-

Posts

30 -

Joined

-

Last visited

Personal Information

-

About Me

Hello,

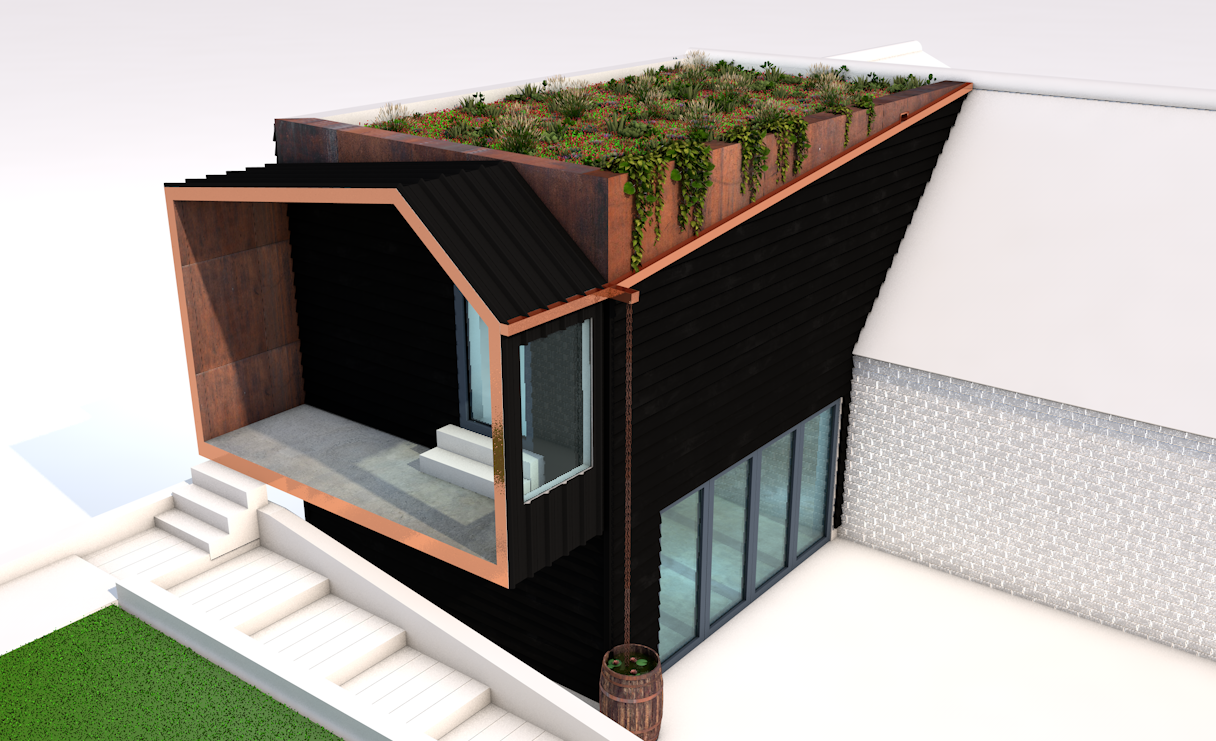

My name is Sean I am a keen DIY'er and im currently self-building a timber frame extension on my house.

I have been searching for solutions to some parts of my build on the net and kept coming across posts on this platform so thought it best to join up and get involved.

-

Location

Kent

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

SeanDean's Achievements

Member (3/5)

0

Reputation

-

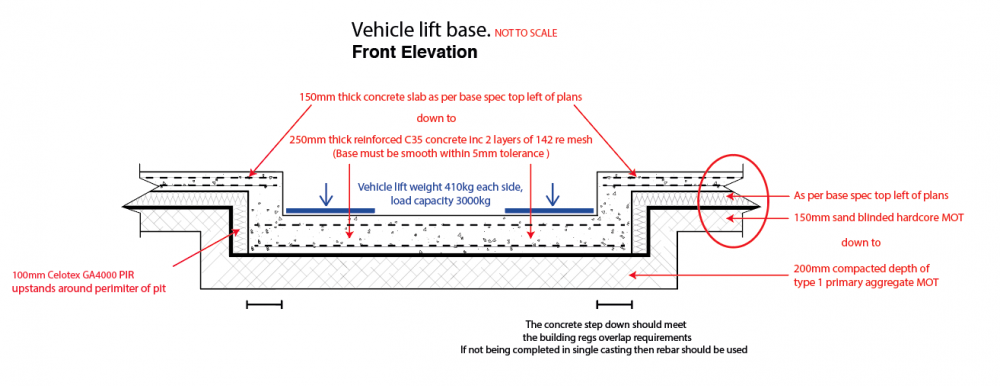

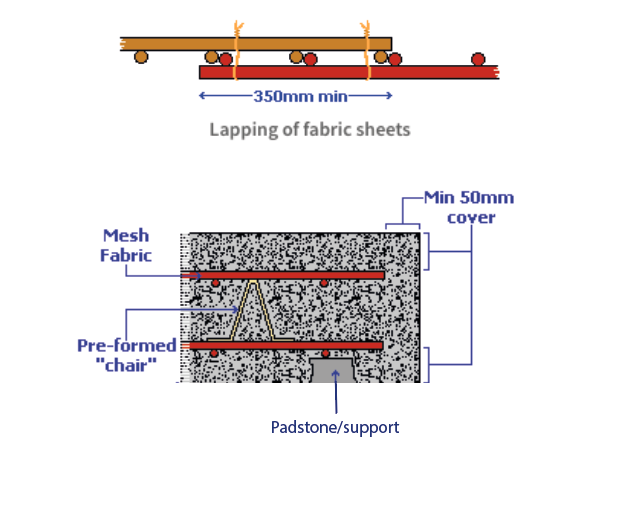

Sorry i'm referring to the two layers of mesh in he entire floor. Im aware the mesh will need to connected if casting in one go its just not on the plan

-

Cheers for your input it's greatly appreciated. Yes, there is no insulation there, it was recommended by the lift supplier and a builder not to put insulation under there. If the garage area was to be converted into a habitual room in the future the pit would be insulated and filled in. I'm just not sure if I should be pulling the second layer of mesh out or be leaving it in, having it in causes issues with the builders walking on it and possibly damaging the UFH but I feel as it was specked this way I should leave it in. I will for sure keep the two layers in the pit regardless. Regarding the thickness of concrete, this is already paid for so reducing the size does not save me any money and is more hassle than it's worth I think.

-

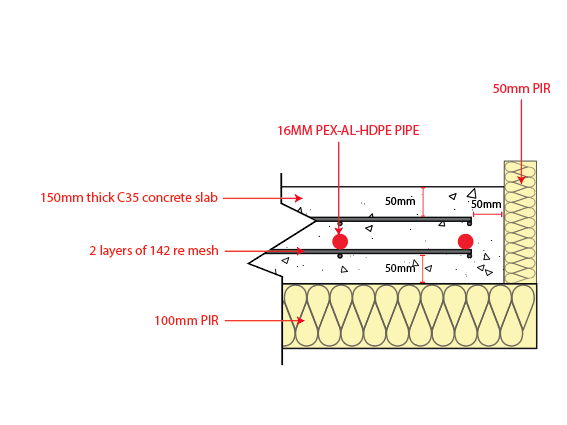

The total area is 50m2, the step is to be cast in concrete. Here is the cross section for the pit, and base. The pit is 270mm deep.

-

@TonyT @Onoff So the current plan is to use chairs for the lower mesh and then continuous chairs for the upper layer of mesh. The builder laying the slab is a little worried as he will be walking over it, do you think a single layer of mesh mid-way is enough or should I be using the two layers as originally planned. From what I'm reading it seems two layers could be over spec'ed but I keep thinking there must be a reason why it was spec'ed in the first place.

-

The original architect spec'ed it with two layers, if it's 100% not needed it could save us fathing about trying to protect the pipe from the top layer of mesh. Is it possible the architect meant layered directly on top of each other rather than spaced apart? (long story short the architect is no longer working on the project) If I was to remove the top layer of mesh am I correct in assuming I would move the single layer of mesh as close to the centre of the slab as possible while keeping the UFH pipe 50mm below the surface?

-

I guess I could add bits of conduit over the points where the top layer of mesh comes into contact with the pipe like @Onoff has done in the images above.

-

Yes, that is correct but also heavy workshop machinery might go in zone 2 as well so thought it best to over-spec the thickness there as well for future-proofing. I guess I could reduce it to 100mm thick but other than saving a little bit of money I'm not sure what I would need to.

-

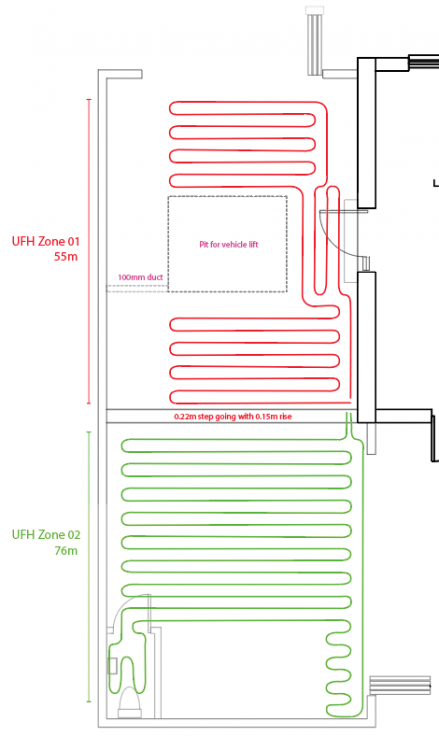

Sorry to highjack the thread guys but I want to check my last min plan for UFH is ok before I start laying the pipe. I might not even use the UFH but thought it best to get it into the slab as I might regret not doing it down the line. Zone 01 is a workshop area and then a step up into zone 2 which is a bar/chill area. The entire space is open plan. So I plan to zip tie 16mm PEX-AL-HDPE pipe to my lower layer of 142 mesh @ 200mm spacing, the base is 150mm thick. I have a couple of questions below, if anyone can help me with them that would be greatly appreciated. - Does anyone see any major issues with my design? - What is the difference between PEX-AL-HDPE and PEX-AL-PEX and is one better than the other? - Am I correct in not running UFH where I might have units/bar or machinery bolted into the ground? - The pipes will not be hooked up to a manifold until later down the line but should I put water in the pipes when pouring the concrete base? Any help with be greatly appreciated.

-

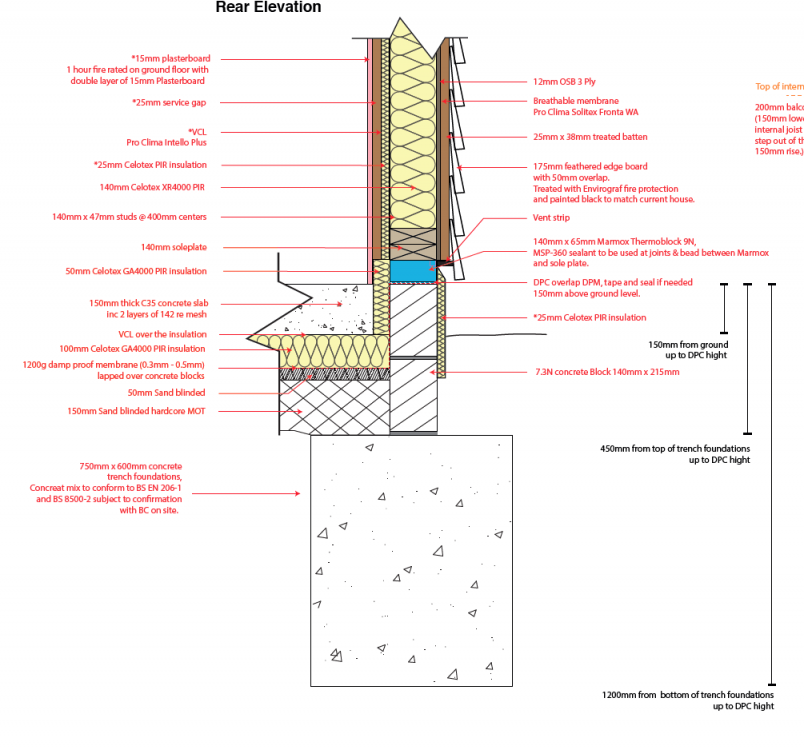

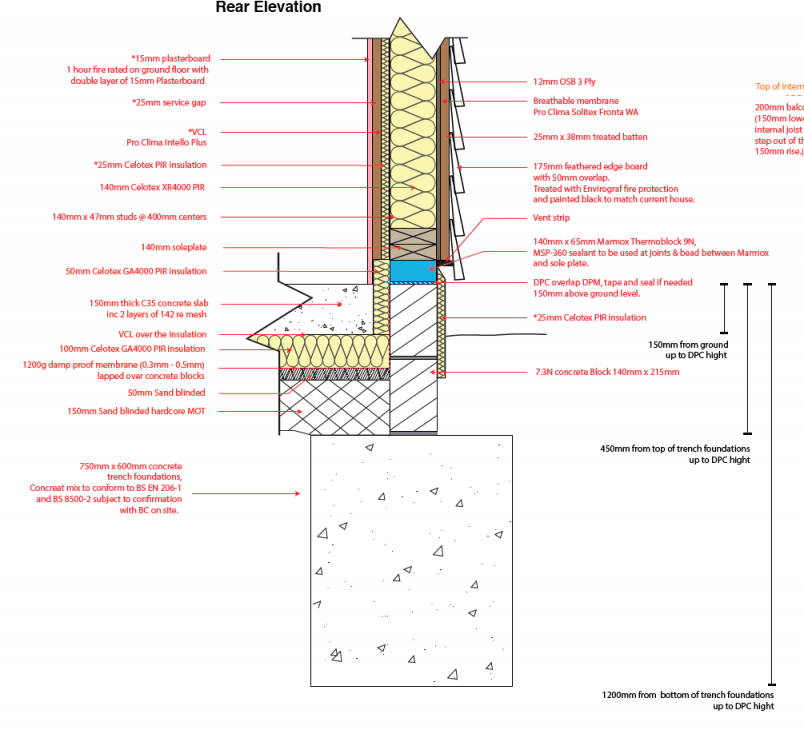

Connecting sole plate to block work with Marmox in between.

SeanDean replied to SeanDean's topic in Timber Frame

- 28 replies

-

- sole plate

- marmox

-

(and 4 more)

Tagged with:

-

Connecting sole plate to block work with Marmox in between.

SeanDean replied to SeanDean's topic in Timber Frame

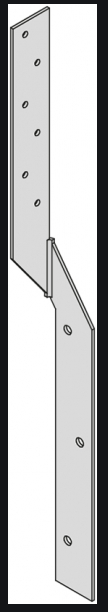

Some really useful responses from you all that have really helped me understand what I need a lot more and the reasons why. I'm going to work on a solution that includes anchor or resin bolts along with a strap like the one below, I just need a solution for sealing the DPC after it's been penetrated along with sealing the DPM if I put the straps on the inside of the build. Any input would be greatly appreciated.- 28 replies

-

- sole plate

- marmox

-

(and 4 more)

Tagged with:

-

Connecting sole plate to block work with Marmox in between.

SeanDean replied to SeanDean's topic in Timber Frame

Cheers for your input, what are your thoughts/solution on penetrating the DPC?- 28 replies

-

- sole plate

- marmox

-

(and 4 more)

Tagged with:

-

Connecting sole plate to block work with Marmox in between.

SeanDean replied to SeanDean's topic in Timber Frame

These look good, but not cheap also some additional work involved regarding insulation needing to be shaped around them.- 28 replies

-

- sole plate

- marmox

-

(and 4 more)

Tagged with:

-

Connecting sole plate to block work with Marmox in between.

SeanDean replied to SeanDean's topic in Timber Frame

Ideally, they would but then that would mean they would need to penetrate the DPM that comes from under the base and laps up over my blockwork. Is it ok to do this and if so do the areas the straps penetrate need to be taped or sealed up some home?- 28 replies

-

- sole plate

- marmox

-

(and 4 more)

Tagged with:

-

Connecting sole plate to block work with Marmox in between.

SeanDean replied to SeanDean's topic in Timber Frame

Thanks this cleared it up for me. I have 12mm OSB 3 ply on the outside.- 28 replies

-

- sole plate

- marmox

-

(and 4 more)

Tagged with:

-

Connecting sole plate to block work with Marmox in between.

SeanDean replied to SeanDean's topic in Timber Frame

Cheers for the info, I have been trying to find the timber connectors you speak of but its proving difficult and I'm just coming across standard straps. I was hoping to just adopt one of the methods, is this wrong and should I be adopting more that one? What are your thoughts on the DPC being pierced when using anchor bolts or resin anchors? I'm not sure what the racking boards are that you refer to, I have researched this but can't find this term relating to timber frame construction. Cheers.- 28 replies

-

- sole plate

- marmox

-

(and 4 more)

Tagged with: