Leaderboard

Popular Content

Showing content with the highest reputation on 05/13/18 in all areas

-

I came across this website, don't know if it is of interest to others. https://portreepassivhaus.uk/ Should be interesting to watch the build progress when I pass by on the way to work.2 points

-

2 points

-

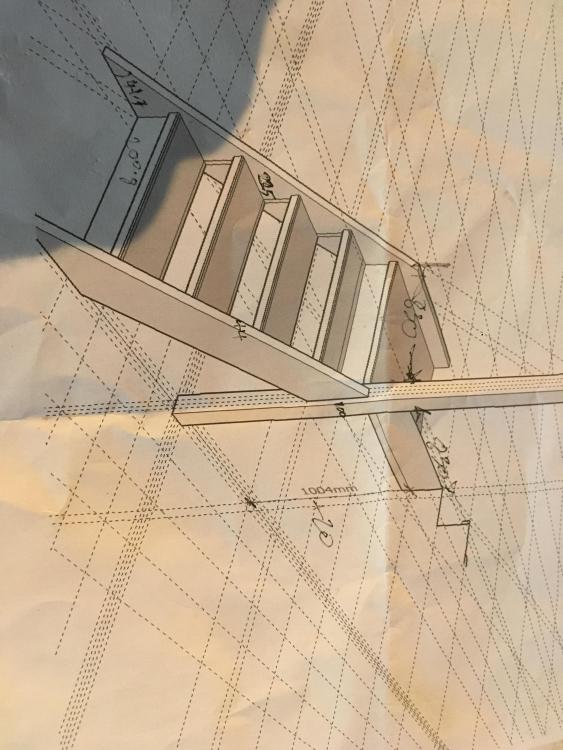

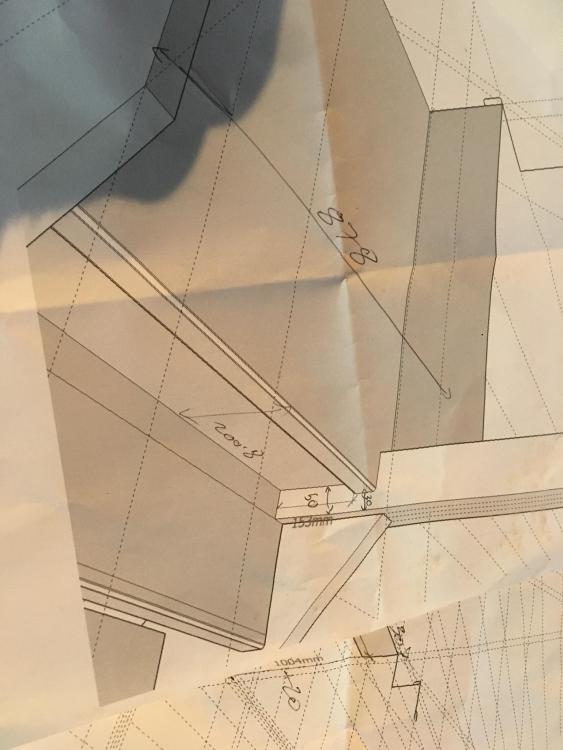

I was going to add this to the stage 1 thread but I feel it deserves its own thread. I am finally starting to make my staircase , all those years that the piles of rough sawn trees have been getting in the way are coming to an end. Yay. I should think some of you already know I started this project a good couple of years ago by cutting down a dead oak tree in the meadow. If not I will provide links to the beginning of the story when I get inside. But either way check out all the progress. The oak is starting out in roughly 55x600x3400mm planks that I slabbed with the chainsaw mill, From that they get laid onto some trestles and cut to useable widths with my skill saw and 3 rails connected together. i found these here little rollers very helpful when trying to get the full slabs into the rights place. Then I put under the little batten to stop it moving while I cut it. so we now have reasonable width 55mm oak planks. Most are over 300mm all have 1 straight side but otherwise they are very rough from the chainsaw. thats is how I left all but 2 lengths because I wanted to get my head around the newel posts. The 2 I put over the planer have come up very nicely so far, The strings treads and risers will be made from the oak if I can get enough out of it but it is looking promising so far. The newels and spindles will be ash. The ash started as roughly 120x600x3900 slabs so I am having to cut them from both sides with the saw but with the rails they are coming out rather well. as for converting the timber i have gone gone a little further with the ash. First job is to cut them to usable length. Then they get pushed over this overhand planer bow up until I get a consistent cut. Then I repeat the process on an adjacent side while making sure my new flat face is hard against the guard so I end up with 2 straight sides and one square corner. from there i take it and put it through the thicknesser useing those faces as references, this give a nice straight even thickness post. now I know what final thicknesses I can achieve with the wood I have I have started making the first jig for housing the treads in the strings. I say first because I will probably end up with at least 2-3 as the lower flight will have draws as risers. After the landing there will be a standard flight finishing with 3 winders at the top. I modeled it all on cad first to optimise the width so it finishes nicely after the winders. its all just lines on ply at the moment but I’ll be getting the router out soon, and thats about as far as I have got. I’d better get back to work1 point

-

Ha ha, don’t you think that’s why I wrote that, so someone would bite . Marmite. Love mine. Wonder if there are uk sellers who buy pipe from such factories though and rebrand it? I didn’t know my solar thermal panels were Chinese until @billt told me.1 point

-

Starting the Ash..., Faye looks totally at home handing large equipment...1 point

-

1 point

-

One of the pungent all in one's? Five Star maybe? I've been using this of late being on the cheap seats. Smells like it should work: https://www.toolstation.com/shop/Painting+%26+Decorating/d150/Exterior+Wood+Care/sd3176/Lumberjack+Triple+Action+Wood+Treatment+5L/p345021 point

-

1 point

-

As @PeterW says, you do have to insulate the pipes, and make sure any joins in the insulation are well taped up. I find that we do get a little bit of condensation on the UFH manifold, but not enough to cause any drips, it just mists up slightly, like a mirror in a bathroom. I did think about making a box around the manifold, with a perspex front so that the temperature gauges and flow meters can still be seen, but I don't think it's worth the hassle. The floor under the manifold is tiled with travertine, and there's a bit of PVC angle bonded to the wall/floor joint to stop any moisture getting to the wall (I did the same behind the kitchen units and around the space that the washing machine slides into), so even if there was the odd drip of condensation it wouldn't do any harm.1 point

-

It won't pay for a telly in the bathroom if it's been spent on EWI. . Life first, insulation second.1 point

-

Yep - simple condensation analysis is all that is needed. In most instances you only need 9mm of insulation anyway to prevent it.1 point

-

A lot... There is a significant thought process that everything that comes out of China is crap - it’s not .... There are some very good manufacturers who produce high quality products and it’s sheer economies of scale that allow them to produce at lower prices. There is a lot of crap out there from across the world - it’s not just limited to China !1 point

-

We looked at Howdens for our vanity units, that was until SWMBO found something completely different in one of the sheds. What I did learn, was 90% of "bathroom vanity" units are in fact just kitchen wall cupboards stood on the floor.1 point

-

Sadly that is how Howdens work - you need someone with an account to get pricing ..!!! It also varies between the branches too - I get different discounts at my “home” branch.1 point

-

1 point

-

1 point

-

We've used it from the local authority tip and it was fine, much the same as as any bagged compost.1 point

-

I think that is totally missing the point that Ultramods is making. There are plenty of resources on the WWW and Buildhub is just one of them. If the site is to succeed as the premier self build site, then it has to have easily accessible high quality information. Not just a library of links. We have Google for that.1 point

-

OK @SteamyTea, go for it. Plenty of free web space available ...... develop your own content .... then link to it here..... Just like @Construction Channel has had the guts, persistence and skill to do.1 point

-

@ultramods Not so different from what our old mate lineweight is suggesting over at the other place. http://www.greenbuildingforum.co.uk/newforum/comments.php?DiscussionID=15720&page=1#Item_30 It is amazing how quickly this sort of idea gets criticised and not acted on (my very first post was about open source housing and got bogged down in irrelevant detail) and being told it is too hard and that there are too many variables. I would have thought that was the whole point of implementing good practices rather than letting everyone reinvent the wheel, or a thermal break, or a gutter and downpipe. What may be useful are some static pages that show basic principles and formula used, maybe even a simple calculator, oh hang on, that has been suggested before and not happened as someone may have an out of date browser.1 point

-

I think this is a perfect use for this product, but I wouldn’t fill a raised bed completely with it.1 point

-

1 point

-

1 point

-

You don't want to go above 1:40 as it will be too steeply sloped, or below 1:80 as it won't be steep enough, so aim for 1:60, but be flexible depending on obstacles etc1 point

-

1 point

-

Twyford do one and I’m about to fit one so if you wait a couple of weeks ..... Double Sink Unit1 point

-

Funnily enough... The little 'un wants a hamster. Everytime she asks I suggest putting a glass panel in the suspended timber floor downstairs so she can watch the rats! But I won't be doing it!1 point

-

My old Dad used to cut down this large weed every year and take it to the local tip to be composted. I was up there one time and pointed out his lovely example of Japanese Knotweed. He said, "Is that what it is I have been taking it to the green waste for 20 years". I bought him some glyphosate, problem solved, he outlived the weeds but they are probably scattered all over Buckinghamshire now.0 points