-

Posts

584 -

Joined

-

Last visited

-

Days Won

4

Everything posted by HerbJ

-

No, I my mistake - I wasn't concentrating and missed the 4x .....ugh Apologies

-

Wet and Forget is similar to this and also works like magic on render and patios and it may be cheaper. Costco seem to do the best deals on this https://www.costco.co.uk/Grocery-Household/Cleaning-Laundry-Products/Cleaning-Products/Wet-Forget-Concentrate-Mould-Lichen-and-Algae-Remover-5-Litre/p/128234 You can get a Gardena Backpack sprayer withe extended lance set that we have used to spray up to our gutter relatiively easy. https://www.gardena.com/uk/products/tree-shrub-care/pressure-sprayers/backpack-sprayer-12-l/970477401.html

-

Commiserations... We had a similar problem when we demolished a house in 2015. Everything was going so well, when the resuts of tests on the white render came back from the lab. The whole of 1930 house was covered in render which had to be removed by hand and removed from site by a team in white suits and protective gear - it gave a bit of a scare to the neighbours. It doubled the cost of demolition from £10,000 to £20,000.

-

Vat claim and sign off

HerbJ replied to nod's topic in Self Build VAT, Community Infrastructure Levy (CIL), S106 & Tax

This may help you recover VAT from contractors. There is a more useful information in the original thread -

We live in Sunningdale on a main road and none of the houses on my postcode and adjacent area have house numbers, only house names. We're not in a rural area. We've never had any issues getting insuraance, buildings or motor......

-

We used Sweet Chestnut for our build in 2015/16. There was post on the subject on April 2022 - see attached. I can take some current photos, if useful?

-

Recommendations for double/triple glazing unit suppliers?

HerbJ replied to Alan Ambrose's topic in Windows & Glazing

I helped my son and daughter in law with to source DGU's. They live in the New Forest so I can't recommend a supplier. However, I found that most traditional, and usually well established, glaziers/glazing companies in that area were very capable of supplying and installing replacement DGU's in existing window frames. They were also competitive and made a site visit and measure before finalising quotations. They also installed, after removing the old blown DGU's and removed all the old materials. the companies who supply and install replacement windows were only interested selling complete new windows/frames or supplying DGU'S that were not specified for the existing windows, because they only supplied DGU's which were suitable for modern plastic frames formats (too thick for the existing frames). -

I have PAUL Novus 450 MVHR for a 5 bed house. I don't live a a city environment but in a semi-rural environment but near to a busy road. PAUL recommend changing the filters every 3 - 6 months. They are synthetic material/paper filters that cannot be cleaned, so have to be replaced. I change the inlet F7 filter every 4 months approximately as they get very dirty - see photo I change the G4 exhaust filter every 2 years or so

-

Critique my MVHR plans - round 2

HerbJ replied to Sparrowhawk's topic in Mechanical Ventilation with Heat Recovery (MVHR)

+1 to this but and you seem to have covered most of the key points. The big question/issue for me is the detailed routing of the ducts, particularly downstairs, in locations where you haven't negotiated "permission" to reduce ceiling height. There is still a lot of investigation and detailed work to be done to ensure that you are able to make penetrations in floor joists without compromising structural integrity BEFORE you start installation. -

Looking good I can see that you have made significant penetrations in your I-joists. Holes may be cut in I -beams but only in accordance with manufacturer's guidelines/rules - see typical guidelines at https://elliotts.uk/ideas-and-advice/i-joist-faqs Have these penetrations been checked by your SE for each specific location to see if acceptable ?

-

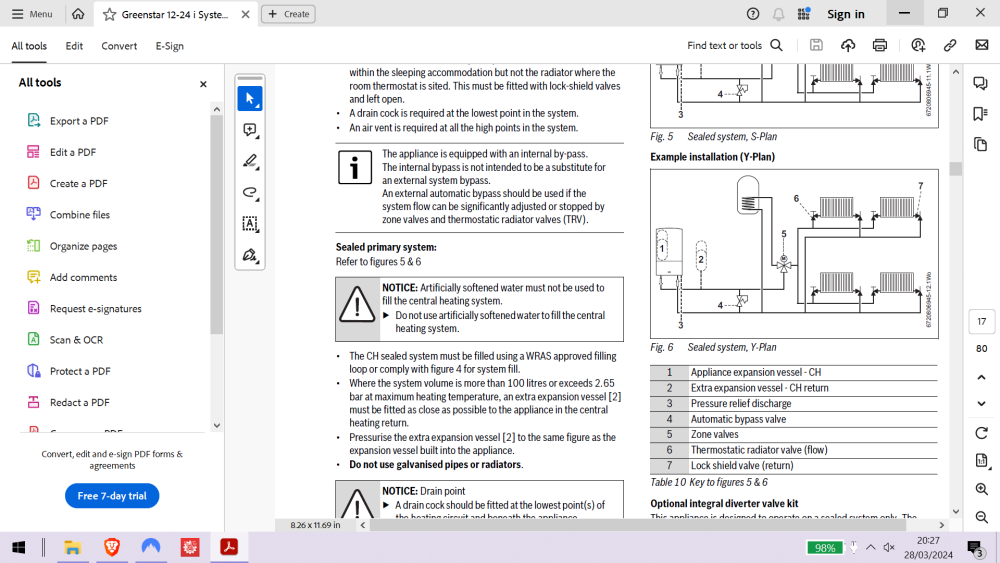

Most gas boilers specifically prohibit the use of "artificially softened" to fill central heating systems, which why the heating system fill-point should be from the mains supply I seem to remember it caused problems with the heat exchangers? I attach the relevant page from WB Greenstar system boiler, which is now 8 years old. Maybe not problem with ASHP and modern UFH systems and it should be checked

-

Have you tried https://www.vieffetrade.eu/ ? They are Italian suppliers, offering a wide range of electrical goods, furniture etc, and they do deliver to UK.

-

H Ian Something you may want to consider. Though they may not suit your situation on a country road..... Outside our community in Spain we have a very busy main road and our main entrance is on a the brow of the curve. We introduced "traffic calming" by installing bollards in the midle of the road, in an attempt to stop drivers overtaking on the blind bend it's a 40kMph speed limt raod, but not unusual for cars to ovrtakinga 80/90 and , occasionally they still go on the other side of road(and the bollards) to overtake! Anyway, we originally installed expensive bollards and they kept being wiped out and cost us a fortune in replacing. In Late 2021, we came across a slimmer and cheap bollard and replaced the lot. The replacement are still standing, though when I looked again at the photos attached this morning a few were leaning and will need some attention this year. . I have no idea if they are available in the UK but I attach a couple of links to Spanish websites (hito is the spanish for bollard) https://syssa.com/es/senalizacion-vial/hito-vial/hito-h-75-desmontable-con-base-de-cauchohttps://gdstore.eu/145-hitos https://gdstore.eu/145-hitos https://www.signet.cl/hitos-viales/3458-hito-vial-amarillo.html

-

Merry Xmas to all Buildhubbers. Best wishes for a peaceful, successful and very Happy New Year

-

Really pleased you are recovering and will get back to full health. Thanks for letting us know and best wishes for quick and full recovery.

-

True, but in my case several microinverters (I have 14) failed to communicate properly and, then not at all, over a 2/3 month period. Enerphase carried out some remote monitoring and reported back as follows: The tests for the Envoy R show us bad communication performance. We advise you to purchase a new Envoy for this system. Furthermoore, looks there is some noise on the power lines hampering the signal of the Envoy down to the inverters. You can install Ferrite Torrids on the wires as they feed into the breakers. These rings help filter out noise. You will need to install these rings on all of your breakers EXCEPT what's on the Envoy and what's on the solar (see attached doc). The best way to solve this issue is to install a dedicated outlet at the sub panel where the solar feeds. More often than not, it corrects communications issues. I couldn't understand how there was suddenly "noise" on the power lines after the system operating quite happily on the same newly installed system for 4 years without any problems. Also, no changes to internet provider or system. The Envoy was already supplied by a dedicated outlet, directly from the main board, in accordance with MI. I replaced the original Envoy R, as outlined above and no issues since February 2020. On the issue of warranty replacement of a microinverter, I suspect they will provide a replacement microinverter but not cover the cost of installing it in the system - labour, scaffolding for access, etc It's an interesting question, but let's hope it's not necessary. Keep us updated @Bitpipe....

-

It's an Enerphase problem with the original Envoy monitoring unit and, unfortunately, the warranty period was not the 25 years of the microinverters. Apparently, the PV system performs quite happily without the monitoring unit but the data it provides is very useful.

-

Hi They're still active and usually responsive. I recommended them to someone last week and they have been helpful with him. I replaced mine with the Envoy S Metered because they told me that the Envoy S (the direct replacement for the original Envoy) was only £80 cheaper than the Envoy S Metered. I have looked online and the difference seems to be about £150+. the difference is that the S Metered has to be hard wired with CT's as it monitors the imported electricity and is capable of monitoring a Enerphase battery installation as well. If you don't need this, then the direct replacement may be OK and will be a easy direct swap. Have a look and see what you think? They moved offices Techfor Energy Ltd Big Yellow Storage Unit 1 Cobbett Park, 22 – 28 Moorfield Road Slyfield Industrial Estate Guildford, Surrey, GU1 1RU T: (0800) 888 6544 www.techforenergy.co.uk I dealt originally with was the Technical Director, Glenn Ashby -Mobile: 07968 098 995 and he is still involved. The person who helped with the replacement of the Envoy unit was George Sands. Cheers Herb

-

Hi Bitpipe I had a similar problem in early 2020 - it started a couple of months earlier but I did not spot it, until many of the panels were failing to communicate with the Envoy module. It was the original Enerphase Envoy Module which had failed. My original installation contractor, Techfor who are still in business, were able to monitor the unit remotely to diagnose that the unit had failed. Like you, all the PV panels were still producing. The original Envoy is no longer available and i replaced IT with an Envoy S Metered module, which has more functionality..

-

Yes, it could one of the many epoxy paving jointing paving compounds sold under various names- Easy joint, etc . My landscapers used GftK’s vdw 850+ Epoxy Paving Joint Mortar, which is expensive but has lasted without problems for over 5+ years without any issues.

-

Radio 4: solar panels aren't designed for this temperature ....

HerbJ replied to ToughButterCup's topic in Photovoltaics (PV)

Mine too - 6.5-year-old system3.99kWp (facing due just slightly west of due south) producing 16.9 kWh up to 1700hr, with a peak at 2.9kW -

Siberian larch vs sweet chestnut cladding

HerbJ replied to PeachyBeechy's topic in General Construction Issues

As promised, photos from this morning. All the cladding was treated with OSMO UV Protection Oil before installation. -

Siberian larch vs sweet chestnut cladding

HerbJ replied to PeachyBeechy's topic in General Construction Issues

Yes, we have sweet chestnut cladding that was treated with two coats of OSMO before installation, so it has not weathered too much in 5 years. It's performed OK and we are still pleased with the choice. The attached pictures are from December 2016, when it was completed. I will take some current and close-up pictures tomorrow.