Search the Community

Showing results for tags 'underfloor heating'.

-

Our boiler was losing pressure, dude came out and couldn't find the leak. Depressurised the system, put inhibitors in and then topped up the system. Since he left our Ufh no longer works. He returned that night and shrugged his shoulders and left again. The night before storm Eowyn kicked off and we were in the red zone. Over 36 hours in with no heating on in the house it is extremely cold and we have 4 young children 8 years and under in the house. Thermostat asks for heat, boiler turns on pumps water, actuator wax melts, but the flow meters don't allow the flow into the loops. Rightly or wrongly I have removed the locking ring on the flow meter and unscrewed them as far back as possible, for the important rooms, and the flow meter is showing full flow. The rooms are so cold I can't see if that has even worked yet. I can't do it to the upstairs system as it is older and different flow meters. Kids rooms are down to 13 degrees and dropping quickly as the temperature outside is to drop below zero. Any help would be appreciated. I've asked the boiler guys to come back ASAP as I believe it is their fault this has happened, but I doubt they are going to appear until Monday (if I'm lucky) and I can't have frozen children and baby.

- 5 replies

-

- underfloor heating

- boiler

-

(and 1 more)

Tagged with:

-

I have a central heating system in our old bunglow which is due to be added to with an additional 3 UFH zones as part of an extention build. Currently the thermostat is a bit of a hack as when I moved the boiler to what is currently the garage, the thermostat struggled to connect via RF due to very thick walls in this old property. Looking to upgrade this and add some Smartness and control for UFH. I'm currently narrowing down options to: Tado - v3 system doesn't appear to have extenders which worries me. X looks very expensive. Customer support from reading on forums seems to be very slow and with rubbish answers Drayton Wiser - Limited support for UFH. People seem to moan a lot about connectivity Heatmiser - We have this at a previous home and after an argument with their returns department I swore I would never buy again but may have to bite humble pie Any other systems I should be looking at or any of the worries above I should not be worried about? House layout with existing rads and proposed UFH zones below. Zone 4 already exists and is working well My main requirements are: Must be able to communicate through thick stone walls Wall thermostats would ideally have integrated humidity sensor. I’ve been battling (and mostly winning) against a lot of damp so want to ensure I am still in control. Ideally would not require separate humidity sensors Should be controllable remotely. Needs the ability to have multi zone underfloor heating integration Will need multiple thermostats. I can go wired but would prefer the choice of battery or wired My boiler is a Viessmann Vitodens 100-w

- 12 replies

-

- smart

- smart home

-

(and 4 more)

Tagged with:

-

Hi All, We are embarking on a self-build and the ASHP was installed yesterday and we are awaiting the commissioning engineer tomorrow to turn on and start heating. I was a little alarmed by the our ASHP supplier planning to just operate the ASHP at its standard operation rather then operating a thermal cycle. From what I have read on line this is important for the concrete screed performance and any floor finishes installed later. I spoke with our tile installer and tile adhesive supplier and they have recommended the following regime which is more or less a 14 day cycle that involves, 5 days of gradual heat increase (2-3C per day) , maintain at expected operating temp for a further 4 days, before a 5 day gradual decrease in temperature. My question is with regard to the expected operating temperature, which I presume is the outflow temperature of the ASHP (45 degree), that the underfloor heating pipework's will be supplying to the screed for these 4 days. My understanding is that the thermostats will be overridden temporarily for the commissioning and the slab will be consistently heated with this 45 degree water - am I correct? If this is so then theoretically will the house be extremely warm for a few days as the slab should come close to the 45 degree temperature?

-

I had some pipe layouts done and wasn't pleased with the density / layout so I read a bunch of stuff on the internet and had a go. - have I got this right? Refurbing an 1850 stone build terrace - - 16mm at 100mm centers - 8 runs of 70 ish m - Total floor area 65m2 give or take Looking to use an 8KW ASHP - for a room temp of 17-20 c flow temp 20-25 c? The floor build up old house geotextile /260mm Glass foam insulation / geo textile / Geo Grid with piping cable tied / 70mm limecrete base (1:1.5 lime NHL 5 / Nosterfield) / 70mm Lime adhesive / upto 70mm thick slate slabs 80's extension 100mm PIR / Geo Grid with piping cable tied / 70mm limecrete base (1:1.5 lime NHL 5 / Nosterfield) / tiles and similar but toped with engineered oak in the lounge Needless to say we're adding lots of Insulation it the roof. Rough heat loss calcs come out around 3kw +Ventilation loss + performance gap etc. Looking forward to your feedback

- 8 replies

-

- underfloor heating

- limecrete

-

(and 6 more)

Tagged with:

-

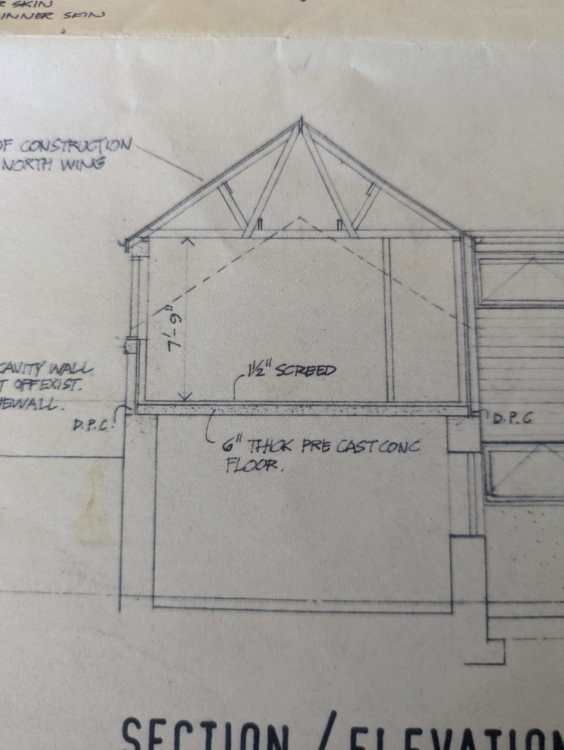

Hi, First time posting so apologies if I break any rules or social norms... We are looking to install a retrofit UFH system to our bedrooms which sit on top of an uninsulated/unheated garage space below. Current floor buildup is: - 150mm precast concrete beam floor - 38mm screed topping. No space to add insulation above the slab without having to raise external glazing that goes to floor so current plan is to insulate the soffit with about 150mm PIR (max. before restricting head height of garage below) and replace the 38mm screed topping with the following: - 20mm retrofit UFH (Wunda rapid response) - 7mm Wunda duoboard - 11mm UFH compatible carpet underlay - low tog Carpet I appreciate that this will likely mean a less responsive UFH system as it will be heating the 150mm slab but hoping the insulation below will still retain enough heat to make the system effective. Really just looking for a critique of the above plan, any thoughts or suggestions welcome.

- 4 replies

-

- ufh

- underfloor heating

-

(and 3 more)

Tagged with:

-

Hi all, about to embark on self-build project. We have plot and planning. The layout optimises solar gain so I am keen to achieve passive house standard. I have noticed on this forum that many self-builders seem to include UFH in their passive house build but I have been told this is simply not necessary... So i'd be grateful for thoughts on this please!

- 54 replies

-

- underfloor heating

- passivhaus

-

(and 1 more)

Tagged with:

-

Hi, I’m going to be at the will of building control/planning as to whether or not I can keep a suspended timber ground floor in my Small Mission Hall in the Outer Hebrides. Whilst I wait for the outcome, I wanted to look into both options. It’s a small building internally (7.500m x 4.500m) so I’m not having a main boiler/central heating system/heat source pump etc. so water is out, I’ll be going for an electric system. I maybe looking at a solar feed system as well. A replacement concrete floor with electric underfloor heating seems a little more straightforward. Possibly better because of its thermal mass acting a bit like a storage heater? However, is it possible to do similar with a replacement suspended timber floor and still utilise relaying the existing floorboards? Would the result (if possible) be equal in terms of its thermal performance compared to a concrete floor? What are the pros/cons either way? Any advice or suggestions welcome…

- 5 replies

-

- timber floor

- suspended floor

- (and 3 more)

-

I am in the process of buying a house. Given kwh cost of electricity - I am hoping to swap out the direct unvented hot water cylinder (in the landing airing cupboard) with a direct equivalent. Underfloor heating manifolds are in the same cupboard. Boiler (feeding underfloor heating) is in the attic. Assuming given presence of a boiler this is possible? Any foreseeable issues and an idea of expected costs would be much appreciated.

- 4 replies

-

- boiler

- unvented cylinder

-

(and 2 more)

Tagged with:

-

Hello, Does anybody know the U-Value required when retrofitting / renovating underfloor heating? There seems to be plenty of resources talking about new builds but finding it hard to find any definitive information for retrofit. For my specific property, I have a ground and first floor. Both having a concrete slab floor with screed over it. I will remove the screed, then add insulation, then UFH pipes, then concrete poured over. Trying to work out how much insulation I need. I'm assuming less required for the first floor. Once I determine the maximum U-value permissible for building regulations, I can use various services such as this U-Value calculator to work out how much of what insulation I need. Any help appreciated!

- 22 replies

-

- underfloor heating

- insulation

-

(and 1 more)

Tagged with:

-

Hi All, I have UFH to install on my new build property, and I wanted to ask how many separate flow and returns are required to each manifold from the boiler. I'd say each to have a dedicated flow/return back to the boiler room, however what are your thoughts to reducing this down to 3 x flow/returns to all 5 manifolds? What are the drawbacks to this? Is it even recommended as it would reduce the heat up time if 2 manifolds are sharing the same flow and return? Will the UFH equipment provider agree/disagree? Setup: lower ground: 1 manifold (12 port) ground floor: 2 monifolds (5 and 10 port) First floor: 1 manifold (12 port) Second floor: 1 manifold (10 port) Thanks C

-

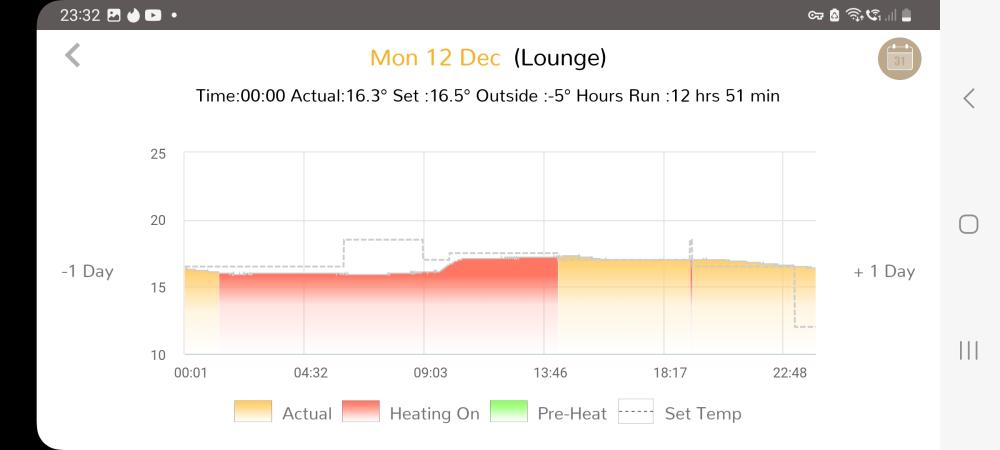

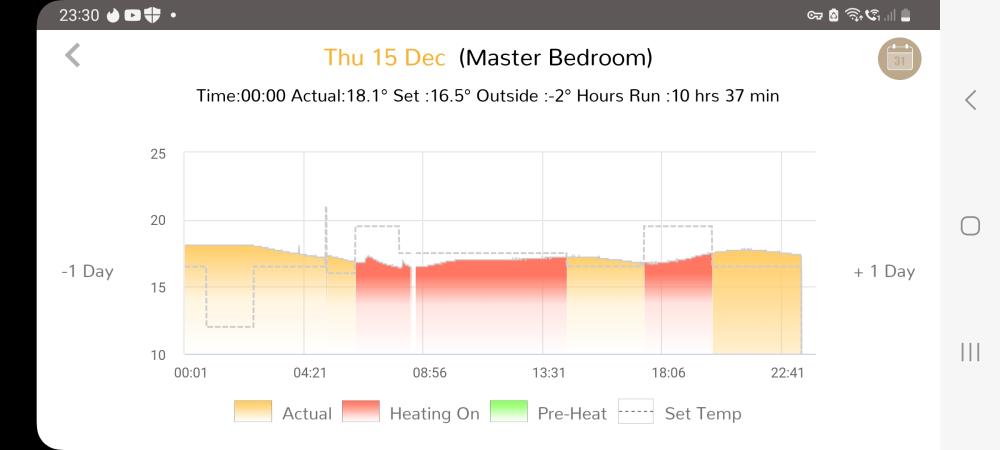

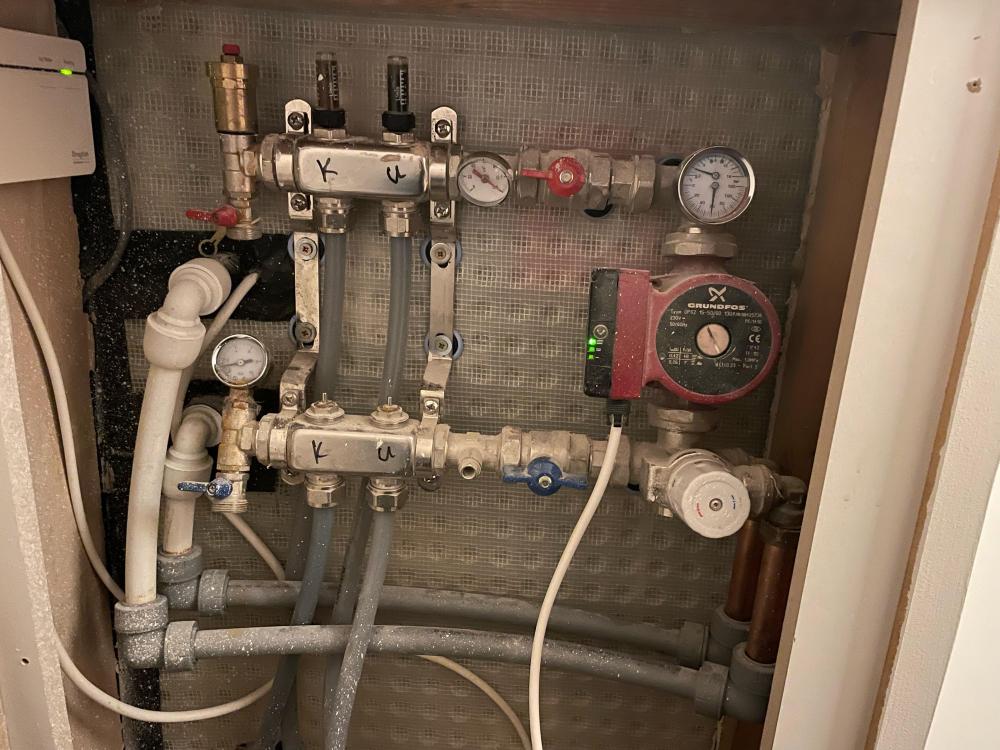

Looking for some help! I am having problems with my underfloor heating only getting lukewarm, even when on for 8-12hrs constantly (see pictures) . It is currently costing £25 to £30 a day and using 150 to 200kw a day to not even be warm and is driving me crazy. I am struggling to get above 16 degrees in some rooms but others i have got up to 19 degrees. I have had heat in the system before. As set out in the background below I have had a Heatmiser system installed and currently having a plumber coming back to try to solve the issue. Any suggestions? Some background I moved into a property just over a year ago. I have underfloor heating in all rooms with one radiator downstairs and one towel rail upstairs. The existing underfloor heating Manifold was upside down and thermostats didnt work very well. Before Christmas last year I had the manifold corrected and a Heatmiser system installed. The system seemed to work although I was spending quite a lot during the winter months. I found that I had less than 100mm of insulation in the loft and assumed that was where I was losing lots of heat. The rest of the property is pretty well insulated, with double glazed windows and doors, insulated cavity walls and now topped up insulation. The system (see picture - system off in picture) 10 port manifold Heatmiser UH8-RF 8 zone Heatmiser Neoair v2 wireless 8 actulators but 9 systems Grundfos pump 2 radiators All rooms underfloor Heatmiser plug boosters - ordered additional ones. Neohub Gen2 Floor is engineered oak through out I have had the boiler at varying temperatures from 60 to 75 degrees Mixing valve - set at 55 degrees Specific problems One of the flowmeters seems stuck - Ordered new one Occasional knocking and clicking sounds Heatmiser thermostats keep going off line Heating switching on during the night Heatmiser thermostats jumping between auto, hold, standby Advised by Heatmiser not to use direct I have borrowed a thermal imaging camera and can see the loops heating up although in most places there is no heat in the floor. Most rooms downstairs have plenty of loops whilst upstairs some rooms are limited. It seems that the system is getting up to a temperature but not full temperature. I would appreciate any advice to get the system to heat up to previous heating levels. Or do I need to install electric radiators??? Mark

- 13 replies

-

- ufh

- ufh freezing temps

- (and 2 more)

-

Hi. Would appreciate some advice. We are currently having wet UFH laid. It’s on the first floor, new build. Kingspan between joists with aluminium spreader above with UFH grooved slots. What would be recommended to go as the subfloor? 18 or 22mm chipboard? We will then be having 5.5mm plywood followed by Amtico LVT (2.5mm thickness). I want to have a subfloor which is ideal depth for heat transfer from the UFH system but also sturdy enough that if doesn’t creek. Many thanks, A

- 1 reply

-

- underfloor heating

- chipboard

-

(and 1 more)

Tagged with:

-

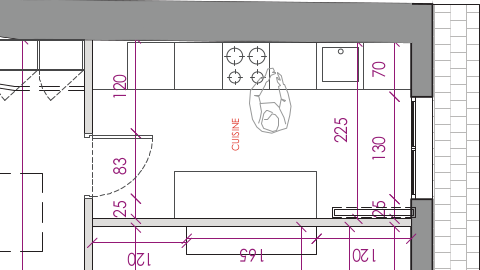

Yet another chapter of my house adventures! The place I've got has a smallish galley kitchen (225cmx405cm, before insulation). It was set up in 2015, with medium-range furniture that my girlfriend rather likes though the architect does not. (It's Mobalpa - the sort of thing that is (I believe) quite a lot more expensive than IKEA without being twice as good; it's not solid wood. The counter is some sort of sturdy black laminate - thank goodness, as I am largely the one who cooks, and I can be messy, apparently, or so have I had it screamed at me. I most definitely do not want to prepare food near somebody else's granite countertop ever again.) Our original intention was not to touch the kitchen, and to insulate the floor from below (it's right above a coop corridor). However, the walls were uninsulated, and the architect was particularly concerned about the overall soundproofing of the streetside wall being compromised if the part corresponding to the kitchen wasn't. So, in the end, the workmen carefully took the kitchen apart - and noticed the long wall was in rather poor condition; we will insulate it after all. In the process, they also had to destroy the current floor - a good thing, since it was vinyl poorly laid on damaged old tile. I will spare you all the things I have been told about how anything I could do to the kitchen decor can only make it worse - I will probably just (a) raise the cabinets and (b) install some extra shelving on the other side. The question now is: given that I have the freedom whether to put the insulation under the floor rather than on the corridor ceiling, what should I do?For that matter: given that I'll get a reversible heat pump, does it make sense to get under-floor heating that can be used also for cooling? That would free up space currently used by a radiator. Or is getting UFH in only one room impossible/too expensive? Or unfeasible (in that it would necessarily create a height difference - though we would presumably insulate the corridor ceiling, as originally planned, as opposed to insulate above)? If we do put in UFH, what we should put above it - synthetic flooring, since it is thinner? I include both the floorplan and an image of the kitchen before renovation.

- 2 replies

-

- underfloor heating

- flooring

-

(and 1 more)

Tagged with:

-

HI Everyone, I have a large 3 bed 2nd floor flat which cannot have gas. I had it refurbished 3 years ago. I took the decision rightly or wrongly to install water piped underfloor heating with a 14.4Kw electric boiler. Sadly I did not project manage the job and the builders were not good at all. They never checked the floor levels before they installed the underfloor heating, and ended up cheating in two of the largest rooms by pouring latex over the top of the heating to get rid of the undulations in the floor. They have since gone bust:-( My issue is the heating is so expensive to run. I am facing an annual electric bill of £8000 or more now, and that is with the cheapest supplier I can find. So I am looking at all of my options to try and reduce the cost. I know I can improve the insulation in the apartment, as there are a lot of cavities around the walls, as being top floor I have vaulted ceilings in every room. Whilst the loft is fully insulated, the purchase of a thermal imaging camera as shown that there are big areas around the sides of most rooms which could not be as easily accessed, and were left by my lovely builders. But insulation aside, I need to try and find a more energy efficient way to heat my home as this is killing me I have considered a heat pump boiler, but I do not believe I would be allowed to install the outside unit here as being a block of flats, putting anything outside is a no go. I have spoken to a heat pump installer who has informed me that the unit cannot be installed in a loft, even if I created a well ventilated area, as it still will not be enough air circulation etc. The boiler I have is slimJim (see link below), I am wondering whether there are other more efficient electric boilers out there, or are they pretty much the same? I am really struggling to think of any other options tbh, and wondered whether any of you guys who are much more knowledgeable might be able to help. I might freeze next winter if not!!! https://www.electric-heatingcompany.co.uk/electric-boilers/slimjim-electic-boilers/?gclid=CjwKCAiAyPyQBhB6EiwAFUuakt2EDYDZtRTPhzZ3ym_crE4Lz4C9swJ_SAN-VDW_ae9Li3hxhRprCBoCorUQAvD_BwE

- 38 replies

-

- electric bolier

- boiler

-

(and 2 more)

Tagged with:

-

Hi, I need some advice on what wet UFH system to get for our renovation of a 1970s 3 bed bungalow. The house had subsidence so in the process of fixing that the floors were dug up and replaced with the following construction: hardcore base, membrane, 150mm insulation, concrete finish. Unfortunately we had no say in this setup so we're stuck with it now. We're left with a 40-50mm gap between the concrete and the base of the front door, which obviously limits what we can do with UFH. There are of course low-profile retrofit UFH options and we'd have liked to have gone with the Nu-Heat LoPro Max with self levelling compound but that is way too expensive for our budget (double what we want to pay). What are our other options, especially considering our 40-50mm gap, and the 150mm insulation beneath the concrete? I've seen the pre-cut boards that pipes are laid in which have no compound/screed on top, would these work well enough with our floor construction? Or should we go down the normal route with pipes in screed but only have 40mm thickness? Insulation below a concrete slab means the concrete becomes a part of the thermal mass, so because it has a slow response time would it make sense for the UFH to be run continuously? We'll be installing an air-source heat pump together with insulation above the ceiling and on the outside of the house with a render and/or cladding, so would this help with the response time and/or be sufficient to run continuously or intermittently? Any help would be really appreciated!

- 4 replies

-

- underfloor heating

- insulation

-

(and 2 more)

Tagged with:

-

Hi - I'm extending my kitchen/diner and want to install UFH. Its extending by 50%, so will have half existing concrete floor and half new floor. The floor in the new bit is yet to be done. The cost of digging out the existing floor is a LOT - I'd like to avoid this if i can. A couple of companies I've seen advertised lay UFH into existing concrete floors by cutting channels and laying the pipe inside. The house was built in 2002, so the existing floor (should) be reasonably well insulated. Example companies: https://www.outsourcedenergy.co.uk/in-cut-underfloor-heating/ and https://www.jk-gb.com/jk-in-ground-ufh.php Has anyone had any experience of this method?

-

I am in the process of building a timber building in the garden and am looking into electric UFH instead of an electric heater. For context, the building is a suspended timber frame on 16 individual concrete blocks. I currently have 100mm Celotex insulation between joists and have placed 11mm OSB3 on top to give me my flat floor. I then plan to use laminate flooring on top. What are my best options here… 1 - do/can I lift up the OSB and place the UFH directly on the celotex insulation and screed over? 2 - do I install on top of the OSB and then screed? 3 - do I need to add another insulation board on top of the OSB and then the UFH with screed? Any advice would be greatly appreciated! Regards, Dan

- 6 replies

-

- underfloor heating

- ufh

-

(and 1 more)

Tagged with:

-

Hello, I’m living in a new build, approx 6 years old, with underfloor heating. Up to about a month ago everything was working well, and the house was toasty. Over the last month, the downstairs floors are failing to heat up. When I look at the manifold, there is hot water at 50 degrees coming from the boiler, but all the return flows for all circuits are cold. All of the circuits are calling for heat and never get up to temperature. I got a plumber out, he replaced the pump on th manifold, that has made no difference at all. Next I flushed all of the circuits to remove any air, again this has made no difference. As a final test, I have closed all but one circuit and am waiting to see if that heats up. Failing that I am at a loss as to what the problem could be and am looking for some advice. regards, matthew

- 7 replies

-

- ufh

- heating system

-

(and 1 more)

Tagged with:

-

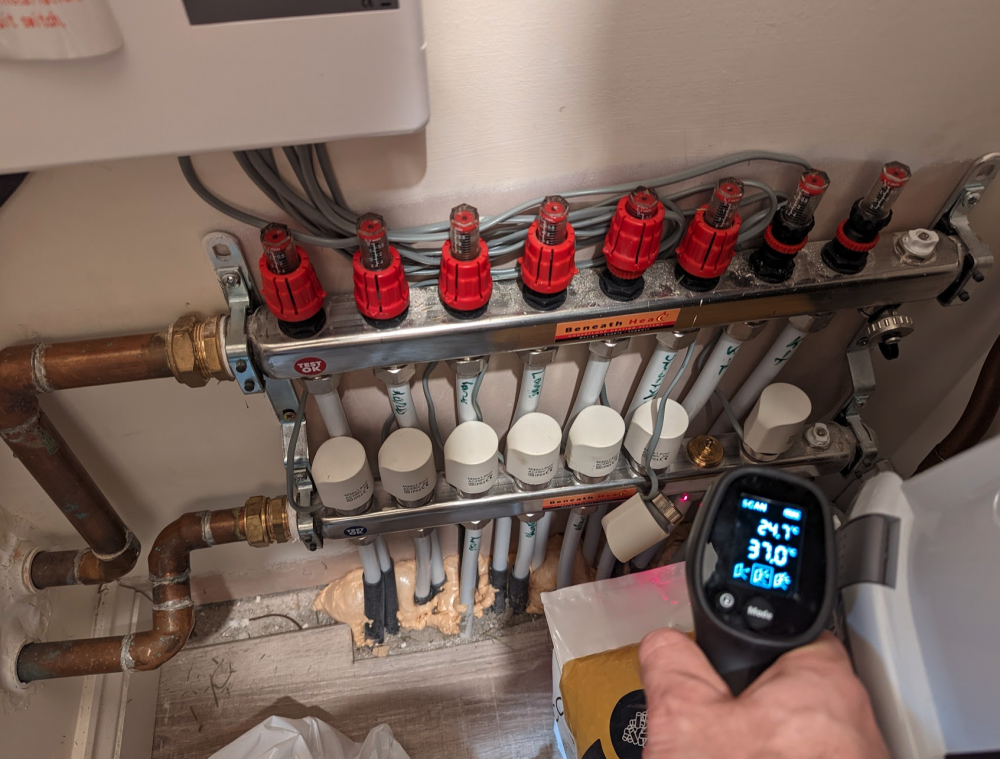

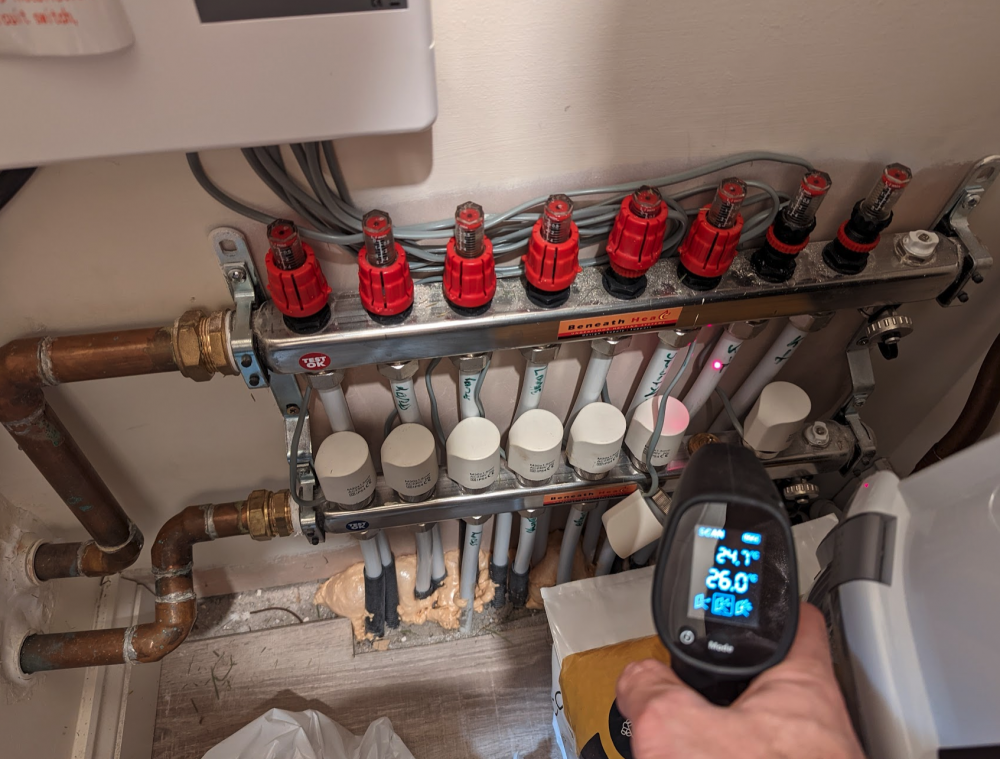

Hi All, We're been living in a new build property for the past 2 years without any obvious heating issues. We've an underfloor heating system that's split across 4 rooms, and is driven by a Daikin ASHP. I've occasionally had to take the actuators off in order to release stuck pins after periods of minimal heating activity, but always noticed that the flow valves show 0 flow when the system is on or off. When pressing the zone pin down, the associated flow meter bounces and a knocking sound is heard through the pipe. After watching a few videos online, I wondered if the system had been connected up around the wrong way, but couldn't find confirmation anywhere. When the system is running, if I manually depress one of the pins for about 30 seconds and take temperature readings off the pipes, I see 37 degrees beneath the actuator at the bottom of the manifold .At the top, I see 26 degrees under the flow indicator for the same loop (see attached photos). Am I correct in thinking the flow into the manifold is around the wrong way? If so, apart from not giving an accurate flow indication, does this cause any problems? The house is certainly warm enough through colder periods (22-23 degrees) but I wondered if the system would be as efficient as possible in this configuration? Any advice gratefully appreciated. Thanks, Ben

-

OK, so we have recently moved into a house which has underfloor heating installed throughout and generally it works really well. The system is fed from the hot water boiler. There are two manifolds, one for upstairs and one for downstairs. Both manifolds have pump which drives the water into the manifold. Upstairs, we have no problems with. Downstairs has three zones, Kitchen, Living Room and Utility/Bathroom. The Manifold is shown in the Manifold_PreStart.jpg file which is how it looks when no heating is on. Heating comes on at 6pm and at that point, the pump starts, shown by the red light in the Manifold_PostStart.jpg image. A few minutes after starting, we get a thumping noise seemingly from the manifold but it is difficult to exactly pin down. I have a video of it which is on YouTube here: - noise starts about 55s into the video. The thumping lasts a few seconds, probably less than 10 and is kinda juddery in nature, its sort of a duh-duh-dumm, duh-dumm. The past few days I have been experimenting with different zones demanding heat via thermostats and when a single room (e.g. the kitchen) is the only one demanding heat from the system, then there is no juddering or thumping. Only when multiple rooms are demanding heat, does the noise occur. For example, today, we had the kitchen and the utility requesting heat and the thumping happened. I don't know much about the system as I didn't install it and there are no manuals etc, but it looks to be mostly Emmeti products. Another thing with this downstairs manifold is that the top "Robot" dial is warped a bit. This dial seemingly measures temperature of the water going into the system. See Warped.jpg. Any idea why this could look like this? Heating is currently on at pressure in the system seems to be about 1.7bar Any ideas what could be going on in this system? The floors get warm just fine by the way. Thanks

-

Hi, I was hoping to get feedback from members who have polished concrete flooring at 75mm (or close to depth) above underfloor heating. I want to maximise my sub floor insulation thus dropping from 100mm recommended by my contractor to 75mm (I have another post getting insulation advice and was hoping here to gain advice from members who maybe have a 75mm slab or close too) I am getting ready for the conversation tomorrow morning with the potential concrete provider and our contractor and was hoping to get advice from others who have polished a 75mm slab on the their experience regarding pros and cons. Many thanks, Joe

-

Hi. I have a new underfloor system which got 4 zones, although they are quite close and not really necessary to split. I wonder how I can control it best via Tado and or Alexa. I would like to turn the underfloor heating off when a max temp reached and/or over night. As I have 4 zones it looks like I would need 4 wired Tado Thermostats, which is crazy. Is there not a way to turn of for example the pump via Tado. or if not can I just turn of the pump with a smart socket using the thermostat temperature via Alexa for example? Thank you in advance for your thoughts

-

So I had some Underfloor heating (re)installed in my kitchen/diner. With the thermostat set to 19C, the floor in the kitchen gets up to about 33C (measured with a gun) while the larger living area rarely gets to about 24C. This isn't too comfortable underfoot and I'd rather the kitchen wan't being heated so much, food etc. The whole area is one zone from the manifold. The water temperature at the manifold is set to minimum (35C) but the manifold temperature gauge says 50-55C when the system is running. the engineer that installed it said to try turning the zone's flow rate down, which seemed to make it worse. I tried turning it up but there is still a big difference between these areas. Is there anything else I can try? 55C seems a bit hot from what I've read, but I don't know how to turn the temperature down any more.

- 4 replies

-

- underfloor heating

- temperature

-

(and 1 more)

Tagged with:

-

While tinkering with the flow meters on my ground floor UFH manifold today the hot water came on. I've heard of hot water priority and I think this is how my system is set up. I noticed, however, that the manifold pump was still running, the actuators were all energised but the flow meters all showed no flow. At this point the manifold pressure was higher than normal too. This seems wrong to me as the pump is working but unable to circulate water through the system as the heating zone valve is closed (as it should be in). The micro switch on the heating zone valve seems to be working as the pumps in the heating and hot water tank cupboard come on when it energises - as an additional point i'm curious about, there are two red Grundfos pumps in that cupboard and they both come on when the hot water or heating are on - is this correct? I've always assumed that one was for the hot water system (indirect unvented cylinder heated by ASHP) and the other for the heating (all UFH heated by ASHP) but maybe they are meant to be on at the same time? Perhaps one is a send pump, one a return pump? I've attached a photo in case anyone is kind enough to take a look. So, in summary should the UFH manifold pump and actuators be de-energised if the heating zone valve is closed due to the hot water priority? And should both grundfos pumps be running at the same time when the hot water or heating are running? Thanks for any help anyone can give me.

- 3 replies

-

- underfloor heating

- heating system

-

(and 1 more)

Tagged with:

-

Hello, I am looking for an underfloor heating technician or installer who can help with controls queries in the Middlesborough or Newcastle area. Can anyone recomend someone who will be able to help me out. Look forward to your support Buildhub team. Thanks RHayes