Search the Community

Showing results for tags 'ashp'.

-

Hi all 👋🏼, I wanted to introduce myself and our project as I anticipate I'll be in hot pursuit of the forums thoughts, opinions and experiences in the forthcoming months. We purchased a 3-bedroom 1970's bungalow in August 2022 but had some planing complications due to a parish council policy that attempted to dictate that "a bungalow must stay a bungalow". 15 months later our planning application was finally granted, albeit with some compromises. Here's a few points on what we're attempting... Replace existing roof (& ceilings) entirely, building up the walls ~80cm, adding a new roof with 1.2m increased ridge height and steeper pitch Upstairs will accomodate two bedrooms, bathroom and "breakout area" overlooking hallway void Large single-storey flat roof side and back extension out to locate 65sqm kitchen/diner Complete re-configuration of downstairs layout Complete replacement of heating system (gas will be cut off entirely) New ASHP (current thinking Valliant Arotherm Plus, one-zone, no buffer) UFH all-round on ground floor (retrofit lo-profile UFH on top of the existing slab (Wunda?), insulated/screeded in new extension). Possibly fan convectors in bed-rooms upstairs Complete rewire I would assume MVHR (current thinking is a radial system installed through new posi-joists, manufacturer TBH but will get BCF to design) New solar panels, and battery (current thinking GivEnergy to unlock Octopus Intelligent Flux) New double-glazing all round (Residence R7 probably) also 2.7m high, ~8m wide sliding doors at rear (either Corteso Cor-vision or Minima) The biggest grey-area for us at the moment is how much to focus on/invest in improving the insulation and air-tightness of the existing exterior walls. I'll raise a separate thread for this in due course. Fortunately we were able to leverage a second mortgage and keep our existing home so we don't intend to live in the place whilst the majority of the work is taking place. The properties are only 0.5 mile apart so I am hoping I'll be able to keep a close eye on the build whilst I work from home. We are also intending to do a little of the work our-selves as possible (i.e. fitting MVHR, UFH, painting & decorating, airtightness membrane?, etc). Thanks for having me and in advance for any advice, Ollie Fleet, Hampshire Plans 24 OD - Amendments Combined.pdf Concept Images Existing Images

-

Just been listening to a podcast with the founder of One Zero Energy company, Howard Johns, who has ideas for making as many houses as possible more energy efficient, quickly without having to pay huge upfront costs. He reckons he can do ashp, battery, solar, cavity and loft insulation in 2 weeks for around £21k (less the BUS grant). But he wants to do lots more, including arranging better finance for those who dont have that money but still need the equipment. Listen hear or read the notes, https://www.houseplanninghelp.com/hph366-could-a-home-energy-transformation-pay-for-itself/ Sounds a very interesting chap with plenty of experience and a real committment to helping as many people as possible. wish I lived closer to him 🤔would certainly be interested in his ideas.

-

Just heard that Air Craft who are based in Chichester and have a stand at the NHBC are going into administration. If, (like us) you have paid them a deposit for an install via a bank transfer you are likely to lose all the money. Lesson to all - pay any deposits on Credit card and benefit from protection under the Consumer Credit Act Section 75.

- 8 replies

-

- ashp

- renewables

-

(and 2 more)

Tagged with:

-

The next design being tried out! Will these work? Is this the next generation? https://businessmanchester.co.uk/2022/11/03/bellway-installs-uks-first-roof-mounted-air-source-heat-pump-in-pilot-project/

-

Hi All, We are embarking on a self-build and the ASHP was installed yesterday and we are awaiting the commissioning engineer tomorrow to turn on and start heating. I was a little alarmed by the our ASHP supplier planning to just operate the ASHP at its standard operation rather then operating a thermal cycle. From what I have read on line this is important for the concrete screed performance and any floor finishes installed later. I spoke with our tile installer and tile adhesive supplier and they have recommended the following regime which is more or less a 14 day cycle that involves, 5 days of gradual heat increase (2-3C per day) , maintain at expected operating temp for a further 4 days, before a 5 day gradual decrease in temperature. My question is with regard to the expected operating temperature, which I presume is the outflow temperature of the ASHP (45 degree), that the underfloor heating pipework's will be supplying to the screed for these 4 days. My understanding is that the thermostats will be overridden temporarily for the commissioning and the slab will be consistently heated with this 45 degree water - am I correct? If this is so then theoretically will the house be extremely warm for a few days as the slab should come close to the 45 degree temperature?

-

HI All, i have an LG 14kw ashp powering hot water and central heating in a 5/6 bedroom house approx 350sqm, i have not issues with the hot water side of things, this works perfectly however, the central heating side gives me issues! when the system works well its great and keeps the house warm but at the moment, once or twice a week the buffer tank which is a 50l cordivari version seems to vent all the central heating system pressure out of of the aav at the top. i have changed the valve a couple of times but still have the same issue, anyone have any ideas what the issue/s might be?

- 14 replies

-

- ashp

- air 2 water

-

(and 3 more)

Tagged with:

-

I had some pipe layouts done and wasn't pleased with the density / layout so I read a bunch of stuff on the internet and had a go. - have I got this right? Refurbing an 1850 stone build terrace - - 16mm at 100mm centers - 8 runs of 70 ish m - Total floor area 65m2 give or take Looking to use an 8KW ASHP - for a room temp of 17-20 c flow temp 20-25 c? The floor build up old house geotextile /260mm Glass foam insulation / geo textile / Geo Grid with piping cable tied / 70mm limecrete base (1:1.5 lime NHL 5 / Nosterfield) / 70mm Lime adhesive / upto 70mm thick slate slabs 80's extension 100mm PIR / Geo Grid with piping cable tied / 70mm limecrete base (1:1.5 lime NHL 5 / Nosterfield) / tiles and similar but toped with engineered oak in the lounge Needless to say we're adding lots of Insulation it the roof. Rough heat loss calcs come out around 3kw +Ventilation loss + performance gap etc. Looking forward to your feedback

- 8 replies

-

- underfloor heating

- limecrete

-

(and 6 more)

Tagged with:

-

We recently had an Aira chap round, (long warranty). Told us a 6kW ASHP would be ok. We're not eligible for a grant because the previous tenant had one installed (even though the grant was £750 over 10 years ago). (We removed the 2012 ASHP—it was a noisy machine, and we’re after something quieter and more efficient - (is this the right thinking?) it's still in the garage). My partner is all for buying new (with a long warranty) I'm up for taking a chance as there's some good value machines out there. - What system would you have if you were to do it again ? Current thinking is 2 zone 60ish m2 under floor heating 16mm pipes 100mm centers + radiators up stairs - aiming to have a low flow temp and take advantage of the thermal mass of the thick walls and floor Looking forward to hearing your thoughts, especially considering the low flow temperature target and potential ASHP options (new vs used) - what should we have on our shopping list - ? Background We bought an old (1850 stone built ) drafty damp house with an ASHP that needed a complete overhaul / insulating / damp problems solving... it's been quite a journey but we now have windows.. so thats nice.. Current Setup Plan: Heating Zones: Ground Floor: ~60 m² underfloor heating with 16mm pipes at 100mm centres. First Floor: Radiators. Aiming for a low flow temperature to maximise efficiency and leverage the thermal mass of thick stone walls and the floor. Heat Loss Calculations: I did some rough heat loss calcs based on U-values from ChangePlan's U-Value Calculator. Heat Loss Breakdown: Area m² U-Value Temp Diff (°C) Heat Loss (W) Extension Walls 44 0.179 25 196.9 Stone Walls 48 1.26 25 1512 Windows & Doors 20.38 0.82 25 417.79 Old Roof 71 0.14 25 248.5 New Roof 34 0.147 25 124.95 Old Floor 56 0.22 25 308 Extension Floor 29.8 0.163 25 121.44 Total Fabric Heat Loss 2929.58 W Ventilation Heat Loss: Volume (m³) ACR Constant Temp Diff (°C) Heat Loss (W) 365.5 1 0.33 25 3025.46 Total Heat Loss (including 20% buffer): Fabric: 2929.58 W Ventilation: 3025.46 W Total: 7364.44 W (7.36 kW)

-

Hi wise forum people, I'm in the process of getting quotes to replace an oil boiler with an ASHP for my farm house. I've got two quotes now in place, one of which was nice and detailed with all the heat loss metrics, and the other which just listed suggested radiator replacements. Despite this, after some discussion, the radiators they both suggest to replace match fairly well, except for the lounge. After a bit of questioning, I got some figures for the less detailed quote and am now having difficulty comparing the two. Company A (detailed quote) say the heat loss of the lounge is 2800 watts, and company B stated 4700 watts. I could understand a little variation, but this seem like a large difference. Further confusion comes in when I compare what each company suggests the CURRENT radiator will produce: Company A: 782 watts Company B: 1732 watts. The both correctly identified the rad as a K2 1000 x 600 mm, and I'm assuming they MUST have to use the same MCS methodology and flow rate and target temperature. There is clearly something funny going on. Does anyone have any ideas what, and if there are other methodologies that could be at play? Thanks.

-

After removing the old heating system a couple of weeks ago, the engineers arrived at 10am Monday morning last week - waiting for the delivery of all the 'bits'! We'd installed a couple of electric oil filled radiators for mum and dad and luckily the weekend was mild. The lorry arrived around 11am, things were unloaded and taken into the back garden, then the guys all disappeared to go and get the pipework..... So after lunch, back the 2 chaps came and installed the ASHP into the back garden, with pipes into the roofspace. (one lives in Stamford, 2.5 hrs drive from here! - no wonder it took a while for them to arrive.) Tuesday, we had 3 guys, ftting the radiators into the place. I was told the electricians would be there thursday and friday to connect everything up. Wednesday 3 guys again, all sorted of things were now fitted into the cupboard and the radiator installations continued. There were 2 under bench blowers in the kitchen as there are no walls for a radiator. They were fitted but not connected - needed an electrician. Two radiators had to be removed and replaced as they had faulty paintwork (nice to know they arranged that themselves, we didnt have to complain). Not sure what happened thursday but no electricians turned up. 🙁 Friday, 2 electricians arrived and started to connect the system. But then one said they had to leave at lunchtime! I was not impressed but to be fair, they carried on, until the system was up and running. I had a quick explanation and off they went, around 2pm. The house was lovely and warm with hot radiators! Yippee. 😁 Saturday as I drove to a friends many miles away, we had a call from the parents - they had no heating! Grrr. But after emailing the 'boss' - within an hour, he arrived at the house and sorted out the problem - air in the system. Heating resumed. 😄 Sunday - Mums 85th birthday. House toasty and all happy. 😁 Dad mentioned a problem with his bathroom radiator which was so cose to the door that it could only be opened half way. email sent to 'boss' who arranged for an engineer to come MOnday. Which he did (from Stamford), he moved the radiator (cursing the idiot who placed it there) and fixed the fronts onto the under bench heaters. All looking good. Tuesday - unknown to me (they didnt tell me), there was no heating again and the 'boss' was called by Dad. He arrived after an hour and got it working again, telling them it was all sorted. But today, wednesday, when I arrived at 9am, the house was cold. Arghhhh!!! After emailing the 'boss' who arranged for his business partner (the elctrician from last week) to ring and come out. In the cupboard, the box which seemed to talk to the thermostat was flashing amber - and not sure that was right, i pressed a button and it turned flashing green. But still no heat after half an hour. I then found a manual online for the thermostat - Drayton Digistat - from which i discovered it had been set to a particular schedule for those out at work all day - ie on for a couple of house in the morning, low during the day, warmer for the evening and off at night! Not ideal for two 85yr olds, at home all day. After installing the app on the tablet - didnt work - and then on my phone, i was albe to amend the temperatures up to 21oC from 6.30am to 22.00pm with 16oC at night. I could see the Digistat registering that change and start the heating symbol. but the radiators stayed cold and the temperature did not change from 17oC. The electrician rang and I told him about the flashing light. I was told to press it till it was constant green which we did. And then i heard the pump start and water could be heard moving. But still no heat. After a couple of hours, he arrived and confirmed that while the App was controling the Digistat, they were not talking to the bix in the cupboard. After some work and a call to the Manufacturers, he re-set the system and everything seemed to be talking to each other. I was able to boost the temperature with the App and the house started to warm up. So thats the current situation - its taken several visits and several days without heating but fingers crossed, it continues to work. When it does work, the place is toasty, and I have to admit that all the guys have been great with mum and dad, moving out the way when needed, and being polite/helpful. And the 'boss' and Electrician have been quick to come out and try to fix the problem. I just hope there are no more calls. Will update in a few days.

-

I thought I'd publish some rough figures for the running costs for 12 months. Details. 85 Sq M bungalow. North Scotland -highlands All electric (heating/DHW/cooking and running * two self catering cabins) 4 kW South facing solar panels. 0.88 ACH EPC A103 Heating set to 20⁰C DHW set to 43⁰C Year to date: Total Electricity usage 3300kWh ASHP usage 890kWh heat and DHW don't know if Samsung gen6 can split the usage? Solar Generation 4254kWh Solar export (given away) 2359kWh. I'm happy with the house, and the heat retention seems very good for our budget build. Heating hasn't been needed since mid April, and has only been on around 6 days this autumn. Obviously my biggest issue is reducing our solar export. I have done nothing in this regard with the exception of manually loading shifting washing machine / drier / dishwasher on sunny days. My issue with solar diverter is that the meter is located 50M from the house (in an enclosure) the house is supplied separately from the cabins so I can't just monitor the house as the cabins maybe using power. I'm in the early stages of exploring using ESP-Now as a CT clamp monitor and building a diverter similar to how @ProDave and others have done. How do these figures look? *We had around 170 days of cabin usage which use electric for cooking/heating and the laundry.

-

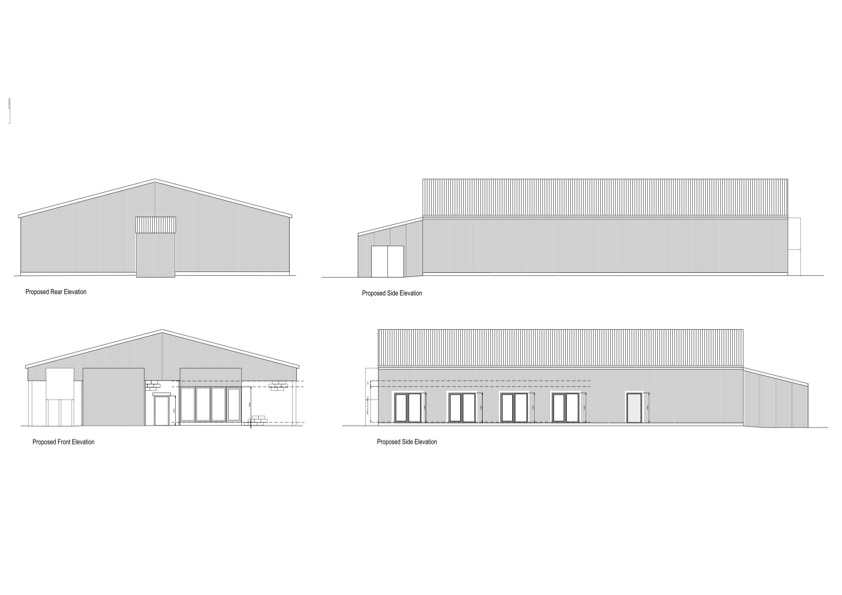

Hi All, I hope someone sensible can help point me in the right direction or offer some useful comments on our project...! We'd initially planned to heat the whole place using an oil fired boiler with a wet system - underfloor tray system for the office space with warm air blower to keep frost off the warehouse space in the winter. But now we're wondering whether we can heat the office area appropriately with an ASHP throughout the year, possibly supported with PV panels on the roof? (It's a large roof, approx 250sqm is south facing, unobstructed - we can trim the trees). Outline as follows: We have a steel portal frame barn which we're converting into a warehouse with internal offices. The existing asbestos roof and steel sides will be replaced with insulated Kingspan panels (KS1000RW 100mm for roof and 73mm for the sides - both with U Value of 0.18 W/m2). The building measures 25m x 17.5m, average height is 5.25m. (see plans) Within the building is the office, which measures 8.3m x 15m x 2.6m. Ignore the additional small building on west side it's being demolished. When it's -3 deg C outside we'll need to maintain approx 10 deg C in the warehouse and 22 deg C in the offices. The place is only occupied during normal office hours. i.e. I'm not worried about keeping it warm at night, just that it doesn't freeze! We guess our heat demand would be approx 4kW for the office area and 16kW for the warehouse. (Maybe someone can tell me if this is miles off?). How can I work out how much energy an appropriately sized ASHP will USE across the year? Furthermore, we've got a great big roof area relative to the size of the office to be heated so can Solar be used to power the ASHP for most of the year? I guess in depths of winter when it's grey and wet the contribution would be minimal... at the time when the ASHP will be doing the most work and COP would be at its worst? What would a sensible output of PV be? Any advice warmly welcomed! Many thanks, Sven Proposed.pdf Floorplan.pdf birds eye.pdf

-

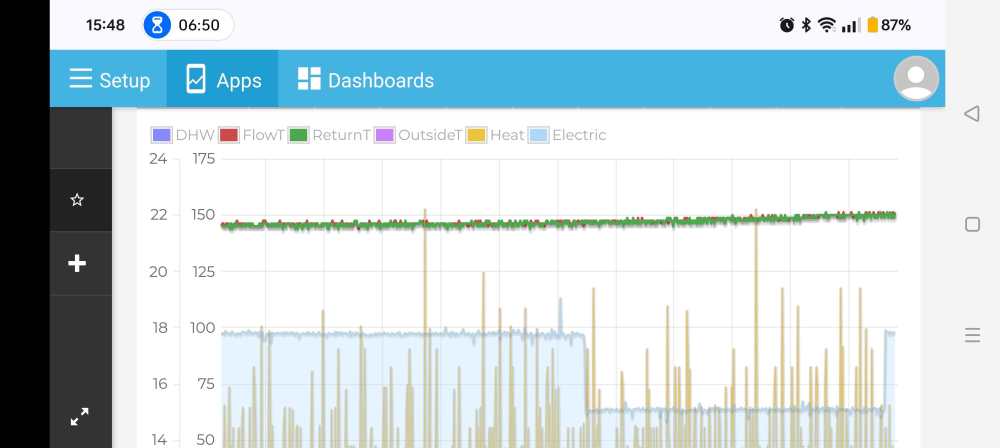

Just been looking at ASHP monitor system, it shows the flow and return temperature among other things. Sun has been out since lunch time. You can see the floor absorbing house heat. For context the UFH pipes are at the bottom of 100mm of concrete, the main rooms to get solar gain are covered in glued down oak floor or carpet. The ASHP is in full WC mode with no mixers etc and circulation pump runs 24/7. Rise in temp is 0.5 degs on flow and return (green/red line) over 2 hrs.

- 6 replies

-

- ufh

- solar gain

-

(and 1 more)

Tagged with:

-

Many heat pump suffer short cycling or fairly short run times in shoulder months, mine included. So in an attempt to understand this more clearly and hopefully developing a coping strategy for all I am after some information. Water leaving temperature will have a target temp let's say 30 degrees, the heat pump has hysterisis for stopping and starting around this temp. So mine (Maxa) it is To start heating CH water the return water needed to be target delta T (between flow and return) + and adjustable 2 degs. So at 30 Deg the flow has to of reduced to between 22-23 Deg. To stop heating the overshoot is allowed to to 0.2 degs over so 30.2 degs. Grant/Chofu heat pumps are Start 8 degs below target (22 Deg) Stop 1 Deg above target (31 degs) The above are adjustable settings What is yours? Make Heating type - radiators, UFH or mixed. Another interesting feature is circulation pump option mode. Run always when there is a heating demand and sniffer mode, with only periodic running of circulation pump, one for a minute off for 10 mins. Do you know how yours operates?

-

Following on from another thread where I asked advice on this heating method, no idea how to link it. Basically, we have had quotes but Im cheesed off that I may lose most of my utility to a cylinder cupboard. Has anyone got a horizontal cylinder in their loft and are there any disadvantages to this. TIA FF

-

Our heating system is currently designed for ground floor UFH and ASHP. So far so good. It has always been in the plan to fit a buffer tank. I'm now beginning to re-think the buffer tank and remove zoning. To give some context, we have a block house on insulated slab and <3kW peak heating load. Floor temperature will change very slowly hence individual zone control seems to make little sense, even with solar gain moving around the house. We have about 600 metres of UFH pipe in the floor at 200 centres. I see from discussion here that there is a school of thought that questions the conventional wisdom of installing a buffer tank to stop short cycling because there is already sufficient volume in system. And so it may be more efficient to remove the buffer tank all together and connect the ASHP diretly to the UFH manifold. Is this a contentious area, or is this well established? If we delete the buffer tank, are we then limited to a maximum of one UFH manifold? I am toying with the idea of another manifold on the First floor, but only for some additional cooling, or maybe heating under bathrooms. What about hydraulic separation? I would need a pump at the manifold of course, so what if this manifold pump runs at different flow rate than the ASHP pump? How does that work without seperation? If I did decide to add another manifolfd for some UFH upstairs, would that mean a buffer tank must be included? Our plumber will be horified at the suggestion of dropping the buffer tank, so I need to be certain of this before I give him his next heart attack.

- 18 replies

-

Can anyone of our electricians @ProDave please explain how this wiring diagram will work on my Panasonic 9kw Aquarea heat pump?Secon Panasonic H Series rev1.3.pdf I understand that the heat pump will require its own supply from the CU but I am a little unsure as to what cables to put in ready for my sparky mate to connect everything up. I think I need to run some 1.5mm flex to run the heat pump ,diverter valve and controls etc but not sure if the power supply for this is fed from the heat pump supply via some fused spurs or if the heating controls are fed from a different source to the main heat pump supply? I understand it would be ideal to have one isolator for the whole heat pump and assoc controls but just a little confused? The heat pump itself has a back up heater for DHW so this is also confusing me as it shows connections for the immersion heater in the drawings but I assume this is the one on my HW cylinder so not sure if the feed for the immersion heater should come via the main heat pump supply? I am just trying to get all my cables in place ( so I can plaster some ceilings ) plus some spare ready for when my sparky is available to connect it all up next month so we can get moved in before xmas and I still have plenty to do! Hope you can help me understand this? TIA

-

I have an ASHP for heating and hot water. Unless I use the “luxury” DHW setting, my shower mixer adds too much cold water as it requires the thermostatic valve temperature differential to be 12 deg C. Does any one know of a shower mixer that will work with a heat pump hot water cylinder feed, i.e with DHW between say 40 to 45 deg C, rather than at above 50 deg C?

- 16 replies

-

New build originally designed around a gas boiler and UFH, flow temp are low as could be, due to 300mm pipe centres. So previous setup was, gas boiler, big buffer, mixer and pump on the manifold. The flow temp out the buffer was consistent, but filled based WC (Weather Compensation) curve. Flow temps varied between 26 and 34 degs (at -9 OAT). The heat pump is installed without a buffer, all UFH loops open, with no actuators, mixer or pump on the manifold, so as simple as it gets. Have a single thermostat, just to give a start permissive for the heating. Couple of observation 1. The min heating temperature of the heat pump is 25 degs, dT is 5.4 degs, so a return temp would be 21.5. 2. After one heat cycle at a low flow temp (26 degs), the floor doesn't cool down enough to allow to ASHP to start up again. So heat pump would not restart. That didn't work 3. At low loads heat pumps cycle, I typically have a 10 to 20 minutes run time and 45 minutes off. The recirculation pumps continues running at all times. If the heating load decreases (OAT, solar gain etc), the heat isn't transferred out the flow as quickly, so the off period of the ASHP increases. 4. To compensate for the on/off run nature of the ASHP, and to get the required heat into the floor, you need to flow at higher temperatures at low loads, than you would expect. 5. So to make up for the on/off nature I increased the flow temp to 29. The flow temp pattern through the floor is typically (8 deg day), heat pump ramps up to set temperature and when it cannot modulate to control dT the heat pump shuts down. The flow temp and return temperature stabilise down to about 24 and flow will slowly cool over over the next 40 minutes, down to about 23 and the heat pump starts. 6. Very small increments in flow temp have an impact on house temp, less than 0.5 degs change in target temp, can be felt in the house. 7. Been tracking the temp on a Shelly H&T today, temperature drift in the house is around 0.2 degs. Have tested the 3 basic modes of operation so far, operation controlled by thermostat, batch charging overnight on cheap rate, and continuous running 24/7 on straight weather compensation. So far leaving it to run all the time seems the cheapest to run and easiest to implement. Have a simple Shelly H&T set up in the hall, to record how temperature moves over time and OAT changes, this will allow fine tuning of the WC curve.

-

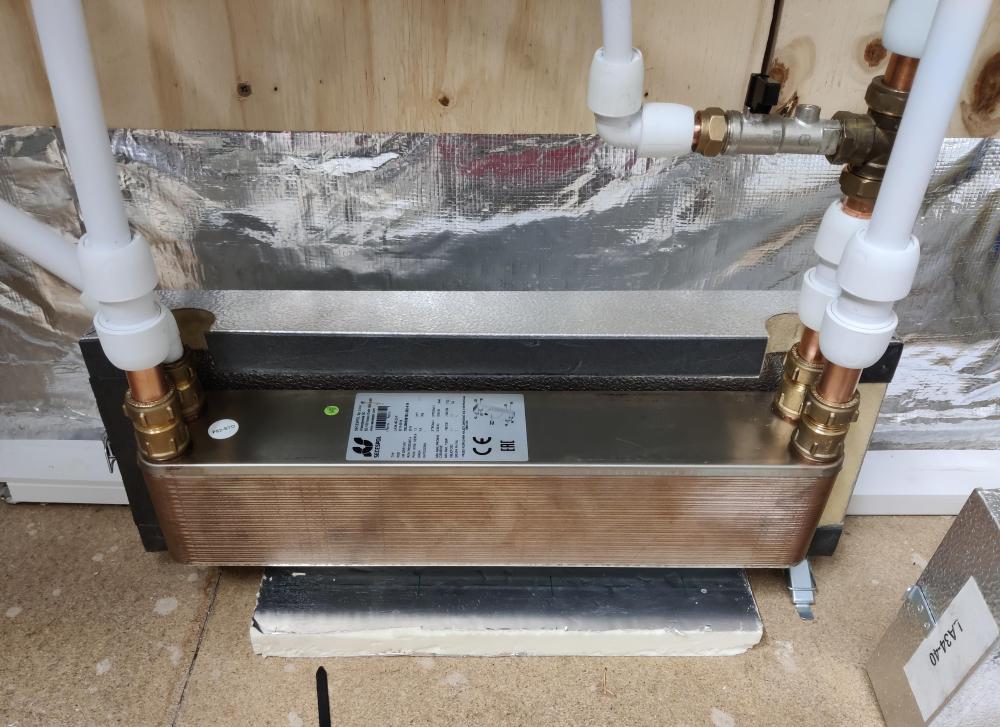

Plenty of information on ASHP is available on this site and very little on hybrid heating systems, i.e. boiler and ASHP. A few manufacturer designed hybrid systems are also available. When we built our house it was with an Atag gas combi boiler. We then installed an ASHP mostly for cooling, but it also heated our house well last winter and provided hot water via an UVC. The system below could easily be replicated by anyone wanting to install a hybrid heating system meaning little or no changes to heating system such as radiators. So the Atag boiler only 2 years old has sat idle for the last year. For periods where the CoP of the heat pump, means gas is cheaper why not marry the boiler and heat pump together. Most of the off shelf solutions, rely on the gas boiler doing the hot water, not what I wanted. Most the time the ASHP is way cheaper than gas (especially with solar). So makes sense to do hot water via the ASHP most of the time. Most ASHP already have all the control logic for hybrid mode built-in - mine does. I have a few location issues which makes the implementation a little more complex than I could be. Boiler and UVC are about 20m plus away from the ASHP, with UFH in the middle. The solution I chose to use has the boiler on a separate circuit to the ASHP. Combi DHW tails are not connected to anything and the isolation valves closed. Phase one Get hybrid hot water heating. Had a 40 plate PHE sitting doing nothing, so inserted in the flow line from the ASHP close to the UVC, the other side to combi boiler heating circuit. Set max flow temp to 60 on the gas boiler. I can change the rate at which the boiler adds heat (gradient), set to a max of 2 degs every minute. Initial run was all manually done to check concept. With ASHP only the reheat time of the UVC is around 40 to 45 mins, with boiler engaged about 20 to 25 mins. During test, I monitoring the ASHP and gas boiler and both work well together, neither running away temperature wise. Now how to automate. All control logic is in the ASHP, to use a boiler as a secondary heat source, you can set different outside temperatures for the following control schemes - 1. ASHP only, 2. ASHP leading, boiler following, 3. boiler leading ASHP following 4. boiler only. ASHP controller supplies 230v as a control signal to the boiler. But boiler is 20m plus away from the ASHP. So used a Shelly relay at the ASHP end and a remotely controlled Shelly relay at the boiler end. Set up a scene in the shelly app, switched live to ASHP end Shelly energised the boiler end Shelly relay. All worked fine. Set the hybrid mode (ASHP leading) to start at 7 degs and a delayed start of 10 minutes for the boiler, after cylinder heating starts with the ASHP. PHE, boiler on left side ASHP on the right. Phase 2 UFH - coming next.

-

I have a boiler that needs repair or replacement in a rented house, and I'd welcome thoughts. The situation is: - I bought property to rent to this tenant in 2016. It is unusual in having 3 double bedrooms, which was why they wanted it. - Good tenant, and I expect the family to stay for another decade (kids are 5-7 old years in local schools, family are all here incl. parents and siblings). They love the house. - It is a 2016 renovated 1910 done by someone else I bought it from - solid walls etc. Not to my standards, but adequate. I keep having to have bits done, which is fine but a small pain. - T is in receipt of housing elements of UC, and child benefit (whatever it is called now) -> may be eligible for Eco4 scheme, which is boiler replacement, or a Heat Pump grant for an ASHP. - Boiler (8 years old) is repairable, but not the best brand. Engineer recommends replacement (they would, but I'm inclined to agree) with a Baxi. I am mainly Ideal or Worcester Bosch. Repair cost £500-1000 suggested. Replacement cost £2-3k depending on model. - EPC is 60D on the sheet, but imo is better than that (I've done a few things, and there are some 'average' assumptions in there.) Had I renovated it that would be at around 75C. - Implication of that is that fitting at Heat Pump could get me over the EPC Grade C requirement which will be coming back at some stage, after Rishi Sunk's "how can I save my arse" 2 year panic attack burning all their achievements - including the landlord EPC ratchet - down. - T says house is comfortable running at a lowish boiler temp (need to check that). - My long term intention is that I prefer no gas (safety and hassle reasons). Options AI see it I have 3 options. 1 - Replace boiler, ideally under boiler upgrade scheme. 2 - Go ASHP with a grant, perhaps via Octopus. Octopus use I think Daikon units. 3 - Go with A2AHPs with a couple of multisplits, and units in relevant rooms. 2 and 3 would require a hot water tank to have space found. Should be doable. I'd welcome all comments, especially around if the Octopus ASHP packages are good, whether ASHPs are easy to manage for tenants, and what lifetime I can expect from ASHP or A2AHPs. Thanks Ferdinand

-

Hi - got my ecodan R32 installed in October and it's been purring away ever since quite nicely. This morning, in Edinburgh anyway, it was near on 0 degrees and there was a noticeably louder noise coming from he unit, as if the fans were spinning much faster etc. I gather it's normal for an ASHP to work harder, and therefore be noisier, when it's cold? When the manufacturer publishes its decibel rating, is it best case or worst case - i.e. on a lovely summers day when doing a DHW top up or at -5 degrees in winter? Thank you in advance!

-

Hi All, i recent brought a Vaillant AroTherm plus ASHP and have started to install it with a set of Vaillant AroTherm plus flex hoses that I purchased from City Plumbing. https://www.cityplumbing.co.uk/p/vaillant-arotherm-flexi-hose-750mm-20165288/p/130849?text=Vaillant AroTherm fl Previously it has been possible to shorten these flex hoses as the work the same way as solar thermal hoses. see here: However it Would appeal that they have changed the why they manufacturer the pipe. As there is no longer a circlip or bolt that fits over the corrugated pipe. Does anyone know where I can get a nut and circlip that I can use to shorten these flex hoses? The reason I need to shorten them is so I don’t end up with an air lock in the flex hose. hope someone can assist? cheers