Search the Community

Showing results for tags 'timber frame'.

-

Just bought a brick and block cavity house (according to the home report) which is actually a timber frame build with brick outer leaf! I should be a surveyor!

-

Hi all, We are into a new build and have a very thermally efficient and airtight design but have been told by our SAP assessor that for the new Part L regs they cannot use standardised psi values as they used to in the past for the thermal bridging calculations of timber frame builds. They perhaps can work them out manually but this may work out to cost around £5k… I can’t imagine we are the first to do this since the new Part L regs came out and have been trying to find values from the structural timber association and our manufacturer as has the SAP assessor. Has anyone come across this before or have an idea on a source for these potentially? I have looked at other forums, there is an interesting one from 2021 on Part L but nothing that seems to help. Thanks

- 6 replies

-

- psi values

- thermal bridging

-

(and 2 more)

Tagged with:

-

As things chug along slowly, I think it's time to move house. previously... We're still working our way through the mire that is purchase (Jebus, could Land Registry make it any harder to work out who all has rights over a sight line?) but at least now I've risked getting the planning consultant on-board. No red flags on the Property Certificate, which is great news. I've got some quotes in for the TF already, but it's surprising how many won't quote until Planning is approved. Likewise prices are in for the Shed. So some stuff I've worked out, some I haven't. I can handle the electrical design (RCBOs all round), but I suspect @Nickfromwales will be leaned on for the heating and foul aspects. But firstoff- and yes I'll be asking the same Qs of the PC- what is acceptable to do on-site prior to full approval? The site has had Outline then Reserved Matters, the planning retained on footings which were confirmed inspected by the BCO. Is it likely that we could go ahead with erection of the shed/ garage so as to utilise it for storage and break accommodation during the build?

- 366 replies

-

- ireland

- timber frame

-

(and 1 more)

Tagged with:

-

I have contacted the following companies for quotes, but I was wondering if there were any others that anyone might be able to recommend from personal experience? Also any personal experience with the companies below would be greatly appreciated. The site is based in the South East, just outside Reading. Companies contacted: English Brothers Merronbrook MBC Fleming Vision Development (https://www.timber-frame-suppliers.co.uk/) Timber Frame Tech (https://timberframetech.co.uk/) Frame Technologies (https://www.frametechnologies.co.uk/)

-

Hello, I'm new to this forum. I've designed a four bed house which I've been discussing with Scandia-Hus, who are local to me. During the process, I've realised their thermal performance isn't as I'd hoped, so I'm now considering MBC, but I've no experience of them. We watched a Scandia-Hus being built near us a few years ago, and it seems to be a well built house. Another has recently gone up, a variation on one of their catalogue houses. Again, it's been a fast efficient build. I'm here in the first instance to find out any comments / experience other members have of Scandia-Hus and MBC thermal efficiency. As I can't see a straight line, we'll be opting for a main contractor option. Thank you.

- 17 replies

-

- scandia-hus

- mbc

-

(and 1 more)

Tagged with:

-

Finally having time to update you(and me) about the progress. It s happening fast now. Finally. https://tintabernacle.blogspot.com/2021/12/the-frame-is-going-up-fast.html

- 6 comments

-

- 3

-

-

- i beams

- portal frame

-

(and 2 more)

Tagged with:

-

To finish my 22 days on site. I started timber framing, decided to start on the amenity block, as this will initially be for our washing machine and dryer, plus some storage. My aim was to get water tight -ish. before I had to get home for the weekend. The poly tunnel (constructed this visit) - is my cutting shed, I set up my chop saw and worked to my cut list. This was proof of concept on my build plans, and it needed tweaking, the roof to wall junction has been modified and will work, but I want a better / neater solution for the cabins. here's my first attempt with the Binno camera. amenity.mp4 The wind picked up (20mph with 35mph gusts, so I needed to get some structure and racking boards in place, so the camera set up didn't happen day 2. I left site with it wrapped, and with the vapor barrier on the OSB roof. (with some 6x2 to reduce the wind uplift. I'll need BC to have a look before I put the insulation on the roof, as I want the insulations and rubber to go on on the same day. This block and the cabins will be clad in Scottish Larch. There's a gap above the door, that needs the final framing to be finished, but generally happy with the result. so far.

-

The next stage of the setup of the site took place over the last 3 weeks. with some good progress. The trip up North, 433mile from our current rental in the NW of England. I set off on Wednesday morning in the 7.5T truck, and the 2 dogs for company. I took some materials with me, and had a gut feeling I was overloaded. I had worked out the approx. weight of what I was taking, but was unsure of the TARE weight of the truck. so I didn't take all I was planning. Luckily the nice guys from VOSA, At Carlisle (Todhills check site), confirmed my suspicions when the invited me in for a check. I was over weight, but the truck and my paperwork were all in good order, and they give the truck a thorough looking at. The upshot of this was me renting another 7.5T truck for storage, offloading the excess weight, driving the remaining 333 miles, unloading, returning the next day with the empty truck, re loading and driving back to site. 1100 miles in 38 hours. not what was planned, but you live and learn.... I arrived back on site on early Friday morning, 02.30am. and slept in the cab of the truck, until I was woke up at 05.10, by the guy delivering the Static, he was at the end of the road... Here's a screen grab of our new home arriving to site, this was 05.25 am... I hired a contractor to carry out the highway works for the site entrance, basically as he had the correct insurance and RAMS it was easier to get this stage subbed out. The idea was he would open up the site, with a 5 T digger, start the initial road and stone this up with around 60T of type 1. I would then meet on site and hire his man for a few days to assist with the pecking of the treatment plant. This didn't go to plan, they had to use a 13T machine, as it was available, so when I eventually get to site on the Thursday, due to the size of machine, the operator has completed the initial works, then pulled out approx. 60M of the road, and pecked the treatment plant hole, and I got this for free... 😁 Having a 13t machine on site, with operator for the Friday, I needed to make the most of it, as I was only paying for the rental of a 5T machine. Mikey the operator, made short work of pulling out the remainder of the road up to the location of the house, in total this road is around 90M. Next I had him strip the area for the house. The house is around 13M x 7M, so I wanted to strip back a working area around the house, my thought was we would hit the bed rock so this was the plan, we marked out a 16M x 11M rectangle, and he set to it, it took him about 2 hours to strip the land and scrape it clean. The above is the bedrock where the house will be, and the road coming up the side of the house. (I used a geotextile as a separation layer for the road, although in sections the road is on bedrock anyway,) You can make out that there is a fall from the top left falling to bottom right, this will be made up with type 1 stone, raising SW corner of the house around 700mm, I will raise the road in this section and use some of the top soil to level this out a bit and soften the impact. The last Job for Mikey was to dig me the trench for the services, he dug a 600mm wide trench about 8M short of the Treatment plant (to allow me access to move the spoil, and a similar distance short at the other end for me to connect to the water. just shy of 60M. Friday was a busy day on 3 hrs sleep. The treatment plant also arrived as can be seen above, I went for a Tricel unit, this was based on cost, treatment, dimensions and availability. Last job for the day was to move the caravan, Mikey helped me with this and we stripped a bit more land and located here temporarily for the night North / South. Saturday I decided to get the water connected to the caravan, for this I needed to complete the trench from the standpipe to the large service trench. I never dug this on the first trip as I was concerned about the electrical supply to my neighbours property. Cables seemed to run across my field at around 300/ 400 mm depth. I used my contact at SSE and he arrange to get the cable moved / deepened. This was carried out a few weeks prior and we discussed the position of the new road, and he made a site visit and we talked about me extending the water pipe trench in both directions so that I could also lay a utilities duct to the road for broadband. So to say I was a bit surprised, and p***ed off when I cut through the neighbours supply cable. The cable was as I was worried about 400mm deep, and the marker tape was next to the cable.... How to upset your new neighbours by having their electricity supply stopped two times (1 for the initial connection, 1 for the remedial works), only for me to cut the cable for a third time.... At least they were very prompt, they arrived after about 40mins, and it took him around an hour to re-joint the cable. I then removed the water standpipe and ran my new water main up to the caravan. It will tee off for the pods at some point, and then continue up to the house. SO now I had running water in the van, and gas for the water heater and hob / oven. Sunday was glorious, so I caught up on my sleep, and had a restful day. Scottish Power were due to fit the meter on the Wednesday, so I needed to get my service cables from the meter box into the service trench and up to the caravan and to the pods. I dug a trench across the road and through to the service trench. I used a 125mm Duct, and inside here I ran some 6mm SWA to supply the pods and some 50mm Duct to run a service cable to the caravan and ultimately up to the house. I pulled the cables through, and I have put a caravan hook up point next to the static. Tuesday / Wednesday, I had 80T of Type 1 MOT delivered in stages, I spread this out using the Back hoe, and vibrating roller. so by the end of Wednesday I have the base in for the road. which will give me good access for deliveries. Scottish power were a no show..... Discussing the caravan with the neighbour they advised turning the caravan 90deg, so it was end on East / West as the stronger winter winds tend to blow from the West, and being side on would ultimately be unstable. I dug out another section of land next to the caravan with the idea of swinging the van around at weekend when Mandy Joined me for the last week. It took me and Mandy all Saturday to move the van, using the backhoe to pull it around. and most of Sunday to get it jacked up off the ground and levelled. We dug 4 pits later on in the week and concreted some anchors in to chain the van down. The van in position with Mandy getting the best job of the week to squeeze under the van and start to insulate the water pipes... Scottish Power let us down again with a missed appointment on the Tuesday with a promise of Friday.... They actually turned up late Thursday and fitted the meter, so we had power on the Thursday night. We spent a couple of days moving spoil around the site to create a mound of earth to shelter and soften the impact of the pods, this was also a planning requirement for the neighbours amenity. Still work in progress and there's 10's of tonnes more to move. Last job before packing up on the Friday was to level the base of the treatment tank pit. At this point we were still waiting for the building warrant. so couldn't actually install the plant. We end the week by getting the Building warrant approved, and the certificate for discharge for the treatment plant both on Friday. Thanks for reading..

- 3 comments

-

- 8

-

-

- the windy roost

- occumster

-

(and 2 more)

Tagged with:

-

Wow, we have finally started, and what a journey. The goal of the last 8 days was to try to make the the stars align. We had planned several meetings / connections deliveries all to happen the 1st week in April, and this was it, lets see what unfolds. Firstly, the plot, being located high up on the East coast in the highlands, which is basically a large un-serviced field has a few logistical issues, the main one being storage, the second distance. We had quotes for containers to be purchased and delivered in the region of 4.5K so alternatives were needed. The initial solution is the back of an Asda delivery waggon, 12ft long, 7ft wide,6ft high, with 3 lockable doors, and racking for the green trays, also a larger roller shutter section. £250 - with working fridge if required - (this may have a second life once were up and running with rare breed pigs🙈). just need to get it from Morecambe 430miles North. Secondly how to get everything to site. We bought an old removals wagon - 7.5Tonne ally box with tail lift. MOT till NOV 515,000KM - 1 careful owner Our hope was for this to get there in 1 piece, and be left on site as storage. the sum of £1200. all in with insurance (which may be cancelled) its has cost us £2K. Talking with my timber supplier, he warned me of impending price rises and possibility of shortages due to the unrest in the UKRAINE. so out of the blue I bought all the timber 450M of 6x2 C24, and 56 off 11mm OSB for the PODS. In addition to this I found a contact selling factory rejects of 120mm PIR insulation. In Scotland the pods need to achieve good U values, so 120mm on roof and in floors was required. Basically this guy buys pallets of insulation that are usually end of production run , or slightly damaged corners etc, and not full sheet sizes. I went to look, as he has had some bitumen coated and fibreglass coated boards. Generally the sheets are all 1200mm wide, min 600 long, most are around half board length, but will need to be trimmed to make them suitable for the warm roof. I did a deal to buy the equivalent of 44 Boards of 120mm some Bitumen coated, some fibreglass for the sum total of £660. This is a massive saving on 'Box Fresh' Now I had a problem, with the insulation tightly packed into the back of the truck and leaving some pockets to slide the timber in I had filled about 2/3rd of the truck, I didn't have room for all the timber or the other stuff I was taking. The revised plan was to cross our fingers and hope the truck will not only get to Scotland , but now return with a view of making another trip. Living accommodation. We found a static caravan, 2 bedroom in V good condition, delivered to site included in the price. The deal was done and he would get the van to site for our arrival on the Thursday, along with the delivery of our other investment an old Ford 550 Backhoe Loader, with buckets and pallet forks. We decided to set off Wednesday evening, with the plan to see where we got before we were too tired, then to sleep in the Wagon / Car. The picture below was us all loaded with 430Miles ahead. Me driving 'Nessie' as Mandy has called her, and Mandy Driving the Car / and trailer. I know we look like 'Travellers' but needs must, what will the new neighbours think when we turn up..... The Journey was horrendous. Setting off at 18.00 the trip was uneventful, with he exception of filling Nessie to the tune of £245 with diesel and not knowing how far these 150 litres will get us. Uneventful until we got to the A9 around Perth, then the snow started. Visibility was poor, and the local truckers seemed oblivious to it. Mandy had a big scare on a dual carriage way where she lost visibility of the edge of the road, and found herself nearly hitting the verge, a stab of the brakes and forgetting about the 16ft trailer saw said trailer try to over take her. Luckily she managed to correct this, and coming to a stop in the dark with snow on the dual carriageway, composed herself and set off again. At 03.30 on Thursday we pulled into a layby just after Inverness. Got our heads down for a couple of extremely cold hours (-4). and set off to the croft, arriving around 8.30.. During the drive we were informed the Static- our accommodation for the week was not going to make it - COVID... I managed to make a few calls and Borrowed a 3 berth Tourer from GOW Plant Hire / Groundworks in Caithness.. What a top bloke.... This is us on site day 1, digger arrived..... The Plot.. So down to it. Day 2 on site Friday. Electricity was to be connected on Wednesday 6th, we needed to dig a 30M Trench and install the cabinet / concrete base. This had to happen. Over to the digger to fire her up.... no go. Quickly the battery went flat. We moved Nessie closer, did a quick 30Mile round trip and bought some jump leads and by lunchtime and still no joy, turning over but not firing..... it was running the day before but they had to jump start as it had been sat in the yard for a few week. Ok looking at the battery it wasn't the correct one, so another 30mile round trip and the owner of a monster battery we tried again. no luck, I phoned a mate mechanic he advised trying spraying cold start into the air intake. ok another trip? , No, he told me to try deodorant as the propellant may well work, one quick spray and the old girl fired immediately. Best smelling digger in the highlands... Now to get to grip with an old backhoe, I've experience with up to 5 tonne 360 machines but never a back hoe, so this took a while to understand how to dig a straight trench next to a fence.. I managed to excavate the connection pit and around 15M of wandering trench by the end of the day. Day 3 Saturday It was cold and no amount of deodorant was working on the digger. The mighty battery was losing power... Time to try Nessie to give a boost, we got the Truck stuck in the mud... FFS. we needed the digger to move the truck, and the truck to help start the digger... This was a testing day, and I know from experience in building game you have days that just fight back, and this day was fighting hard. Mandy set off in search of some supplies and some cold start. By lunch she was back, I had made the shuttering for the cabinet base just needed the digger to get the concrete over to the hole. Cold start didn't work and we both felt deflated... Numerous attempts with planks, stone etc to free the truck were not working. As a last resort as the sun was now out and shining we gave the cold start another go and the digger jumped into life.. Obviously not a morning person... We moved the truck to relative safety of some drier ground with the aid of the digger and concreted in the cabinet. Another 10 M of trench, and we made a start exposing the water main. I noticed the digger was beginning to be sluggish and leaving hydraulic oil pools, when I check the level it was nearly empty. So Parked up the digger, next to the truck, batteries next to each other - just in case. We retired to the un heated caravan, and I went to the Generator to start it, we had a 2KW heater that helped take the chill off, A couple of pulls and the cord snapped😂. the day was going to round 12 like it or not. So tools out and repair underway. Day 4 Sunday. No Hydraulic oil till Monday so left the digger alone, and marked out the position of the pods, and the septic tank, I wanted to do some digging here to confirm the suspicion that the rock level was high, and some breaking out will be required. We hand dug a trial hole for the water main, as we found electricity cables running towards where the trench was going. We hit rock 300mm below ground, so were happy to dig this with the machine on Monday, We also started unloading the insulation and timber from the truck. We sandwiched timber and insulation with visqueen and ratchet straps to create a heavy mass that hopefully wont blow away whist were not there. Day 5 Monday. With Hydraulic oil on board and the shelter of the truck the digger fired first thing, and we were off. Mandy continued un loading insulation. We dug a small trench for the water (we new the main was laid in a blasted trench to a depth of 800mm) we had to breakout our trench with a 110V Breaker to obtain the 600mm depth and hand dig to expose the water main, I left Mandy to this while I dug the septic tank hole, I got to a depth of around 800mm before I hit the rock. This will need pecking out now. We installed a homemade standpipe, and blue pipe, then asked for a track inspection via the online portal. We were given date of 11/12/13April, but we put a note on to say we were on site until the 8th. They responded and the Meeting was set for Wednesday 6th - result. Day 6 Tuesday - the night was very windy and wet. A cold and wet start, We finished off the electrical trench, laid the ducting / draw cord and all was set for connection the next day. Made a start on the pods foundation dig. Day 7 Wednesday - electrical trench was full of water, and the ducting was floating. the heavy rain drains towards the sea, and thus straight into this trench, I was concerned that the Install may be called off. SSE turned up around 10.00 and were not bothered in the slightest. They connected a new length of 95mm Wavecon to the pole and jointed the existing 2 houses and our new supply - 2 core 35mm straight concentric to this 95mm cable. Resin pour joint box, and fitted the 100A cut out in the cabinet. They were done in 2 hours. left me to throw the cable in when the resin had gone off. Scottish water inspected the trench, and this has been signed off and will be added to the works list, hopefully a few weeks. I filled in the cable trench, We managed to rough dig out the pod foundations and found the rock is close to the surface. so the slab foundation will be pretty much mass fill concrete around the perimeter, with some MOT to reduce the thickness to 4" for the slab. This will then have a Radon barrier on top and a floating floor insulation on that, Due to the poor living conditions and more rain and wind we made the decision to leave Thursday morning. Day 8 Thursday, We packed up the caravan and Nessie then dragged the caravan out of the mud with the digger. The trailer was also dragged clear with the digger, but Nessie was so at home she didn't want to leave. I was pushing here through the mud, but she was sinking. Fortunately tour Farmer neighbour saw our plight and came along with his massive tractor and dragged her clear. We left site battered, bruised but happy in the knowledge that no matter what was thrown at us, we had achieved what was required and more to boot. Thanks for reading... its all possible, Mandy made a few videos if you want to see them https://www.facebook.com/The-Windy-Roost-101816829105927, you can follow the progress there as well...

- 9 comments

-

- 8

-

-

We have an MBC timber frame house with an insulated raft foundation. The house is cladd in larch but we need to finish the polystyrene base. We want to render it but how do we do this. Do we need mesh first or a special render that would stick and be flexible enough.

-

We recently bought a small timber frame bungalow, which requires some repairs to the exterior render, as there is damaged to the section where the plinth meets the wall, I have attached pictures of the area. Unfortunately, so far we could not find anyone, who could offer use an explanation or solution to the problem. As seen on the picture attached the grey tape (which seems to be some sort of flashing tape) is broken and coming off on several areas around the house, exposing the metal edge guards and allowing cold and moisture into the walls, as on the interior the skirting boards are cold and when furniture are places directly on the wall causing condensation and mould. ( as a short term solution, We have now left a minimum of 10 cm between the furniture and the walls, which seem to solve the problem of sweating skirting boards and mould). Q1: Does anyone recognise what this exterior gab between the plinth and the wall is for?! is it just decorative or does it serve any purpose, like breathing of frame or expansion gab? Q2: can this gab be closed and the house completely covered with an additional layer of acrylic render? Q3: if the gab needs to be kept, how can we repair the damage? Any help and advice is greatly appreciated! PS: As far as we can tell the house is built up of the following layers, starting on the inside: plasterboard, yellow insulation wool, OSB board, insulation board, acrylic render with embedded mesh and sits on a concrete foundation.

- 44 replies

-

- timber frame

- plinth

-

(and 3 more)

Tagged with:

-

Local people in my area realise that following a very long delay I may soon be able to start selling plots. I am frequently being asked to recommend a good timber frame company, sometimes prospective plot purchasers call it a kit house. Their definition of good encompasses such as design, quality, cost and more. My development is in the far north west of England in West Cumbria. More than 50% of my possible clients seem 'almost' to be going down the custom build route, but correctly they are still calling themselves self builders. I am hopeful that persons on this forum can advise me on how to answer "who & what is good etc". I realise & accept some replies may be more suitable in a Private Message.

-

- kit house

- timber frame

-

(and 1 more)

Tagged with:

-

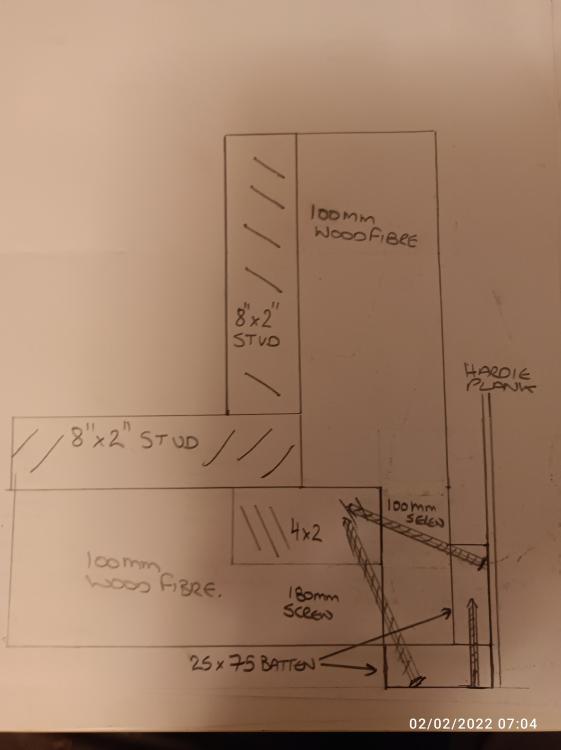

Hi all, whilst waiting for the building warrant I'm getting into details. My proposed build will be timber frame, with an external layer of 100mm wood fibre insulation on the exterior wall. The original plan was to render this, but with documented issues, I've changed tack and will be cladding with Hardie board. When it comes to the installation of the Hardie board I need to be able to fix the corner trims securely, but with 100mm wood fibre this is difficult. I've drawn a solution and welcome comments. (just realised my Stud layout is not correct- forgive me, but the details work) main questions would be, as i've never cut wood fibre, how easy will it be to cut the rebate in the ends of the boards, I have a large table saw / circular saws etc. Does anybody see an easier solution? Any problems? TIA A thought I've just had as typing this, as the frame will be made on site, is to change 1 of the corner studs to 10x2, thus removing the 4x2? need to draw this might need some really long screws.

- 6 replies

-

- the windy roost

- timber frame

-

(and 3 more)

Tagged with:

-

The story so far. My background of building has helped; our modest budget dictates the house will be modest and simple. Highland planning guidance wants single or 1.5 storey houses, ideally traditional looking, or architecturally beneficial. Architects as a whole are probably the most important people to take Ideas and turn them into a deliverable home. Unfortunately an architect for us is unaffordable. We have a budget, and we have to squeeze and leverage every penny from it. So doing away with every fee / service we can has to become a mindset. So we sketch out our plans, make paper models for floor space, list what we want, we need then categorize these into must haves. Our must have boiled down to: 2 bedrooms, Office space, utility / boot room, WC in / near the Boot room for when were outside, Kitchen, Lounge, Bathroom I spent hours reading blogs, and topics, researching timber frame companies and the like. Once we had the outline we now needed the land. We visited lots of crofts* for sale, some as little as 10K some with building some with houses with land from 1 acre and 50 acre. Made enquires for electricity on 1 plot to be given an estimate of 30K for connection. Eventually we put a cheeky offer in for the croft and after a bit of back and forth bought our croft. I printed off lots of drawings from successful applications on the planning website, and used these as basis for the information we needed, to make the whole project possible we needed to add a couple of camping pods into the mix, and to this we needed lots of drawings and lots of information. I never asked for quotes as I knew we couldn’t afford somebody else to draw them. I have used cad before, a long time ago when I was in engineering, and to a lesser extent for building works (floor plans etc), but I had never produced scaled drawings. I found the software Arcon Evo, and this seemed like a solution. I downloaded the trial and started messing around with it. It’s buggy, but after a few hours I was thinking I might be able to pull this off, so I spent £300 for the full blown version, and set out drawing. The software is clever, you can make your own walls, similar to build up in a U value calculator, you draw in plan and it creates the 3d model. Once you’re happy you can create plan elements, these are automatic and form the part of the drawings. You then add the plan elements to a plan. This is your final drawing. For example, You create North, South, East and West plan elements, and you can add dimensions, text etc. You drag these elements into a plan called elevations. If you change the floor plan all the plan elements and plans change dynamically. But it is buggy in places so you have to check all is good. As this was not just a house but pods we needed drawings showing the site elevations, landscape plans etc. We now needed a land survey. The plot is 8hr 30mins approx. from our house so we put some feelers out for getting a land mapping done. £1500-£3000 to produce detailed digital levels and dimensions.... We set off around 2pm on a windy day in July, with my trusty dumpy level, 100m tape and sighting staff, also some red flag metal spikes. We arrived in Inverness around 9pm and stayed in a lovely B&B in Inverness for a mere £130 had breakfast at 7.30 we were on the croft for 10.30. The plan was simple, walk around the area the house was going to be, look out to sea and make sure we position it for the best views (there are 2 houses and a stone barn between us and the sea). Then from here get the levels to make sure the drainage works. And start measuring. The sea harr didn’t help, I couldn’t see Mandy more than 35M away never mind read the staff. We set our datum on the corner of the field on the road, we measured in 10M increments to the position of the house plot around 80M in then created a grid of 10M sq 40M x 50M, using our little metal red flagged sticks to mark the way. I had to reposition the dumpy level a few times due to visibility and used previously measured markers to re-define the datum. An hour or two later cold and wet we had the measurements we needed. After a brew in a café, we set off home getting in around 10.30pm just shy of 1000miles. Total cost around £300. I created a full set of drawing, to include Floor plan, elevations, sections, site plan, pod plans, plot elevations, landscaping plan, 3d plan for the pods. - I sent in a Pre planning application, this is a little thing in Scotland where they like you to ask in advance for planning before you ask for planning. Pre planning took 8 weeks, and was a report saying in general it seems ok, they would need more info on X and Y and drawings for A & B. with this I changed and amended the drawings and put forward my full planning application. I did get the feel that me not being an Architect, did rub them the wrong way, but after a few discussions and changes here and there planning was granted around 8 weeks later. so home drawn plans can and do get planning approval.... I have been asking questions on this forum and reading posts / blogs so added my Introduction with the plans.. The feedback was generally positive, but the big black cloud was the post from @ProDave with regards to the problems he has had with the render on Wood fibre approach. This is the blog I found to work and copied the methodology. How did I miss the posts regarding his troubles? @Russell griffiths, and others also got me thinking about the exposure, so a few restless nights with the calculator and looking for options, we plan to change the external finishes; the planner has been responsive and sees no issues with my request to change the external to Fibre cement boards (Hardie Plank). And also change the roof from Metal roofing sheets to Forticrete SL8 thin leading edge concrete tiles. These changes will give a cavity between the rain shield and wood fibre that I will wrap with Breather membrane. That brings us to present day. Now waiting for the formal quote for electrical connection. And an issue with the water main being made from Asbestos concrete running across our proposed entrance, so we need some trial holes before they make a decision on what needs to be done….. Shopping List: JCB Backhoe loader Static caravan portable storage small touring caravan - cheap as chips - this will be lived in by me for a few weeks at a time until we can get access, water, power and drainage for the static sorted. *A trap we nearly fell into is if you buy a croft you need to follow the rules and work the land, you are bound by these, there are upsides of available grants for help, and this is the bit you need to be careful about. If you buy part of a croft i.e. 2 acre, you’re still bound by the rules, but you won’t be able to apply for grants as the original croft will by default have this entitlement. You need to own the whole croft, and as far as I know this is a minimum of 4.5 Hectare, (11.2 Acre) to be able to apply for grant assistance.

- 8 comments

-

- 2

-

-

Hello, I have decided to convert part of my garage into an office and though this would be a good place to come for advice. In it's current state it's a timber framed timber cladded garage with plywood sheathing on the inside rather than the outside. The frame is larch cladding, breather membrane (not sure if it has battens behind the cladding and over the breather membrane), 60mm batten then 12mm plywood sheets. A lot of stuff seems to have the sheathing on the outside unlike this one but I would rather not have to take the outside cladding and breather off if I don't have to though I don't know how hard or not that would be. I was wondering what insulation would be best to fill in between the studs with if they are straight behind the breather membrane. I am guessing I want something breathable but I don't know if rockwool slabs or wood fibre would be ok directly behind a breather membrane. Finding info on this doesn't seem to be very easy. Also if I wanted thicker insulation in the walls would I be ok adding internal battens to the frame and then placing the internal sheathing on that (going straight through the battens and into the frame) or would that nullify the ability for the sheathing to prevent the frame twisting etc. The floor is a solid concrete floor with a single course of bricks under neath the sole plate with a dpc under the sole plates. I am also looking to install a stud wall inside the garage to keep some of the building as an uninsulated garage space. Should I place another course of bricks where I want the stud wall or could I put a sole plate directly on the floor with the dpm either going under it and up the cold side (still inside the garage) or a dpc under the sole plate and lap it up on the inside and keep the dpm on the inside of the sole plate and lapped up against the turned up dpc? Thanks in advance for taking the time to read this a lot of questions I know. Cheers, TJL

-

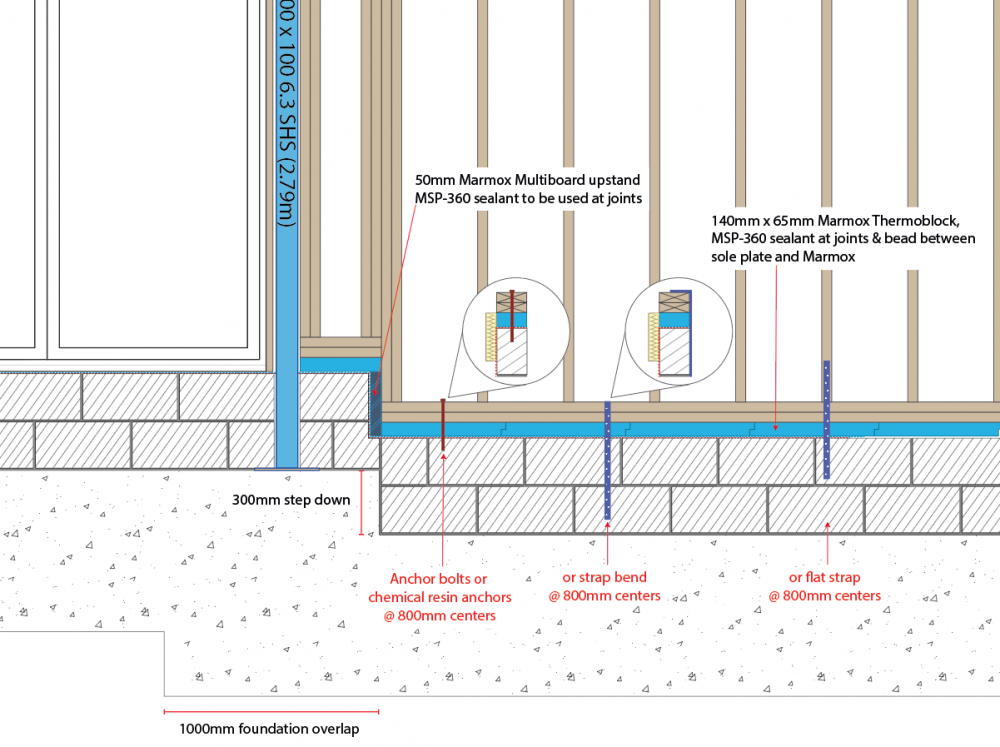

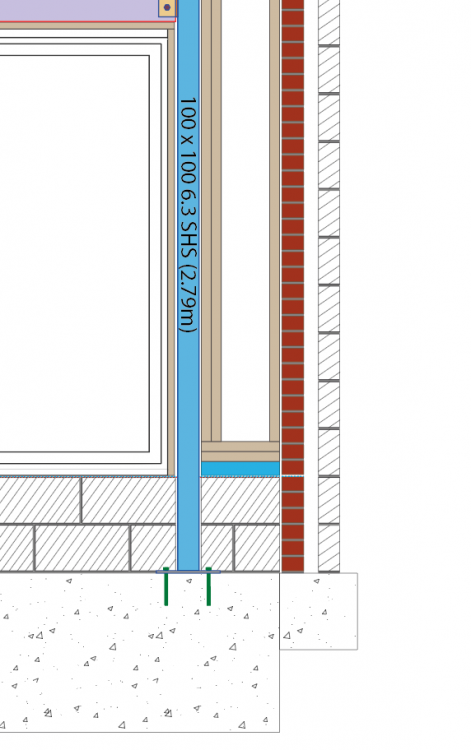

Hello all I'm at the stage where I'm looking for the best solution to strap/bolt down the soleplate of my TF to the blockwork and I am looking for your opinions/advice. I'm currently looking for one of the following options fixed @ 800mm centres: - Anchor bolts down through the soleplate. - Chemical resin anchors down through the soleplate. - Strap bend on the outside of the blockwork going up and over the soleplate. - Flat strap on the outside of the blockwork that goes up the studs. Any advice and help would be greatly appreciated.

- 28 replies

-

- sole plate

- marmox

-

(and 4 more)

Tagged with:

-

I'm looking for some guidance on how to join a new timber frame to an existing wall. The timber frame will be clad with timber feather edge board so no brickwork to tie in with a wall starter kit. Do I just fix the timber stud to the brick wall with resin anchors, a vertical DPC and then some sort of flashing in the corner? Any help would be greatly appreciated.

- 4 replies

-

- timber frame

- brickwork

-

(and 4 more)

Tagged with:

-

Hello, We've had an offer accepted on an early 1970s era timber framed house. On our second viewing we noticed a crack running across the ground floor ceiling and into the top of the wall (photo attached). The same part of the ceiling also has a much larger but more localised crack which is sagging slightly (photo in next post) The ceiling has been recently painted but very faint waterstains are visible. The room above the ceiling is the WC, with no visible issues. The room next to that is the bathroom, again with no visible issues. One of the windows in the room with the damaged ceiling sticks - the one next to it doesn't and neither do any of the doors. Other issues - We also spotted a bit of damp where the plumbing for the washing machine is located, and some grey stuff sticking of out a hole which makes me think there's mineral wool insulation. I have photos of these and can post if helpful. Should we be worried about the ceiling cracks and other issues? What might be causing them? Would it be so difficult to fix that we should look for something else? We haven't commissioned a survey yet but will be doing a level 3, but first want to make sure that these issues don't scream "avoid"! Thanks very much for any advice!

- 5 replies

-

- timber frame

- damp

-

(and 3 more)

Tagged with:

-

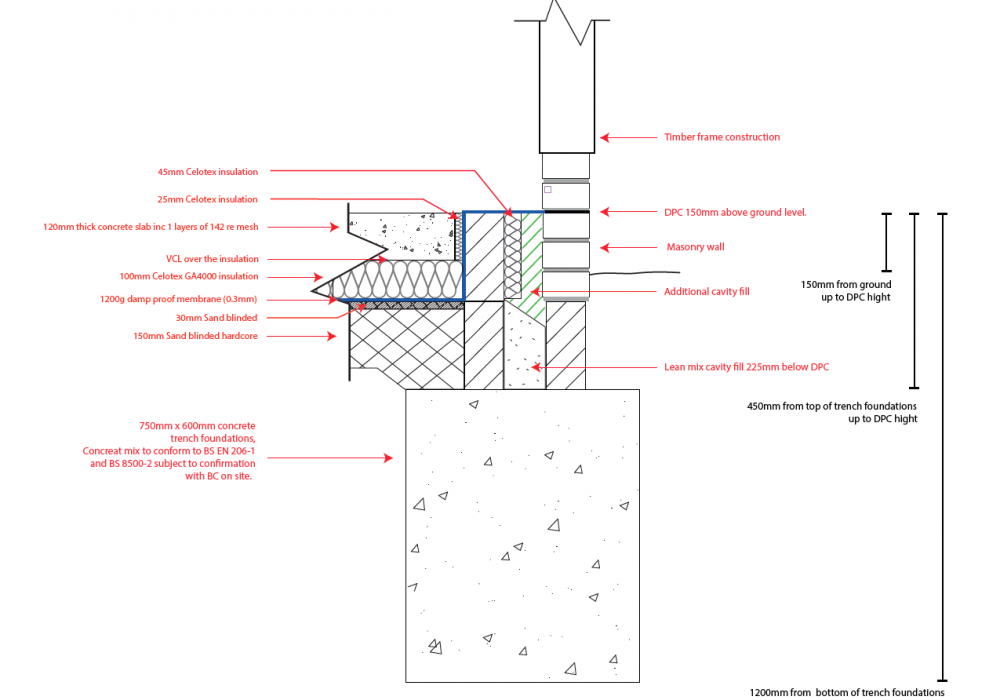

Hello all, I'm after some help understanding if the following drawing is correct for a timber frame building to sit on. The building is a two-story extension and is to be clad with timber feathered edge, not a brick cavity wall. Any help would be greatly appreciated, Cheers.

- 21 replies

-

- timber frame

- foundations

-

(and 4 more)

Tagged with:

-

Im just wondering if anyone knows of any online sources of ready made plans for timber buildings? I have been toying with the idea of a self build for a while now and am just investigating options. I used to make oak frames in my 20s and that has always been the dream, to live in an oak framed house that I built myself. As this would be quite a physical and financial undertaking I was thinking of initially building something simpler, as Im sure I could build some of these flat pack versions that are available nowadays... and then building the dream home onsite over time. Lets just assume; land, planning, regs. are all in place and a non issue. Im not upto speed with all the latest regs, most efficient materials etc, and I know environmental is a big thing now... so was wondering if there was a library of timber framed plans somewhere for self builders perusal, that included e.g. materials, regs etc? Just as a starting point really to see whats achievable, and so I dont have to dig out my CAD 2006 lol. Probably wishful thinking but if you dont ask you dont get. Thanks.

- 5 replies

-

- timber frame

- selfbuild

-

(and 1 more)

Tagged with:

-

My first post but have been avidly reading the posts and blogs and learnt a huge amount about building - so firstly a thank you to build hub. I woulld really like your views on my proposed construction. I am embarking on the construction of a garden studio at the end of our garden. It is a tight site so that the rear wall and side walls are against the garden wall on one side and a blockwork worshop on the other. The rear garden wall will act as the cladding to the rear (coated with basement waterproofer) and the side will be clad with a steel cladding as it wont be seen. The front will be timber clad. In terms of construction - I want a warm building but it doesn't need to be excessive as I will lose too much internal space so I know whatever I chose it will be a compromise - i just want to make the right compromise! I could do with your views on the following: Floor (would it be better to put 150mm EPS below and none on top or will the sandwich mean it heats up quickly but also retains heat better?) 100mm EPS (DPM below and above) 100mm reinforced concrete slab 50mm EPS or PIR Chipboard and LVT floor finish. Wall A Cladding onto battens Protect 200 wrap OSB (9mm) 100mm timber frame filled with 100mm Earthwool slabs to provide some thermal mass. 50mm PIR VCL Batten with plasterboard finish. or would it be better to insulate externally to reduce risk of condensation and so go with: Wall B Cladding onto battens Protect 200 wrap 50mm EPS glued to OSB (9mm) 100mm timber frame filled with 100mm Earthwool slabs to provide some thermal mass. 50mm PIR VCL Batten with plasterboard finish. Sorry - lots of questions but your adivce and thoughts would be really appreciated.

-

Hello, First time posting, so be gentle, and sorry it's a bit long! We have an extension project in planning/just started building stage. For various reasons which I won't go into, I have sacked the structural engineers that were working on our project and am now left with an almost complete foundation design along with some part calculated beams where the extension will join the existing house. I tried, without much luck, to get the original and a possible replacement structural engineer to explain why the foundation design is as it is, and thought I would ask on here to see if anyone can explain to me why I appear to be being dense... (I am a Chartered Engineer by the way so I reckon I have a fairly decent brain, just not a structural engineer). The situation: we have a house that has been extended at various points in the past. The original is mid to late 1700s, followed by a 2 storey extension built we think sometime between 1900 and 1930 (single skin construction, slate dpc and no dpc under the quarry tiles bedded on thin concrete). Tacked onto the side of this part is a single storey extension that I am guessing is 1950s or 1960s - it appears to have cavity walling and a concrete floor, along with modern footings. Summarising slightly, but we are joining a 2 storey prefabricated timber frame extension to the side and above this single storey extension - the ground floor of which will be open plan - hence the current exterior wall will be demolished. The initial engineers designed a block and beam ground floor (clay soil, with trees around 15m away). We had soil analysis done and this recommended depths of 1.95 metres in one corner away from the current house, and 1.4m adjacent to the 2 storey part of the current house (i.e. a spot that is currently inside the house). The foundation design calls for the total removal of the concrete slab and the footings that make up the existing single storey part of the house. As the new footings would then join onto footings that will no way be to modern standards, let alone meeting the 1.4m depth specified by the soil analysis, they have said the existing house will require underpinning, but only where the new footings join the old. I don't understand why we can't keep the current footings and flooring and join onto them. Differential movement has been muttered by both the sacked and the potential new structural engineer, but again I don't understand how the design mitigates this - in fact to my mind it would exacerbate it...? In that if we carried out the design, one wall of our current house would be tied to the new, much deeper footings and at the join points would be rock solid, but surely that same wall would now be at risk of cracking because the footings are not even? And the other walls of the house that range from early 1900s footings (i.e. some, but not deep) to mid 1700s footings (I.e. almost none) could now move at a vastly different rate to the extension and that one wall of the existing house. Surely this will just introduce problems away from the extension? The prospective engineer suggested it is an indemnity issue - is that really it? Does that mean crack in new extension = insurance payout but crack in existing part of house that isn't the new extension = no pay out? Who's risk is actually being protected here??? Or am I missing something?? I look forward to any replies, hopefully someone will help me from tearing my hair out!

- 13 replies

-

- timber frame

- foundations

-

(and 1 more)

Tagged with:

-

What should a timber frame house first floor flooring be like? Been in my new home a year and having alot of noise issues whilst walking on them then also creaking when downstairs? It started a minth or so after moving in.Thank you

-

Hi all, we're currently in the plan drawing phase with the architect for our West Sussex project. We're trying to get away from using oil based products in the build and I am drawn towards using hemp for the insulation of the house. The architect has said that the calculations to get wall U values of around 0.15 with hemp we would need at least 400mm thick walls. We'd rather not lose that much internal space if possible so we're investigating a potential hybrid solution where we use hemp in the timber frame walls and then cover it in another insulation to obtain the required levels. he has suggested we look at the Actis products. I remember reading about the debunked claims on their old product (and have read through old threads on here about the multi-foil insulation) and am a bit sceptical but by using it as a secondary layer and it being so easy to fit that I could do it myself is quite a tempting solution. so, I guess my question to the forum is has anyone used hemp as an insulation material? can anyone think of a different (preferably non-oil based product) that could be used as a secondary layer to reduce the cold-bridging from the timber frame that isn't Actis? or can anyone suggest that Actis have got their act together and now have a product that is worth using? he was talking about the hcontrol hybrid Actic product with the built in vapour control. thanks in advance.

- 26 replies

-

- hemp

- insulation

-

(and 1 more)

Tagged with:

-

Hi guys, I'm looking for some advice and example foundation and slab detailing for timber frame construction. This is what I have in mind so far. Foundation: 300mm of concrete (my soil type is hard ballast) Single 140mm block up to DPC Start of TF construction with 145mm sill plate Slab: Hardcore Sand 60mm floor grade insulation 150mm RC slab 65mm screed One more important detail is that the new construction is set 135mm below ground level, so the internal first floor level is below the external ground level. What options do I have here with regards to the foundation? I can see two options. Dig a trench around the building around 375mm so the exterior ground does not come in contact with the house, and maybe add in a french drain. Have a higher DPM to external ground level and add some insulation to cope with the external ground being in contact with the foundation above first floor level. Any thoughts and comments very much appreciated as always Cheers!