Leaderboard

Popular Content

Showing content with the highest reputation on 07/19/18 in all areas

-

A few photos of the stone work that has now started on site, whilst others continue to prepare the upstairs for the first fix. I have also included an image of the "biscuit screed" laid upstairs over the UFH pipes. Close observers and those who have read previous entries, will notice that the windows have been corrected with fire battens fixed. Anyway, the stone is called a local blend and is made up of Perthshire stone, Cumbria stone and Borders Buff. The Quoins have a hint of lilac to them, to have blend in with the colour palette of the stones. The Red things seen in the photos are glass fibre Fire Socks - They fill the cavity at the corners and other strategic locations. Either these can be used or indeed 45mm x 45mm battens.4 points

-

Git! I've been thinking the row from the top of bottom? 2nd in from left or right?3 points

-

3 points

-

3 points

-

The government seem to have given a boost to small scale battery storage, as they've announced that not only are they scrapping the FIT subsidy next year, but they are also not going to allow microgenerators to be paid anything for any electricity they export to the grid. So, if looking to fit PV, then several things become paramount. The first is to maximise self use, which may lead to the adoption of East/West arrays, or even flat arrays, more useful than South facing arrays. Secondly, not fitting a PV diverter system to heat hot water with excess generation would be daft; it becomes essential to try and use as much electricity you generate as possible, as there is no merit in giving the power companies a free subsidy with energy they don't have to pay for. Finally, with the price of battery systems dropping, this move may well swing the balance to make home storage more attractive. Losing e few pence for every unit exported to the grid effectively increases the return on any battery system. That could make all the difference in terms of cost effectiveness.2 points

-

I agree. I did all my own plans, planning application, building regs submission etc, never having done it before, and didn't find it that hard. If it saved me as much money as quoted above then I'm well chuffed - it might just have pushed my average hourly rate on the build closer to the national minimum wage...2 points

-

Don't get too disheartened, once that stone's rendered it'll look completely different!2 points

-

2 points

-

One thing that amused/infuriated me is that he was proposing that our planning consultant would do the planning submission and liaise with the LA. You'd have thought for £15k he would take on some form filling.2 points

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Just checked and the price of the Sofar 9.6 kWh system has dropped again to £3,858 inc VAT and delivery. This is a system that includes a 3 kW backup supply outlet in the event of power cuts, and one where the price seems to be dropping very regularly.1 point

-

1 point

-

Just one thing to add. I am really regretting doing this at the moment AND it certainly isn't going to leave me with a lump sum at the end which was going to pay my way for the next 2 years and then supplement my pension once I reach state pension age. I am probably going to have to go back to work (after being 'retired' for 3 years once I move into the new house. BUT once I am in there, despite all the compromises I have had to make and despite not having the money left at the end of it all. I won't regret doing it as much as I would have regretted not doing it. If I hadn't done it I would have forever wished I did. In my imagination I would have known it would have been stressful and that some things would have cost more, caused stress or just been so frustrating but I would never have predicted this so I would have regretted it for the rest of my life.1 point

-

1 point

-

Wanna see a f**k up? Not only is it miles out, I did it as an L shape and forgot it needs to wrap round into the cupboard in a "U"!1 point

-

1 point

-

What’s an architect ..?? Did plans and BRegs submission all in Visio along with calcs for steels ... £50....1 point

-

Laying out for the dry run. OMG this is boring! Too much of the same does me in!1 point

-

Put it on and give it 5 mins to go tacky. Use a dry 4" roller to 'squeegee' the excess tanking out or it'll take ages to dry.1 point

-

Well impressed with these sharpening stones! It's really tidied some of these edges allowing a white chamfer the same as the factory edges.1 point

-

Tile adhesive should be after everything is fully tanked. Bed the blue flaps into more tanking.1 point

-

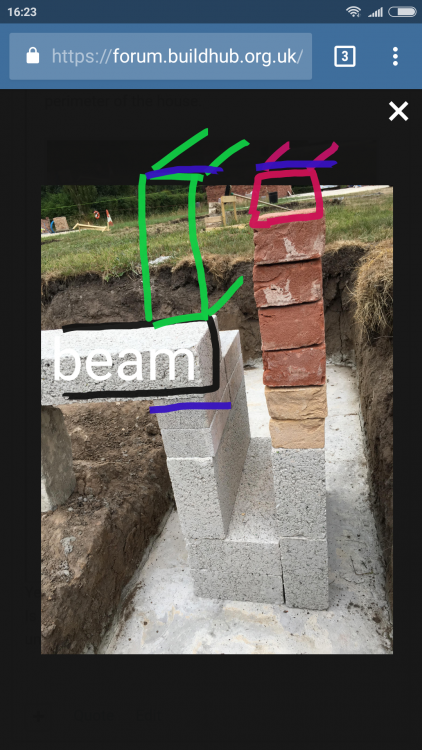

Will the beams not be 150mm so if they are sitting on the top of them 2 courses of concrete bricks they will match the outside first 2 red bricks. If you build a soap bar, see link below, between the beams then you can start of with your blocks on the inside. Put the dpc on top of the first course of block and on the out side skin it will be on top of another brick in the pic. The blue lines would be the dpc with an extra layer under the beams. https://stowellconcrete.co.uk/concrete-soap-bar-blocks/ The 150mm high blocks.1 point

-

No Use Ardex AF200 with a 4 mil trowel You can walk on the matting as soon as it’s down With any matting it’s important that you don’t get to much adhesive under it If you mark out for on length You can roll it out with your hands Then flatten the Ditra down with a grouting float Then any tile can go into it with a flexible adhesive No priming needed1 point

-

We have just paid similar fees on a project with a build cost around £2.5m and final value of £6m. I think the quote is out by a factor greater than 4.1 point

-

Didn’t see the last bit Ditra is your best option ive used Ditra on my three bathrooms Don’t use tile adhesive to stick it down Ardex or simalar Hardly any build up Waterproof and will never give you any problems Ardex about £30 15mtrs coverage sites £5 ish sqmtr1 point

-

I have been researching the external window film to try and deal with my overheating problems. The very nice people in Bognor Regis said it would be fine for my Internorm laminated windows and gave me a quote. I asked a more local supplier for a quote too. He asked exact spec of glass before going any further, looked at spec and then said he would advise against fitting flim as chances of glass cracking were very high. I went back to BR ppl and they still said was OK but I pressed them and they went to film manufacturer who ran a thermal test on my glass spec. Result back today, film not suitable for my glass. I am glad I pressed on this. If I had just taken the it will be fine route and window glass cracked would be a big mess, there is a small possibility -subject to further tests - of some silvered slightly mirrored film being able to be used but I cannot contemplate that in my location. My windows glass is very thick triple glazed laminated both sides. If anyone else has this spec be very careful about sticking film on. Get thermal rests run before installing film. Back to square one on my overheating problems now...praying for a change in the weather!1 point

-

http://solutions.3m.co.uk/wps/portal/3M/en_GB/3MWindowFilm/WindowFilm/Products/ 0845 600 9543 F1 point

-

We used a relatively local firm, GP Systems who were OK, but I'm not sure what sort of area they cover. They are based in Basingstoke, so a good hour's drive away from us. This is their specific page about the 3M Prestige film: 3M Prestige1 point

-

Over 22mm P5 i use 6mm at 400c and 9mm over 600c. I've never laid a thicker ply that that other than to purposefully raise the floor. I put the glue down for ply over Egger with a vinyl floor layer trowel so the PVA has a 2-3mm notch. If there's movement in the Egger your screwed anyway as the tiles will still give. If the Egger has been gas nailed down they're usually 3 to a joist. I always fix 5 10x2" per joist so would recommend screwing next to every nail and ensuring there's 5 fixing to a joist.1 point

-

Agreed Thats why I use an adhesive No point in back buttering the tiles if there are voids under your board I think the 6 mil backer has become so popular As it allows you to put thicker tiles down If you use 18 mil ply you can end up with quite a step1 point

-

1 point

-

It’s fine stuck down with flexible Dont forget to sbr the back of the board We do it all the time W specially if there are any bad shapes on the floor Fill any hollows stick your boards down Leav an hour then screw down1 point

-

Do away with the tiles and use rubber backed carpet. Shag pile. Could be multi use ?1 point

-

What’s wrong with traditional ground bearing slab ..? No-one is mentioning passive slab here - if you want speed, low cost and simple then ground bearing slab (with UFH if desired) is the lowest cost and most well known solution that’s completed in the shortest time. I would never want water under a floor - that’s a sure fire way to get damp and settlement issues.1 point

-

OMG that’s crazy! I’m not sure what construction method you are using but we had a basic design in mind and the timber frame company did all of the plans, SE calcs and certificates and provided the actual frame for a lot less than that!1 point

-

1 point

-

I know, I was responding indirectly to @PeterW's intervention. In 6 months our weather has swung from so dire it put the building industry into temporary economic contraction which then dented national GDP and now we have the driest spell since the drought of 1976.1 point

-

I've had a few birds nest in the garage - will be boarded out next year - I will miss not seeing them.1 point

-

I hope so.....its a biggish claim and there are all those homeless shoes and handbags out there just waiting for me to recycle a bit of vat LOL1 point

-

cheers everyone. @Dreadnaughtthis bit of the wood is a prime candidate for a bit of 'rewilding'. It'll just be left to do its own thing and we'll concentrate on areas with better soils. I think there were some beavers in the area few years ago. One of the old farmers (now deceased) who lived on the other side of the Glen had the distinction of being the last person to trap a big cat I think! @joe90 we're going for a bit more modern timber frame - we don't have the skills or the know how to do that and meet building regs (though it can clearly be done).1 point

-

1 point

-

Pretty much how I cut pb: I don't have a long on T square like that though!1 point

-

I'm quite pleased with that. Going to play with the Rubi cutter now! Falls good: Was aiming for 13-26mm and it's about 18mm. Level not short enough here really but it falls:1 point

-

1 point

-

1 point

-

I figured then if the kids can leave their socks in the dining room floor I could lay out a bit of pb, some tiles and a length of sharp metal. The fact SWMBO's out has nothing to do with it...1 point