9namjam9

Members-

Posts

13 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

9namjam9's Achievements

Member (3/5)

0

Reputation

-

I just realised that noggin in the bulkhead could obstruct a rigid pipe... I'm wondering if I can remove part of the bulkhead joist that's against the wall and core thru directly behind the extractor. Not sure how structural it is..

-

I found this study that shows compressing flex duct even by about 10% halves its cfm compared to the same diameter rigid (or flex at full extension). I think I’ll try shoving some 125mm rigid pipe in through a new hole. https://www.energyvanguard.com/blog/the-science-of-sag-flex-duct-and-air-flow/

-

Is rigid duct that much better than corrugated? also, do you know where I can get 5m of rigid plastic 150mm/125mm/100mm ducting? I can't seem to find any more than 2m long

-

Yeah I ditched the crushed plastic duct and replaced it with new aluminium 100m duct , before I realised it wasn't wide enough for most modern extractors. By then the floor had been put down. I was thinking maybe I could push/pull rigid ducting through a new hole in the wall, though as I said, there's a lot of RW3 in there now that might make things tricky.. Why would it be noisy?

-

When I was looking around the attic yesterday, I notice the main enormous beam (probably not the proper term for it!) that holds the main part of the roof up (its an L shape roof), is only held in by bricks and mortar on one side. There is a similar sized beam that meets it at 45 degrees on the other side, but I just wanted to check if it looks normal and safe to be balanced like that!

-

My 350m3/h cooker hood is 4.5m from the exterior wall, and is currently connected to an exterior vent with 100mm aluminium ducting inside a bulkhead. I'd like to have better extraction, 500m3/h or more, and it seems like I need 150mm duct for higher powered hoods. Unfortuately the floor has been glued and screwed down over the bulkhead now, so I was thinking maybe I could connect the 150mm duct to the old 100mm duct and drag it through the bulkhead? It might be tricky because there is quite a bit of insulation in the bulkhead now, and additional timbers to level the floor mean the duct has to bend around a timber as it exits. Then I would need to core a bigger hole in the exterior wall - is it possible to cement up the old hole in the cavity wall and core a hole about 10cm to the right, so the duct doesn't have a kink at the end, or would that weaken the wall? Any other ideas? I would go straight out behind the hood, but there are timbers, pipes and a waterproof membrane that make it complicated...

-

I was just quoted £700 to run the soil pipe out of the roof. No scaffolding is needed. It seems like alot to me?

-

I wouldn't find that simple but yes that's what i thought might fix it. Just wondered if there is an easier way

-

So I noticed the main soil stack in the house I just bought terminated in the attic and was open for 6 years since the house was built , so its caused mould on the timbers around it. I put a Durgo air admittance valve on so it wouldn't pollute the attic, and the toilets would flush OK, but since then the bathroom drains have been stinking up the place, the bath p bend in particular i think. Its not dried out. I'm guessing this is positive pressure from the soil stack maybe? Do I need to get the soil stack extended out of the roof, or is there anything else I can try?

-

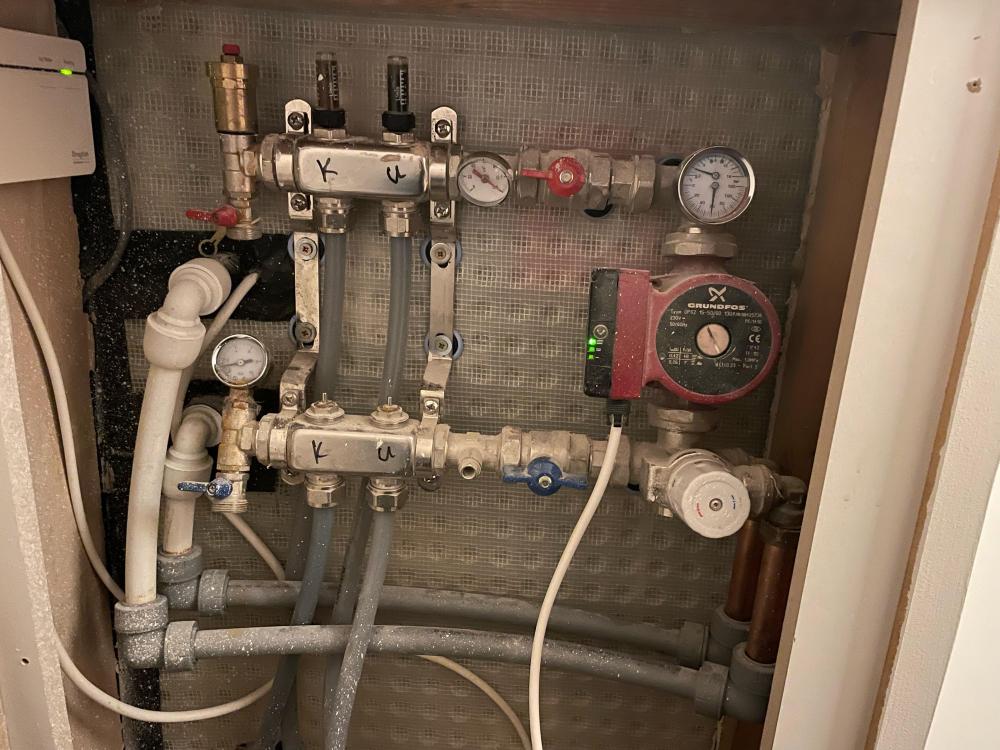

It's down as far as it will go, but the water is still above 50C

- 4 replies

-

- underfloor heating

- temperature

-

(and 1 more)

Tagged with:

-

I'm looking to get real wood flooring to lay over a chipboard sub floor. A neighbour has "strip wood" flooring which he says is thin strips of wood glued to a screed that is poured over the chipboard subfloor, much cheaper than engineered wood apparently. I can't find anything much using google. Where can I find out more about this? Is it any good?

-

So I had some Underfloor heating (re)installed in my kitchen/diner. With the thermostat set to 19C, the floor in the kitchen gets up to about 33C (measured with a gun) while the larger living area rarely gets to about 24C. This isn't too comfortable underfoot and I'd rather the kitchen wan't being heated so much, food etc. The whole area is one zone from the manifold. The water temperature at the manifold is set to minimum (35C) but the manifold temperature gauge says 50-55C when the system is running. the engineer that installed it said to try turning the zone's flow rate down, which seemed to make it worse. I tried turning it up but there is still a big difference between these areas. Is there anything else I can try? 55C seems a bit hot from what I've read, but I don't know how to turn the temperature down any more.

- 4 replies

-

- underfloor heating

- temperature

-

(and 1 more)

Tagged with:

-

I just had a couple of fire door linings replaced as they were not deep enough after I overboarded the stud wall they are set in. The original linings were made with 30mm thick timber, and I only realised this evening that the new linings are made of 20mm thick timber. One of the doors was also replaced with a heavier fire door , about 45kg. The frames seem sturdy and the doors close fine, but I’m concerned 20mm isn’t thick enough long term for such heavy doors. Also there is now a 4cm gap on one side of the doors filled with foam which doesn’t seem very fire safe…. What do you think?