Leaderboard

Popular Content

Showing content with the highest reputation on 06/19/17 in all areas

-

Well I started my build March 16 with the best intentions of producing a blog for the site. Well, full time work and two children plus the build meant the blog feel by the wayside, so instead of a blog I thought I could at least post some finished pictures, and if anyone has any questions on what I ve done I can answer them. Anyhow here's the back of the house, with the sliding doors opening up to the open plan kitchen/dining/lounge...2 points

-

Many years ago I had a summer job helping an electrician wire an office block in Staines. Finished the 4th floor and we had a double socket left over. Eventually worked out the plasterers had gone right over one of the boxes. Electrician asks me what I think is the best way to find it? I suggest we go down to the floor below to find the rough location then use his metal detector. No he said. Best way is just to jab holes all over the plaster until we find it, that way the plasterers will learn not to do it again.2 points

-

probably not, but im sure it would be "good enough" plenty of foam Mr Malcolm probably had a finished bathroom2 points

-

Good review of the Powerwall 2 here. The ROI aspects obviously need taking with a large dose of salt as the install is in Australia! However, some interesting info: http://www.automatedhome.co.uk/carbon-footprint/tesla-powerwall-2-domestic-solar-battery-installation-photos-details.html1 point

-

For the guys I've used the invoice gets paid within the week. Spark seemed shocked I'd paid so early. Only fair - but I don't pay anything on advance.1 point

-

I thought that but you can get a bare Makita for like £60. Not worth the grief of another incompatible battery type imo.1 point

-

Have a look at my photostream of my (can you believe still unfinished) sliding gate: https://flic.kr/s/aHsjYQgVgE My mate John's sliding gate, we actually used my parts for his and then when his kit came thru he gave me the parts used. I got the idea for his curved enclosure from the Burj Al Arab hotel in Dubai. I supplied the Unistrut, steel sections, made the shafts and rollers and gave him the leccy enclosure and glands etc and advised on the layout etc. He did the welding and most of the wiring: http://s1071.photobucket.com/user/johnnaughton/library/Sliding Gates All three sliding gate kits from Easygates. http://easygates.co.uk/liftmaster-sly-electric-gate-opener.asp All 3 of us have the 500kg 230V kit. Been in and working for years (except mine) They do a 24V version. Google "12v diy sliding gate" EDIT: That reminds me I still haven't made him his Knightrider LEDs to inset in the block paved drive! Keep hoping my boy will do it with a PICAXE chip. I bought it ages ago. Like father like...1 point

-

I've the previous incarnation of the gennie- £65 at the warehouse clearance last autumn. It's pretty impressive- smart throttle using a stepper motor. Doesn't idle down that low with no load and hunts a little under low loads when cold, but as @Crofter says it pushes out the watts...1 point

-

Here's some pics that hopefully help - the grey strip is a trim piece for the Epdm to give it a nice edge.... One of my final outstanding jobs is to put some composite decking down in the balcony. Need to measure up and work out what adjustable feet and frame I can use as the overall threshold needs to stay quite low.1 point

-

I ll have to try and find the final detail - essentially it's a flat roof with firrings to give it a fall either side (high point in the middle), and it has been built up with a couple of timbers on the outside edge which the Epdm membrane runs up, across and down. The balcony has then been screwed down with coach bolts through the timbers, and every other screw it is going past the timbers and into a steel section below.1 point

-

I've got the generator. It's not as noisy as some of that type, but noisier than a Honda suitcase gennie, obviously. I've not used it much but so far have been quite impressed- starts easily, very portable. I use it to drive a 1400w pressure washer which it does much better than even my limited arithmetic suggests is possible.1 point

-

Bosch make wine chillers with glass doors. Perhaps the doors are interchangeable with their fridges.1 point

-

My experience has been that cash flow can be a real problem for small traders, especially if they get one or two late paying customers. A couple of the guys we had working on our build gave us a slightly better price because we purchased all the materials, saying that they would rather make a few pounds a day less on their labour price than have to bear the cost of a load of expensive materials up front. I made a point of paying them all at the end of each week, too, provided the work was OK.1 point

-

1 point

-

We've got exactly that effect on our untreated cedar cladding. Rain seems to wash the colour out far more than UV affects it.1 point

-

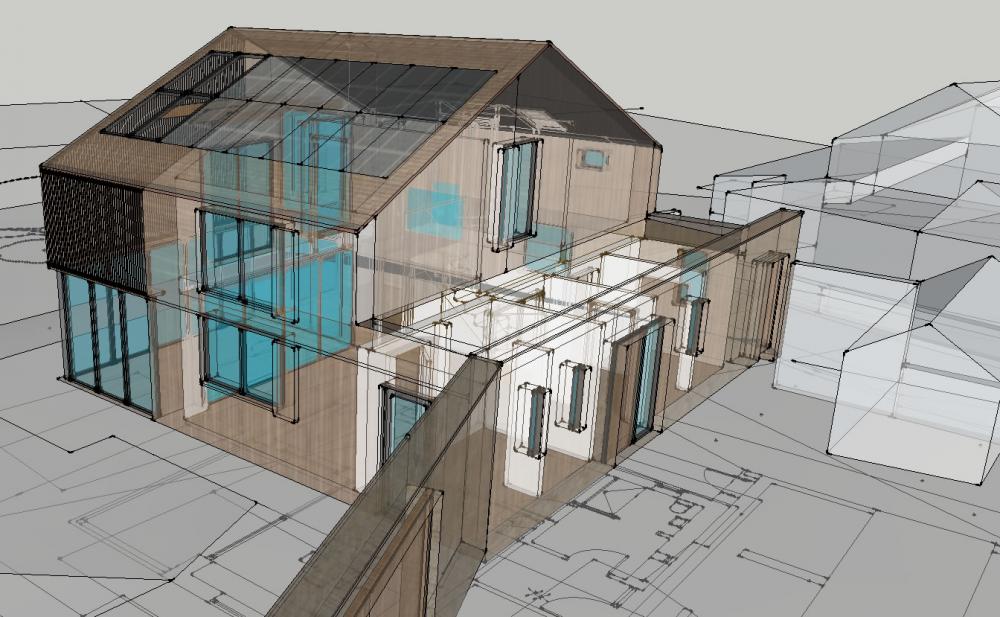

This week has been hard work, but for all that, there's a lot to show for it. This post is an update - much more detail to follow when things have settled down in a week or so. First of all, what's the end in mind? Have a look at this. Its roughly 10 by 10 with an internal garden (on the left hand side - the dark area is open boarding to allow air to circulate freely) The Piggery (of which more later) is the small (wire-frame image) building on the right of the image. We are using an ICF called Durisol. This shot shows a corner detail with our (as yet roofless) Piggery in the background. The blue marks show where the blocks were cut to size: and where the gap is a little bigger than finger width. A little foam was injected into those gaps. Here's a more general shot taken at about mid morning. As yet all hand laid, dry, no concrete. You can see the main contractor (Dan) framed by the the front door framework. The house fairly shot up... Here's where we'd got to by Wednesday And here's where we are today. A couple more window gaps to make, the final pour of concrete and that'll be it for the main build. Everyone walking past says something like 'Where did that come from then?' I always take the time to talk to anyone who expresses an interest. It's important to explain to locals what's happening. There's a very big anti-build atmosphere centered on the Local Plan - it has identified the A6 corridor (100 meters away) as the main area on which to achieve Wyre Borough's housing target. Why the A6? It's a little higher than the local flood plain - ie. the area west of the M6, but East of Blackpool. Lot's of development has already taken place on known flood plain area round here; and justifiably, the LPA is taking stick for it. I'm knackered. Lot's of challenges, lots of hard work, lots of satisfaction. It didn't all go smoothly. Next post, much more detail and an analysis of what issues we faced and how we solved them. The good bit? Needing to buy an SDS+ drill. (The term 'need' is correctly applied in this instance @Ferdinand )1 point

-

My recently completed self build in Wales is used as a holiday home mainly at weekends. The building is only small (net 71sq.m) and with the intermittent use my electric usage is very low so the £100 annual standing charge is inevitably a very large percentage of my overall bill. I've therefore been looking around for a supply option which doesn't have the standing charge element. I thought this may be of interest to those of you who, like me, have low electric demand. This weekend I've switched to Scottish Power's "PowerUp" tariff. The idea is that you pre-pay for your power up to a year in advance. The further ahead you pre-pay the lower the kWh unit price. If you buy a 6 month package the unit price is only about 0.5p/kWh more than the standard variable rate but the big advantage is there's no standing charge. I should therefore save about £90 a year. Ian1 point

-

That sounds about right. The B&Q website says it does 100m2/l which I guessed must be a typo! If not, it would be the best value paint ever1 point

-

1 point

-

Correct We replicated the concrete / EPS detail that MBC rely upon for their twin wall system and it all worked fine. We worked off drawings initially but I made them come measure the actual basement before going into production - caused a few weeks of delay but gave peace of mind. The challenge you will have is ensuring that the non MBC elements are sufficiently airtight (our basement is a big waterproof concrete box so no worries there for us). Suggest you give them a call for a chat, I know that they've done at least one other 'hybrid' build in the past.1 point

-

Our tackers did a very neat job of the socket holes (and MVHR plenums, toilet pipes etc..)- only ever a few mm gap all round - can't imagine doing it any other way tbh. For downlights, these were drilled after decorating by the sparky who'd noted all his cable positions before hand.1 point

-

Hmmm, @Nickfromwales, the bathroom issue...... it would be a shame to get it finished: we'd have no other miscreant to whom we could point as being worse than we are. Can't you just hear it...... "Well yer lucky @Onoff's not doing [...] aren't ya!" No, his procrastination is, to all of us, a valuable asset. Long may it last. Second thoughts, Much Longer May It Last1 point

-

Again thanks for looking at this for me. I'll wire the house to set the system up as above. it addresses my issue of using two locations and keeping the cctv traffic away from the house network1 point

-

Does seem a bit odd, so the invoices are not for work done, but for stuff the builders is ordering for upcoming work? If they are for work done, but the builder needs this cash for upcoming materials then it should be fine as your friend is paying in arrears. In this case I try to pay quickly to help the builder's cashflow. If the payments are in advance then there are maybe two choices (assuming that he would rather not change builder during the project) Either keep the payments small and frequent so he never has too much cash at risk. Or perhaps he could pay the builders merchant direct so that the materials would belong to him and not the builder in the event of a problem although everyone would have to agree to this.1 point

-

Like it. Did you manage the build two, sell one, then be mortgage free trick? I found a picture of the inside.1 point

-

Tile bumper or bumpa is like a conveyer belt to carry tiles up/down. Let your builder arrange the scaffold, then there can be no disputes and he will get exactly what he wants. If the extension is only over the garage I would suggest it would be worth your while just emptying the garage and letting the rain get in rather than wasting time and money with a temporary roof. Now would be time for a good clear out!1 point

-

Hi & welcome. Q1 re bumper I'd imagine the. builder is referring to a tile bumper to get the old tiles down & stored until they're needed again. As for scaffold-are you organising this yourself? Normally the builder would do it & ask for the lifts at the heights they want.1 point

-

I know the site pavingexpert.com was much recommended over on eBuild. With my boy driving soon (hopefully) need to think about extending the parking area. Just been looking at it and thinking what a cracking site it is. Posting here for the benefit of new members: http://www.pavingexpert.com/1 point