Leaderboard

Popular Content

Showing content with the highest reputation on 08/31/19 in all areas

-

I’m not a mod either but it’s because the previous one turned into a pissing contest of opposing views, and shitloads of reported posts citing racist comments et al, which kept the mods continually busy trying to keep on top of before someone launched a counter attack, and this is a self build forum, not the Daily Mail comments section. Other ‘pointless’ threads as you put it tend to be easy going and report / mod free. None of the mods signed up to moderate political clashes, they are here to oversee self build posts and keep this forum free to use and spam free.4 points

-

I've just run our house through SAP again, using the new emissions factor for electricity, and the CO2 emission has changed from -0.9 tonnes to -1.94 tonnes per year. That's a change from our house being roughly equivalent to about 40 mature trees, in terms of effective CO2 sequestration, to it being roughly equivalent to about 86 trees. The impact of this on offsetting the CO2 produced when making the concrete in our slab is that the CO2 "debt" of the ~10m³ of concrete in our slab has now been offset, (assuming that each m³ of concrete released around 410kg of CO2 during its manufacture) so from now on the house will be pretty much CO2 negative for the rest of its life.2 points

-

This is the kind of hint people do or don’t get. Thank you. Nick, the data is the HUGE amount of effort that went into the last poxy Brexit thread, and that data has now received more input by this one needing the same effort. Read my last. Trolls and other persistent arseholes ‘rock the boat’ and we simply prefer plain sailing on calm waters. This is a volunteer operated forum, run for the benefit of its members, seed funded by the FMG and it’s also continuously maintained by the FMG in ‘our’ spare time. Any dents in the availability we have to give to the forum are frustrating and time-consuming, and these replies are such dents. Any more ridicule will be unwelcome, and the posts that bring such content will be deleted without further notice or explanation. For the benefit of our members, ongoing decisions are not made by any one individual. Behind the scenes we discuss such things at length and move only when we have arrived at an unanimous decision, as per our constitution. We act according to our own guidelines so as to ensure all ‘reviewed items’ are dealt with fairly. Thanks in advance for your cooperation. Mods.2 points

-

I would caution here .... Whilst your BCO is signing off your build, they aren’t experts in construction (ask @JSHarris about this...) Is this private or Council BCO ..? You need to meet the Building Regulations and there are lots of options how to do that, some just have a set way of doing things. If you’ve got to go to 1.6m, and use ClayBoard then seriously consider an insulated slab for the whole build as it is borderline cost at those sorts of depths.2 points

-

1 point

-

1 point

-

@Patrick sarcastic head on. You had a go at cutting a tree down ?? look how that ended !!! sarcastic head off, your piling contractor will want a PIN in the ground on every pile location. You will need to set out the very rough area of your house, let’s say it takes you 2-3 hours. You then clear the site. Then you will need to set up some profiles detailing wall locations let’s say another 3 hours. Then you will need to mark out pile locations, I believe you have 30 of these, let’s say another 2 hours. I am very much into people getting stuck in. But you need to weigh up a few things, how long is it going to take to build this? Are you paying rent or a mortgage? Do you have a mortgage on your plot, all these things will have an impact on cost versus time. You could dig your own clay and make your own bricks, Er no don’t be ridiculous. When I was starting to think about mine I actually considered buying a concrete mixing truck and driving to the concrete plant and mixing it all myself, I even thought about buying a concrete pump. i soon decided this was a step too far.1 point

-

@Mr Punter thanks. They're T&G boards, long side perpendicular to joist and staggered rows. Only butt joints are on diagonal lines of the roof hips but those joists are tripled so plenty to hit. I've deliberately held off doing the VCL and ceiling battens underneath so I'll be able to see from below that all the fixings have made it into the timber. Also considering making up a wee guide block to start the screw at perfect right angle to the deck.1 point

-

It is tricky to do setting out manually if you have a sloping site, different levels or steps in foundations. If the plan is straightforward and the site is flat then no need for a Total Station bod.1 point

-

I would look at https://www.screwfix.com/p/timbascrew-wafer-timber-screws-gold-6-7-x-200mm-50-pack/6787j . 50p each, wafer head and you will get 50mm embedment into the OSB / joist which will be plenty. Can you check from underneath to make sure the fixings are locating OK? It is quite easy to miss a 45mm wide target especially if you are butting board edges over a joist. It may be better not to line up the boards with the joists - just lay in staggered rows and screws along each joist.1 point

-

No it's just the length in the wood that matters. I had an issue with stainless steel screws shearing off until I got the pilot hole size right - but stainless isnt as strong as regular steel.1 point

-

1 point

-

Used mine for the first time yesterday. Hooked it up to a Bosch crosscut saw and a Bosch Hoover (its own current sensing device never worked). There's a five second delay in both 'spool-up' and ''' spool down ' time. Works fine. I'll try using the Hoover as the master and crosscut and table saws as the slaves next.1 point

-

There's a little flag in the corner of every post, it's called the "create lots of work for admins" button. People start pressing it more in politics (or religion) heavy threads. I started using online forums (back then, email lists) in 1995 and this has always been the way, nothing special about brexit in this. I think this specific discussion is both useful and relatively uncontentious if people concentrate on the immediate impact of no deal brexit to building supplies and trades (even if it is speculative discussion). As soon as it meanders onto the long term impact it invariably gets entangled in the wider politics of decisions and outcomes, and then the admins will get more work and the usefulness of the discussion decreases (in the context of a selfbuild forum) (Sorry cross posted with newhome, but I think we're saying the same thing ?1 point

-

What may seem like a lot of heat may not be. Air takes 1 J.kg-1.K-1 to heat. So a relatively small cupboard may seem to be warm, but it has not taken much energy yo heat it up. All my lighting, if I left it on, draws 30W, I hate leaving lights on, but in the scheme of things, it is 100th of what my kettle draws.1 point

-

Hi @MickD Your hot water unit ( if I have the principal correct ) utilises Exhaust Air Heat Recovery, so is reliant on heat from the whole house. Just vent the heated air from the AV cupbaord directly into the space immediately outside the cupboard and the heat will be recovered regardless. I'd be very worried about having so much air flow through my sensitive electronics, when the solenoid closes, as that would promote the influx of dust etc in much higher concentrations as opposed to just convection ventilating the equipment via high and low ventilation 'grilles'. Look how much crap builds up on the back of even a slimline TV without such positive channelling of all the dust etc directly past it . Put a coupe of air movers ( 2 x 100mm Papst fans ) in the lower opening and just get a bit of airflow to stop stagnation of the heat, and leave the MVHR and EAHR to work their magic without any intervention. I'm old school and still run a Yamaha DSP A2, but bloody hell it throws some power out!! Was running Kef 104.2's until the neighbours moaned so now run Q65's It's not the same.......1 point

-

Yes - with a warm roof (insulation above the structure) there's no requirement to ventilate. You make a "sealed parcel" of insulation, top deck and waterproofing sitting on top of the structural roof. At least, that's what I understood from advice from insulation and GRP manufacturers (and put on my building warrant drawing) so hope it's correct!1 point

-

Had to drill through the existing footings when I renewed my mains water. What a bitch! There's a metre of pipe insulation down inside the duct and Wiska gel on top to hopefully fully seal the duct.1 point

-

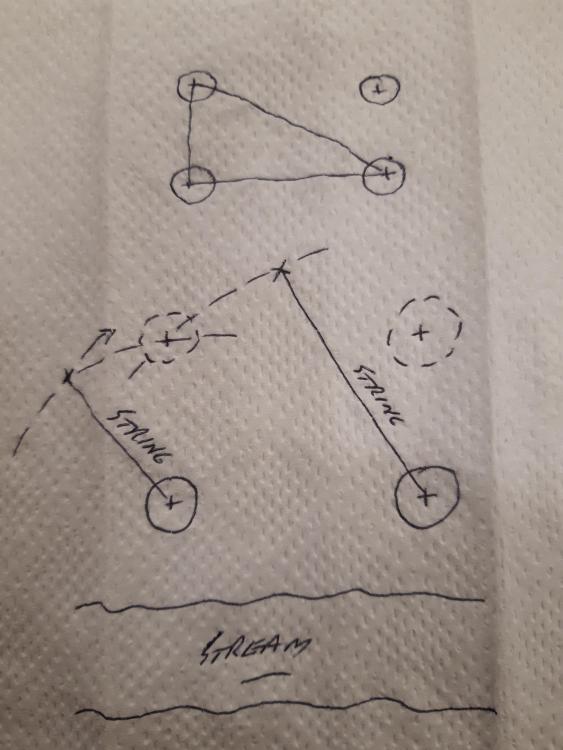

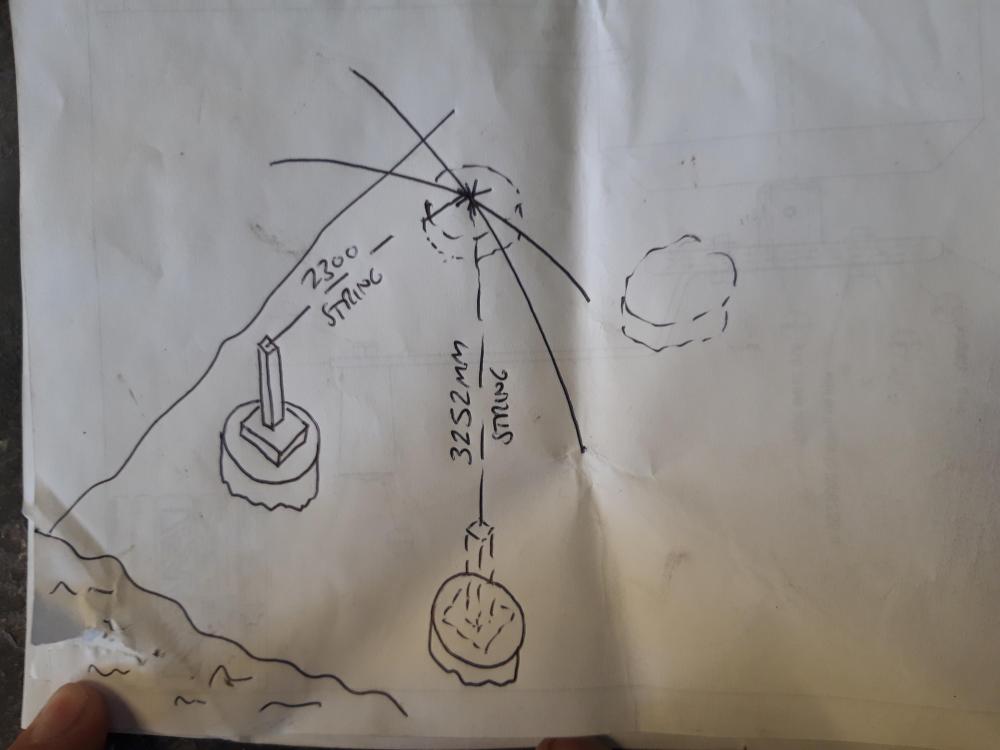

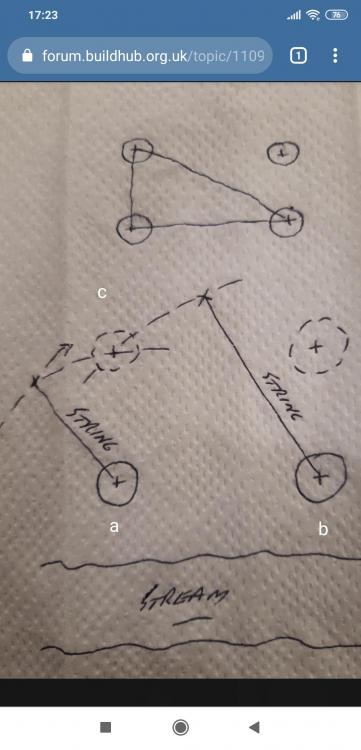

1m tall bits of wood with a base plate nailed to the bottom. Sit it on the lower plinths. Weight down with bricks. Two bits of string, where the arcs meet...or one big of string and a knot at the intersection. Tie other ends around nail in centre of 1m high posts, pull tight, knot marks centre of up slope plinths. 2300x2300 square? Diagonal bit of string will be 3252mm.1 point

-

I don't even know why I need one but for a fiver its "buy it now" as its bound to come in useful one day* *assuming I can find it in the "safe place" I've put it in the shed/workshop/garage/loft(s)1 point

-

never liked those hangers prefer a saw slit and sit normal ones in, don't have to do the whole birds mouth1 point

-

Two steels is the answer - sorry ..! Engineer who designed that wants a slap, and has completely ignored the lateral forces of the two different pitches. Also, the 356 has been chosen for the deflection over the span, as the intermediate is the same size. What is the total span of the open space as there looks to be intermediate walls in that design..?? Ridge board, steels around 7-800mm down from the ridge apex and stick decent ceiling binders in as that is one very odd roof design ..! Have you got the engineers sections to show what they think it will look like on the posts too..??1 point

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)