Leaderboard

Popular Content

Showing content with the highest reputation on 05/14/22 in all areas

-

5 points

-

I've been poor at uploading pics over the last 12/13 months and we are now about 2/3 month from finishing (hopefully). So the construction is ICF on a 200mm concrete raft faced with natural stone and block work with K rend - well two rafts as one is at first floor level being built into a hill. Monopitch warm roof is GreenCoat PLX steel. Hopefully the pictures will tell the story. We live in an old quarry and are lucky enough to have great views. Flat roof annex on our current home was demolished to make way for the new build. Existing house will be sold shortly.2 points

-

If you run resilient bars at right angles to the joists you will get a nice flat ceiling, vastly improved soundproofing and only lose 18mm ceiling height.2 points

-

2 points

-

Yes, staple it tight to the ends a bit big, build it into the wall then afterwards unstable it, glue/pin it to the wall about an inch only and plaster over it to create an airtight barrier.1 point

-

If anhydrite screed has been used, NOTHING will stick to it until the laitance has been mechanically "scrubbed" from the surface. At that point you will see the shiny semi-gloss finish reduced to a surface that looks a little like a pumice stone. That opens 'pores' in the screed which then allow such primers / adhesives / SLC's to be absorbed / key into the surface.........and then you're in business.1 point

-

Hi, We’ve just bought a 60’s bungalow (luckily mostly asbestos free!) with wooden outbuildings, and beginning the process of converting it into a modern energy saving smart home, and the outbuildings into a design studio and a workshop. Jon1 point

-

We're going to be using a mix of black corrugated steel and black charred wood on our Nudura build. Would also be interested to hear what others experiences are with wood cladding as we will be having gaps between the boards. I was planning on just using a black membrane behind.1 point

-

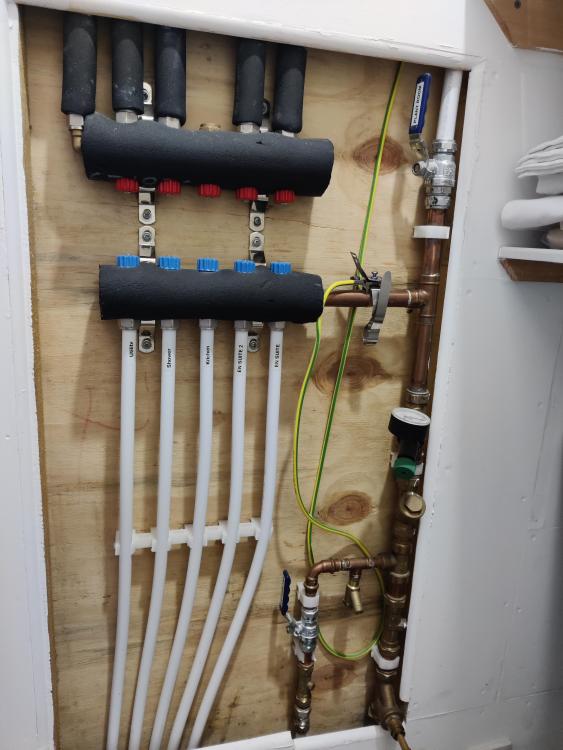

Initially the plumbers used MCLP crimp fittings for us. A couple of thoughts. The system looks like it would be capable of very high pressure as the system mimics hydraulic fittings. I suspect it is almost impossible to get a leak if the joint is crimped properly. Scraped pipes seem to be less of an issue than with push fittings. (I didn't have any issues however) All connections need a special tool, although it could be rented. Its not very DIY friendly if you want to make a small alteration later in that respect. If you decide to change a fitting your only option is to cut it off and throw it away. There's no second chances unlike de-mountable push fit fittings. I found the inner bore of the crimp fittings is quite restrictive compared to Hep2O or copper although in practice the flexitails for most taps seem to be smaller than both anyway. The MCLP pipe is semi rigid which has pros and cons, it can make a tidier setup in the plant room as it retains its shape when bent but is more difficult to cable through joists etc like Hep. The 10mm Hep is almost like running electrical cable. In practice the need to isolate outlets at the manifold individually won't happen that often in a domestic setup. If it does need to happen for a period with Hep2O manifold in a radial system all you need to do is demount that pipe and put in a stopper. 15 secs work. Here in Ireland we still use the old imperial fitting. (bangs head against wall emoji) The MCLP is continental 12mm 16mm 20mm 26mm etc.The fittings we use are British metric, 15mm 22mm etc so a typical connection done by the plumbers was MCLP 26mm pipe 26mm to 3/4 Irish crimp fitting with brass tail 3/4 to 22mm nut and olive 22mm British isolation valve 22mm to 3/4 nut and olive 3/4 brass tailed crimp fitting to MCLP 26mm MCLP pipe. Mental compared with a push on 22mm Hep2O pipe valve on 22mm pipe I replaced it with. Not such an issue in the UK but worth considering how you will combine MCLP and British fittings. Another point ( I know people will tell me to use a water softener) is that with all plastic and Stainless Steel Hep2O won't degrade like copper/brass in an acidic borehole water situation.1 point

-

You won't get the flow rate with 10mm for a shower, bath or kitchen sink. 10mm pipe is easier to work with but there isn't really a cost saving so just do 15mm for everything except the hot sink outlets. I did all my WC s in 10mm as I had a 10mm manifold separate from the rest so can be run on recycled or rain water.1 point

-

Actually I don’t know what screed my builder used but from reading I believe so, others here might know better @Nickfromwales ?1 point

-

You mean similar to the backing given by Fensa on my window installation? Yeah, I'll pass thanks1 point

-

Yep Muck away is going up daily Massive fines for farmers taking muck away and the plot owner1 point

-

Grab lorry’s went up £50 each grab a couple of weeks ago, no more red diesel for plant. The price of rebar is up 30% I think? Just can’t keep up.1 point

-

Have you done ground investigation and do you have a SE signed off foundation design? Anything tricky about your site - access, slope, ground composition? Have you looked into an insulated raft foundation and compared labour / materials etc? Insulated raft is similar to ICF so you may be able to do some of the work yourself to save on labour costs, or not require as much labour as you're not excavating down. Also, some TF companies like MBC will do an insulated slab as part of their package but will not do preparatory groundworks.1 point

-

Exactly right. And directly in line with my experience of Durisol. My inexperience caused an increased build cost. A reasonable guess at the additional cost of the blowouts (7 in all) - less than £1000 - one pour roughly (?). By the 3rd blowout, I'd put together a blowout kit, and had shallow pits ready for that pour's spillage + 3 clean wheel-barrows and half a dozen shovels, couple of concrete rakes and a smoothing-thing. Everyone was briefed on what to do when (not if) one occurred. Needed a team of 4 to manage well. 5 better still. Just doable with 2 One guy had nothing else to do but to look for leaks. (Johnners) or me. And as a result of the spillages, I now have 3 nice super- flat concrete work-surfaces around the garden - one for the pizza oven and bbq area, one for SWMBO's shed and greenhouse and one outside the front of the house: that's a mess because I got it wrong - left it too long before smoothing off. There's always a way to turn a WhatDaFukMoment into something positive. Always. You just have to get it as wrong as I have as often as I have.1 point

-

Well @SteamyTea, I've yet to see a build where Durisol is the outer skin. In terms of what I have written about it, I think its fair to argue that my own incompetence, inexperience and openness should not be taken as a factor in the criticism of a product. I may be wrong, but I think I might be the only person to have written quite as much about Durisol on this board. One person's musing on one discussion board is hardly a good evidence base on which to make fairly large purchase decisions. I had absolutely no prior experience of building. None. I appointed a company that was over-trading to help build the house. I sacked them far too late. So I (we) just got on with it. And now I'm sitting in a warm house that I've built by my (our) selves. I would have made just as many stupid errors with any other build method. Come to think of it, had we chosen brick and block, the errors would have been worse. A combination of opportunity, Durisol, effort, commitment and guts has constructed a house worth about £500k. And nobody knows or cares what the build method was. But what I find of most value is the learning experience I've had along the way. That's priceless.1 point

-

Bogging should say nogging Also you will have to notch out 5 mil for the straps that hook into the cavity and sit on the top of three I joists0 points

-

0 points

-

Welcome to the electric future. Can you offset with PV?0 points