Leaderboard

Popular Content

Showing content with the highest reputation on 12/07/23 in all areas

-

Think the best way to install a heat pump or boiler is as simply as possible. No zones, no buffer, limited interaction with thermostats, design for sub 35 degs for most the year, set to WC and leave it manage itself. In real life zones are required for many, if more than two zones and/or coupled with a mixer valve, you need a buffer, as the mixer valve or a zone can close. If you need a buffer, install either in flow, return or across flow and return, as a glorified min flow loop with capacity to help mitigate short cycling. When a 4 port buffer is used, it is really important to design well, have good internal design to promote stratification and flow either side of the buffer be balanced to prevent mixing. 35 deg flow temp, should achieve a CoP of 3 at zero and about 5.25 at 12 degs. Most the winter is nearer 7 than 0, so if flowing at 35 that should give a CoP 4.5, if you can flow at 30 a CoP over 5. But we all make things more complex than they need to be, mostly at the negative impact to CoP.2 points

-

Would just add that from the info you’ve provided I was able to identify the plot and the previously submitted drawings which you feel you’ve improved upon with your design. You have a lovely plot and area as far as I can see an opportunity to build something fantastic. yes some challenges around plot shape (I had same problem). Looking at the previous drawings -v- what you’ve come up with I’m really struggling to understand where the improvement is and if you posted the existing drawings here alongside what you’ve come up with I’d be really surprised if anyone would agree there is an improvement. HOWEVER there may be a great reason why your unusual new layout and choices (no windows in rooms) is perfect for you and your circumstances and the former layout is totally unsuitable. So this goes back to my first reply if we have an understanding of your needs and wants and circumstances we should get much better advice to you. Though most self builders here will absolutely defend your right to ultimately build what your want to design and layout wise, as I do, we’ll also definitely advocate alternative ideas to help you make the best decision. you’ve indicated you are retired and don’t intend to move again. In which case I’d be advising you not to build this house with consideration to the aging process and ensure you have a living space downstairs that could be converted into a bedroom, with a shower if needed. Easily done. as a I say wait till @ETC sees your post he’s openly offered to assist people in your circumstances. I can’t wait to see what he comes up with TBH and I’m certain it will be a better alternative.2 points

-

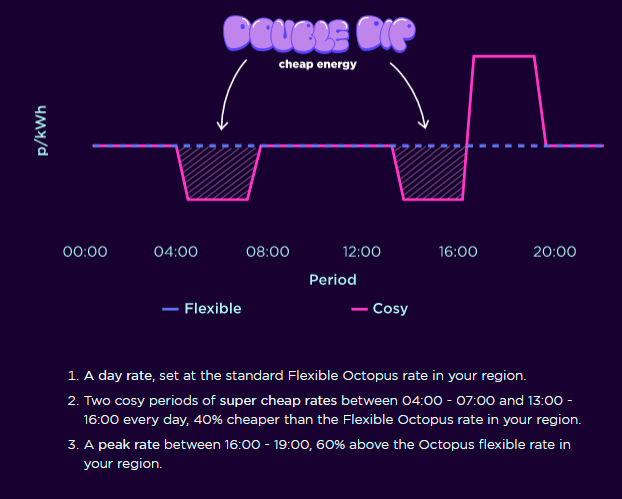

My gripe is there is not an off peak tariff available that does not in some way penalise you for at least some of the "normal" usage times. And in part my resistance to having a smart meter. There really is this thing that late afternoon / early evening electricity is expensive, but being all electric I do not want to be forced into a position where I either have to cook and eat outside a time I consider "normal" or pay through the nose for the privilege. People keep pedalling the notion that smart meters are for the consumers benefit, where the reality it is for the grids benefit to try and even out demand through time of use charging, i.e force behaviour change, cook your dinner at some other time being just one of them. I also have solar PV so have a natural desire to use as much in the daytime, so do as much of my heating then, heating at night counters that so seems to conflict with having solar PV. So on balance at the moment I will just stick with a single rate tariff on a dumb meter. Appreciate other views differ.2 points

-

My lessons learned about buffers People want zones, they think (or have been told) its the good thing to do or have a mixed system with different flow or temperature requirements. The more things you add the more important the buffer becomes. Operated my system without a buffer, but fully open on WC. But one part of the system really needed a different temperature and different running regime. So added a buffer for two different things. UFH in house required a mixer so I could operate at lower flow temperature, chose an ESBE mixer, this stays fully open until set point is reached, then closes to almost fully closed, killing forward flow from HP. The other reason is a small zone of 2x 50m loops can operate on its own if required.1 point

-

Why is a mid point valve even installed on a heat pump, goes against every install manual I've read (loads of them). If connected to an unvented cylinder a mid point valve requires a 2 port valve to positively isolated the cylinder. It should be a diverter and fail to the heating side being open, DHW cylinder being closed unless powered. The other way as @ProDave says is 2x 2-port. But they need to be timed so both are not allowed to open at the same time, which isn't idiot proof.1 point

-

I think you have to change the whole valve head and body. And there will be some wiring changes. Personally I prefer the dependability of individual 2 port valves. As I understand it a 2 port valve is a ball valve. A diverter is less sophisticated, think rubber bung swings round to block unused port.1 point

-

Send him to Lancashire please . He'll never ever want for work. Lucky you are indeed1 point

-

Have you looked at he HSE run site https://selfbuildportal.org.uk/healthandsafety/ They describe the above. In short, yes if you are the Client but are also directing work and haven't appointed a PC and are also quacking like PC then you are the PC.1 point

-

As warm air rises, have you checked the air temperature up there? You may find a ceiling fan can shift enough to raise the temperature lower down. You could try it out with a desk fan first if you have one.1 point

-

Are you able to provide photos of the plot to understand views etc. what size sqm are you looking at building. What are your circs ages, family, WFH, kids, dogs, house for life etc etc. have a look at Danwood homes website will have a few designs of houses that might give you some inspiration. @ETC will help with some good ideas when he sees the post.1 point

-

1 point

-

Isn't the problem that you have the weather Compensation curve/line set wrongly? There's not even one right answer to this, if you run your heat pump 24/7 you can get away with lower water temperatures than if you don't and the heat pump is off some of the time. But it should be possible to adjust the settings if they're not working for you and get settings that do work.1 point

-

Yes, there is a rule of thumb (2/3 vs 1/3), but note that it relates to R value, but thickness.1 point

-

Sorry it's that peak rate late afternoon / early evening that would rule it out for me. It's 60% above normal rate to that would make it about 44p per kWh to cook my dinner. No thank you.1 point

-

1 point

-

1 point

-

1 point

-

From reading yr post in the UFH thread it would seem you have a lot of setback, 3 deg would be more normal. Also many ppl increase the target by 1 or 1.5 deg during the cheap periods to provide a reserve of heat so the HP runs less in the peak. Whether you can do this with the setpoint or the WC will depend on how yr controls work.1 point

-

Leave it on 24/7 and let it defrost when required. is your Samsung installed per midsummer wholesale instructions or per freedom instructions?1 point

-

I'm not running my heatpump yet, but I guess you have to be flexible in your approach, you have to find what works for you in different scenario's. I've been reading the various threads and trying to take the conclusions and build up my own plan, because I just know this time next year I'll be joining in with the various ASHP threads as I try to find the right balance on my HP install. As users we will have to come to a compromise by trying to eek out every last drop of efficiency vs being comfortable, and if that means a couple of quid extra per day when it's baltic outside then so be it. Life's too short to be freezing in your own home.1 point

-

1 point

-

1 point

-

SE first, wind loads, live loads, connections, torsional loads have more effect than the mass of a structure1 point

-

That's talking about the fixings to install the propassiv itself, not for subsequent bulky items attached to and hanging off the propassiv. In most cases these will involve drilling through the propassiv to fix into a rawlplug in the wall behind it. That's where taping and/or sealing the drilled hole really comes into its own In a few places in the loft I used self drilling masonry screws to attach items on top of the OSB and these worked well. (although in many cases they ended.up being removed and reinstalled so I taped over the holes then, not actually aware this was the recommended practice)1 point

-

I’m no professional plasterer but that looks like someone forgot the scrim when it originally got done1 point

-

Most* monoblock HPs have a pretty powerful built in pump. For example the grant/chofu HPs have 10m or 12m head. It's unlikely he will need a additional pump, those are only needed for very big and complex systems. In fact if he has UFH fitted downstairs he may need to remove that pump and run direct. Historically, installers have often put big hydraulic buffer tanks in, which do need additional pumps, but the thinking now is to run the systems with a few "bells and whistles" as possible. The ideal is a single 3 port valve and no zoning. If (big if) his heating system was designed with a 55C flow temp, which was recommended in 2019 but not an actual requirement then the HP should be able to run at about 45C to give a similar output on those rads (the mean flow temp of a radiator spec'd for a boiler flow temp of 55C is 45C because they have DT of 20C across the rads. A HP has a smaller DT of about 5C so will have a Flow temp of 47.5C for the same mean rad temp of 45C) One test would be to turn his boiler flow temp down to 55C (or lower) and see how he goes. If his house is nice and warm with a 55C or lower flow temp, then he probably doesn't need any significant changes to his heating system. *I believe the Samsung Gen6 monoblocks use an external, customer supplied, pump.1 point

-

A is good (A1 is non-combustible) F is bad - easily combustible. So an A rated plasterboard is better than the requirement for a C rated surface. Knuaf class their board as A2 which is limited combustibility probably because of the paper surface. Do not confuse spread of flame classifications such as these with fire resistance. That's something else. The BCO is saying your ceiling should resist the potential for a flame to spread across the surface to an equivalent standard of at least C-s3, d2. So thats C - limited contribution to fire, then s3 relates to smoke generation in this case emissions with a high volume intensity (scale is s1 to s3). Then d2 which refers to the tendency of the surface to produce burning droplets (scale d0 to d2). D2 is the tendency to produce high/intense dripping droplets. So your ceiling must be better than one that has a limited contribution to fire, produces high volumes of smoke and produces high/intense levels of droplets. Well a plasterboarded ceiling will have an A2 limited combustibility rating (as per Knauf), probably has a s1 rating (emissions absent or very limited) and a d0 droplet rating (no burning droplets). I can't see why a BCO should ever query a plasterboard ceiling when tested against the C-s3, d2 classification required by Table 4.1 of requirement B2. It's way better than that.1 point

-

I'd have to check, but I'm 98% sure you don't need to skim. You could ask him where it says so. I suspect he's bluffing it. I went on a fire course where they showed an actual fire test, that demonstrated that even open joints ( exposing a few mm of timber) stayed integral. That's just btw, for your comfort. You'll be filling and taping?1 point

-

Back to the question and my first response https://www.ofgem.gov.uk/environmental-and-social-schemes/boiler-upgrade-scheme-bus/property-owners "We do not check EPC reports for eligible self-builds." So no need for an EPC if you qualify as a self build. Fig 2 on page 28 of the attached clearly say no EPC needed at any stage, in the guidance notes by ofgem. So fill your boots and get it installed ASAP. BUS PO guidance V2.3.pdf1 point

-

Yep...trying to sort the problem out myself because no builder can know it all. He's a nice guy and all the people who work for him on our job are also lovely. He'll do whatever I ask him to do but I'd rather bring him along on the journey of discovery. Not sure he'll get deep into the heat calculations but he'll listen to what I want.1 point

-

I did this recently in my site office that may one day become my summer house. 4 :1 like you said. It worked a treat. My mates dog has been licking it off though 😆0 points

-

0 points