Leaderboard

Popular Content

Showing content with the highest reputation on 07/25/17 in all areas

-

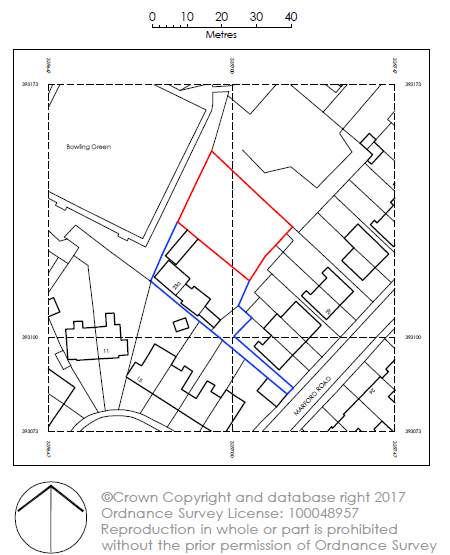

It's very, very difficult to get double yellow lines, even when there have been several accidents at a spot that would have been prevented had cars been prevented from parking so as to allow better visibility. We fought for around 15 years to get parking restrictions imposed on the road outside our old house, to no avail. Even when a Discovery hit another car coming out of the adjacent junction and overturned the local authority still won't authorise a parking restriction, and that's despite several requests from the police that having such a restriction would reduce the high accident rate at the junction. Looking at the plans I can see the issue, it is that building to the South of the entrance, that is right on the boundary. The fact that you're living with your parents makes no difference at all, as you're applying for planning permission for a new dwelling, so the planner must assume that means a new family as well, as you could sell the plot as soon as you get PP (that's how they will think, I'm afraid). Personal circumstances very rarely have any weight when it comes to planning policy, you have to make the case within the policy that applies for your local authority area, plus the NPPF. In this case I think you stand a good chance at appeal, but an appeal has to be focussed on the precise reasons given for refusal, and must address those with evidence that will satisfy a planning inspector that the reasons given for refusal are not adequate. There is a presumption in favour of approval in the planning process, even though it seems at times that it's the other way around, so all you need to do is provide enough evidence to undermine the specific reasons for refusal that have been given. You may well benefit from paying for a planning consultant with specific experience of dealing with highways and access issues, as that could prove to be money very well spent. I rarely suggest, or support, paying for help related to self-build, but planning is one area where the inside knowledge that a good planning consultant will have is really worth it. Often planning consultants are former planning officers, and although this shouldn't make any difference, the fact that they may be former colleagues of current planning officers, and probably known to the planning inspector, does seem to make a significant difference.2 points

-

We have an MBC slab. The only prep done to it by our tiler, before laying around 45m2 of large format travertine, was to sweep and vacuum the concrete and apply a very thin PVA sealing coat to it. Ours didn't need any levelling, as it was within a few mm of being dead flat, and we have the travertine running flush through four doorways from room to room. We have no expansion joints, and they are not needed, as the slab has steel reinforcement and so won't crack. The slight difference in the coefficient of thermal expansion between the concrete and the travertine is accommodated by using flexible tile adhesive. The flooring has been down a couple of years and is still as perfect as the day it was laid. In terms of cost, I think we paid around £20/m2 for labour, and around the same again for the travertine. Add in the cost of adhesive and sealant and the total cost came to around £45 to £50/m2. Not sure where the calcium carbonate is going to come from with a normal cured RC35 concrete slab mix, either.2 points

-

Did you mean manege? The extra traffic excuse sounds spurious but common, Two to three traffiv movements a day will not block up anything as far as I can see. You probably need to look at providing appropriate visibility splays, depending on the type of road it is. Posting a scale site location plan may help us comment - but remove the identifying information. Depending on layouts, that could mean redesigning your entrance. Perhaps go back to your architect / planning consultant and see what they say, or have a phone conversation with the Planning Officer. I believe you get a second free go, or an Appeal, now that you have been refused. F2 points

-

Another vote for Knauf Earthwool Frametherm 35. It's less nasty to handle than most forms of glass wool, rigid enough to place in between the studs of a timber frame and just stay there without slumping, even on a 45 degree roof, and does not need to be an absolutely perfect fit like completely solid insulation boards. Increase your frame to 190mm and fit two 90mm layers. An extra layer of solid insulation inside or outside will get you to a good U value. There is also almost no waste at all, unlike cutting solid boards. I was going to use blown in insulation originally, but changed tot he earthwool when I found it was about half the cost, gave the same U value, and wa a DIY job saving the cost of getting it installed and meaning I could work at my own pace.1 point

-

Comes complete with a previously owned sink in "near perfect" condition .1 point

-

All sounds good but two things come to mind. Air tightness will make your insulation work hardest for you so attention to detail there will pay great dividends. Domestic hot water installations in the 'eco' sphere is a difficult one as there are so many solution there has been many a discussion on it here so you will need to pick your way through it I am afraid.1 point

-

Trouble is, simplicity is in the eye of the beholder. To some, whacking in a boiler, burning some dead dinosaurs and allowing the energy to simply leave the house is "simple" because it's what everyone knows how to do.1 point

-

Yep, rockwool / earthwool between rafters, then celotex or similar across rafters. Perfectly respectable U values can be obtained. Certainly worked for us and we live in a very exposed location.1 point

-

In that case then I suspect that it may well be that there's been a misunderstanding, or there are politics at work within the local authority. Never underestimate the influence one or two people can have on the system - I've seen cases first hand where it was blindingly obvious that "undue influence" had been brought to bear. It shouldn't happen, but it can, and in my experience it is very difficult to prove that this is what has happened. A free resubmission, with a clear section included in your new Design and Access Statement that spells out, in words of one syllable, that the access complies with section XXX, paragraph YYY of the planning policy, that the road is category ZZZ or whatever and that the visibility splay requirements have been fully complied with, should do the job. However, as previously mentioned, check to make sure that every single reason for refusal is adequately rebutted. Again, the D&A is the ideal way to do this, as you can include photos, lots of text, etc, that makes it harder for the planners to refuse the application. I'm a big fan of writing a comprehensive D&A with an application, with the proviso that you need to take a bit of care to not make a rod for your own back by including things in it that you might wish to change later, as the D&A may well become a part of the approval!1 point

-

As an example of the capacity of water to move more heat energy than air, as @Crofter says, here are some numbers that illustrate this (with a bit of playing fast and loose with the terminology - but the comparison is still valid): 100 litres of water that is 20 deg C warmer than the room needs will be able to shift 2,300 W of heat into it. 100 litres of air that is 20 deg C warmer than the room needs will be able to shift 0.67 W of heat into it. To move the same amount of heat with air, rather than water, for a given temperature difference, means moving a volume that is about 3,400 times larger. This also helps explain why an MVHR system can't shift very much heat around.1 point

-

One good idea is to always think of the cost of running the building for 10 or 20 or 30 years as part of your budget and include it in your spreadsheet models. Even people in normal (ie subnormal) houses can do it using the crude numbers from the EPC - though here we are very rude about EPCs. You may not be there for that long, but it will help you to get the principles right and avoid eg complex things that will need mending. There can be things for using things that are complicated or really cheap and requiring replacement, but each case needs to be justified. KISS is right 99% of the time. Ferdinand1 point

-

Kytun is manufactured in Ireland, so should be readily available in NI. We used it, on the recommendation of one of the MBC guys, as I'd not heard about it before. Well worth it, as the finish is very neat plus the slates are secured from the wind at the verge.1 point

-

When you go on streetview you can start to see their problem a pared cars along / one the kerb will obscure the view as you emerge into the road. That said it does not look like a fast road. 20 is plenty kind of place, so should not really be a problem. Looks like an immediate appeal, as you have suggested, will be your best route once you have written your case out. Several things do stand out - it is defo brown field site so development is to be expected, and the dropped kerb for the existing entrance indicates traffic is expected finally you might argue that double yellow lines 20m each way on your side would solve the problem but will incur the wrath of your neighbours1 point

-

May you have an issue with Fire Engines? It looks more than 45m from the road and I am nto sure than drive is over 2.75m wide or that there is space for an appliance to turn around inside.1 point

-

1 point

-

My hairdresser operates out of converted farm buildings and they are all eco. UFH run by GSH. She says GSH UFH is a nightmare, cant get heat when you need it and its not controllable enough and reaction times are slow. That is the only form of heating so they resort to the fan heaters. She has been there 3 years and they have tried all ways her husband is an electrician so not unused to controls etc. Is it bad UFH or bad GSH supplying who knows!1 point

-

Hoovered and then primed on mine as well, no other surface prep required. Due to the UFH my tiler insisted on Ditra matting "to avoid grout cracking". I personally didn't think it was necessary but I've only tiled bathrooms so it wasn't much extra and I didn't want the the fact I would have gone against his advice to be used if there were any problems in the future. I'd avoid sanding/grinding. My experience is that few trades have worked directly on to a power-floated C35 slab and all underestimate how hard the surface is. It will likely be a much bigger job than they expect, and from what I can see, unnecessary. More importantly though: Eeeekkk... Hopefully MBC are putting that right for you. Can you use self-levelling compounds for that thickness? You may need a cementitious product. Is it just a few high spots that could be ground down, or are there hollows that didn't get enough concrete poured. That also questions how much coverage you have over your UFH, be careful if you need to drill or screw into the slab.1 point

-

Hi, We have a GSHP. It works reasonably well - and doesn't use a lot of electricity to provide our heating and most of the DHW. However it was expensive to buy, install and maintain. There have been a couple of problems with it over the last few years - and each time was quite tricky to resolve - given there are very few people around me who know anything about them - and nobody who understands the particular model. If doing it all again I would look at ASHP more closely. In fact I might just look at an old school oil fired boiler! That would cost more to run - but I'll be dead before the GSHP pays for itself through the difference. We have had the GSHP for 5 years now - I guess they don't last forever and in the next few years I may have to replace it. Given I already have the brine loop etc (the tricky underground part) then I will probably be sucked back into getting another GSHP! Not sure how I feel about that :(. - reddal1 point

-

@Badger visibility splays...maybe a long shot but is there any way you could locate the new bungalow on the site layout drawing so that it shares your parents driveway? The Planners argument about extra traffic in & out of the site can be argued with some advice from experts. I had a commercial project with that issue and we successfully got around it1 point

-

That looks like something that *may* need professional advice, but post here so we have a little look. There are concepts such as (iirc) *internal* splays - depending on the width of your access and how far you can see if you drive up the middle. F1 point

-

I think I got the arithmetic right. The GSHP option was going to cost about £4,000 more than the ASHP we fitted in the end. The running cost saving would have been around 10%, so about £25/year. £4,000 / £25 = 160 years. Happy to be corrected if I've made an error. I semi-agree, but everyone needs to do their own sums to see whether or not that argument holds true. The capital cost of installing direct electric water heating, using something like a Willis unit with a standard immersion heater element, would have been around £80 to £100 at the most, saving over £1,900 on the cost of our ASHP. Assuming a COP of 3 for the ASHP then our bill would increase from around £250 to about £750, but then adjusting for the reduced unit cost of running direct heating on E7 (not a good thing for an ASHP, as it means running it at night, when it's colder and when the noise may be more noticeable) the direct electricity running cost comes down to around £375 to £400 per year. The £1900 capital cost difference between direct electric heating running on E7 and an ASHP running on a standard tariff would be enough to pay for about 10 years worth of running costs, as a very rough estimate. It would be reasonable to guess that 10 years may well be around the life time of an ASHP, so for us it would be a finely balanced economic argument either way. There is certainly a lot to be said for the simplicity and reduced maintenance cost of a direct electric system, however we also use the ASHP for summer cooling, so there is an additional benefit there.1 point

-

Are these two heros confused as to whether or not you have a liquid screed . All that needs doing to a fresh concrete slab, if finished reasonably well, is a good douse with a flexible tile primer, watered down 50/50, and left to dry. You'll go through a lot so a disposable mop and bucket is the easiest route or a roller. Put plenty on. Silicone expansion gaps at the door thresholds for a slab of that size laid in one straight run wouldn't hurt, but as its a low temp slab it really shouldn't be an issue vs a higher temp retro-fitted system. id go with the two who want to lay direct, and, fwiw, I don't use Ditra mat unless it's a wood floor or an unknown substrate, eg extreme circumstances. Make sure any self levelling is done ONLY where the low spots are. I hate it when people level the whole floor, making the high points even higher. Waste of time, materials and cost. Ask these questions of the two more sensible candidates and see what their response is.1 point

-

Have you looked into Air to Air Heat Pumps. They have a good CoP, are cheap to buy and can often be self installed. On a more general note, the best heat pumps are water source ones, then ground source, then air. They all need to be seemingly oversized and run with the output temperature lower than the maximum. The downside of ASHP is 'frosting'. This is caused by a combination of air humidity, external temperature, desired temperature output and amount of time the unit is running. Space heating and domestic hot water should, if possible, be separated, they do different things, at different times and at different temperatures. When trying to decide on the best heating method, start with electrical resistance heating as this is generally considered the lowest capital cost but highest running cost. If, say an ASHP, comes out more expensive after 7 years, then it is not worth considering. You will need to have a good estimate of your thermal energy usage, but you need that anyway.1 point

-

1 point

-

Welcome. Its sad to see a first post based on frustration. I don't have much time just now, but here's what you can do to start First rule: don't give up until you have been refused at Appeal Research the Appeals process yourself Read this board in a focused way: do a search for Appeals (Home>Search>'Appeal' or 'Appeals') Read your LPA documentation carefully, then search for similar refusals in your LPA Take professional advice: be very careful to research the adviser thoroughly before engaging him or her look for the advice given during similar applications Read widely about the local context. (Other members here (BH) would question that advice) I will try to find our checklist on preparing an Appeal. I can't remember where it is, but I will spend a bit of time today looking for it. Most important of all, do not give up. It took us 15 years of asking, wheedling, reading and thinking about it - not to say dreaming of the day when.... Finally, you might want to post a photograph (maybe Google Map) of the problem area. Although you may want to consider privacy issues before doing so. We'll cast a fairly experienced collective eye over it. You are not alone. Ian1 point

-

You could always use.... On second thoughts, I'd better not open that can again1 point

-

Adding some boards on the bottom transoms and then putting a few blocks onto those also stops the movement too ..!!1 point

-

Go with two layers of rock wool at 95mm each and then add a 30mm overlay of PUR and you have your 0.15 for pitched. Then seal it up with membrane to stop the real leaks ..!1 point

-

But think also about whether you need a heat pump at all. If your key criterion is cost, you could save the vast proportion of the capital cost by doubling or tripling the running cost. If your house needs a very low heat input, why invest in a heat pump? Do the maths.1 point

-

Welcome to THE forum. @JSHarris makes all the key points and has the experience to back it up. Looking at it in the round the only way to make GSHP cost effective will be to get the installed cost down to ASHP levels. The only way to do that is to get the equipment very cheaply and do all the digging in yourself. Go for ASHP unless you can get a supplier to subsidise the install.1 point

-

Welcome, As above, it really comes down to economics. A GSHP might be a few percent more efficient than an ASHP, but the installation cost is likely to be at least double, probably triple, the cost of an ASHP if doing a DIY installation. A fair bit of the cost is hidden, it's things like the much greater volume of antifreeze, and the ongoing cost of replacing that every few years. GSHPs are also inherently more complex, with an additional brine pump, plus brine heat exchanger, filters etc. When looking at the whole life cost, the tiny efficiency advantage can't usually recover the additional capital cost through life, so overall a GSHP may cost a fair bit more over the life of the unit. In terms of ecological cost, then again the ASHP wins, not so much because of the energy used, but because it probably has a smaller impact on the local environment. As an example, our house is fairly low energy (it's not a certified Passivhaus, but would easily meet the Passivhaus requirements). In winter we need a few hundred watts of heat to keep the whole house at around 21 deg C (the floor area is 130m2), and in general our ASHP fires up for about an hour or two once every two to three days to charge up the slab and keep the house at an even temperature. IT might come on for an hour or so every day in really cold (sub-zero) weather. The ASHP cost £1700, including delivery, and took me around half a day to install. The total installation cost was under £2,000. The cheapest GSHP I could find cost around £4,000, and even with a DIY installation would have cost another £2,000 to install, more if I'd opted to use vertical borehole collectors. In winter we use between £0.20 and £0.30 worth of electricity per day for heating and DHW pre-heat, for around 100 days, so the cost is around £250 (ignoring our PV generation contribution to that cost). If we had a GSHP, it might be around 10% more efficient at best (bearing in mind that things like the brine pump increase the energy use over and above the basic COP difference), so a GSHP might save us around £25 a year. To recover the additional £4,000 cost of the GSHP, without accounting for the cost of antifreeze replacement, would take 160 years.................1 point

-

I can understand the concern, as the OSB is only 10mm thick, I suspect. Screws would seem to be a better bet than ring shank nails. I've had lots of 75mm ring shank nails pull out of out larch waney edge cladding (which is nailed to 50 x 25 counter battens, lined up with the frame studs, under 10mm OSB)and have had to go around easing out the old nails and replacing them with decent screws. It's important to choose the right screws, too. I made the mistake of using some screws with thin shanks and they just sheared off from movement in the timber within a few months. I've replaced them all with screws with shanks that are thicker than the threaded part and they are all holding up really well. FWIW, I used good quality galvanised ring shank nails originally and they were all driven in properly, with their heads set just beneath the outer surface of the cladding. There was no sign of corrosion, the damned things just pulled themselves out with repeated small movements of the timber. I had places on some walls (the East and West facing ones only) that looked like hedgehogs, with the nails poking out maybe an inch from the cladding.1 point

-

Wait till you're knee deep in muck and gutters after throwing a track and see how many swear words you can mutter. The bigger the digger the easier they are to drive and a lot more fun but by god can they do a whole lot of damage in the blink of an eye.1 point