Leaderboard

Popular Content

Showing content with the highest reputation on 06/05/24 in all areas

-

Hello, I am Sarah an architect turned self builder in Hampshire. Having worked for the last 15 years designing new large scale new housing developments in London, I am now turning my hand to building our family home on the site of an old bungalow. We have been living in the bungalow since 2022 and have a planning consent for a renovation project. However after much consideration we have decided to go for a knock down and rebuild, to ensure that we can complete the project to high performance specification, whilst reclaiming the VAT. We have submitted a new planning application and are awaiting the outcome of that. We are seeking to build a two storey house, from timber frame (from Kithurst Homes) with a insulated raft foundation (Kore/Greenraft or similar). The house will be rendered in lime render with a clay tile roof. We are keen to use natural building materials wherever possible, and whilst we are not seeking passivehaus certification we are following passivehaus principals wherever possible. Ie. high levels of insulation and airtightness, MVHR, PVs etc. We would love to hear from fellow southern self builders, as whilst we are familiar with the design process, we have limited contacts with local builders etc. so any recommendations would be greatly received. I intent to project manage the build myself and am happy to get involved with some DIY, but currently have limited skills in that department!2 points

-

2 points

-

A self-build mortgage would not be appropriate as the property is already built. I think @Jilly intended to refer you to the companies that offer self-build mortgages rather than self-build mortgages themselves. Also, Birmingham Midshires seem to no longer be trading so not a perfect example! 😉🤣 But there are plenty of others to choose from Halifax for example, which has the same commentary of "Yes, provided there are no more than 15 properties on any one development site and construction has been monitored by a professional consultant. We only require this where the new property is to be occupied for the first time." Halifax and Natwest both have mortgages at 4.45% fixed on an external comparison site so I'm sure with your specific details you could end up with a similar offer from Halifax without the warranty issues.2 points

-

They are in bands, so typically single-phase transformers are 16, 25, 50, and 100 kVA; three-phase are 25, 50, 100, 200, and 315 kVA. So if the existing 16kVA is insufficient, the step to 25kVA may not be enough and may not be cost-effective; hence the 50kVA. Or they could be upgrading to a three-phase 50kVA transformer and future-proofing requirements in that location for more heat pumps, electric car charging etc.2 points

-

If you've got 150mm of high performance PIR insulating the room from the ground, why would anyone think half inch or so of cheapo pipe insulation would be good enough to insulate the HP flow and return from the ground. You wouldn't accept water slowly dripping from a pipe so there's no reason to accept heat slowly "dripping" from the pipes.2 points

-

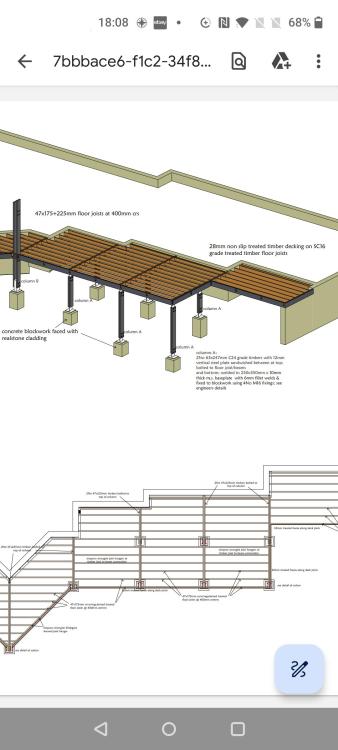

Building Control have signed off the plan already. They were only interested in the Balustrade height. Doesn’t need planning permission. Lots of other work did but when the planning officer visited he confirmed that the 30cm rule was from the ground adjacent to the start of the deck. Even with a structural engineer I’ve found in the past the conversation starts with “How do you want to do it” So I’m just looking at options so thanks for all your ideas!1 point

-

I think your being picky Quick tap with a chisel Zero chance of damaging Ive a faulty one that I hit several time a with a lump hammer and made no impression Or send it back1 point

-

1 point

-

so get it changed. If it was easy to correct and they cared to do quality control, then it would have been wiped or chipped off at source. Hence presumably it is a highish risk. How thick is it? Is this yes, its a faulty product or yes take the risk and chip it off, or yes, use it and find out too late if it leaks ?1 point

-

IMO the PH certification is OTT. We wouldn't get it for our house. Our planners imposed a cottage style to fit in with the village street scene, so no solar on roof and smallish windows on principle (SSE facing) elevation and no windows on gables because of overlooking neighbours, so very little solar gain. However, with now 7 years in the house, I actually think they were right: we like the look and feel of the house. What is more important is that house has low energy loss, and a high internal thermal capacity, so it works well as a single zone and we can keep the whole living space at a pretty constant comfortable temperature 24×7. No zones, no zone controls and valves; nothing complicated, pretty much no moving parts to go wrong and therefore no maintenance costs. In my case I have 4 power relays in my Consumer Unit Expansion and a Grundfos circulating pump, all of which are simple and cheap to replace on failure. The system works well with Octopus Agile so the house is cheap to heat using resistive heating. Having an ASHP would save me maybe £400 a year -- less the £200+ maintenance contract -- but the discounted cost of procurement and installation would be at least 30× that of the annual saving, so doing this makes no economic sense. I do have 3 oiled filled <1kW electric rads (~£60 each) that I do use for time dependent top-up in the worst winter months and these are controlled by my HA through Tasmota smart plugs (~ £15 ea). Again my HA handles these automatically to make best use of cheap Agile rates. The running cost of these is in the above figure.1 point

-

Thank you both - I think I shall do exactly that...1 point

-

I did my brother's deck of similar size with 100mm posts. Spaced them at 1200mm. No issues.1 point

-

Concrete piers? Something like Sonotube they use in the US.1 point

-

The screws are cheap and DIYable for decking, sheds etc. e.g. https://www.groundscrewcentre.co.uk p.s. I bought a bunch of green oak from these guys during covid: https://www.uk-timber.co.uk/58-structural-green-oak-beams Oak is more expensive but much longer lasting than treated softwood. Use A4 stainless fixings.1 point

-

I'd sooner keep the larger diameter and forgo the insulation on any tight sections rather than drop the diameter down.1 point

-

Thanks Jilly. Good suggestions. The owner is in discussions with the architect on the build so I'm hoping they come up with some solutions today. In the meantime, we will speak to some other brokers.1 point

-

I’ll throw in some other options - green oak beam on ground screws?1 point

-

Try another broker, it’s definitely doable. Some thoughts: Speak to a structural engineer? What are the risks? Would a high excess product work? Can you take on the house insurance that the owners have, as in the case where there is a previous structural issue? Approach the insurance company who covered the build itself, they would have wanted the build details? If you can prove it’s insurable, that will surely help? Speak to the owner. If they want to sell to you, they might have some suggestions.1 point

-

1 point

-

So it means you need to request a "formal offer" only then can you discuss it and negotiate it. The formal offer should state which items are contestable (could be done by others) and which are not. I got my quote down a lot by doing all the contestable work myself. On the subject of capacity, I was offered a 12KVA supply as the most that was available, any more would require a transformer upgrade. That is ample for our needs.1 point

-

To be frank, I have no idea. I suspect it is to put people off from commissioning the work. The following is a direct quote from an email where I queried this on my desk-based estimate that was more than £30K for a connection where the existing transformer is 1 metre from the site boundary. "As you may have read a budget estimate is an indication of the likely costs. A Budget estimate is not a formal offer for connection and cannot be accepted. These are desk top exercises, we do not carry out any detailed design work and the assessment is carried out as a desktop exercise that do not take account of any site specific considerations. The new costing rules are not factored into the budget estimate, and would depend on certain factors which would be accessed when providing a formal offer."1 point

-

The problem is you don't really have anywhere to go with this I don't think - there's no competition for the Grid, so they can name their price. £15k seems better than I would have expected for a 50kva transformer to be honest, although I appreciate it's not in the budget. It'll cost you more than double that to consider a proper off-grid solution.1 point

-

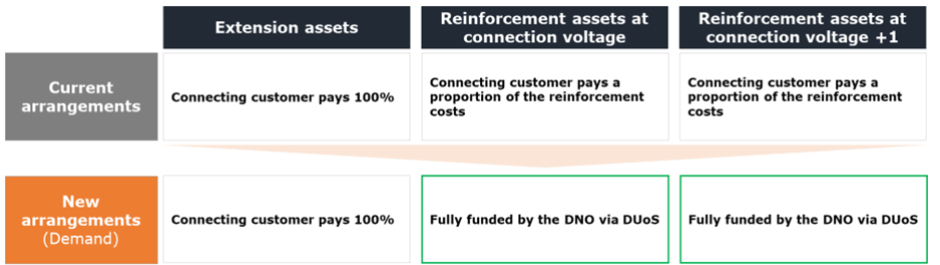

When did you get the figures from National Grid, and were they desk-based estimates or actual costed quotations? The rules changed from 1st April 2023 and you should no longer be paying for reinforcement assets (cable and transformer upgrades) and should only be picking up costs for extension assets (the actual connection). OFGEM Access and Forward-Looking Charges Significant Code Review https://connections.nationalgrid.co.uk/significant-code-review/1 point

-

Yep . You’ve got the glue it completely down otherwise it won’t be doing its job .1 point

-

This has been a challenge for me too. We wanted a tiled bath panel for that built in look but it’s not easy to make it removable so it isn’t but tiled in a way we could get it off without destroying the rest of the tiles and I have a spare pack of tiles. We have coomb space on the back wall behind the bath so I’ve convinced myself I could cut that wall out and gain access to the bath without destroying the bathroom. I’m a bit unconvinced by this but should the need ever arise that will be my first way in attempt. However I did speedfit the taps so they are easy to fix/replace assuming I could get the right spaced taps again (could be worth buying a spare tap set I guess). Therefore it minimises what could wrong under the bath. I took the same approach with the showers opting for a digital showers so all the mixer equipment is in the coomb so easy to get to. There’s nothing in the walls to go wrong with it being just plastic pipes and control cables and I ducted the control cables. I found all this the hardest bit of our build to plan for future maintenance.1 point

-

Since our last entry we've been concentrating of getting the standing seam roof covering on. It's one of those jobs where it would be nice to do someone else's roof before doing your own. We're using a roofing system from Blacho Trapez, broadly similar to the Tata colourcoat. It requires no crimping and minimal special tooling. It's around half the price of Colorcoat. The HPS200 coating we chose comes with a forty year guarantee. Our first impressions is that it's a quality product that's really well thought out. I'll raise a topic thread on the roof system with detail information from our install.. Here's a link to the Blacho documentation for more info: https://www.blachotrapez.eu/pl/26/instrukcje It was another Buildhub find. Back in April we came across an entry where one of the members @Patrick Who wanted to buy his roof abroad and was looking for someone to share transport cost. Enter Patrick, we exchanged emails and found we were going to need a roof on a very different time frame as Patrick is still in the site clearance phase and we were going to be ready to start in around six weeks. Lots of emails were exchanged and there was much head scratching over which components to order, In the end it turned out that three Buildhub members wanted roofs making sharing transport even more attractive. Patrick had been in contact with Blacho for some while, he's multi lingual himself and has a Polish wife. Without their help it would have been just too complex to sort our way through the parts catalogues even with the help of google translate. Having managed to get a list of parts we thought would do the roof, it occurred to us it would be good to get the guttering from the same source. It proved to be a step too far, we decided against it as the chances of getting all the required components correct the first time round was just too daunting, All is not lost though as it now looks as though there may well be an opportunity to get some steel guttering from them in future to replace the UPVC we have. Back to the roof and installing it. The three roofs were ordered and transport arranged to collect them from the factory on 03rd and deliver them to the UK on the 6th. The other Buildhub member ordering a roof is Greg, who is a builder with a yard with plant to unload and was happy to store the roofs ready for collection. The initial plan was to have all three roofs delivered to Greg's place and then we would collect, again Greg could help out as he has a lorry. The only slight problem was some of our roof sheets are 7.2M long and too long for the lorry. More negotiation with the transport company and they agreed to do a second drop off for a an additional 200Euros. All set for an 11:30 delivery on the 6th, we had arranged to have help to unload, no machinery just bodies. To our surprise and dismay we turned up on site at 7:40am on the 6th to find the delivery lorry already waiting...with just Pat and I to unload...by hand. Help was at hand in the form of the two guys who had come that day to do our roof insulation spray foam. They were brilliant, and between the four of us we had the roof sheets off their palettes and safely stacked on site. In addition to the sheeting there where also two smaller pallets for the other roof components, such as barge boards, eaves edges, screws etc. The lorry driver was getting a little fraught by this stage as it was all taking longer than it should have, not aided by lack of a shared language and the delivery documentation all being in Polish. Having unloaded and sent the driver on his way we started to look at the delivery documentation, this time under less time pressure. It turned out we had most of Greg's and some of Patrick's accessories. No big deal as we had already arranged to follow the lorry to Greg's yard to say hello and to borrow some roof tools that he had kindly offered to lend us. Meanwhile the delivery of the materials for our render arrived, 72 x 20kg sacks plus 20 x 25 kg tubs all to be shifted onto site..Just got that cleared when our MVHR system arrived, hotly followed by a soffit board delivery. Once done we set about loading the roof bits, only to find the length and volume of bit's overwhelmed the Jazz and we had to borrow a van great for volume but not so good for the 2M lengths and required me driving with my seat fully forward. Two and a half hours of agonizing cramp we arrived at Greg's, said our hellos and exchanged parts so we had the bits we needed to complete our roof. Finally got home around 10pm, oh the joys of a self build. A day to draw breath and it was time to start putting the roof on. The sheets themselves are 540mm wide and supplied to the customers required lengths up to a maximum of 8M, Being just 0.5mm thick steel they are not heavy but they are fragile, picking up a long sheet badly will result it it creasing, so care is required handling the sheets. The sheets had been packed at the factory front to front with polystyrene packing spacers which had stuck to the surface of the sheet requiring it to be cleaned prior to installation. After a bit of head scratching we decided to use a ladder to support the sheets. With the ladder tied to the scaffold we loaded each sheet, one person pulling the sheet from the top and another raising the bottom of the ladder we managed to slide the first sheet onto the front of the roof. All a bit “Heath Robinson” but it worked. Each sheet was then fixed in place and the process repeated. Soon we had a good part of the front roof in place. Cleaning loading and fitting was taking about an 90 minutes a sheet. Doing uninterrupted areas of roof with decent access proved straight forward and the front part of the main roof was done in a couple of days. Then we started on the rear of the house. This part of roof has two large roof lights and requires sheets to be joined as the roof length 10M exceeds the 8M max sheet length. The roof has two sections one slightly shorter at 7.2M, the largest of the sheets we had ordered. It quickly became apparent that there was no way we could get a 7.2M sheet onto the roof from the rear of the house. At this length the sheet is very fragile and requires multiple supports to stop it from folding. We quickly abandoned any hope of using them. Fortunately we had ordered some surplus material, so not the end of the world. We decided to start on the side of the roof with the roof lights to allow us to minimise sheets cuts. Partick had kindly volunteered to come over to get some first hand experience of the Blacho system. We started framing the roof lights. All did not go to plan and found that we had a 10-15mm alignment problem, nothing to do with Patrick just a bad datum line. No easy way to correct this so we removed the sheets and started again from a more accurate datum line. Second time round was a better result all round and we were able to continue across the main roof section. A lot of work but worth it..now we just need a good downpour to validate the flashing. . By good fortune a thunderstorm provided a test for the flashing, all was nice and dry round the roof lights. Sigh of relief all round, the roof is now on.1 point

-

So I'm still here, plugging away. Apparently I have a roof that is constantly underestimated in terms of the amount of work required. Both chippies and roofers took weeks longer than expected. Still, all part of the fun! Since my last update the cut roof elements were completed, dormers etc. Tiling was completed this Monday. I've insulated the loft. Marley Cedral cladding has begun in the past couple days. Next steps are for fibreglass flat roof to hopefully be completed on the balcony on Monday, then rear bifold doors and front balcony Velfac sliding doors to be installed. I will then FINALLY be 100% watertight and ready to attack the inside in anger. Few photos of various bits and bobs below.1 point

-

Can we know more about what this comprises - bikes, scooters, rodeo simulators......0 points

This leaderboard is set to London/GMT+01:00