bassanclan

Members-

Posts

1352 -

Joined

-

Last visited

Everything posted by bassanclan

-

Work out your volume. If you are 1m x 0.5m and probably 0.5m wide, each hole will be 0.25 cubic m of concrete. If you are doing 24 holes at a time you have 6 cubic m, so a full ready mix load.

-

If you have the bit that fell off fix it back with some resin https://www.screwfix.com/p/rawlplug-r-kem-ii-styrene-free-polyester-resin-300ml/32863

-

Depends on the size of the stove

-

I am planning an extension and was looking at options for different wall construction and their various u values. Then I realised I don't care about U values. I am interested in the heat transmission out of the room, not out of thee room, potentially through a cavity and more bricks. Is there a way of measuring this? Anecdotally my father in law's house of solid brick wall and 50mm "kingspan" drylining feels warmer than my 100mm kingspan filled cavity wall. The U value of my wall will be better, but because his insulation is nearer the inside of the house it feels warmer. Over an extended period of time of heating a room my house would lose less heat, but often the desire is to heat a room quickly for a short time. E.g before going to work etc. How can this be modelled?

-

They call them LVT

-

18mm ply is another option to consider

-

18mm chipboard

-

Another vote for Schneider Lisse.

-

Have you checked the flow rate temperatures to and from each radiator? It may be a lockshield needs adjusting

-

The correct thing to do would be to ask your window supplier to manufacture the windows without trickle vents being drilled. And supply the trickle vent plastic bits separately. If the building inspector insists on fitting them, then screw them on to the frame, but don't actually drill to provide ventilation.

-

Lintel for new window heads in 330mm thick walls

bassanclan replied to jayc89's topic in RSJs, Lintels & Steelwork

Real stone is always going to be pricey. Have you got a quote for wet cast? -

How many panels/lites in a 2.4m wide window gap?

bassanclan replied to puntloos's topic in Windows & Glazing

Depends on the rest of the house. 4 would look more "normal" mass building sites have windows in 600mm increments but if you have large, 800mm windows elsewhere it makes sense to follow that pattern -

Lintel for new window heads in 330mm thick walls

bassanclan replied to jayc89's topic in RSJs, Lintels & Steelwork

Yes that is the problem with dry cast heads. Wet cast is probably 40% more last time I bought some, but then you have no lintel to buy -

Lintel for new window heads in 330mm thick walls

bassanclan replied to jayc89's topic in RSJs, Lintels & Steelwork

You could buy wet cast heads which are structural and don't need a lintel (they are the lintel) and then a concrete lintel for the inner leaf -

Planning condition not been met but work started.

bassanclan replied to Barryscotland's topic in Planning Permission

It reads to me like they want the DETAILS of the footpath, not that they want it installing prior to commencement. A drawing and specification is what they want -

3 bed semi down south refurbishment cost

bassanclan replied to Aks's topic in General Self Build & DIY Discussion

Depends on how much labour you are putting in. Are you giving the keys to a builder and saying give me back the finished house in 3 months? -

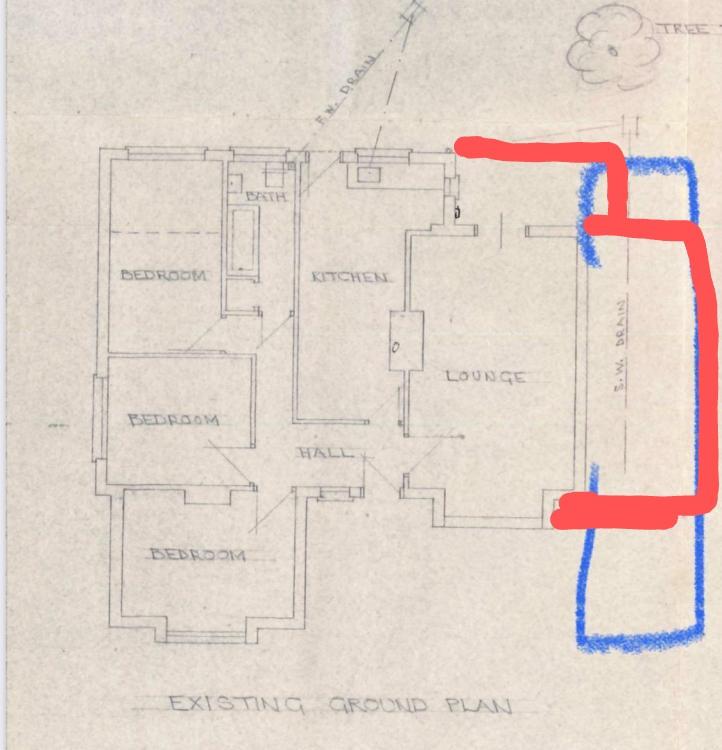

Your blue line is not permitted development. As the area in blue is shown as standalone and some come forward from the lounge. Given your existing extensions, it would be permitted if it didn't come forward of the lounge and was no wider than half of (25'1" -9'4"= 15'9") approx width of original kitchen+bathroom+bedroom - dining room. - essentially 7'10" Alternatively the extension flush with the lounge, front and back could be 1/2 the width of the original house, so would be stepped

-

https://www.ebay.co.uk/itm/Redland-50-roof-tiles-/324504156500?mkcid=16&mkevt=1&_trksid=p2349624.m46890.l49286&mkrid=710-127635-2958-0 Have you looked on ebay or Facebook marketplace?

-

Cast Stone mortar joint - poor quality, any remedy?

bassanclan replied to maxdavie's topic in Bricklaying, Blockwork & Mortar

Its not physically difficult. There are many thin joint systems which are used on blockwork etc with 3mm joints, but they use a glue rather than sand and cement- 4 replies

-

- archtecture

- home design

-

(and 1 more)

Tagged with:

-

Cast Stone mortar joint - poor quality, any remedy?

bassanclan replied to maxdavie's topic in Bricklaying, Blockwork & Mortar

We used cast stone cills some of which came in two halves. 3mm joint is not practical, 8mm would probably be the minimum, but if the plinth lines up to the corners it suggests that the designers specified 10mm. In my case the cast stone manufacturer provided the sand and white cement which was colour matched.- 4 replies

-

- archtecture

- home design

-

(and 1 more)

Tagged with:

-

https://www.wundatrade.co.uk/shop/home/water-underfloor-heating-solutions/screed-floor-heating-fixings/clip-track-with-self-adhesive-backing/