Myatix

Members-

Posts

21 -

Joined

-

Last visited

Personal Information

-

Location

Denmark

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Myatix's Achievements

Member (3/5)

1

Reputation

-

Hi All, i recent brought a Vaillant AroTherm plus ASHP and have started to install it with a set of Vaillant AroTherm plus flex hoses that I purchased from City Plumbing. https://www.cityplumbing.co.uk/p/vaillant-arotherm-flexi-hose-750mm-20165288/p/130849?text=Vaillant AroTherm fl Previously it has been possible to shorten these flex hoses as the work the same way as solar thermal hoses. see here: However it Would appeal that they have changed the why they manufacturer the pipe. As there is no longer a circlip or bolt that fits over the corrugated pipe. Does anyone know where I can get a nut and circlip that I can use to shorten these flex hoses? The reason I need to shorten them is so I don’t end up with an air lock in the flex hose. hope someone can assist? cheers

-

@NickfromwalesI understand what you are saying but in a closed heating system there is very limited air in the system if the installation has been done well. It’s a closed system, also you can’t see the rest of the installation from the images I have provided. There are numerous automatic bleeding valves in the system and in the boiler which are all above the manifold and will naturally bleed any air, if any out of the system. But thanks for your input! I am happy to go with the manufacturers recommendation.

-

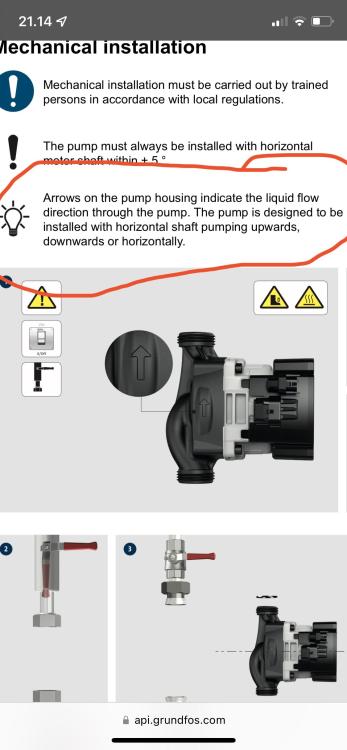

@NickfromwalesI just downloaded the pump installation manual from Grundfos and I am sorry but what you are saying about the pump is incorrect. As you can see from the screen shots above.

-

@NickfromwalesCan you please share the installation guide you are referring to with the big ❌. Thanks for the input!

-

it depends on the IR gun! Most ir guns take an average reading from a set area depending on the distance from the pipe and the ir guns I have used tend to take an average reading from a minimum of a 40mm area which means that they also include the temperature of the surface of the area behind the pipe. It’s not just the red dot that is the point of measurement. anyway this is not what this thread is about!

-

Exactly! You can’t use an IR gun to get an accurate flow and return on a heating system

-

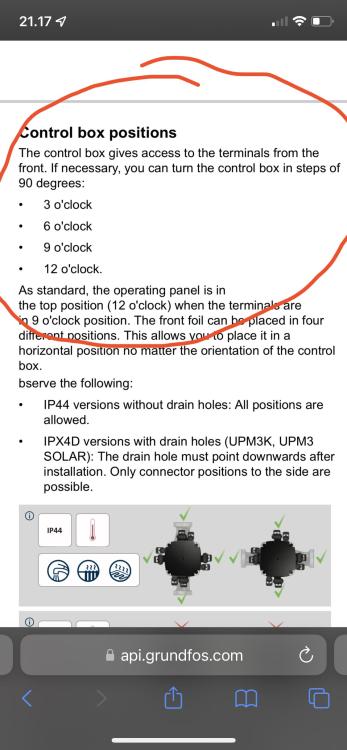

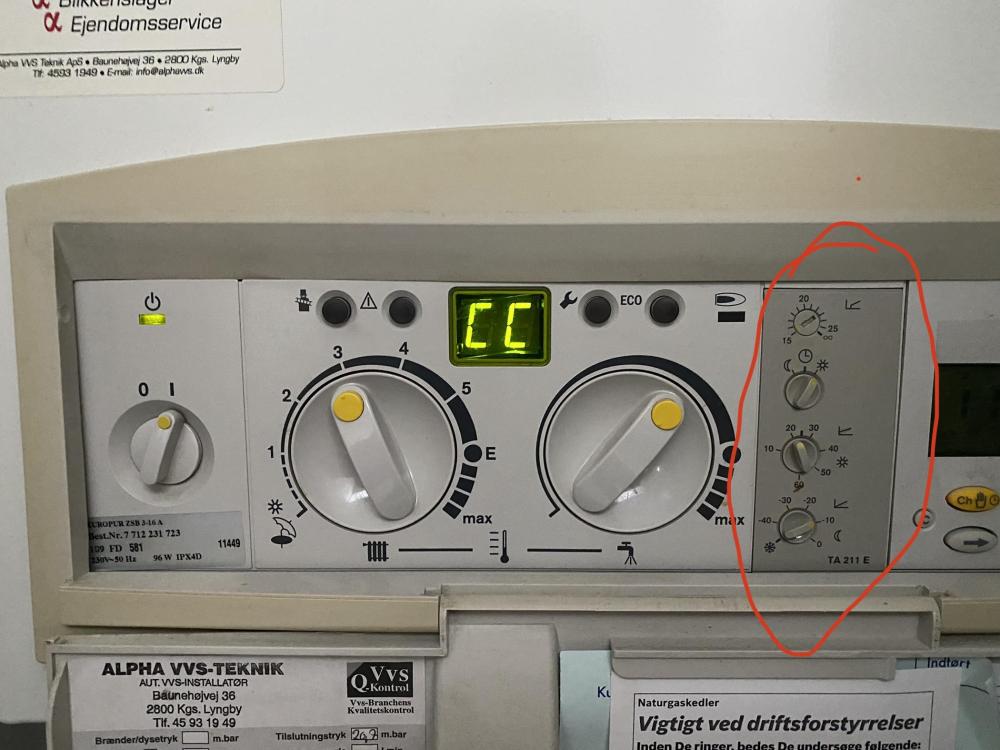

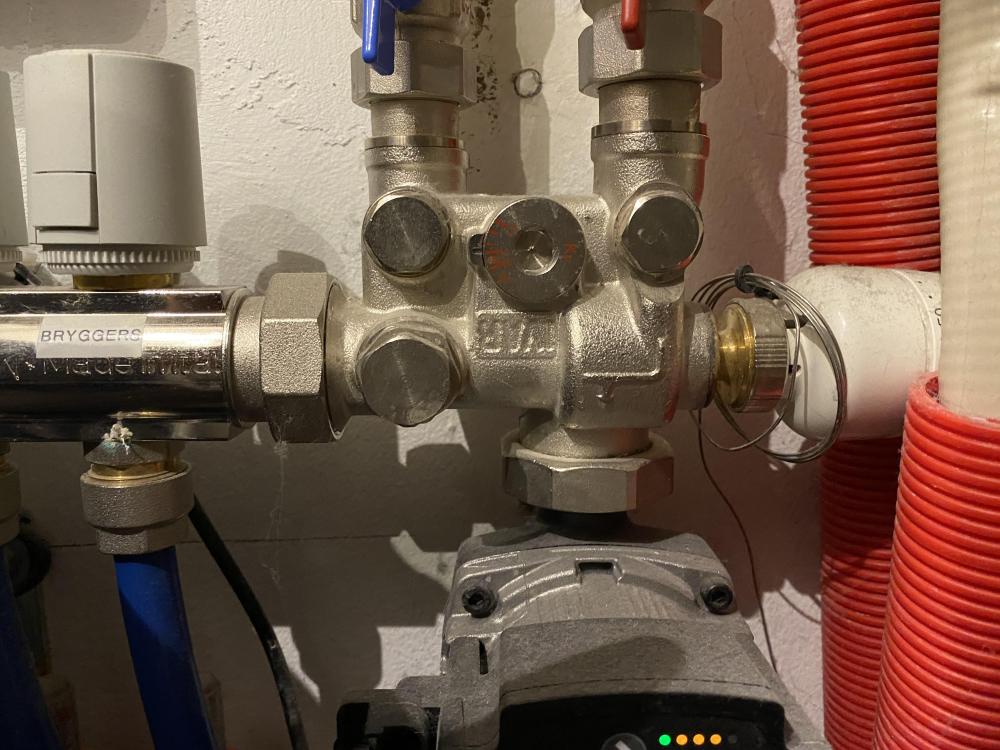

Here are the details from my MCS Heat Loss Calc and the UFH Design details. I have also included in the flow rates (l/m) to set the flow rates Now I need to optimise the manifold and flow temperatures at the boiler but this is were it gets tricky. Because I can set a flow temperature of 35 degrees from the boiler but the actual flow temperature at the actuator is about 24 degrees and 23 degrees on the return. My guess is that this is because of the mixer valve.

-

Okay I actually tried with an infrared thermostat and it gave stupid readings. I then purchased a testo pipe thermostat and the flow temperature was about 10 degrees different to the infrared gun stat I initially used. Great if it worked for you but my infrared stat was miles out and I think I am much more likely to trust a calibrated Testo pipe thermostat.

-

Also at what point does it make sense to measure the DT? Is it when the heating has been on for 20 hours or when you just turn on the heating? Presumably this depends on the thermal mass of the floor and how long it takes to get up to temperature?

-

this looks very cool! I have already done my Heat Loss Calculation using the MSC Heat Loss calculation spreadsheet and the w/m2 came out at 38w/m2. This is on the generous side. The issue is it’s very difficult and in accurate to calculate the flow temperatures if the mixer valve is mixing the return cold water with the calculated Flow temperature. This means that the actual flow temperature going through the ufh loops is lower than the boiler flow temperature as it gets mixed before flowing through the floor circuits??? This was the main reason for me asking about the mixer valve as it seems to be a waste of energy to mix cold return water with hotter flow temperature than you need because the mixer valve is cooling it down prior to flowing around the floor???

-

Thanks for confirming its okay! Back to the original subject of the thread! Should I change my mixer valve settings so it doesn’t mix and have the boiler run at a lower temperature to save money? should I be using the weather compensation on the boiler? If so any tips on setting it up?

-

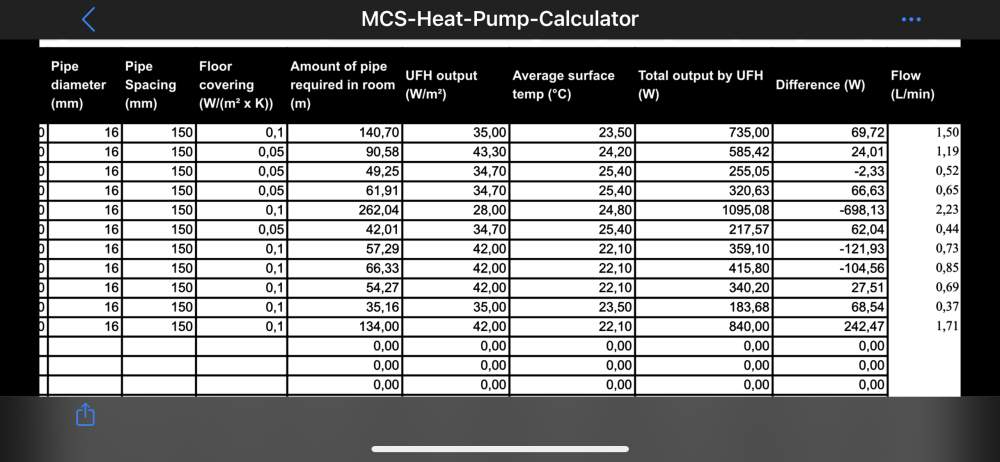

Hi NickfromWales, Thank you very much for that! I had never noticed that, but I think it’s fine! If you look at the flow direction on the pump it’s correct, the front of the pump has been turned 180 degrees but if you look at the image below you will see that the pump direction is correct. (See the arrow showing up the pump direction on the back of the pump). I can see why the plumber mounted it that way, there is no space in the cupboard to mount it the other way up… I also presume that is why he has moved the automatic bleed valve? So there is no issue there! But thanks anyway!

-

Thanks for all the comments! according to the MCS Heat Loss Calculation the flow temp needs to be around 35-40 degrees but I should point out that I live in Denmark where we calculate the minimum temperature at -12 rather than -3 in the northern parts of the U.K. I don’t think that a 55 degree surge of hot water would effect our floor as the thermal mass of a 100mm concrete slab would need that 55 degrees to run for at least an hour or more to have a significant impact. I do have a very old weather compensation unit on the boiler but it has been disconnected. My guess is that it didn’t work well or wasn’t commissioned properly. we are planning on installing an ASHP in the near future but until then it would be nice to get the optimum efficiency out of the boiler without spending a huge amount on gas. Current gas prices in Denmark would mean an annual gas bill of £7000. On the mixer valve shown above I can adjust or completely stop the valve from mixing the flow and return by adjusting it with an Allan key. Any advice or tips would be great fully received.

-

Hi All, I have an old gas condensation boiler and have a house with 100% UFH in a 10cm slab with 400mm of insulation under the slab. Currently my UFH manifold uses a mixer valve to mix flow and return so the temperature isn’t too high flowing in to the floor. This doesn’t seem to make sense to me as I don’t need high flow temperatures as I don’t have rads. would it not make sense to have the boiler run at a much lower flow temperature (35-40C) and the remove then switch the mixer vale over so it doesn’t mix?

-

The reason I wanted to know if the uniStor immersion could be changed is based on the statement also found on the MYPV website stating with regards to their own immersion heater. Due to their special design, there are only very low thermal surface loadsof the heating elements, which directly contributes to an increase of the product life-span. I didn’t really want to buy a cylinder that would last 25 years and find out the immersion broke as a result of using the AC-Thor???