Leaderboard

Popular Content

Showing content with the highest reputation on 10/03/19 in all areas

-

hah.....i've had to write to the parish council to ask them to stop referring to ours as such. Everyone in the village who meets me tells me i'm building one. Such is the understanding of 'eco'....having a green roof is next to godliness. This despite the hardly covert way in which i've thundered 150 lorry loads of muck away through the village and brought in 10 lorry loads of concrete.2 points

-

In amateur astronomy it's well understood that clouds are caused by people buying new telescopes.2 points

-

Hi all, Wow tons of responses - I will get to them but a few important common themes: - Completely agree there is some structure missing - you just haven't seen it -We did lay out our "In a few paragraphs" definitions, also the Architect has come by and talked with us for 3 hours, following her own process as well. I should find it and include. - Ordering - we actually ranked/prioritized our items in the 'real' version of the spreadsheet, where L1 is high level points, L2 was more narrowed down ideas and L3 was small details probably not worth fretting about. I removed those for privacy reasons (I was in a bit of a rush) Funny, that some of you saw the list as "If anything is missing, it's an excuse not to do it" while so far I was reading things as "if anything is there, there's no excuse to leave it out" OK gotta run. More responses later2 points

-

A lot of the details on your list your architect won't be one bit interested in. Things like your av equipment, lights and ethernet requirements will be dealt by your spark. All your bathroom details by your plumber and wherever you intend to buy the goods from. You need to strip that list right back to things like how you want the house to look from the outside, white render or wood cladding or stone. What you want it to be made from, timber, block etc. The size of the rooms and how you move from room to room, things like do you want a kitchen or a kitchen dining room play room entertaining room all in one type setup. Position of Windows and their heights so you can look at a view for example. How well insulated the want the house to be, you won't be able to sleep in a bedroom that is 24 degrees. Basically all the structural elements is the only things the architect really wants to know. Then it can be drew up and you can see if that suits what you had in mind. Change the bits you don't like then after a few revisions you will have your plan. Once you have your plan then you can go to a timber frame company, groundwork crew,spark, plumber,mhrv, lift supplier etc and let them have a look at it and see if it all can be done the way you want it to be done. You can then change an internal wall position for example if it needs to be done for your lift.2 points

-

I like gloss rollers, can do a door in a few minutes. Since getting my scaffold tower, it has rained everyday for the last 3 weeks. So the best way to get back to the external stuff, is to start the internal painting.2 points

-

I've found that zoning doesn't really work effectively in our house, so I have all our UFH zones running as if they were just a single zone. The whole lot is controlled with a simple room thermostat in the hall, plus a simple programmer that is set to turn the whole system on or off. Seems to work OK, and is easy to use, as the controls are simple (I like simple...).1 point

-

Welcome ROB - suggest an intro in the intro section, and perhaps a project blog (PM an admin). You can do airtightness with either, but don't overfocus on the walls - you will get better resutls first with floor and loft if it is already 0.46. Do not forget the bit of wall between the floors, though. Work out your whole programme before you start, and build a thermal model using the @JSHarris spreadsheet produced by a member here. Take time to think it all through and do your homework. Of those go internal - external will cost at least 10-15k, and by the time you have done 2G, normal insulation plus underfloor, etc, new CH, and so on it will not be worth it unless you get a grant, or there is a very good reason. Perhaps for a forever house. I have costed up for 4 or 5 over the years, and it has never been able to justify the cost. Then spend money on doing all the obvious usual things, and you should get to an EPC B or so. Two threads, about reno of a 1970-ish bungalow in 2017: And some possible quick wins. Ferdinand1 point

-

Except the slot and wedge method will be mostly watertight before the final render. My method won't be. But this seems the normal method used up here.1 point

-

I would run a bead of whatever cheap silicone you have knocking about along the bottom edge of the wall to form a temp bellcast to throw the water out from the wall away from the gap till you are ready to finish that front.1 point

-

I think it may depend on where you live, so worth checking. Here, when we bought our plot we didn't have to pay stamp duty, and until the house was built and almost finished we didn't have to pay council tax either. I was threatened with having to pay council tax at 150%, as a second home, shortly after we were issued with a completion certificate, but I provided evidence to the local authority that we were self-builders, that our existing home was on the market, and that our intention was that our self-build would be come our principal residence. They gave us a 6 month period of grace before they would start to charge us council tax at 150% on the new build. I had the impression that they would have been OK to extend this period of grace if we had trouble selling our old house, subject to us providing them with evidence.1 point

-

I'm on our parish council, and one of those who always refers to our place as "the eco house" is a fellow councillor...1 point

-

We built platforms from pressure treated timber and WBP to set the tray into the floor slightly. Used a top access/top fitting trap but check the trap will seal against the underside of the tray before gluing it all down. Don't set top of tray flush with floor tiles or the door seal will scrape. Set it say 5mm higher. If you are going to tile the floor over any cracks or joins in screed essential to use some kind of decoupling mat or the crack will propagate through the tiles. Found this out hard way on some stone flooring.1 point

-

What irritates me the most about all of this, and yes the skipping of PP annoys me, but possibly not as much as this, is the waste. The environmental price tag on that development and it could all just end up a pile of broken masonry and twisted metal. That is sad. I assume they can keep the tennis court - can't see that harming anyone, well maybe, if the players get tennis elbow.1 point

-

The basic principle of a pad stone is used to spread the load over a larger area than would otherwise be the case. I'm not an SE but the calculation goes something like... Find out/calculate the maximum safe pressure (Newton's per square mm) that the blocks can withstand including safety factors. Calculate the load in (Newton's) on each end of the beam. Divide the pressure by the load to get the minimum bearing area (square mm) Divide the minimum bearing area by the width of the wall to get the minimum length of the bearing (eg how much of the beam must rest on the wall. Regs say this must be >100mm). If that minimum length is more than the beam allows you need a pad stone to increase it. (Eg if the minimum length calculates out at 240mm and your beam only allows 100 or 150mm then you need a 250mm pad stone.) What I'm not sure about is how to calculate the load or the safety factor required. Pad stones are more commonly required where a beam is at 90 degrees to a wall because the bearing area is fixed by the width of the wall and width of beam. Think cheese wire cutting cheese.1 point

-

Welcome. I went out of my way to try and ignore anything badged "eco", really on a point of principle, as it's become a bit of a marketing term that means little in terms of how any product performs, what it's whole life impact on the environment is etc. Unfortunately there are some people in our village that refer to our house as "the eco house", just because it's a fairly airtight and well-insulated house that needs little energy to heat, and it annoys the living daylights out of me. What we built was a low energy house, that has a relatively low level of embodied energy in it's construction, and which is a net CO2 sink, rather than source, over the course of a year. Because of the particular incentives that were on offer at the time we built it, we have no energy bills, no water bill and no sewerage charge, so the running costs are just council tax and insurance. We also made a point of not including anything that would impact on air quality, so we have no appliances that burn fuels. The latter is pretty critical living where we do, near the bottom of a deep valley, as we get severe, and pretty toxic, winter air pollution from those that insist on burning wood. We designed our house in 2012, and since then things have moved on a bit, so there is now a greater choice of build methods, energy conservation measures, etc available. It's also far more common to build to the sort of energy performance level that we built to now. We've learned a lot about how a passive house behaves, and some of the key things that have a significant impact on comfort, and there are definitely one or two things that I'd change if we ever decided to build again (which I doubt we will).1 point

-

The green line updated version of mine: https://m.clasohlson.com/uk/Cocraft-HL-20-SG-Cross-Line-Laser-Level/41-1267?gclid=Cj0KCQjwuNbsBRC-ARIsAAzITudcapjkXHRC_cIt0m8pZMUcsUqPP3VMnI8nRJPJGSRYXmcQqwWA7V0aAh1PEALw_wcB1 point

-

I wouldn't do it like that, you would be screwing into the end grain of the noggin / strap, which is never very good. @pocster way I think is stronger. Plus you don't need to cut the strap to the precise length.1 point

-

Looking at the responses you seem to be getting feedback on two different types of laser. The most common laser used outside on a building site is a rotating laser that does not paint a visible line and has a range +15m. These are cube in shape and about 10" across. Builders typically set them up in a fixed position on a tripod for most of the working day and then use a receiver on a staff to get levels. The old model I used just gave an audio sound and an lcd up/down display to indicator high or low. This is a single handed operation. Typical cost £400 to £600. A much cheaper type of laser paints visible lines. At night on site my dewalt can cast a line to at least 25m but I only use it up to 10m. This is really an indoor laser hence I use it outside near sunset, in practice I only have 40 minutes between it first casting a legible line and the whole site getting too dark to stumble around looking at levels. Mine cost £135. I would like to own both and serious outside building pros use the expensive rotating cube lasers. In practice I have got a lot of use from my indoor line laser outside. I check my blockwork heights every few courses and check how vertical a blockwork door aperture is. I have also learned how to check levels of things like poured concrete, drainage gradients and the level consistency of my block & beam floor. This requires using a 2x1 batten of wood, marking the position of the laser line on the wooden staff at a reference point and then wondering around site looking to see if the line is high or low against the reference mark. This again is a sunset operation. One downside of using a visible line laser for obtaining heights across a site is the limited angle of projection of the line, I would guess it is not much over 90 degrees.1 point

-

1 point

-

That's pretty much it but I meant have the noggins level with the front sole plate so the screws aren't in shear. Neater too imo.1 point

-

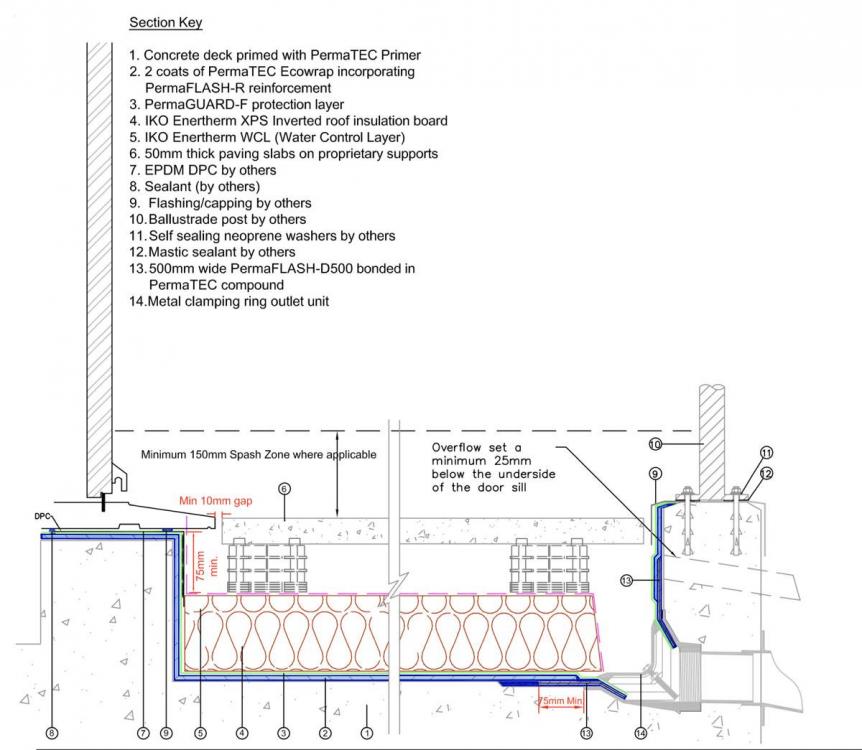

I am not keen on the inverted roof with the waterproofing under the insulation as the insulation can be compromised by water under it. I prefer a layer of OSB or cement board over the insulation to carry the EPDM.1 point

-

Sure...it is limited aesthetically, though they can achieve 'tile effect' ( https://www.westwood-uk.com/news/balcony/full-pmma-waterproofing-system-with-fantastic-tile-effect.html ), but wouldn't really be able to convincingly match an interior tile.1 point

-

Someone has been collecting all our bees and now you have a bonnetful ! I agree that it is an excellent list of wants .. meaning that you have collected all the details that you have identified, and rationales etc, into a systematic form. An architect will need something higher level, as they will come in with concepts and ideas, a framework to hang the detail on. But they will start from the concept "forest", rather than a big list of individual trees. You now need to talk more about what sort of forest you eg dark and intimate or broadleaved with nuts to eat - pick up on concepts such as your love of light spaces etc, paths to the back (rather than a "1.1m path for diggers etc"). Two risks of supplying so much detail are firstly that that gets treated as all of it, so you have given an excuse if things you have missed get missed completely, and that you unintentionally limit the architect's creativity. So I would be planning to either supply more of a summary, and say that your supportive thinking is attached, or holding off slightly with the full information. Depends on the individual you are dealing with. In any case, you have an excellent checklist for practicality of design. Can't imagine living with only having one shelf for wineglasses, though. What about whisky and cocktails? F1 point

-

1 point

-

I was at a shop and saw a jacket I liked in a sale. So took it to the counter where the girl got the concept of 70% off the price wrong. So go the jacket for less than 20 quid. she discounted the discounted price. It was a White Stuff one and everyone was impressed just how fashionable I was. I found my Converse flipflops in a carpark, another 50 quid 'saved'. Today, I shall put on my jeans from Poundland, they cost a fiver, T-Shirt from Sports Direct was 3 quid, fleese from Mountain Whorehouse was 6 quid. Socks 2 quid a pair. So clothed for 16 quid. Walking jacket and boots adds on about £300 to that.1 point

-

His description seemed to suggest it was just a standard triple filter. Expensive to run, as the cartridges need changing every 3 to 6 months. If you just want to take chlorine out, then a carbon filter will do the job, but it really needs a 5 micron filter in front of it to make sure it doesn't get prematurely clogged. If looking to fit one, then I suggest ignoring the standard 10" or 20" filter housings, and going fora 10" jumbo housing, as it will have a much better flow rate. Block carbon filters are more user-friendly than granulated carbon, as they need far less flushing after replacement. TBH, I'd only bother if you live in an area where the water is heavily chlorinated, where a carbon filter will make a very noticeable improvement.1 point

-

Lovely typo in the Bosch website .... should be 0.025 degrees ..!! So more acceptable ..!1 point

-

When I looked into earth sheltered houses, most seem to use basement construction techniques, with waterproof concrete floor, walls and roof. I always liked the idea of an atrium style design, with either an open courtyard in the centre, or a glazed dome, like Mole Manor, to let lots of light down into the middle of the house.1 point

-

Pity we don't seem to have anyone building an earth sheltered house. I've always been fascinated by the idea of building one.1 point

-

Yes. You just refer them to VAT Notice 708 which tells them what to charge you. Ask for a revised quote. It might help to give them a "certificate" which is essentially a letter confirming that the work they are doing is on a new house under construction and providing the planning reference number, the plot address and your name and address. VAT 708 also mentions such a certificate but I think it's only compulsory for work on a charity building or similar. It's not officially required to zero rate work on a new dwelling. The only proviso for all this is that your house must not be completed when the PV is installed. It must still be under construction.1 point

-

Better hope it’s more accurate than the Manufacturers tolerance of 0.25 degrees on vertical ... or 10mm in 2.3m....0 points