Leaderboard

Popular Content

Showing content with the highest reputation on 09/05/19 in all areas

-

3 points

-

I'm a bit surprised you've not already got a design SAP, TBH. BC asked for my as-designed EPC as a part of the full plans submission. The design stage assessment will have picked up if there's a DER/TER issue, so as long as the build meets or exceeds the spec used for that then it should be OK. I have to question quite why anyone self-building would deliberately choose to build to the minimum allowable spec, basically the same as a crap volume build house, though. The standard in building regs isn't high, and it's pretty easy to exceed it, and get a more comfortable and easy to heat house, for barely any increase in build cost.3 points

-

Your architect is talking b*******s. If your timber frame moved enough to "break pipes" I would be VERY worried in his design ability. There are 2 ways to do it, either using aluminium spreader plates, or as we did in our previous house, using a biscuit mix as the heat spreader, but that option needs the joists sized for the extra dead load at design stage. Our present house has UFH on a suspended timber floor downstairs (biscuit mix) and just the bathrooms upstairs (spreader platess) UFH is usually Pex Al Pex semi flexible pipe or similar, so it can take a good deal of movement without worry. If your frame is going to move like your architect thinks, I would worry about all the normal plumbing which in our house is copper, mostly soldered.2 points

-

2 points

-

received_353721582178019.mp4 received_386584338673936.mp4 received_575825816287754.mp41 point

-

1 point

-

1 point

-

Rollers are nearly always custom sizes and are tolerant to variation in height of 80-150mm due to how they are designed. The size of the box is key, as is whether it is single skin or double skin as this can also have bearing on how the tracks are installed. A quick look at the specs and between 290-380mm seems to be the range of gap needed to the top of the opening from the bottom of the rafters. That equates to a block and coursing brick, to a block and two coursing bricks above your lintel. If you have 10 courses of block plus 2 coursing bricks to play with (perfect 2400 ceiling) then your lintel needs to be on course 9, leaving the blocks and coursing bricks above. Easier to do as a pair of coursing rows with a block final. That would give you an opening of 2025 for your garage door. That’s a gnats taller than a “standard” 6’6” garage door.1 point

-

Funny you should say that, but back when we were having problems with the Sunamp controller misbehaving (now fixed, they changed the design to eradicate the problem) I fitted an 8 litre/minute flow restrictor to the shower. It just replaces the normal rubber washer where the shower head connects, and after several months the slight reduction in flow rate, from around 10 to 11l/m to 8l/m, hasn't been commented on, so I've not bothered to remove it.1 point

-

No. The showers will still flow "too quick" even with all HW piped in 15mm and the Stiebel in line.1 point

-

@Nickfromwales will probably be along shortly advocating aluminium spreaders.1 point

-

@zoothorn I feel a sense of déja-vu coming over me... The wall thickness depends on the u-value, and the u-value on the wall thickness. So even though you don't need to show the u-value or provide it to the council in advance, you most certainly do need the precise u-value info in order to get the wall thickness right. You cannot tell the builder what the wall thickness should be, he needs to tell you what it is (after he has done his u-value calculations). You therefore also cannot tell the builder any of the critical dimensions that depend on the wall thickness. In terms of actually drawing it, there are many many ways including various free or cheap drawing and CAD software packages (the latter being able to draw to scale and calculate / mark dimensions from the drawing). However I think it will take you a fair while to find one, install it and learn how to use it. And if you use it incorrectly you will introduce (costly) errors into your plans. My advice is still therefore the same as it was - draw it by hand and take extreme care that you are not accidentally specifying something that the builder should be deciding for you.1 point

-

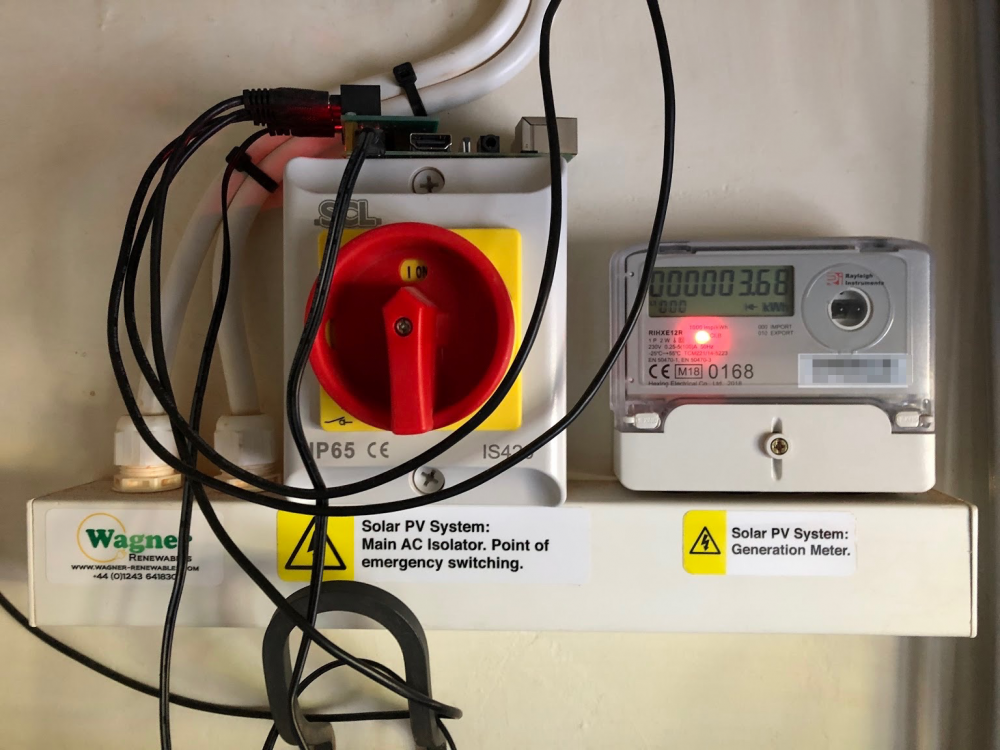

2 x standard inverters - essentially 2 separate systems which are then combined on the AC side and then fed via the export meter and main isolator. 3.9kWp system (13 x 300w panels) but realistically its two smaller systems and never gets anywhere near that peak based on shading and orientation. Export limitation is also in place but never kicks in.1 point

-

1 point

-

So with 100mm cavity you will need extra internal insulation to meet regs. Your quickest approach is to use 75mm EPS right butted to the inside face blockwork and then fill the remaining gap with 6:1 sand cement to hold it in place.1 point

-

Wagner are very amenable chaps - speak to 'Mark the spark', I'm sure he can suggest some options for you. His tales of much larger PV + battery installs will make you jealous!1 point

-

1 point

-

1 point

-

Originally ours was to have skeilings (1 3/4 ?) but decided last minute to go full 2 story (kept ridge height the same so planners not involved) extra cost was bricks only (6 rows), builder said no extra cost on labour as saved faffing elsewhere.1 point

-

As long as the DIN rail mount meter has the right approval, then there shouldn't be a problem. Might be more expensive, as a lot of the cheaper DIN rail mount meters don't seem to be approved to the same standard as normal ones, and normal ones are very cheap (typically less than £30), probably because they sell large numbers of them. The measurement accuracy standard is EN62053-21:2003 A1:2017, Electricity metering equipment (A.C.) Static meters for active energy (classes 1 and 2). It's a bit questionable as to whether some of the popular DIN rail meters from the far east actually comply with this, I suspect, as one or two I've bought don't comply with other aspects of EU certification (they work OK, but the CE marks are fake).1 point

-

Well I have two guns and one is 5 years old and the other is 3 years old, I do not look after them..... they get used and abused, I never clean them unless shit hits the fan, ie I drop it and the bloody can gets separated from the gun....... at which point it’s all hands on deck to remove the plastic that’s left in the gun and spray with cleaner before putting a new can on it. I very rarely remember to shut it down / screw it shut..... I never flush it out with cleaner unless there has been a disaster. As I have two guns on the go at all times I often don’t use one of them and it will sit for weeks / months with foam in it and still works ! So my moral is don’t faff about if it’s not broken, have a spare gun just in case... When the ends get really dirty with a build up of foam I just cut it away with a sharp knife, if foam is leaking out the end I i bash it on a rock ! Always seems to work. 50 + cans....... lost count..... probable 100 but don’t want to talk about it.1 point

-

I've mentioned before our experience when buying a new house with serious defects that had an NHBC warranty. It was a completely meaningless piece of paper, because, in reality, NHBC just do all they can to avoid having to pay out, and it was blindingly obvious in our case that no one had properly inspected the construction to ensure it was OK. The only reason for having one of these useless bits of paper is as above, if a lender needs it. Quite what benefit it is to lenders I don't know, as there are so many tales of these warranties not being worth the paper they are written on that I'd have thought that lenders would have picked up this by now.1 point

-

Yes - I have quite a few Velux and achieved <0.6 ACH in my airtightness. The Integra ones are wired to mains and come with a wireless controller as they're located too high up to reach. I also have their external blinds on the east / south facing windows and internal blinds on the west facing ones (SK10) which are reachable. 2 x VELUX Electric Centre-Pivot GGU MK04 006621 INTEGRA incl. EDN Flashing 2 x VELUX Top-Hung GPU MK04 0066 incl. EDN Flashing 2 x VELUX Top-Hung GPU SK10 0066 incl. EDN Flashing 2 x VELUX Electric Centre-Pivot GGU PK10 006621 INTEGRA incl. EDN Flashing1 point

-

1 point

-

1 point

-

Not a lot That why there are so many of these 3 & 4 storey houses being built and so few bungalows A large part of your build is site excavation and drains We blew nearly a third of our total spend getting the slab and garage bases in and drains1 point

-

You’ll also see,when people have resorted to using washing up liquid instead of the real deal,pitted mortar deteriorating within a few years. And you know the hoddy was patting himself on the back as the compliments rolled in for his ‘lovely creamy mix.’1 point

-

@zoothorn it may seem pendantic, but there is a very important difference between "common" and "standard". Yes, 100/50/140-150 is common. It is often the most cost effective way to balance the various constraints in the most common conditions. But that does not make it standard. Standard implies it will always be valid, and there are many, many situations in which it is not. This is where it gets particularly dangerous. If you do a neat careful drawing of a common construction detail, it is very easy for the builder to assume someone has checked it is valid for your situation. And because it is common, they won't question it. Which then leaves you high and dry if in fact you needed something less common to suit the constraints on your build. In my experience, in problems often boil down to one of two causes: * A client who was vague when they should have been specific. e.g. "make it roughly 4 feet wide". Builder uses a full sheet as that's easiest for him and the client doesn't seem to mind. Later turns out it needed to be exactly 1.1 metres, and it's too big. But the builder made what he was asked to make. * A client who was specific when they should have been vague. E.g. "make it 140mm thick". The number is plausible, and builder assumes the client has done the calculations to get the specific value. Later turns out the client meant "make it have a u-value of 0.18", and there's not enough insulation depth. But the builder made what he was asked to make. I have seen this happen again and again, not just in construction-related fields but also in software development (my current trade) and elsewhere. Or, think of it another way. Imagine for a moment you do hire an architectural technician to do your building plans. Would you prepare them a drawing showing what you wanted? No, of course not. You'd give them the planning drawings and tell them to draw up construction details and come back to you with any questions. When you pay a technician to draw construction drawings, you're not really paying them to draw - anyone can do that. You're paying them to do the calculations and make the decisions required to know what should be built. The drawing is just the way they communicate those calculations to the builder. In your situation, you are not paying someone for drawings. But you are paying the builder to do the calculations and make the decisions that a technician would have done. The builder may do some drawings (e.g. for a panel supplier) or he may do it all in his head. Regardless of how he chooses to communicate with his team, he has taken on the role of the technician. If in the midst of that there are drawings floating around that you've done based on what you think is "standard" there will be conflicting information. And conflicting information always, always means trouble. The more carefully you draw, the more it looks like you've put a lot of thought (and knowledge) into what you're drawing. And the less likely it is that someone will query it. People don't like to think unless they have to. If there is no drawing at all, the builder will have no option but to think about everything. If there is a rough sketch, it will still be obvious nobody is meant to actually work from it. You need to insist the builder does all the thinking you're paying him to do. This is the only way to ensure you and he are on exactly the same page about who is responsible for what. If his role is as you've described it to us, he should be able and happy to work from the planning drawings.1 point