Leaderboard

Popular Content

Showing content with the highest reputation on 06/22/19 in all areas

-

Units are never included in the data set, other than as a header to tell the CAD package what they are. All entities are just expressed numerically. Back when we first got CAD at work (AutoCad, running on a DOS PC, pre-Windows by a few years) we used the new CAD/CAM system in the workshop at our parent establishment for manufacture. Our drawing office designed a new form of Mk46 torpedo tail nut (which includes the motor exhaust valve) using the new CAD system. They were really proud of the thing, which was to be machined from stainless steel. It's dimensions were such that it should have comfortably fit in the palm of the hand. A few weeks later we had a phone call, saying that there was a truck with a delivery for us, and did we have a forklift available to unload it. Lots of scratching of heads, wondering what the thing was, until the pallet was unloaded. There, in all it's glory, was a beautifully machined tail nut around 3ft in diameter, weighing around 1/4 of a ton. The CAD file had been transmitted to the workshop minus the unit header, so mm had turned into the AutoCad default of inches, making every dimension 25.4 times too large...3 points

-

2 points

-

2 points

-

Not a dumb Question Ive employed tilers particularly younger ones That have combed the backs of floor tiles The idea is to get as much contact as possible A smooth thin layer will do this2 points

-

When I first had oak worktops I hated them too. Too much tippy toeing around if you want them to stay looking pristine, joints have moved slightly despite being biscuited and glued and sanded and oiled all around. Unless you want the rustic look They're a bit needy for my liking. Might have that solid laminate in next place2 points

-

What matters is the distance between your foundations and any neighbouring building (not the boundary). And the depth of your foundations. Google "Guide to party wall act". It has diagrams that explain the depth Vs distance issue.1 point

-

I would stand it up at the back, lay the mortar / sealant and lower the front down. The purists will say the back couple of inches might not have much muck under it, but that's what I did in our last house and it never gave problem.1 point

-

Don't do what I did. This is our's in place (it's 2000 x 900 and weighs about 70kg): The stupid way I chose to fit this (it's a tight fit between the walls from left to right in that photo) was to slide the tray in place, spaced up on battens, then lift the right hand side up, propping it in place with a bit of 2 x 2. I then mixed up some mortar, spread it on the floor (being exceptionally careful to not nudge the prop), then I took the weight of the thing and pulled out the prop. I'd intended to lower it carefully on to the mortar bed, but this was not to be. I got it within about six inches of the floor then dropped it. By pure good fortune it happened to end up dead level in both directions, so I just left it and went home, thankful that it hadn't fallen on my head...1 point

-

Thanks everyone. Good advice. I am trying the AutoCad iPad app at the moment and see if that works and will turn to the other suggestions too. @lizzie, good point. I do have the .PDFs but I find I am always needing that one extra measurement that the architect has not included, especially as I am doing my own thermal modelling.1 point

-

Cant you just ask her to send you pdf files? Its easy and quick for her to do.1 point

-

1 point

-

1 point

-

Use draftsight it is free and reads all the Autocad formats except 3D.1 point

-

1 point

-

If you only want to view the .dwg, then it may be that one of the free viewers will do what you need: https://www.autodesk.com/products/dwg/viewers (I've not used them, as I have a copy of AutoCad, but they look as if they may do the job)1 point

-

1 point

-

I can't, in the medium term, see much difference coming for domestic users. People struggle with dual pricing already. If that was changed to even triple pricing, say day, evening and night, the general population would just not get it. One only has to listen to You and Yours to realise how people fail to understand even basic price switching, let alone variable rates.1 point

-

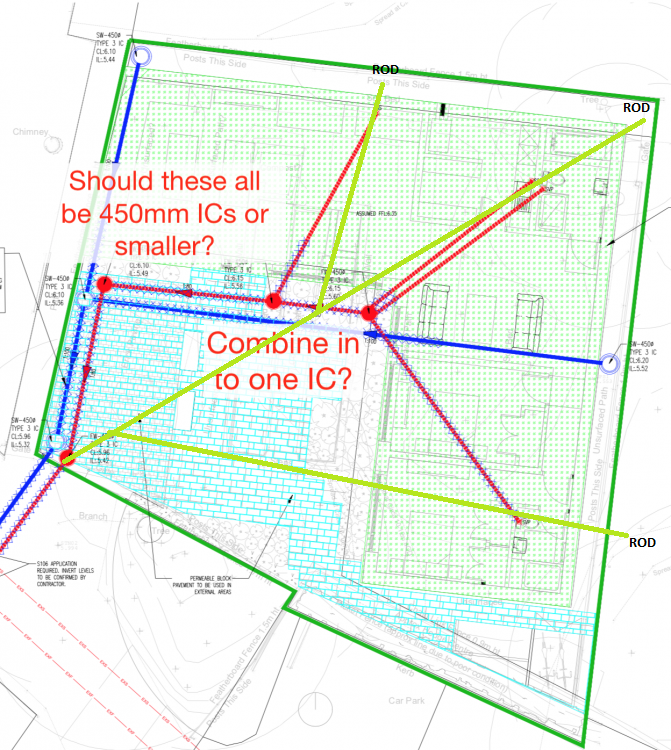

this is how i would do it if it was me, providing you have the depths to be able to do it, there is no need for loads of inspection chambers as long as you have rodding points as shown, you should not have a run that you cannot rod as you are talking about foul drainage you want to keep is simple, follow the "KISS" principle, straightest shortest route, least amount of joins nice shallow angles , your shyte does not need to do a full lap of your house1 point

-

Called Economy 7 isn't it. Used to be a third of the price, now it is under half the price of the E7 Day rate. Not surprising as the idea was to mop up excess nuclear during the quiet times. Not much nuclear online these days.1 point

-

For wall tiling there’s not much need for bb with the exception of heavy tiles such as limestone The bb is to make sure there is full contact Floors can be a disaster If you use a bag adhesive for walls Nothing will shift them Especially direct onto PB If you use two 6 mild Yiur tiles will slide As I say don’t use the inch side to BB It sort of defeats the object1 point

-

You don't "comb" the back of the tile usually, just smooth across the back of the tile with the flat side of the trowel to fill all the indentations and ensure full adhesive contact1 point

-

I read about a case recently, where a council had told a bloke to take down the fence along his front boundary. 2mt high. He told the enforcement officer to sod off. The guy then got an enforcement notice. Told the council to sod off. The council then told him they would take him to court, and get an order for them to remove the fence, and charge him for the cost, and all the legal fees. He told them to sod off. Ended up in court, and because the hearing was near to the fellas' house, the judge said, "Lets go and take a look" They rocked up at the house, and the judge stood of the edge of the tarmac, which was the boundary, and stuck out his arm. Did'nt say a lot, and returned to court. The judge then said to the councils representatives in court, that if the fence had been either on or very near the boundary, that he would have been able to touch it with his outstretched arm. As he could'nt the fence could not be considered to be on the boundary, or even near it.... The result was he told the council to sod off.1 point

-

Thanks for the replies. Caught up with the guys today and they really did get caught in a sh*t storm. The cement had to be dumpered 100m to the pad which they did quickly to reduce waiting time but then the track came off the 8T digger. They were forced to push a 8 cube pile by hand with one man trying to get the track back on. As @Construction Channel said it simply got away from them, nobody’s fault and nobody died. Im not one for shouting and screaming or blaming. Self buildings hard enough without falling out with people that have worked bloody hard for me over time. As as for the solution well we’re going to add a concrete screed cap.1 point