Leaderboard

Popular Content

Showing content with the highest reputation on 12/03/23 in all areas

-

From engineering toolbox . com A 22mm pipe at 45 Deg delta T will lose 8W/m with 25mm insulation but an uninsulated one will loose 60W/m Say a HRC of 50m running 8 hrs per day. 52W*50m*8hrs is 20.8kWh per day. At 25p/kWh its about £1900/year of a difference. Obviously a 15mm pipe will be less and you need to subtract the additional heat generated from your space heating bill to get an idea. The key point for me is that an insulated line of 50m would still be £300/year. Design it out and use 10mm pipes and short runs wherever you can.2 points

-

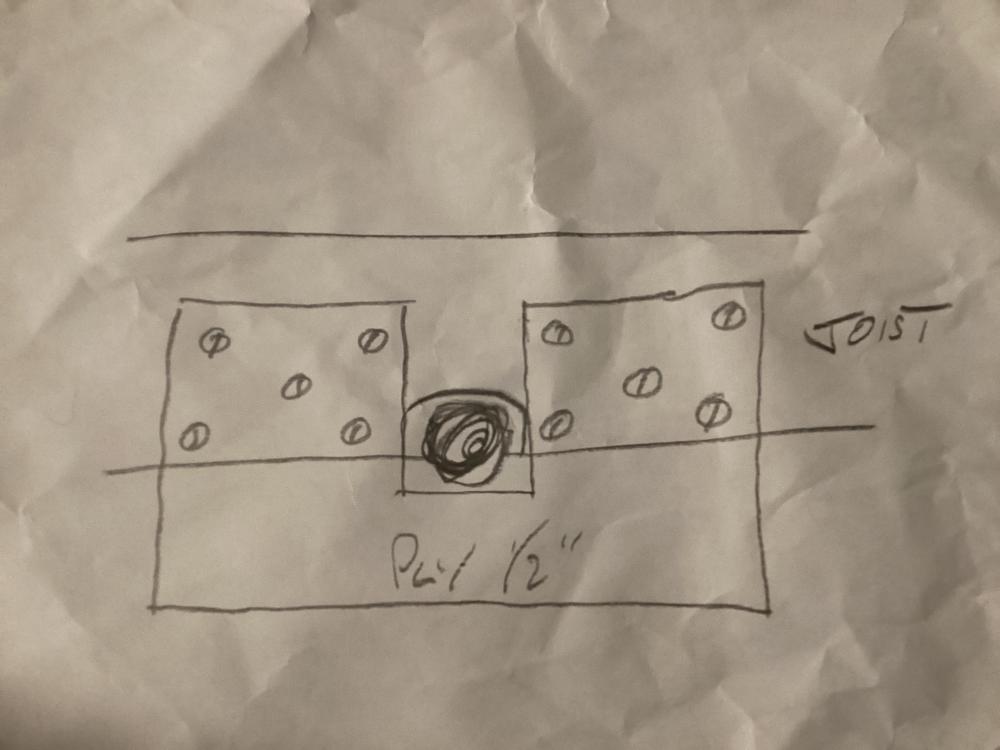

Aa said, I've seen worse and you'd be amazed at what plumbers will do butchering their way through these, only to then hide it below some ply and tiles!! Sister joists, glued and screwed well and forget about it!2 points

-

Our guys cut them in situ with a circular saw. Whole blocks as usual, set ridge height, wooden battens down to wall plates, cut off anything above with circular saw.2 points

-

I say that you should take it seriously, for strength and deflection. That 20% depth reduction is taking away 1/3 of the strength, and it will be bouncy. As above, fix a timber or ply to the side, or both sides. Jump hard on it before and after and note the difference. There's no reason to skimp, so make it 600mm long , or even more. And use plenty of screws.2 points

-

Is it ideal? No. Is it something to worry about? No. Traddies will have seen much worse and it’s been like that for years. Stop worrying, learn from it and carry on.2 points

-

I am not convinced these "credit" market things do anything more than create some non productive jobs to move some money and bits of paper around a system so some companies can claim to be smug and "met targets" The fact we seem to be "solving" the problem with schemes like this gives me little hope that we will ever actually solve the real problem.2 points

-

I'm juggling with our windows, part O simple method & PHPP. I'll also go to TM59 if it'll help get what we want. My objective (I think) is to get a set of windows that are OK for heat loss and make the best out of solar gain in the shoulder months while alleviating mid-summer gain. The windows are nearly all West & East with very few North & South. So, I'm currently modelling automated external blinds & low G glass for protection against overheating but allowing us to benefit from positive solar gain when we can. My questions are: + is there a better way to optimise shoulder months by using brise soleil in addition to automated external blinds? + can I realistically reduce heat loss (in PHPP or real-life) by using automated internal thermal blinds as well? + is there are sensible way to include (in PHPP or real-life) a conservatory-type structure in all this?1 point

-

We’ve just got a hicmicro B01. Works well. Using it to check for cold bridging and completeness of insulation now the frame is up. Deliberately kept away from one which attaches to our iPhones partly because the iPhone adaptor is moving to usb C.1 point

-

The signal from the stat might not be reaching the receiver (assuming wireless?) Manually boost (press up arrow to a few degrees above the ambient), go to the boiler and see if it fires up. I find the signal range pathetic and the general performance of the NeoAirs to be terrible and generally unreliable. Don't spend more money on them.1 point

-

H10 is a 10mm Ø rebar. If they're giving you that information they should be at least supplying you with either a RC drawing or a Bar Schedule so you can give that information to a bar bender. It should take them 10 minutes to give you that information. It's straight forward. Although they have specified a B705 mesh. It should be B785 mesh! Have they specified which way the mesh is spanning? B mesh has a set of main bars (in this case 10mm Ø at 100mm centres) and distribution bars (in this case 8mmØ at 200mm centres). The main bars should span the way they've designed the span of the suspended slab for. Now it may be the case it's not critical but it's worth asking.1 point

-

1 point

-

To be fair, that isn't really a thing. As cooling methods go it's pretty poor. It has limited power and condensation is an issue if you try and push it. I'm not aware of any manufacturer that offers *slab* cooling as an approved option (there are some that offer fan coil cooling) It's only done as a hack by some enterprising "prosumers". A2A cooling, on the other hand, is pretty.much how it is designed to be used for the majority of installations. *heating* is the "hack". There are units out there that cannot heat. But you are right, excluding the A2A class on the basis that it is mostly for cooling is a bad move, especially now. 1) it's not strictly true, A2A optimised for heating is now a mainstream product 2) cooling during extreme heat events might actually be a sensible idea for the UK What we need to do is strongly discourage (or at least not subsidise) unnecessary "comfort cooling". By this I mean using air con to make a space unnecessarily cool to address poor building design. So no building a glass office box then using a air con to make it 16 degrees during a heat wave so everyone wears jumpers. A simple approach would be to not subsidise any heatpump that can be set to cool below (say) 28C. A2A would be (small) subsidy worthy. There could be subsidies for those that have the space to fit a UV cylinder heated by one. Heck maybe someone might come up with a head unit that transfers to water for UFH so you can have UFH downstairs and fan coils upstairs.1 point

-

Ah could not see those, yes but as said above sistering or ply will mitigate any risk of the timber You removed.1 point

-

The only really power cut proof heating systems are ones that use no electricity at all (eg wood stove) and if you have one fitted already it's not a bad idea to keep it as a back up. Ironically my wood stove with back boiler was the backup for my gas boiler when we were without gas for 2 weeks a few winters ago due to a fault in the main! The vast majority of power cuts, for the vast majority of people are fairly brief events lasting less than a few hours. Whilst "what happens during a power cut" is a factor, it's not the huge differential between HP and gas that some make it. In the majority of cases the answer is "the same thing as if you had a gas boiler"1 point

-

1 point

-

With very porous concrete it might be best to apply a wet mix first, to let it soak in and bind the top layer, then a thicker coat over it. It will give recommendations on the container.1 point

-

Ohhh can't remember when we did ours. It was at least 50/50. Maybe 25/75 water to PVA.1 point

-

Do the electricians apply the same thing to wiring with SWA cable? I suspect it has more to do with plumbers charging £3.40 for a 15mm tee of Hep2O and 1 minutes labour, and 70p for a copper tee and 10 minutes labour. It's very hard to convince someone to change when their livelihood depends on it.1 point

-

Completely agree. Targets are the "wish it and it'll come true" equivalent for politicians. Plain A2A heat pumps were excluded. They are the cheapest form of heat pump and can readily deliver a COP of 4 or 5 for £1500 installed or £37B for the UK. You could just bolt one into the hallway or living room or every house and let them accommodate the "base load" of house heating with exiting gas to top the heating. At a grid CO2 of about 200gCO2/kWh and a gas boiler CO2 of about 300g/kWh with a COP of 4 you could would have heat in your house with an A2A HP at 50g/CO2. Even if you shifted half of your energy use to the A2A you would take your CO2/kWh from 300g/Kwh to 175g/kWh of CO2. A 42% reduction in household CO2 emissions for less than the cost of Hinkley point C. Yeah, lets exclude that. 🤪1 point

-

1 point

-

We've got a generator - got it prior to the heat pump, but it runs the heat pump with no issues.1 point

-

To be fair a gas boiler would run for hours, or probably days, on battery using an Inverter with island mode. A HP would deplete a domestic battery fairly rapidly. I’m all for cutting pollution and would fit a HP in place of my gas boiler, but would rather have a backup supply of heat for if (when?) the grid fails. Will be keeping my gas fire and would consider a log burner if not. I don’t like sitting in the cold, especially when it’s due to the £@&&wits in charge and their half baked, short term plans and targets.1 point

-

What about nailng a roofing batten vertically on the ridge line, tying a stringline at the ridge height and pulling to the eaves?1 point

-

1 point

-

1 point

-

Think about your eyelines if what you’ll see. The windows will help a lot but I think think turning to the right at the top of the stairs could feel tight as you’ll need to walk into the middle of that hallway before turning right due to the wall at top of stairs, as your eyeline will be in line with the comb height, but those windows there will help a lot. When they’re at the studwork stage you could just mock up using large pieces of cardboard or whatever, and it should be easy to pull the bed 1 studwork in just a bit if you need to when you see it at 3d and IF it is an issue, as it may not be in real life. Bed 1 reducing from 4.1 to 3.9 could make a big difference to hallway but remains a nice size and shape bedroom. If you did do this it would also let more light into that little 1x1 area in front of the bedroom to the right. As a I say you’ll be able assess in 3D and change accordingly during the build IF it is a huge problem, almost certainly at no extra cost or delay. Just a tiny observation being a bit OCD but have you considered centring the top of stairs window with the staircase as it only needs to move a smidgeon (technical term) to do so. Also would strongly recommend built in wardrobes it appears as if that’s not your intention. We made some good choices and some bad ones for our self build. Built in wardrobes was definitely on the good list. Good decision to have your bedroom at other end of house to kids, and love what I assume to be a laundry chute, something I wish we’d done. hope everything works out ok for you.1 point

-

1 point

-

I’ve built in Nudura so a couple of ideas. Cut a plywood template, add a couple of bits of roof batten to it so you can lay it on the face af the block and it runs parallel with the block edge every time. Or you can build up to just below your gable and screw a batten to the face of the block up at an angle that you need, then snap on the next block, then cut along the batten, this method you might need to get to the outside face to do the cuts, or you need to un snap them and cut on the floor.1 point

-

Pictures would be good, I do like looking down a drain. What sort of answer did you want ? they could be all yours, or they could be from next door. They could be rainwater, they could be sewerage, it could be a grease trap. simple answer. Lift the lids and run a tap. Easy peasy lemon squeezy. You can actually get a drain dye to put in your sink, toilet to tell what one is yours. Go on get out there.1 point

-

That depends on how you view risk. If the site is covered in big holes with sharpened bamboo canes in the bottom like they used in Vietnam, then the risk of somebody getting hurt is high, if it’s a flat piece of grassland with a good quality fence all around it then the risk is low. If you are the the owner of some land you should really have some sort of cover to cover any risk, kids come on it and build a camp from some timber and stab themselves with a rusty nail in the timber, we are living in a society where everyone wants to blame someone else for their mistakes in life so better to talk with a company about your whole build and get a little bit of cover for now until you get going.1 point

-

Probably not a very helpful suggestion, but that's why I like a 45 degree roof pitch, everything is so much easier. But a more useful suggestion I made a big square out of 3 bits of timber forming a 3, 4 , 5 triangle. you could make a similar jig but calculated to give you a 42 degree angle.1 point

-

Lift the lids and have a look, run a tap and see where it comes out. Problem solved.1 point

-

Not sure what the physical layer is, I think it’s something custom, but it’s designed to re-use old thermostat wiring. quite a few master and slave shields/interfaces are available. I might grab one. The plan would be to read the target flow temperature, calculated by the load compensating opentherm thermostat, from the thermostat. Convert this into a modbus flow temperature packet for the target heat pump, and then send it to the heat pump. A web front end (it would connect to your home wifi) would allow for customisation/selection of the heatpump from the list of those supported.1 point

-

We have installed the loop because the furthest room is a long way from the source. it will be pumped only when necessary, with a convenient switch. so it wont be on constantly. Surges do happen. we've a lovely shower but the thermostatic valve has far from an instant reaction. That seems clever. I need a think about that. I think that's the point. it isn't heating a useful space, just the void. The void could be a very large space, in volume or area. Could be the warmest space in the house. I haven't found anything about condensation on the cold, but that wouldn't apply if the hot were insulated. btw that was section 9. there is lots about heat sources before that.1 point

-

The government is so terribly good at solving things with targets. Ask them how their smart-meter rollout targets are doing.. As you say - simply address the price ratio between gas and electricity and the market will solve it itself. Like all these tinkerings, I expect massive unintended consequences.1 point

-

I don't know but I have read somewhere that they're considering doing so. As well as rodent damage, plastic pipes have been known to soften or go brittle when in contact with some sealants, and fire block mastics. Wiring can suffer the same way when in contact with incompatible materials. But apparently it's errors in assembly of push-fit plastic connectors that causes most leaks.1 point

-

Sounds just fine, a bit less than us but we do a lot of tumble drying... I think we've done 50 on the whole house today. It has been hovering around freezing and lots of laundry has been done.1 point

-

Hi @Gaf i think the term is internal comb height certainly that’s what it was referred to by my builder. my roof pitch is 45 degrees and the internal comb height is 137cm throughout. In our rooms this is not a problem for example where we have chest of drawers, bed headboards, etc. in context of me being tallest person in-house at 172cm. We also have several dormer windows and some veluxes which obviously impacts positively on this. Obviously in a room nobody stands up against the wall with toes at the skirting board unless they’re mental. your dilemma however is a 120cm hallway which inevitably requires you to be close to that roof angle. in one our rooms we have a set of drawers, the front of which if projected up creates an artificial comb height same as yours. To the bemusement of my wife I then stood on 13cm of books and measured out 120 cm from front these drawers to replicate what you would have. firstly, the height is fine functionally but with 120 wide if your hallway is long, without natural light it would in my opinion feel tight narrow and low. Your eyeline would be at the roof angle. I’m not saying a 120 hallways is too narrow but in context of comb height it could be. clearly raising the comb height will improve this but other options perhaps to move the hallway wall out by even 10-20cm. Even if this makes the rooms slightly smaller. also veluxes here would help immeasurably as this gives you en extra 20-30cm from eyeline. Can you post your plans. If your hallway is just a metre or so long you should be ok but if long and no windows….1 point

-

1 point

-

1 point

-

Don't be too disappointed as PVGIS predicts 3470 kwh/Yr for us and our actual is 35xx - 37xx/Yr since 2015. The post you were commenting on was quoting a 1.9kwp system which is a modest system and pretty small if you're wanting to go off grid.1 point

-

Big space, no insulation, big bucks to heat!!! My workshop is similar, I did put a heater above the bench facing me when working on the bench. Frankly even warm clothes only go so far, when your fingers are cold they don’t work properly. I rarely work out there In The winter.1 point

-

0 points