Leaderboard

Popular Content

Showing content with the highest reputation on 03/17/17 in all areas

-

Then go for a cavity that is a min of 150mm wide and get the beads blown in. Don't let the builder put cavity insulation in as the beads will give a better real world result. Also means you save some money as the beads don't have to go in till just before it's plastered so helps cash flow at the start.2 points

-

@ProDave I'm in the process of switching to Iresa, 12 month fixed, 20.65p S/C. 11.136 p/kWh https://selfservice.iresa.co.uk/sales/home?bsbId=AA Edit to add - this is based on North of Scotland area, may well be a different price elsewhere.2 points

-

Shame they're going out of business given their attitude.2 points

-

Well, I can't answer your question because I don't know what U value I am building too!!! But, like you I want value for my buck. I am building in a part of the country with a mild climate, using block and brick and 200 mm cavity with dritherm 37 full fill. I will do my best to make it airtight. Currently getting prices for windows and my local joiner ( who has a glazing design expert on call) can get double glazing within 0.1 U value of other triple glazing I have been quoted for. In in my opinion my build is cost effective and value for money ( I am a Luddite).2 points

-

2 points

-

Right.... Wunda aren't able to help here - they only have the smaller one in the 35-65 so I'm trying an alternate source. @joe90 I will order one and see what the score is - I may end up importing these things by the sounds of it !! The other one will get used as the TMV..!2 points

-

I thought I'd play 'devil's advocate' and give you an alternative viewpoint. I've just completed a new build holiday home bungalow in N Wales of 71m2 (internal area). After looking closely at the economics of building something to Passivhaus standards of insulation I decided instead to keep things very simple and instead designed it to comply with minimum building regs standards. We exceeded the minimum building regs standards by a small margin and, as built, our predicted energy demand is 43 kWh/m2/yr compared to the Passivhaus standard of 15kWh/m2/yr. We're using bulk LPG (which is approx double the price per kWh compared to mains gas) yet the predicted annual cost to heat the house works out at £135/year compared to £45/yr if it were to Passivhaus standards. Our annual space heating demand is predicted at 3,012 kWh £90/year is not a lot of difference and it would be circa £45 if we had mains gas available. The building is very small to keep costs low and this size issue was a factor in the decision to go with minimum building regs compliance. For example it has meant that I was able to keep external wall thickness to just 270mm maximising the usable internal area of the building (140mm timber stick frame with external cedar weather boarding). Just a thought for you to consider. Ian1 point

-

A lot of the best ways of improving bang for buck come from the basic design and layout. Mark Brinkley explains this well in the Housebuilders Bible. Looking specifically at energy performance, you want to tend towards a square footprint and avoid complicating the basic box shape. Don't overdo the glazed area (even good windows are far worse insulated than poor walls, and obviously cost much more to boot); consolidate many smaller windows into individual larger units. Don't have a chimney. All of these factors improve thermal performance yet actually lower build cost.1 point

-

1 point

-

In our last house we ran a low temp oversized radiator system (33C flow temp at 0C ambient). We had a wet towel rail in the bathroom. Made no difference in terms of speeding up the drying process as it didn't / couldn't throw out anything meaningful heat wise. Not worth the effort IMHO.1 point

-

The simple answer is build what you can build to suit your budget. Price every option up from block to timber frame and work it all out. Each method has its pros and cons and it's only you who can make that choice. Once you decide on the method then it's not that hard to work out how much it costs to get each u value. @JSHarris has done a good calculator where you can play about with different u values for everything from the walls to windows and see how much better of you will be if you go 0.1,0.2, etc lower. No matter what method you go all the u values you will work out will be how good it will be in a lab, how close you get to that will depend on how much care and attention is paid to all the details you need to get correct during the build. No point in paying for 200mm insulation to be put in a cavity or between studs if it's installed badly. Is there a specific reason for going for a suspended beam and block floor??? Poor ground conditions for example.1 point

-

I once bought silver line sds 1meter long drill bits, they were so soft at the electric drill end that the hammer action riveted them over and they would not come out of the chuck, never again.1 point

-

It seems to be a bit of a controlled "going down the tubes", ie. they knew the Insolvency Practitioner was turning up today, rather than him turning up unannounced. I went straight up there and made sure my order was all marked up as "Property of ....", While I was then arranging a Luton to go and get it collected, they called me back and offered to deliver it as long as I could take it that day, which of course I did. I must admit they've done their best to achieve the best possible outcome. One loose door fell out the back of the delivery van and damaged the corner, they've taken it back and have promised it will somehow be refinished and returned today.1 point

-

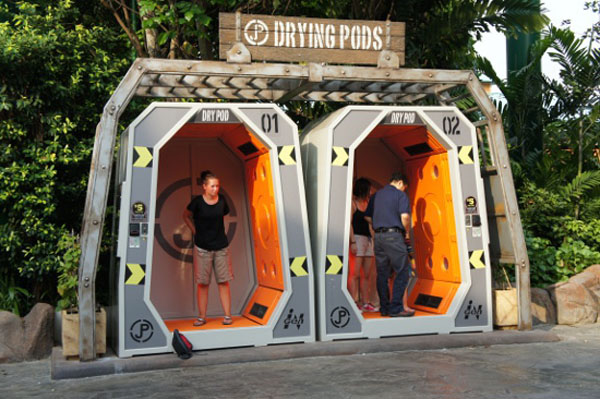

Not really a proper test, but I fitted one of these: http://www.clothesairerstore.co.uk/index.php?main_page=product_info&cPath=21_32&products_id=122 in the utility room, above the sink and work top, with an MVHR extract terminal directly above it. I've dried hand-washed towels on it and they always dry completely over night. Because the extract duct is right over the centre of the drier I suspect towels dry more quickly than they would on a towel rail. On the topic of towel rails, I managed to find a wide one (1300 wide, 400mm high) that will (hopefully) overcome the problem of towels being on top of each other. I fitted the smallest electric element I could find to it, and have it connected to a time switch (outside the bathroom). I'm hopeful that this will be enough to dry towels OK, but I'm sure that some will end up in the tumble dryer, just to get them fluffy.................1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

results from tonights shower. Faye's towel weight before : 634g after: 663g Ed's towel weight: before: 504 after: 557 things to be considered, Faye didn't wash her hair ( i will get results for this tomorrow) whereas I did. I wiped myself down in the shower whereas Faye didn't. my towel was a lot warmer, fluffier and smaller than Faye's (doubt any of these make much difference but they were observations i made) I have got a LOT more hair not on my head than Faye has1 point

-

Anyway I really think I also like the idea of underfloor heating for our bathroom Terry, it'll be great for drying the bath mat, along with the heated towel rail everything will dry out really well, shame we can't have the fluffy towels, maybe we will need a tumble dryer too, we could fit it in the utility maybe1 point

-

I can see a forum wet towel competition coming soon. I am not sure I want to see that (might turn into a wish I could unsee that moment)1 point

-

Just get a towel rail then and don't connect it Tell her it's somehow connected, use your imagination battery, mobile charging, and hope she doesn't read this thread.1 point

-

Telford are who I use primarily TBH. They'll make a cylinder bespoke but others have bought them elsewhere, so maybe ask in a separate thread as that'll be a subject of its own, ( so best not to bury it here ). No real need for high efficiency ( aka high recovery ) coils with a low energy house as you just never need to inject that much heat in in any one go. More 'slow and steady' with a heat pump.1 point

-

1 point

-

**Update** Took the bull by the horns and contacted the Building Society direct- wow, they could not be more different. Nice, efficient, helpful and explained to me that we are looking about midweek next week, and that I should feel free to ring them any time! So that's a weight off my shoulders. There's no reason at all we shouldn't get it, but you need to see that bit of paper before committing further money, just in case.1 point

-

I can confirm that the Wilo is a lot quieter than the same size Grundfos. We have a Grundfos (the newer low energy model) on the UFH, and that pump is in the utility room, downstairs. On the DHW preheat system I fitted the same size pump, but a Wilo, and it's much quieter; so quiet that it's very hard to hear when it's running. When the time comes to replace the UFH pump then I'd fit a Wilo, just to reduce the noise (not that the Grundfos is really noisy, it just makes a slight noise that I'd like to get rid of).1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)