Search the Community

Showing results for tags 'joists'.

-

HI all, I have used this forum for years but finally have to pose my own question rather than simply leech off others… I am replacing the existing felt flat roof on my 1970s kitchen extension with a warm roof build up of (existing) 18mm ply deck / Alutrix vapour barrier / 150mm PIR / 18mm ply / EPDM. I would like to add a flat roof light while I am at it which brings me to my question(s)… The roof dimensions (exterior) are 3.8m x 4.2m and the joists are 150 x 50mm at 40cm centres spanning 3m. I have currently narrowed down to two options which are as follows: 1. Install a 1m x 2m rooflight which would mean cutting 4 joists - I was planning to treble the joists at both ends and double the headers on the long sides (sistering joists and using hangers/fixings etc as outlined in building regs). 2. Install 2 x 1m x 1m roof lights which would mean cutting two joists for each - in this case I would only double the joists at either end but still double the headers. This design would leave two whole joists between the two roof lights. Option 1 is both cheaper and easier in that the EPDM could be a challenge with two roof lights to work around and clearly one window is cheaper than two! However, i feel that option 2 is better structurally but I would really appreciate some input as to the proposed design for option 1. One corner will also sit above a window lintel which is unavoidable in either lay out! Any advice would be greatly appreciated! Many thanks in advance, Will

-

At the risk of sounding like I know what I'm talking about, should I dwang my joists? All those in favour say 'Aye', all those against say 'Nay'. Where's he dug that up from then? Here This is the relevant passage. '... The slimmer JJI joists have been plated at their ends and dwanged (horizontal braces) to form a rigid structure. Two thicknesses of 12mm plywood will cover the ends, followed by the green vapour membrane being folded up over to give a vapour barrier. Insulation board of 140mm thickness will be fixed on top of that to bring it flush with the Durisol blocks below.... ( https://edinkist.wordpress.com/diary-of-the-build/)

- 18 replies

-

- air tightness

- airtight

-

(and 3 more)

Tagged with:

-

Hi, I’m installing a sedum roof onto a 20 sq m garden room GRP flat roof. A common system seems to be: drainage layer on the bottom, then substrate, then sedum roll on top. But some companies sell a lightweight substrate roll e.g. https://thegreenroofcompany.co.uk/product/sempergreen-lightweight-system/ while others use a loose growing medium e.g. https://www.sedumsupply.co.uk/green-roof/growing-mediums/ instead. Is either one better? And I’m concerned about the weight if using a loose growing medium. My calculations are: Joists - 21.5cm deep x 5cm width 40cm between joists centre to centre span 4m (front to back of garden room) https://www.timberbeamcalculator.co.uk/en-gb/span-table/floor-joists?load=1.5&class=C24 says with up to 1.25 kN/sq m, ie 127 Kg / sq m weight, joists can be 4.414m long Total weight per sq m: Sedum roll 400kg (I bought it, that’s what it weighs!) / 20 sq m = 20 Kg / sq m Growing medium (recommended 1.5 - 2 bags / sq m) say 1.5 of the 25Kg bags: 37.5 Kg / sq m or when wet multiply by 1.5? So 56 Kg / sq m GRP 14 Kg / sq m Plywood 4 Kg / sq m TOTAL: 94 Kg / sq m So it is under the 127 Kg / sq m maximum, so should be OK? Can anyone check this and say if they agree?

- 4 replies

-

- sedum

- green roof

-

(and 1 more)

Tagged with:

-

mornin. Pretty easy one for the guys this morning. Ive got a situation where i need to bring up my cold feed for the washing machine and the wall is very close to the joist. There will be units over the pipe work. The wall is back to bare brick so it will need boarding which makes it even more tricky as it will project at least 20mm further. Do i: A) bring up between the brick and joist, manipulate the pipe to bring it past the board and then clip. Means the board wont be able to go as low as i would ideally like, or i could cut a channel from it B) go the other side of the joist and manipulate it back over. Means i can board lower but the pipe will be exiting the floor quite far out is possibly further out than the service void of the units C) chamfer the joist. Probably no good as its taking too much structure away but i threw in the picture for reference D), convert plastic to copper under the floor and then bring copper up with a few 45 bends. Means a joint under the floor which i was trying to avoid. Any opinions on best practice?

-

I’ve taken down a cavity wall that separated the kitchen & attached garage. Planning what to do with bringing new joists in garage to meet existing. Image below shows existing joists bearing onto what was the inner leaf. New joists will be coming from ledger plate off to the left. Originally thought I’d lap them ~100mm beyond the inner leaf. This is going to throw off chipboard ends landing on a joist part way through the room. would butt ending old and new be crazy? Bearing in mind that new would have 150mm bearing on the old outer (garage) leaf?

-

Hi, I'm about to begin lifting the original 'pine' planks flooring in my victorian terrace home. Then to lay American Ash (19Depth x 138mmWidth) planks, & I could just lay them again straight on the joists as originally. Being on the ground floor, there's the typical 3ft 6in ish 'crawl space' beneath, which has a well designed 'air-draught' thru; And at base just the original reasonably dry soil within brick foundations. See photo attached. I've added 80mm of Celotex between the joists several years ago. Original planks survived fairly well in the environment just described though had cupped, doubtless a long time ago, & had been 'face nailed'; I'm thinking I'd secret nailing this time thru groove in T & G might minimise cuping this time? Would my new floor also benefit from 'shielding' from the elements, especially water vapour, down in that under-space? Perhaps I lay a 6mm plywood base ? &/or lay a Tyveck type breather membrane, on the joists ? I've been a decorating, some carpentry, tradesman for years. I'd much appreciate anybody's ideas / suggestions before I start. Thanks in anticipation !

-

Hello folks. I'm converting an old brick garage into an office. Currently I'm levelling up the brick courses, as the old (rotten) roof achieved its slope via the bricks. These slopes weren't very pretty though and I'd been informed that the correct (modern) way to achieve this slope would be through the use of firrings. Mulling it over I've been wondering if I shouldn't just cut the angle I need into the upper side of each of the rafters though, being oversized at 195mm (I couldn't source 170s at the time, that could be delivered to my area), I wondered if I could sacrifice some of that extra depth, that I don't really need, to achieve the slope instead. Just wanted to know if I might be missing something, like bowing/sag, and that it's actually a bad idea? Thanks in advance.

-

Good afternoon everyone, I hope you are enjoying the bank holiday weekend! I'm new here, I've had a look around and I can't see a topic on the issue I have (which I guess is a good thing!). There is a bit of a backstory here so please do bear with me. I moved into my house coming up to 4 years ago, there was a wall in the kitchen that didn't make much sense in being there so I spoke with a (former) friend who I knew as a builder, he came round and had a look and noticed that above one of the walls I wanted to remove, there had been 3 (partly) replaced joists that were held together with a few wood screws, he advised me that I needed to put 2 x 12mm coach bolts through each them and then I'll be ok to remove the wall below. So that's what me and my old man did one weekend, there was a pillar which was part of an old wall which I left in as I liked it as a feature, (this was 3 years ago) the wall got removed bit by bit with no issues. Fast forward to last week (W/B 25/04/22), I want to remove the pillar now to fully open up the kitchen and the remaining wall that formed a breakfast bar. I wanted to get a builder in to confirm that I was able to remove the pillar with no issues and that's when everything seemed to snowball! I spoke to one builder (Monday, last week) and he asked me to send over some pictures and he'll let me know when he would be able to get out to have a look. Tuesday afternoon rolls around and I get a phone call saying he thinks I'll need a structural engineer, he gave me the number of a mate of his, I then spoke with him, he thinks I'll need an RSJ, I want to avoid this where possible as it'll have to be a 7m to reach side to side of my kitchen. I've been Googling (as you do to try and learn about the issue) and found that I might be able to replace the joists as the span is 3200mm (ish) using C24 47x175mm timber, I spoke to the structural engineer and he seems adamant that I'll need an RSJ (he hasn't been around to look yet) I looked at the average price of a 5m RSJ supplied and fitted and it seems to be just over £1k, not something I was expecting and not something I can “just pay for” either. So, after all that, my question is, can I not just replace the joists so that they sit wall to wall? I understand it’s a floor boards up, wiring out and ceiling down etc but I’d prefer to do that than have a 7m RSJ in my kitchen. I put the acro's in as a "just in case" it's been fine for the last 3 years. Any advice is much appreciated

- 11 replies

-

Looking for wisdom from this forum on how to maintain an uninterrupted airtight layer between the ground floor and the first floor in our retrofit (solid brick mid terrace). The joists run front to back and on the front we have to do IWI (On the rear we’ll be doing EWI so my assumption is that we have a thermal bridge issue to solve on the front; but the rear won’t be such a challenge). I have seen a few different solutions proposed for this: i) rehang joists on joist hangers ii) create a new wall plate on which to rest the joists iii) support from below, leaving a complete gap between floor and wall iv) employ the “Tony tray” method Options (ii) and (iii) aren’t really suitable for our small footprint, bay window shape and structure. I don’t much fancy option (i) with a brick wall… so am extremely interested in the Tony tray option but haven’t been able to find an example of how to use it in a retrofit… is it possible? Can the airtight (breathable) membrane be wrapped around a joist in situ? And if so how…? Any pointers to diagrams, photos or videos extra appreciated! I can accept maybe not being able to achieve an airtight layer in it’s entirety, but what worries me is leaving the end of the joist getting damp in the brick area, which is beyond the insulation and airtight layer. I plan to use only natural breathable insulation, tho, so maybe my concern is unwarranted? thoughts extremely welcome!

- 5 replies

-

- airtightness

- joists

-

(and 2 more)

Tagged with:

-

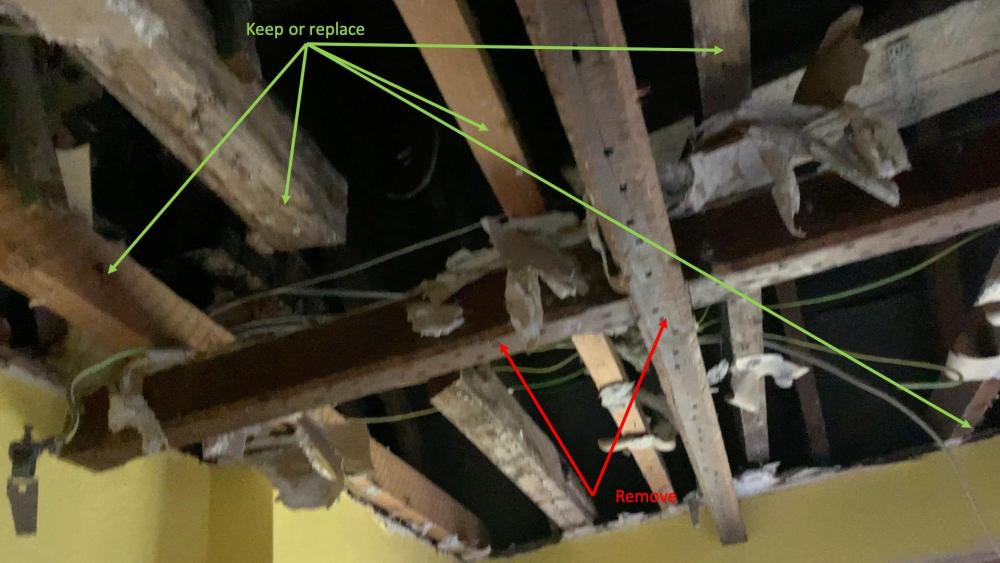

I am in the process of renovating an 18th Century building. Planning to have a vaulted ceiling but to leave the original ceiling joists in place. Below the joists there are what look to be "decorative" joists in place. Would removing these likely cause a structural issue? They were not originally a part of the building fabric. Picture showing joists which I plan to remove or repair/replace Decorative joists before plaster removal Loft space before plaster removal

-

Help. I’ve just moved into a new property and due to the age (only 5 years old) they have fit their camber flooring with glue not nails/screws. They floor boards squeak and I need to know where the joists are! I have been told a stud finder will work but I don’t see how it could as it would be already detecting the wooden flooring so how would it know where the joists are? Can anyone help me to find the joists. Thank you so much

-

I’ve noticed a bit of bounce in two rooms upstairs during our build project and am thinking would doubling up on noggins between the joists help to stop or reduce this bounce? Chipboard flooring has been laid and screwed in. Nothing has been added to the joists underneath yet so that’s why I’m asking now while it’s still possible to up the noggins number. What else could be done?

-

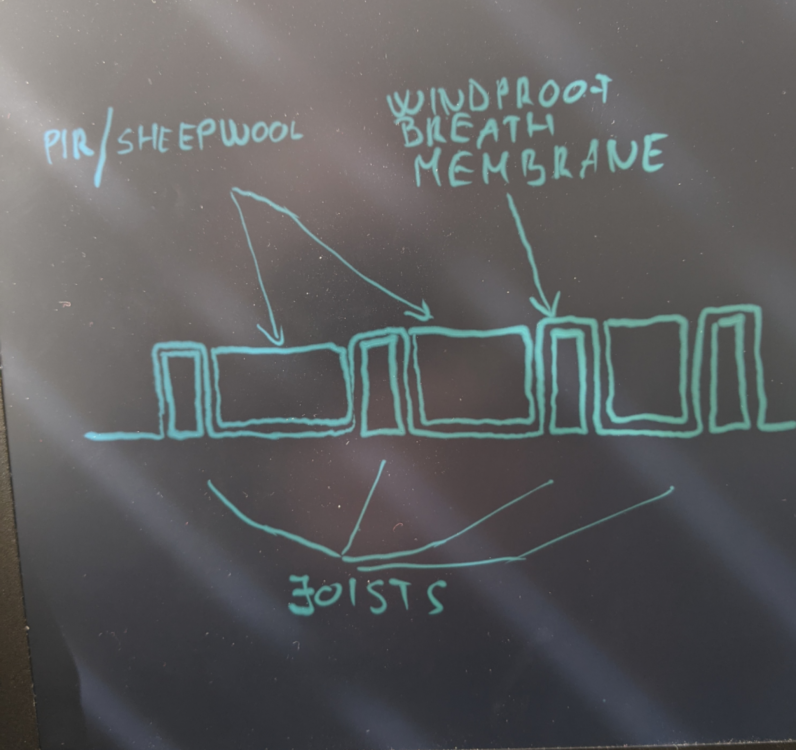

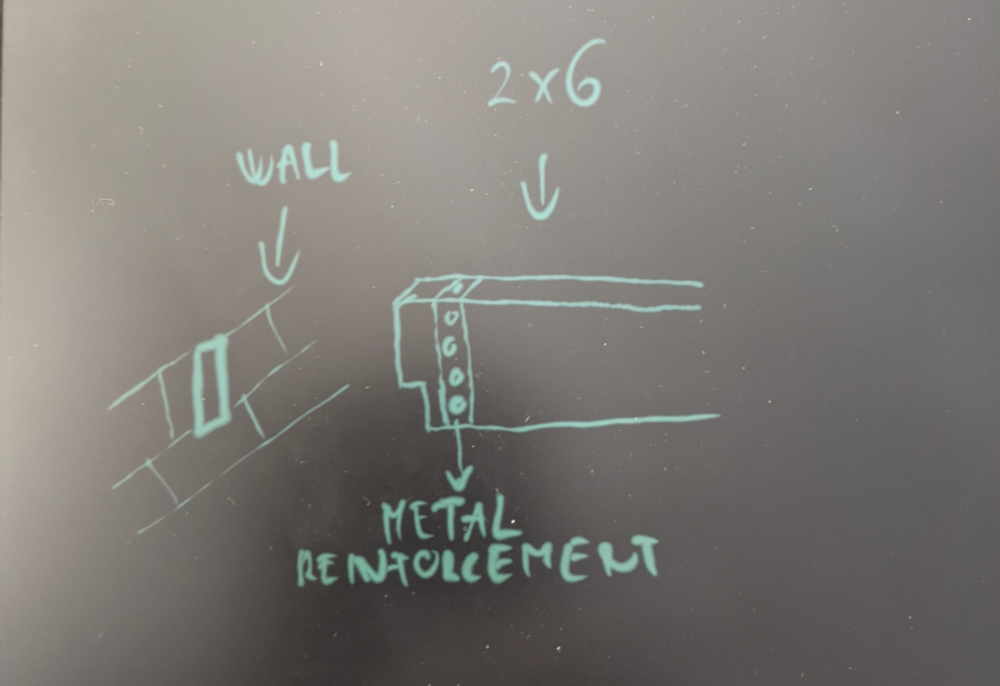

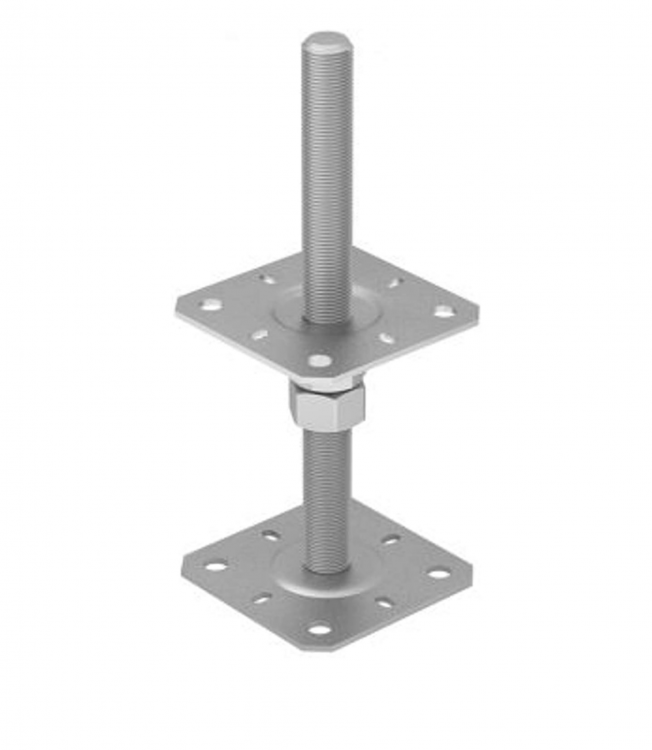

Good morning All! We bought an1960's semi detached house in Stockport a year ago now. I am already insulated the loft area with 200mm rockwool, added OSB boards, make a new cutout and installed a loft ladder. Now we need to upgrade and insulate the ground floor. Ground floor is a suspended timber floor with no insulation at all. Currently there is carpet, 22mm T&G floorboards (most of them have no T&G due it was lifted up by previous owner/builder) on 2x4 joists. Under the joists there is a 300-320mm air gap for ventillation. Roughly 400mm distance between centre of joist. The whole floor area (including kitchen, chimney in the middle and understairs area) is 35m² (7m deep 5m wide) The joists running along 7m front to back. I do not see any wet/dry rot when inspected in a few paces when lifted floorboards and the area under it is fully dry. No sign of wet areas or mould. Since we moved in the floor is a bit springy, and most of thr floorboards are creaking. When we moved in, i was lifted the carpet and removed the nails from few of the 22mmx140mm floorboards and add some screws to stop creaking. What we planning/have in mind: -We want to insulate it. And make additional slepper walls. This is 100% and here comes the things that would be good to do: -Change the 2x4 joists to 2x6 -Add new floorboards to subfloor -Upgrade the groun floo to UFH And now here comes a all my questions: Sleeper walls: I made some research and as far ask I know i need to make a honeycomb structure to do not block wentillation (what is quite obvious) How it need to be done? I mean first make a 100-150mm trench perpendicularly to the joists, fill it with concrete, let it harden, add DPM and then brickwork (class 2 engineering bricks)? As there is no guarantee that the height of the brickwork will be exactly at the bottom of the joists, what do I need to use to fill the gap between the bricks and joists? I have another method in mind as well: Same trench and concrete like above, but instead of brickwork use some adjustable metal joist support like in the picture? Joists: I think it would be beneficial to change it, bcs all of them as old as the house (i think) and I am not sure that it can handle the load of the new floor/UFH/ tiles. Plus it will be a peace of mind that all theese joists are new ones, so i do not need to touch it for a long time. I was make a lot of research on the internet in the last past months, and I don't get straight answers to my questions: Is it a good idea to change the existing 2x4 joists to 2x6 and how should it be done? I mean as i know (but maybe I am wrong) where the joists attached to the wall there is a cut-out in the bricks. Should I make a bigger hole to fit the 2x6 or reduce end of the joist with 2 inches in the deph of the hole in the wall and strengthen the joist after the cut? (See pic#1) Or just replace with the original size? Or it is a wasted time and money and just leave it as it is if there is no dry or wet rot on it Insulation: Which insulation is more beneficial? 100mm PIR, earthwool or sheepwool? I am thinking on PIR or Sheepwool. But there is a lot of different application processes on the internet. Everyone say different how it need to be done. Some of them says a windproof breath membrane MUST be added first and then the PIR or sheepwool insulation. (See PIC) The others says that will make the joist rot on the surface it is covered with it. Others sas the membrane should attached straight under the joists. Others say not any type of membrane needed. Just insulation and floor boards. With the PIR should I need to apply expanding foam between the wall and the insulation. Or (as few of them says) MUST leave 10-15mm gap between the insulation and the wall? Which for my opinion makes the insulation as useful as an ashtray on a motorbike... Do i need to cover the ground with any kind of membrane? If yes which is the one that i need to run with? Floorboards: Which boards to choose? PAR 22x140, chipboard, OSB, plywood, NoMorePly? Some of them says 22mm chipboard become like weetabix after a few years. some of them says 18mm ply is the best and few of them say NoMorePly is the best. And what structure is the best prior to UFH? I have one in my mind which is: Floorboard then pre trenched hard board for the UFH pipes, then a thin layer (1-2mm) of membrane, and the tiles/hardwood floor on the top. In this case how thick the different type of floor boards need to be? Or it is much more better and efficient to install the aluminium plate for the pipes onto the insulation and then ue the floor boards and tiles/hardwood floor? A few details to get a bigger picture: I can not stand that the floor is moving under us as we walking on it and all the contents of the cupboards moving like glassware, flowers pictures etc... The other thing is that if we will have UFH, we would like to have tiles on it. And if the floor is moving I think all of you can imagine the comsequence.... The main thing is that when it will be all done, I don't want/ I can't lift tiles, UFH, floorboard to change/repair insulation/joists/floor boards. But I guess you all think the same. currently have a carpet which we would like to change to tiles or hardwood floor. We still not deceided yet. 3 of us (my wife, our 3 yrs old daughter and myself) living in the house and there is no option for us to move out while the work carried out. I know it will be kind of a pain this way, but this is the only option we have. I would like to do DIY because this way I can save £1200-£1500 on labour only to make the sleeper walls, and/or replace bad/all joists... And i really like to DIY as much as I can. I am already made big built in upboards, decking with roof on it, isulate the loft and boarded, insulate and reroof garage, etc... And i am keen for woodwirking/woodturning. Because of that I am feling quite confident to do it I am plannimg to do it in around 2 weeks excluding the heating. Until the UFH i will put the carpet back temporarily. I think this is doable. Any advice, comment or help is greatly appriciated. And please feel free to correct me if you think something above i wrong. And as I am living here only 10 yrs ago also let me to apologise for any grammar mistakes that I made above. Thank You in advance! Joe

-

- insulation

- floorboards

-

(and 1 more)

Tagged with:

-

Evening all, New person here ? Myself and my husband have just bought our first ever house and business. Two Scandinavian Style A-Frame Lodges, One to Live in and one as a self catering rental property. Both in need of renovation in all shapes and forms! Look forward to getting stuck in and picking brains on here ???

- 4 replies

-

- wooden building

- insulation

-

(and 2 more)

Tagged with:

-

Getting prices back on a tender for a full refurb of a 1930s semi, together with double storey rear extension and loft conversion. Big variation in price for upgrading the the existing subfloor of the first and second floors (the second floor being the floor of the loft). As much as £10k +VAT difference. I had specified that first and loft floor joists should be inspected and only replaced if necessary, and that the joists should be reinforced with noggins and additional joists in one of the bathrooms (because heavy stone bath tub in that bathroom). Although those joists will be 90 years old, there is no damp/rot (as far as I'm aware), and so I don't see why we should necessarily replace them. One builder has said that in his experience joists this old always need replacing and given the amount of changes I'm making to the floor layout (I'm moving the stair case, for example), it's going to be easier to rip everything out and start again with new joists. He therefore thinks I should budget for this at the outset, rather than work off provisional sums depending on what is revealed when we expose the subfloor. A separate point is that the "subfloor" is already exposed in the loft, so if he wasn't being lazy he could just go up there and show me why he thinks the existing joists aren't good enough. Thoughts anyone?

-

Hi, I am currently working on a basement extension in my 1890s terraced house. There was an existing basement to the rear under the dining room but I am extending towards the front under the living room. My question is about removing sleeper walls under the living room. A structural engineer has seen the existing basement and was happy that the first wall could be removed and a wooden support be put into the party wall and across as the joists above only support the floor and is not structural. Having taken this wall down as advised and new support put in I am faced with two sleeper walls going towards the front. Can I remove these and replicate the wooden support as the first OR as they are sleepers do the supports need to be steel? The living room, dining room above has no supporting walls internally. The pictures are of the first sleeper I came to and would like to support, remove, replace with wooden beam into party wall either side.

-

Hi people, I'm new to the site and it seems to be very helpful in most situations so I thought I'd give it a try. I'm a roofer by trade so haven't done much carpentry/joinery and I've been asked by a client to put a roof starting from the joists. It's a new build (family room in the back of the garden) that's roughly 5.8m x 5.6m and the client is thinking about putting an RSJ in to stop the roof from sagging. Could this be avoided by tripling up 8" x 2" C24 timbers in the centre and going out from that at 400 centres? With an overhang the joist lengths will be roughly 6m long. The actual roof will be a warm deck Fleeceback Ruberbond EPDM and it may have a small (1m x1m) velux dome installed as well. Any help or ideas will be appreciated as I havent don't much carpentry before. I'd like to tackle it myself (with a friend) as I'm always wanting to learn more and it seems like a good straight forward one to do once I get a good idea of it.

-

Need advice please: FF bathroom is due to have a square(-ish) bathtub (1050x1250mm, 600mm deep). Total water capacity 428l. Users will be above 110kg. Now the floor structure is timber joists N. G2,47*250mm Grade C24@0.40mCTRS (taken from SE plans). We've made that double joists, bolted together. The new builder (we've had a change of builders this months, don't ask...) says it would probably need a metal plate support on top of joists to ensure the full bathtub does not cause joists movement. Architect says maybe not. Any opinion please?

- 1 reply

-

- floor structure

- bathroom

-

(and 2 more)

Tagged with:

-

Hi All My first post - so a bit of a rookie! I am designing a flat roof back and side extension to my Victorian Terrace and I want to expose the wooden joists of the flat roof into the exposed steel beam (like in attached pictures) I am trying to work out how these are fixed into the beam which is a UC 254x254 - obvi the traditional approach would be pack with timber + hangers but as it will all be exposed Id like a more aesthetic solution. As far as I can tell, I need a 'nice' looking hanger to fit inside of the beam that can be painted with intumescent paint along with the beam and am looking for recommendations for these. Or, do steel companies design this into the beam as it looks like in some of the pictures? I did email one to ask but the answer was no. Any recommendations for these as well! Thank you in advance.

- 3 replies

-

- joist hangers

- joists

-

(and 1 more)

Tagged with:

-

I was glad I didn't do a final check for level when I stopped working on the mezzanine joists last night. I would have had another really bad nights sleep. Look at this.... this is how un-level I managed to nail the joists hanger: no, the red laser line isn't disappearing to infinity, it's 30mm out at one end and 0 on the other - over 2 meters For those of you wondering what self-build does to you - it makes you tired enough to make significant - and sometimes costly- errors All I had to do last night was recognise how tired I was tack the joists in position with cramps and one or two nails go home But no, I had to hammer home 24 nails on the joist hanger with one end of the joist 30mm too low. In the cold light of day it beggars belief . The remedy? Make a 2 meter long stealer piece (wedge) : half a day's work and thank God for Debbie's Christmas cake.

- 16 replies

-

- self building

- tiredness

-

(and 2 more)

Tagged with:

-

This week has been difficult and pleasing in equal measure. Never installed a joist before, but now 8 are up, sitting there waiting to be nailed in place. No nails yet - just push fit. Fussing them into level-ness was interesting. Mostly I managed to get them level enough to of split the laser beam - half on, half over the top. But doing that job made me look at the joists in great detail. The top surfaces have some very small bumps and dips above and below the laser line. Nothing substantial. Since I don't know what I don't know, should I get the belt sander out and make sure that the bumps are levelled out? Planning to nail them in and then put temporary boarding on them tomorrow: quite exciting because it's a bedroom - somewhere to put up guests?

-

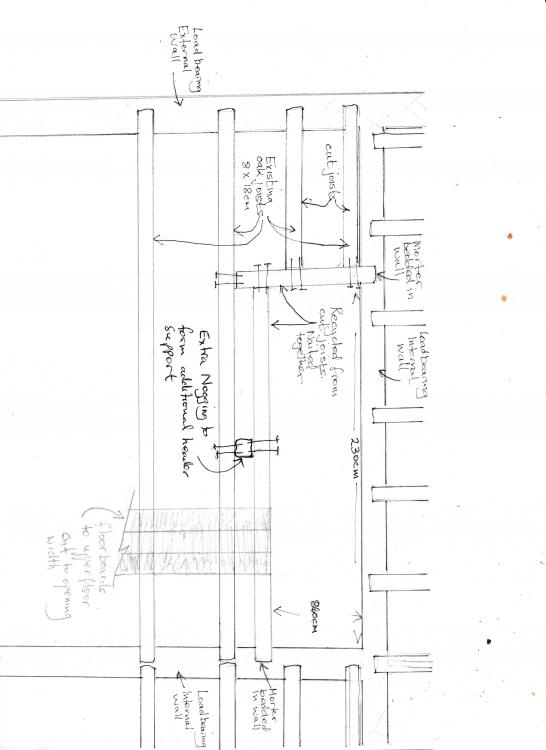

Hello everybody, Here's hoping there is someone who can help with this.... I am converting the loft in my old house that has exposed beam (joists) ceilings. I need to make a stairwell opening. I do not want to use joist hangers or brackets as these will be visible. The joists are 3x8 inch (8x18cm) oak joists in very good condition, no worm or rot at all. The span is 4M and joists are at 52cm. I hope you can see my sketch. My plan is to support and cut back 2 joists to form the opening. To reuse one to form the header and the other the length of the opening, to reduce the opening width. I do not have the space upstairs to have the wider opening to the next full length joist. Please could I have you advice on this plan and will nailing these be adequate? I hope that makes some sort of sense...... thanks for looking.

-

I get that masonry wall floor joist hangers are favoured over traditional in-wall fixing of joists in the pursuit of airtight homes but can these hangers cope with 100 years of cyclical loading? Here is my beef. Driving a metal nail into a brittle masonry block to attach a hanger feels like an abuse of such dissimilar materials with long-term failure designed into the fixing. Next add 100 years of 80kg cyclical loading as humans walk around inside the home, stir in some thermal expansion and contraction loads on the hanger attachments and surely after a decade or two the hanger nails will start wobbling in the blocks? Then finally for a laugh apply that process to light thermal blocks. Are my concerns unfounded? The no nonsense commercial builder of a plot nearby has fitted his metal web floor joists direct into the inner blockwork and these blocks are heavy structural blocks I think.

- 20 replies

-

- joist hangers

- metal joist hanger

- (and 6 more)

.thumb.jpeg.0c0f18d34c098c73dfc014980f3136b4.jpeg)

.thumb.jpeg.0f0cd171af675a71e80ef0b59a03dd29.jpeg)