and there are a number of things that I'm not sure about, so the advice of the forum would be greatly appreciated. I work as a S/E handyman and domestic electrician, but have previously worked in construction for a number of years (with a large gap in the middle while I went travelling) and have done a bit of everything. Cheers1 point

-

Joining metric to imperial always needs an adapter designed for the job. There's no way an old BSP imperial pipe will fit into a metric fitting. Even Philmac sell separate imperial alkathene to metric MDPE fittings, as a specific part. Their standard MDPE range are metric only. The fact that 3/4" alkathene (the nearest size to 25mm MDPE) has an OD of 26.6mm minimum, 26.9mm maximum, is enough to show that there is no way that an O ring sized for 25mm OD has a hope in hell of even being stretched over the pipe, let alone forming a reliable seal. I frankly wonder where you get your supposedly "expert" advice from. If I had to guess I'd say it was from people who don't know their arse from their elbow. FWIW, I've laid 100's of metres of 3/4" black alkathene over the years; it was the standard water pipe run around the farm for water troughs in the fields. The stuff is noticeably larger in diameter (and was more robust to handle, due to the thicker wall thickness) than the lighter weight metric MDPE we have have now.1 point

-

I would look up the rules for doing a credit card charge back. You probably have to give them time to deliver but there may also be a time limit on doing a charge back. Best not let one exceed the other. I noticed that although they list Paypal (as an option at the bottom of most pages) if you go to checkout there only seems to be an option to pay by credit card. So it's possible they are just harvesting credit card details and addresses? Keep an eye on your credit card statements!1 point

-

I've got the 18v dewalt one - brilliant. Its resting now before the final bit of boarding. Its not for sale!1 point

-

My son just has a chuckle whilst we were going through the box with the sliding gate motor, controls, photocells etc. 2010 I bought the kit...1 point

-

Nothing at all wrong with Philmac fittings. I've used 3 or 4 different makes of MDPE fitting (bear in mind that we have loads of MDPE pipework, courtesy of having a borehole plumbed with the stuff) and my favourite is Plasson, but Philmac comes a close second. TBH, all MDPE fittings are much of a muchness, with the sole exception of the tat that Screwfix sell (easy to tell these from others, they use a lip seal rather than an O ring). The best online supplier I've found is Pipestock, but they are just down the road from me (well, a half hour drive away): https://www.pipestock.com/1 point

-

HMRC accept DIY store till receipts for low values but for larger ones you might need to ask for a proper VAT receipt. They can hand write you one with your address on it. Note it should be your address not your builders or anything like that. All Labor must be zero rated to you. If someone does supply and fit then both the labor and materials must be zero rated to you. If you pay VAT on labor in error you cannot reclaim it from HMRC. Not "some vat free labour". All labour on the house and some things "closely associated with" the construction of a new house should/must be zero rated to you. The exception is services - things like an architects services are standard rated and can't be reclaimed. As @JSHarris said... You do not need to give anyone a certificate. However some inexperienced trades are nervous about zero rating to you. In the first instance refer them to VAT 708. If that fails it might help to convince them if you give them a certificate but that's just a letter detailing your name, address, plot address, planning reference number etc. You write it yourself using words something like "This is to confirm that the work done by Fred was carried out on a new dwelling at the following address, planning reference etc" Edit: Cross posted with @newhome1 point

-

Buy the 18 volt dewalt and I will have it off you in 4-5 months time. ?1 point

-

Can the BCO dictate the design like this? I'd have pushed back on this, as the BCO cannot tell you what you can and cannot build, all he/she can do is ensure that the BRs are complied with. There are lots of houses built partially, or even wholly, earth-sheltered, and they have all been able to comply with BRs OK. As you say, having one structure that performs both functions, and which frees up some useful space in the process, does seem to be a bit of a no-brainer, especially as your already a bit pushed for space in that direction. There are several well-proven ways to build a structure like this, too, especially as, in your case, it doesn't look to be more than a single storey wall that's needed. Grand Designs had one earth sheltered house that was two stories high with three walls that were effectively retaining walls, the one built in and old quarry in Cumbria.1 point

-

Depends entirely on the heat capacity of the floor slab and the thermal time constant of the house. A concrete slab acts like a storage heater, with a heat output power that is proportional to the ∆T between the floor surface temperature and the room temperature. This makes it somewhat self-regulating, as if the room temperature drops the floor will deliver more heat, so bringing the room temperature up. When the room is up to temperature the floor heat output will just match the rate of heat lost. Our floor slab has an area of about 75m², so is close to that for the ground floor of a 160m² 2 storey house. That can store about 4 kWh/°C ∆T. If the slab was heated to 4°C above room temperature it would store about 16 kWh, enough to provide 1 kW of output for 16 hours*. A UFH heated slab like this is broadly the same as an electric storage heater rated at around 2.5 kWh, in terms of heat capacity, but other parts of the house also store a fair bit of heat as well. For example, our 130m² house stores about 1.6 kWh/°C in the plasterboard and skim, and that provides a useful thermal buffer store of heat that helps to regulate the internal temperature. It's probably possible to maintain a "just meets building regs" house at a comfortable temperature with maybe 70% E7 and 30% peak, using UFH. Bit of a guess, but I doubt the ratio would get lower than 50/50 even in really cold weather. With a heat pump with a COP of 3, even 50/50 peak/off peak is going to cost less than 4p/kWh of delivered heat, which is still pretty cheap. * Not strictly true, as heat output is proportional to ∆T, and Newtons law of cooling applies1 point

-

Idealcombi futura, aluminium window with PUR thermal break. Available inwards or outwards opening. Alu clad uPVC can get higher performance than timber (with the right version) if top performance is what you are after. E.g. the foam-filled energyline 91 P from gaulhofer (via ecowin)1 point

-

How about the simple 'Jamaican Joint', can grow your own in a planter.1 point

-

What figures? I think you get kW and kWh confused. Or, if you prefer your own units1 point

-

What size are the 400kg windows? The weight isn't the real concern, it's the pressure exerted on the support area that determines what's needed. If the pressure's too high for the normal max working stress of the material then the area that's loaded needs to be increased to reduce that pressure. A bit of timber can do that, if need be, but best to work out the pressure to see if that's really needed. Our whole house rests on EPS - there's nothing else supporting it at all.1 point

-

Are you being allowed to run from the local main into the water meter yourself, this is usually a utility type job?1 point

-

Just work out the compressive load on the insulation by dividing the weight of the window with the supported area under the cill. For example, if the window weighs 100kg and has a support area under the cill of 2m x 0.1m, then the compressive load is 500kgf/m² (100kg / (2m x 0.1m)). Converting that to units of force (Newtons) gives a force per unit area of about 4.9kN/m². EPS 300 (at 1% compression) is rated for 100 kN/m², so would be overkill. Even EPS 100 (rated at 45 kN/m² at 1%) is massively stronger than needed. Check what Nudara use (I doubt it's going to be less than EPS100) and then do a quick calculation to see how things look. (To convert from kg/m² to kN/m² just multiply by 0.00981)1 point

-

Develop a good feel for when the pipe clunks fully home. Someone here recommended using a marker pen so you can see when the pipe is fully home. Put aside the required number of inserts before beginning and make sure none are left at the end. Pour a bucket of clean water before closing the stopcock and cutting through a pipe, so you can clean bits dropped on the ground. (Saves an embarrassing trip to the neighbour with bucket in hand). Measure carefully because the stiff pipe cannot be forced into alignment with a tight radius in the final 1m.1 point

-

Use the longer insert. Moisten everything before tightening. Don't use ptfe tape. Tighten just beyond hand tight. You'll soon know if something is wrong.1 point

-

For ultra-dense, there's structural thermal breaks like: Farrat https://www.farrat.com/structural-thermal-break-connections Armatherm https://www.armatherm.com/thermal-break-materials/ Which presumably you could just use a few blocks of and fill the spaces between with standard non-dense insulation. I assume expensive though.1 point

-

1 point

-

I don’t think they have a lot of choice Exspecially if they are on a deadline Thats why all the major players sub vertically everything out It would be great to employ three or four gangs of plasters or electricians But they either wouldn’t cope with the workload or you would be paying trades for waiting till work is ready I do some jobs for small builders We dry line and skim a five bed house in a week They are tiny jobs and I make 50% more than the commercial work and get paid right away Everybody is happy Ive a school to start for a local builder next week Around 1500 mtrs of framing birding and taped We will have ten days to have it ready for painting He employs two good plasters But they would simply take to long Unfortunately it is how the building trade works now I’m banking on a recession which would help me and all self builders to plan ahead All my jobs are on a fixed rate But I can’t blame someone who is offered six weeks work at double what I’m paying We used to fix plasterboards for couple of quid each Now I pay £1.50 per board for carrying them in With two Ukraine brothers that will load three packs each in a day If you get good trades it is more by chance than design The rates that the two guys are quoting give them room to manoeuvre Personally I would rather things take longer and get a better job When things go quickly Ie six months you will have little or know control The larger company won’t hold things up for a couple of weeks because the tiler of choice is on holiday They will push on The two guys will tell you we will get on with Something else It’s only a couple of weeks Your a long time looking at it if it’s not just right1 point

-

-so about 15kPa, EPS100 with a 1% deformation at around 45kPa would be O.K., perhaps use EPS300 to be safe - here are several possible high compressive strength options foamglas - https://uk.foamglas.com/en-gb/applications/foamglas-perinsul marmox thermoblock - http://www.marmox.co.uk/products/thermoblock purenit - http://en.puren.com/fileadmin/user_upload/products/industrie/purenit/en/Purenit_ENGLISCH_2016_SCREEN.pdf compacfoam - http://www.compacfoam.com/26-compressive-strength.html - none are exactly cheap though. KayMetzler EPS.pdf1 point

-

Mine too. My only recent experience of switching mains with microprocessors is using the Sonoff TH16 which controls my fridge. What I envisage for most of the controls of my house is using a separate Wi-Fi-connected microprocessor running a relay board. Control via MQTT with messages like “relay/A49C73A4AE30/03 1” to turn relay 3 of the board with that MAC address on. Probably a few instances in different parts of the house. That's likely fine for small loads (lights, motorised valves, perhaps some pumps noting their inductivness). Where something a bit heavier needs switching then the directly microprocessor controlled relays would switch additional 230V-coil relays. I don't think I'll need anything which needs switching at high frequency (like a PV diverter) so the only likely use I'll have for SSRs is in the battery management system for last-ditch emergency protection of the battery bank if a cell is becoming over charged or discharged. The main reason for using SSRs there is the need to switch fairly brutal loads (120 amps at 50 volts DC) which could be done with a contactor but those themselves would have a not insignificant power draw 24h/day. I've also had thoughts about latching relays for this job.1 point

-

My immersion diverter uses a 25 A Crydom SSR, switched directly from a microcontroller pin (5 V at ~8 mA, well within the ~20 mA capability for a PIC pin). The SSR I used was a panel mount D2425, which has an input range of 3 - 32 VDC, so will just about work OK from a 3.3 V logic output (it needs ~6 to 7 mA to turn on). The SSR is just bolted to the back of a small diecast box; that seems fine as a heatsink. The dissipation when turned on is about 15 W maximum, according to the datasheet, but in practice it seems to be less than this, as the box barely gets warm to the touch. It's been working continuously for a few years now, with no glitches or problems.1 point

-

I switch my immersion heater with a solid state relay. That provides the isolation between the controller and the mains. I chose a SSR that has a 5V input. But I still did not want to switch it directly from an Arduino output pin. So it is switched with a PNP transistor that pulls the SSR input pin up to 5V when the Arduino output goes low. So the Arduino only sees a tiny output current when switching and would be unlikely to ever be damaged by any reasonably conceivable fault. Of course I chose a SSR rather than any form of mechanical relay due to the frequency of switching (turned on for anything between 0% and 100% of every half second time period. you would not want to be switching a mechanical relay at 2Hz all day long) Edit to add, I also chose a 25A SSR for the immersion heater. Re heatsinks, I just opened my box of heatsinks and chose one that looked about right. It runs just warm to the touch on a good day when the PV is generating well and heating the HW tank.1 point

-

We nearly went with Scotframe. I loved that they fitted the doorframes and staircases etc. But the VAT layout and reclaim is a massive drawback1 point

-

Well it's as close to a lawn as it's going to get. I'm pretty happy with it to be honest. It's took a lot of work to get it to this standard from a cow trodden tufty field but it's well worth it. Best advice I can give to anyone else wanting to do this is keep mowing it once a week, start on a high blade setting and work down as the grass improves. Chain harrows work wonders to pull all the dead grass out and smooth out lumps and bumps . And roller it plenty as well.1 point

-

If anyone's looking a bargain on an ASHP... I've happened upon an unused showroom model Lailey and Coates inverter monobloc. Unfortunately it's a 6kW unit and so a bit small for me to take advantage of. I'll not quote the price I was offered it at but suffice it that it was *well* under a grand inc shipping to NI. Complete but untested. Contact is Richard at greensquare.co.uk if anyone fancies taking a punt on it.1 point